graphics graphics mount print mount print print guard

advertisement

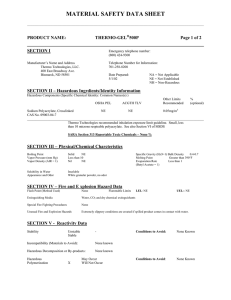

MOUNT GRAPHICS GRAPHICS GRAPHICS PRINT MOUNT MOUNT MOUNT GUARD PRINT PRINT PRINT MOUNTING TAPES PRINTING FILMS MOUNTING TAPES MOUNTING TAPES MOUNTING TAPES LAMINATION FILMS PRINTING FILMS PRINTING FILMS PRINTING FILMS GUARD GUARD GUARD LAMINATION FILMS LAMINATION FILMS LAMINATION FILMS Premium quality is our standard 2 Handling instructions ATP offers a wide product range of self-adhesive digital printing materials for many different applications as well as matching self adhesive overlaminates. In order to achieve optimum application results please follow the handling instructions. Storage and handling instructions ATP GRAPHICS products are delivered as roll goods and should be stored vertically on the roll block-support (included) or suspended with roll-core end blocks. Never store the rolls lying-down. The products in the original packaging must be stored in dry conditions with a relative humidity between 50 – 60 % and temperature between + 18 °C – + 22 °C. Do not expose the products to direct sunlight or store next to a heating radiator. Please consult our technical data sheets regarding the shelf life of each product. Opened rolls should be stored in their original packaging and covered with a protective cover. We recommend to use only material with the same batch number for one graphical application. In this context ATP ensures that every film roll consists of material of the same batch no. and consequently does not have any splice. When different batch numbers are used the technician should make tests to find out possible differences in using the films and in the quality of the graphical application. Printing instructions In order to avoid surface detoriation or contamination the digital printing materials must be applied with reasonable care wearing cotton gloves. Before printing the digital printing materials must be acclimatised to room temperature in order to avoid border corrugation. All ATP PRINT digital printing materials require different printer profiles and RIP software settings. With regards to drying temperature please activate maximum temperature limits. Monomeric materials can be dried between 50 °C and 60 °C and polymermaterials between 60 °C and 70 °C. The exact value depends on amounts and types of inks used on the print and the speed ofprinting. Very high temperatures can cause PVC films to cockle or wave, high shrinkage and yellowing of the PVC. Excessive heat can also lead to softening of the film and therefore overexpansion in the printer. When this phenomenon appears please reduce the printer temperature immediately. With regards to the application areas (in- and outdoor) please make sure that durability of digital printing materials and ink correspond. After printing the digital printing materials are to be stored at least 24 h at room temperature in order to achieve sufficient drying. Lamination To protect your printed materials from scratches or damage we recommend the use of ATP lamination films. ATP GUARD films help you achieve the desired colour tones and give your materials the right gloss, matt, semi-gloss or textured effect. The lamination films also guard your printed materials from UV radiation whilst providing protection from humidity and abrasion. Make sure that the chosen protective film is compatible with the print surface; e.g. combine monomeric printed vinyl with monomeric overlaminate vinyl or polymeric with polymeric films. Lamination instructions can be found in the ATP PRINT product tables in our ATP GRAPHICS brochure. For excellent results cleanliness is of the utmost importance. Contamination can 3 be removed easily with conventional cleaning detergents. Before laminating the printed films the prints must be allowed to dry completely in order to avoid inclusion of solvents not yet evaporated which could result in image rub-off. Insufficient drying of printed films may also result in damaging the lamination film adhesive which causes bubbling. Another effect of insufficient drying is the re-solvation of the semi-dried ink. ATP GUARD protection films and ATP MOUNT mounting tapes can be cold laminated but in order to achieve better flow characteristics and to avoid silvering, we recommend a lamination