Addendum #1 Specs - UC Hastings College of the Law

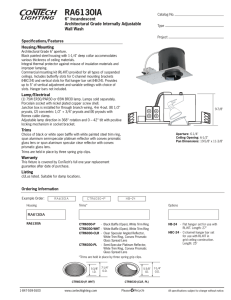

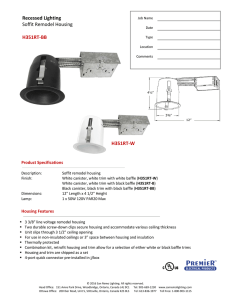

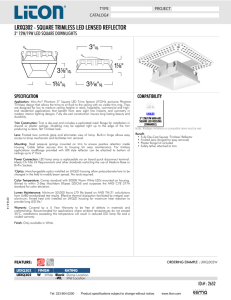

advertisement