On The Properties of Linear Expansion

advertisement

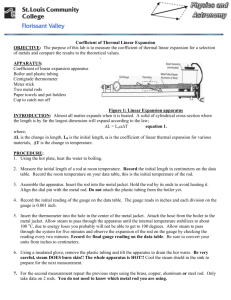

On The Properties of Linear Expansion R.L.Griffith,M.R.Levi,A.Okunyan,A.Okunyan ∗ 09/08/2005 Abstract between the atoms causing the material to expand. If the temperature change, is such that the material does not go through a phase change, then it can be shown that the change in the object’s length, , is given by the equation Keywords: Thermodynamics,Solids,Linear Expansion The linear expansion coefficients were calculated for three different metals, a linear expansion apparatus was used to measure the change in length of a metal pipe. The three metals that were studied were, copper, steel, and aluminum. The temperatures had to be acquired for the room temperature of the pipe and at maximum temperature for the pipe (using a thermister). once the change in temperature and the change in length were calculated the derived equation for linear expansion can be used to solve for the coefficient of linear expansion and compared to theoretical values. Some of the experimental values were found to be in agreement with the theoretical values. Some errors were acquired during this experiment. ∆L = αLi ∆T (1) where Li , is the initial length of the object before heat is added, and α is the linear expansion coefficient of the material. From Equation 1, we see that ∆L, is not only dependent on ∆T , but also on the initial length of the object, Li . So, the longer the object, the greater change in its length. A thermister thermometer was used to calculate the temperature for the metal rods. In this experiment we have acquired the ∆L , the ∆T , and the Li , so if we rearrange equation one we can solve for the linear expansion coefficient and compare it to the theoretical value to calculate a percentage error for this experiment. we will use equation 2 for this procedure, which is Diagram Metal Rod L Stainless steel pin Bracket on tube α= 2 ∆L Li ∆T (2) Method Slotted bracket 2.1 Equipment Used Dial gauge spring arm Diagram of Thermal Expansion Apparatus Equipment Thermal Expansion Apparatus Steam Generator model TD-8556A 600 ml beaker Tap water Digital Multi meter(Fluke) wooden block Figure 1: Diagram of thermal expansion apparatus. 1 Introduction It is found that most solids expand when heated. When heat is added to most materials, the average amplitude of the atoms’ vibration within the material increases. This, in turn, increases the separation 2.2 Serial 8558A n/a n/a n/a n/a n/a Procedure The length of each rod was measured before they were heated, this is the Li that will be used equation 2, the measurements were made from the inner ∗ The authors would like to thank Los Angeles City College for the use of their facilities 1 edge of the stainless steel pin on one end, to the inner edge of the bracket. The metal rod was then mounted onto the apparatus and the thermistor resistance was recorded for the initial temperature of the rod. The steam hose was than connected to one end of the rod, and the rod was allowed to be heated to maximum heat. then the ∆L was recorded from the dial gauge. The final reading that was recorded was the final thermistor reading, which determines the heat of the rod at that point. the process was repeated for each different metal rod. With these recorded values we can then calculate the linear expansion coefficient for each metal. For a more detailed explanation of the procedures used during this experiment please refer to lab:2 in the Los Angeles City College physics lab manual. 3 The experimental values for the linear coefficient were calculated using equation 2 from the values obtained in the experiment, the values used for the equation are found in Table 2. the theoretical values were obtained from the Physics: for scientist and engineers, Volume 1 text book Table 19.1 pg.588. 4 Conclusion The purpose of this experiment was to confirm the accuracy of the linear expansion properties of solids discussed in the introduction section. The results acquired confirmed that this experiment was prone to some errors. Possible sources of errors could have been acquired for the initial temperatures of the metals rods, by not allowing for the thermister to reach full equilibrium. Another source of error could have possibly been in the calibration of the gauge scale, by not setting it to zero initially. Errors were also acquired in the conversion of resistance to temperature using the thermister. A close approximation was used for the values of the temperatures using the table provided with the apparatus, which can also be included in the errors acquired. Results and Discussion There are three calculations to make for this report, The linear coefficients for copper, aluminum, and steel are calculated using the data that was acquired during the experiment. Li = The initial length of each metal rod Trm = The initial temperature of the rod 5 Thot = The final temperature of the rod The author would like to thank Roni, Alina, and Arman for their help with conducting this experiment. ∆L = The change in length of the rod, measured with the gauge scale References ∆T = the change in temperature Thot − Trm . [1] Los Angeles City College, Lab Manual, Lab number 2. with these values we can then calculate the linear expansion of each metal using equation 2. Metal Copper Steel Aluminum Li 698 698 698 ∆L 0.9 0.63 1.17 Trm 26.0 28.0 25.5 Thot 90.0 90.0 89.5 [2] Serway & Jewet, Physics for scientist and engineers Volume 1, 6th Edition. ∆T 64.0 62.0 64.0 Table 2.1 Values obtained during experiment The units used for the lengths are in millimeters and the units used for the temperature are in degrees Celsius. Metal αCu αsteel αAl Theory 1.7 × 10−5 1.1 × 10−5 2.4 × 10−5 Exp. 2.01 × 10−5 1.45 × 10−5 2.61 × 10−5 Acknowledgements Error 18.23% 31.81% 8.75% Table 2.2 Calculated values obtained from experiment 2