temperature between 40 °C and 60 °C. To achieve optimal mechanical durability between the laminating- / mounting films and print medium the laminated product should be put aside until the final bonding strength has been achieved, usually a few hours after lamination. Laminated and/ or mounting prints must be rolled up and transported with a large radius as possible and with the laminating film on the outside of the roll in order to avoid tunneling. Bonding ATP digital printing materials can be applied to a wide range of surfaces. They must be clean, dry and free of grease, dirt, silicone and other contaminants. For best results clean the surface with a standard cleaner followed by a suitable solvent such as isopropanol (IPA) which will completely degrease the surface. Be sure to allow the surface to dry completely since solvent residues may cause bubbling between film and surface. ATP digital printing materials are suitable to apply to wet surfaces. Temporary whitening may appear but will disappear after a short period once the adhesive has completely dried. Do not use the product under the recommended minimum application temperature which can be found in the appropriate technical data sheet. Generally bonding should be made under stress-free conditions. Removal For advertising graphics removal we recommend to start with one corner and slowly peel off the surface with a 60° – 90 ° peel angle. It may be helpful to use a hot-air blower or metal scraper but this must be used with caution to avoid surface damage. The use of ATP GRAPHICS products allows for easy removal from a variety of surfaces with low or no adhesive residue. Especially recommended for no adhesive residue upon removal is the use of the removable product GM-107 R/P. In the unlikely event that some adhesive residues remain on the surface they can easily be removed with a lemon-based cleaner or solvent (e.g. heptanes, isopropylicalcohol, acetone). All our products are subjected to strict quality control in accordance with our total quality management system ISO/TS 16949, DIN EN ISO 9001 and DIN EN ISO 14001. The published data is based on our present knowledge and experience. The values are intended only as a source of information and are given without guarantee and do not constitute a warranty. Purchasers and users should independently determine prior to use the suitability of this material for their specific purposes. It is the responsibility of the purchaser and user to determine possible patent rights and existing regulations prior to use of the products. Our technical application division is at your disposal to give you advice for your materials and applications. ATP Products are to the greatest possible extent solvent-, chloride- and heavy metal-free. For this reason no special procedures or precautions are required during the disposal of the products. Our products may be considered as environmentally friendly. 4 MOUNT ATP Graphics products are REACH and RoHS compliant. 5 MOUNTING TAPES Application Product Surface 70 µm polyester film, 12 µm transparent polyacrylate, permanent, pH-neutral both sided siliconized special paper, white, 125 g/m2 11 4 – 40 °C to +150 °C > + 10 °C 70 µm polyester film, 12 µm transparent polyacrylate, permanent, pH-neutral both sided siliconized special paper, white, 90 g/m2 11 4 – 40 °C to +150 °C > + 10 °C 70 µm polyester film, 12 µm transparent polyacrylate, permanent, pH-neutral both sided siliconized glassine paper, white, 63 g/m2 11 4 – 40 °C to +150 °C > + 10 °C 70 µm polyester film, 12 µm transparent both sided siliconized special paper, white, 90 g/m2 open: 11 closed: 6 open: 4 closed: 1 – 40 °C to +150 °C > + 10 °C 70 µm polyester film, 12 µm transparent both sided siliconized glassine paper, white, 90 g/m2 open: 11 closed: 1 open: 4 closed: 1 – 40 °C to +150 °C > + 10 °C 70µm polyester foil, 12 µm transparent polyacrylate, permanent, both sides, pH-neutral both sides protected with a 30µm ultra-clear PET-foil 11 4 – 40 °C to +150 °C GM-740-25 GM-740-40 GM-740-50 400 µm adhesive film without carrier (transfer) transparent polyacrylate, permanent, pH-neutral both sided siliconized PETfilm, 36 µm, Fingerlift 25 8 – 40 °C to +130 °C > + 10 °C GM-425 250 µm Soft-PVC film, 80 µm white modified polyacrylate, permanent both sided siliconized glassine paper, yellow, 90 g/m2 35 14 – 40 °C to +130 °C > + 10 °C GM-216 160 µm paper-tissue, 12 g/m2 white modified polyacrylate, permanent both sided siliconized glassine paper, yellow, 90 g/m2 25 16 – 40 °C to +160 °C > + 10 °C GM-210 100µm paper-tissue, 12 g/m2 white modified polyacrylate, permanent both sided siliconized glassine paper, white, 90 g/m2 13 9 – 40° C to +130° C GM-626 260 µm PES/PVA-scrim white modified polyacrylate, permanent both sided siliconized glassine paper, yellow, 90 g/m2 to +130 °C > + 10 °C – 40 °C to +100 °C PRINT PRINTING FILMS GUARD LAMINATION FILMS BANNERBOND (with FINGERLIFT) Suitable for applications on even and structured surfaces as well as for load-bearing bonding of banner materials (PVC). Suitable for indoor and outdoor applications. Double Sided PVC Tape High strength white double sided PVC-tape for bonding onto even and rough surfaces (e.g. heavy displays). High adhesions levels to a very wide variety of surfaces including various plastics, wood, glass, aluminium and other metals. Suitable for indoor and outdoor applications. Double Sided Nonwoven Tape High bond strength double sided tape for bonding onto even and rough surfaces (e.g. heavy displays). High adhesions levels to a very wide variety of surfaces including various plastics, wood, glass, aluminium and other metals. Suitable for indoor and outdoor applications. Double Sided Nonwoven Tape High bond strength double sided tape for bonding onto even and rough/structured surfaces (e.g. fibre boards (MDF) ). High adhesions levels to a very wide variety of surfaces including various plastics, wood, glass, aluminium and other metals. Suitable for indoor and outdoor applications. Double Sided Scrim Tape for Textiles High bond strength scrim tape for use in a wide variety of materials, particularly suitable loadbearing bonding of banner materials (textiles). Suitable for indoor and outdoor applications. ➊ measured after 24 h on steel ➋ bonded on aluminium ➌ special roll dimensions available on request Adhesive open side: polyacrylate, permanent closed side: polyacrylate, semi-permanent, pH-neutral open side: polyacrylate, permanent closed side: polyacrylate, removable, pH-neutral Liner Rolls RecomHeat Tack Peel adhesion dimensions ➌ mended resistance ➊ [N/25mm] [N/25mm] according to according to ➋ according to application Width Length AA-B-12-07 temperature (mm) FTM9 (AFERA 5001) (m) Carrier Premium Mount Adhesive For the permanent, self-adhesive lamination of even surfaces. Very well processible, GM-107 P provides excellent adhesion to almost all materials like plastics, films, wood, glasses or metals with excellent flatness. Suitable for in- and outdoor application. High Quality Mount Adhesive Permanent adhesive for the mounting of a wide variety of substrates. Excellent processing characteristics, providing excellent adhesion to a wide variety materials GM-107 Q like plastics, films, wood, glass, aluminium and other metals. Suitable for indoor and outdoor applications. Economy Mount Adhesive Permanent adhesive for the mounting of a wide variety of substrates. Excellent processing GM-107 E characteristics, providing excellent adhesion to a wide variety materials like plastics, films, wood, glass, aluminium and other metals. Suitable for indoor and outdoor applications. High Quality Permanent / Removable Mount Adhesive Permanent / removable adhesive for the mounting of a wide variety of substrates. Excellent processing characteristics, providing excellent adhesion to a wide variety materials GM-107 R/P like plastics, films, wood, glass, aluminium and other metals. Removable adhesive with good bond strength and removibility with very low adhesive residue. High Quality Permanent / Ultra Removable Mount Adhesive Permanent / removable adhesive for the mounting of a wide variety of substrates. Excellent processing characteristics, providing excellent adhesion to a wide variety materials GM-107 ER/P like plastics, wood, glass, aluminium and other metals. Removable adhesive with good bond strength and removibility with no residue. Very suitable for glass applications. High Quality Crystal Clear Mount Adhesive For the permanent, self-adhesive lamination of even surfaces. Very well processible, provides excellent adhesion to almost all materials like plastics, foils, wood, glasses or GM-107 CC metals with excellent flatness. Especially designed for mounting of photographs, large size transparencies onto glass, acrylic glass, etc. Suitable for in- and outdoor application. Total thickness > + 10°C > + 10 °C > + 10 °C 1040 1300 1400 1550 50 100 1000 1300 1400 1550 1040 1300 1400 1550 50 100 25 40 50 25 1000 1000 1250 1000 50 100 6 GUARD ATP Graphics products are REACH and RoHS compliant. 7 LAMINATION FILMS Application Total thickness GL-410 P G 100 µm Soft-PVC-film, 70 µm, polymer transparent, glossy polyacrylate, permanent, pH-neutral glassine paper, 63 g/m2, single side siliconized, white Polymeric PVC-film High quality optically brilliant polymeric PVC for lamination of various print media. GL-410 P SG Suitable for long term outdoor and indoor light box applications. Particularly suitable for applications requiring very high clarity 100 µm Soft-PVC-film, 70 µm, polymer transparent, satin polyacrylate, permanent, pH-neutral glassine paper, 63 g/m2, single side siliconized, white 11 GL-410 P M 100 µm Soft-PVC-film, 70 µm, polymer transparent, matt polyacrylate, permanent, pH-neutral glassine paper, 63 g/m2, single side siliconized, white 11 GL-410 G 100 µm Soft-PVC-film, transparent, 70 µm, monomer glossy polyacrylate, permanent, pH-neutral glassine paper, 63 g/m2, single side siliconized, white 11 GL-410 SG 100 µm Soft-PVC-film, transparent, 70 µm, monomer satin polyacrylate, permanent, pH-neutral glassine paper, 63 g/m2, single side siliconized, white 11 GL-410 M 100 µm Soft-PVC-film, transparent, 70 µm, monomer matt polyacrylate, permanent, pH-neutral glassine paper, 63 g/m2, single side siliconized, white 11 120 µm Soft-PVC-film, 100 µm, monomer polyacrylate, permanent, pH-neutral glassine paper, 63 g/m2, single side siliconized, white Momomeric Soft-PVC-film High-quality monomeric PVC for cold lamination and protection of printed media. Suitable for short to medium term indoor and outdoor applications. Structured PVC-film High-quality, monomeric textured PVC for use in a wide variety of applications including various floor graphics (fulfills slip resistance standard DIN 51130 - R9 Rating), as well as pop-up materials GL-412 Carrier Surface transparent, structure with stamping Adhesive Liner Peel adhesion Recommended ➊ [N/25mm] according to application (AFERA 5001) temperature Product 11 11 Heat resistance ➋ according to AA-B-12-07 UVprotection extension in years ➌ > + 8 °C – 40 °C to +90 °C > + 8 °C – 40 °C to +90 °C >5 > + 8 °C – 40 °C to +90 °C >5 > + 8 °C – 40 °C to +80 °C >2 > + 8 °C – 40 °C to +80 °C >2 > + 8 °C – 40 °C to +80 °C >2 > + 8 °C – 40 °C to +80 °C Rolls dimensions ➍ Width Length (mm) (m) >5 1040 1300 1400 1550 1600 50 1040 1300 1400 1550 1600 50 >1 900 1040 1300 1400 1550 – 40 °C to +80 °C >1 900 1040 1300 1400 50 Structured PVC-film High-quality, monomeric textured PVC for use in a wide variety of applications particularly harsh environment floor graphics (fulfills slip resistance standard DIN 51130 - R10 Rating), as well as pop-up materials GL-420 200 µm Soft-PVC-film, 170 µm, monomer transparent, structure with stamping polyacrylate, permanent, pH-neutral glassine paper, 63 g/m2, single side siliconized, white 11 Structured PP-Eco-film High-quality, textured PP for use in a wide variety of applications including various laminating applications for example pop-up materials GL-515 150 µm PP-transparent, 120 µm transparent, structure with stamping polyacrylate, permanent, pH-neutral glassine paper, 63 g/m2, single side siliconized, white 11 > + 8 °C – 40 °C to +80 °C >2 1040 1300 50 GL-107 PET 70 µm polyester, 36µm transparent, high-glossy polyacrylate, permanent, pH-neutral 30 μm ultra-clear PET-foil 11 > + 8 °C – 40 °C to +110 °C >1 1040 1300 50 High Glossy Polyester Film High-quality glossy polyester film for cold lamination and protection of printed media. Suitable for short to medium term indoor and outdoor applications. ➊ measured after 24 h on steel ➋ bonded on aluminium ➌ under standard european climate ➍ special roll dimensions available on request > + 8 °C 8 PRINT ATP Graphics products are REACH and RoHS compliant. 9 PRINTING FILMS Application Product GUARD Repositionable, polymeric soft PVC-film High-quality, polymeric PVC film, suitable for colour intensive and brillant prints for long-term advertisment both indoor and outdoor. Conformable polymeric film suitable for use in curved surfaces and long term outdoor prints. High adhesion to a wide GP-410 P g AE variety of substrates including diverse plastics, foamex, glass and aluminium. Excellent printing performance on a wide variety of solvent, eco-solvent, latex and UV digital print machines. The structured liner enables to apply the film dry and without air bubbles. Carrier Surface 100 µm Soft-PVC-film, polymer, 80µm white, glossy GP-410 P 100 µm Soft-PVC-film, polymer, 80 µm white, glossy GP-410 P g 100 µm Soft-PVC-film, polymer, 80 µm white, glossy GP-410 P C 100 µm Soft-PVC-film, polymer, 70 µm transparent, glossy LAMINATION FILMS Repositionable, polymeric PVC-film High-quality, repositionable, polymeric PVC film, suitable for colour intensive and brillant prints for long-term advertisment both indoor and outdoor. Conformable Polymeric film suitable for use in curved surfaces and long term outdoor prints. High adhesion to a wide variety of substrates including varying plastics, foamex, glass and aluminium. Excellent printing performance on a wide variety of solvent, eco-solvent, latex and UV digital print machines. Total thickness Repositionable, monomeric PVC-film GP-412 wg Monomeric, repositionable PVC film suitable for use in a wide variety of applications with flat and slightly curved surfaces. Suitable for colour intensive and brillant prints for short to medium GP-412 wm term advertisment both indoor and outdoor. High adhesion to a wide variety of substrates including varying plastics , foamex, glass and aluminium. Excellent printing performance on a wide GP-412 wg R g variety of solvent, eco-solvent, latex and UV digital print machines. GP-410 wg Repositionable, monomeric PVC-film Monomeric, repositionable PVC film suitable for use in a wide variety of applications with flat and slightly curved surfaces. GP-410 wg g Suitable for colour intensive and brillant prints for short to medium term advertisment both indoor and outdoor. High adhesion to a wide variety of substrates including varying plastics, GP-410 wm foamex, glass and aluminium. Excellent printing performance on a wide variety of solvent, eco-solvent, latex and UV digital print machines. GP-410 cg 120 µm 120 µm 120 µm Soft-PVC-film, monomer, 100 µm Soft-PVC-film, monomer, 100 µm Soft-PVC-film, monomer, 100 µm white, glossy white, matt white, glossy 100 µm Soft-PVC-film, white, glossy monomer, 80 µm 100 µm Soft-PVC-film, white, glossy monomer, 80 μm 100 µm Soft-PVC-film, white, matt monomer, 80 µm 100 µm Soft-PVC-film, transparent, monomer, 70 μm glossy ➊ measured after 10 min on steel ➋ measured after 24 h on steel ➌ bonded on aluminium ➍ under standard european climate ➎ special roll dimensions available on request Adhesive Liner single side siliconized polyacrylate, permanent, PE-coated paper, pH-neutral, grey white, 160g/m2, structured single side siliconized polyacrylate, permanent, PE-silicone paper, pH-neutral white, 140 g/m2 single side siliconized polyacrylate, permanent, PE-silicone paper, pH-neutral, grey white, 140 g/m2 single side siliconized polyacrylate, permanent, PE-silicone paper, pH-neutral white, 140 g/m2 single side siliconized polyacrylate, permanent, coated paper, white, pH-neutral 120 g/m2 single side siliconized polyacrylate, permanent, coated paper, white, pH-neutral 120 g/m2 polyacrylate, single side siliconized semi-permanent, coated paper, white, pH-neutral, grey 120 g/m2 single side siliconized polyacrylate, permanent, coated paper, white, pH-neutral 120 g/m2 single side siliconized polyacrylate, permanent, coated paper, white, pH-neutral, grey 120 g/m2 single side siliconized polyacrylate, permanent, coated paper, white, pH-neutral 120 g/m2 single side siliconized polyacrylate, permanent, coated paper, white, pH-neutral 120 g/m2 Rolls Durability RecommenHeat Peel adhesion Peel adhesion Recommendimensions ➎ ➊ [N/25mm] ➋ [N/25mm] ded applica- resistance ➌ in years ➍ dation ATPaccording to according to tion tempe- according to (not prinWidth Length Laminates ted) AA-B-12-07 rature (AFERA 5001) (AFERA 5001) (mm) (m) 8 11 8 11 8 11 8 11 8 11 8 11 4 6 8 11 8 11 8 11 8 11 – 40 °C to +90 °C >7 GL-410 P >+ 10 °C – 40 °C to +90 °C >7 GL-410 P >+ 10 °C – 40 °C to +90 °C >7 GL-410 P >+ 10 °C – 40 °C to +90 °C >7 GL-410 P >+ 10 °C – 40 °C to +80 °C >4 GL-410 >+ 10 °C – 40 °C to +80 °C >4 GL-410 >+ 10 °C – 40 °C to +80 °C >4 GL-410 GL-412 GL-420 >+ 10 °C – 40 °C to +80 °C >2 GL-410 >+ 10 °C – 40 °C to +80 °C >2 GL-410 >+ 10 °C – 40 °C to +80 °C >2 GL-410 – 40 °C to +80 °C >2 GL-410 >+ 10 °C >+ 10 °C 1050 1370 1400 1520 50 762 1050 1370 1400 1520 1600 50 100 762 1050 1370 1400 1520 1600 50 100 762 1050 1370 1400 1520 1600 50 100 10 Adhesive descriptions GRAPHICS MOUNT MOUNTING TAPES PRINT PRINTING FILMS MOUNT PRINT GUARD Polyacrylate, permanent Polyacrylate, solvent-free, which provides superior ageing and weatheribility performance. This adhesive is pH-neutral and environment FILMS friendly. It shows an outstanPRINTING ding combination of high bond strength (cohesion) and high tack. Excellent adhesion to a very wide range of surfaces including low energy surfaces like PP and other plastics. Polyacrylate, permanent (Transparent or grey adhesive colour) Polyacrylate, solvent-free, which provides superior ageing and weatheribility and UV LAMINATION performance. ThisFILMS adhesive is repositionable, pH-neutral and environment friendly. It shows a combination of high bond strength, high cohesion and tack. It offers excellent adhesion to a very wide range of surfaces; including low energy surfaces like PP and other plastics. This adhesive is highly water and solvent resistant and therefore makes bonding on wet surfaces possible; allowing easy, bubble free and repositionable application possible. The grey coloured adhesive increases the opacity to give high hiding power, while the bright whiteness of the printing surface is maintained. Polyacrylate, permanent Polyacrylate, solvent-free, which provides superior ageing, weatheribility and UV performance. The adhesive is pH-neutral and environment friendly, giving the enhanced benefit of avoiding discoloration of the print or inkjet media. This adhesive offers extremely high transparancy. It shows an excellent combination of high bond strength, initial tack allied to excellent laminating properties and flow characteristic (no silvering). In addition this adhesive provides excellent adhesion to printed and unprinted medias; such as films, paper, photos and plates. This adhesive is highly water and solvent resistant and therefore makes bonding on wet surfaces possible allowing easy, bubble free and repositionable application possible. MOUNTING TAPES PRINT GUARD LAMINATION FILMS Polyacrylate, semi-permanent pH-neutral and environment friendly. It offers semi-permanent properties allowing removability from a wide variety of substrates over a long period of time. Polyacrylate, removable Polyacrylate, solvent-free, which provides superior ageing and weatheribility performance. This adhesive is pH-neutral and environment friendly. It offers removable properties with very low residues from a wide variety of substrates over a long period of time. Modified polyacrylate, permanent Modified polyacrylate, solvent-free, which shows increased adhesion over time and offers superior ageing and weatheribility performance. This adhesive provides excellent adhesion to a wide range of surfaces including low energy substrates such as PP and other plastics. PRINTING FILMS GUARD Polyacrylate, semi-permanent (grey coloured) Polyacrylate, solvent-free, which provides superior ageing and weatheribility and UV performance. This adhesive is repositionable, pH-neutral and environment friendly. It provides semi-permanent properties and it is removable after a longer period. It additionally shows a combination of high bond strength, high cohesion and tack. It offers excellent adhesion to a very wide range of surfaces; including low energy surfaces like PP and other plastics. This adhesive is highly water and solvent resistant and therefore makes bonding on wet surfaces possible; allowing easy, bubble free and repositionable application possible. LAMINATION FILMS 11 ATP adhesive systems AG Sihleggstrasse 23 P.O. Box 127 CH -8832 Wollerau Tel: +41 (0) 43 888 15-15 Fax: +41 (0) 43 888 15-10 Feb 2012 / PSCH ATP adhesive systems GmbH Eichenhofer Weg 71 D-42279 Wuppertal Tel: +49 (0) 2339 / 909-749 Fax: +49 (0) 2339 / 909-506 ATP Alltape Klebetechnik GmbH ATP-Allee 4 D-99826 Mihla/Buchenau Tel: +49 (0) 36924 / 362-0 Fax: +49 (0) 36924 / 362-16 info@atp-ag.com www.atp-ag.com