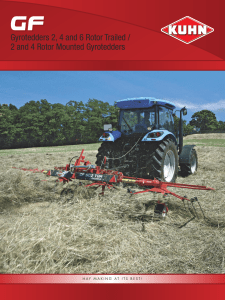

Gyrotedders GF 1001 Series

Gyrotedders

GF 1001 Series

E F F E C T I V E T E D D I N G !

KUHN

Gyrotedders

KUHN, the world leader in rotary tedders, continues to provide farmers with Gyrotedders that aid in increasing productivity while reducing losses in the field.

KUHN mounted, semi-mounted or trailed Gyrotedders offer the following benefits:

• Preserve the nutritional value of hay with gentle tedding – higher quality hay that ultimately increases profits.

• Expand productivity with extended working widths and high capacity while maintaining manoeuvrability – reduce operating costs in the field.

• Benefit from a long list of useful innovations such as DIGIDRIVE ® multiple finger couplings — increase the service life of the machine and reduce maintenance costs.

• Quality and reliability from the world’s leading manufacturer of rotary tedders – solid support and a high resale value.

KUHN offers solutions for tedding while meeting your requirements in terms of: COST REDUCTIONS GOOD PRACTICES

COMFORT – QUALITY OF LIFE PROXIMITY – ADVICES PEACE OF MIND - SERVICES

Gyrotedders

GF 3701 MH - GF 4201 MH

Small tedders with all the features of large KUHN tedders

3

• Specially designed for low power tractors, these tedders are ideal for use on small or hilly areas.

• An operating width of 3.70 m or 4.20 m and nevertheless very compact for transport, these machines can access any field corner with great ease.

• The small diameter rotors ensure impeccable tedding quality for fast drying and quality forage.

Easy folding and unfolding

In order to change from the working position to the transport position, the outer rotors are raised manually to the vertical position.

S P E C I F I C A T I O N S

Working width (DIN) (m/ft)

Number of rotors

Number of tine arms per rotor

Rotor drive

Headstock

Tyres

Weight (kg/lbs)

Minimised lift requirement

The compact hitch design considerably reduces the distance from the tractor to the implement’s centre of gravity. Low horsepower tractors can be used with a minimum of front ballast.

With the tines safely pointed inward the transport width is reduced to 2.17 m (7’1’’).

GF 3701 GF 4201 MH

3.70/12’2’’

4

4

Through DIGIDRIVE ® -coupling

4.20/13’9’’

4

6

Fixed Pivoting

15 x 6.00-6 Balloon

327 452

Rotors pivot by 180°

Once raised, the rotors lock automatically.

- For additional security and reduced storage requirements, rotors pivot 180°.

- With the tines safely pointed inward the overall transport width is also reduced.

Pivoting headstock: true mobility

The pivoting headstock provides flexibility and manoeuvrability.

- Even while turning, the tedder is always in line with the cut crop.

- When raised, the hitch automatically centres and locks the implement in line with the tractor.

Comfort and safety go hand in hand

Multi-purpose wheels

Folding and extending of the outer rotors is controlled hydraulically from the tractor.

Transport locks are also released from the tractor using a release cord.

- Wheel height adjustment is through an eccentric. The turn of a simple handle alters the angle of the machine to best suit the density and stubble height of the crop.

- Wheels are also capable of being turned manually for oblique operation, as at the edges of fields and along hedges.

4

Gyrotedders

GF 5001 MH/T - GF 7001 T

Simple and economical

5

• Fitted with 4 or 6 rotors, the GF 5001 / 7001 offer one of the most interesting price/working width ratio,

• 6 arms per rotor for a high output especially in long and dense forage

• forged finger DIGIDRIVE ® couplings,

• simple and quick adjustment of the rotor angle to suit the density of the crop.

S P E C I F I C A T I O N S

Working width (DIN) (m/ft)

Number of rotors

Number of tine arms per rotor

Rotor drive

Headstock

Tyres

Oblique position setting

Weight (kg/lbs)

Three swaths in a single pass

With a width of 5 m (16’5”), the GF 5001 MH and T Gyrotedders are recommended for use with a 2 m (6’7”) disc mower where three swaths are tedded without the tractor running over the crop. Two windrows from a 3 to 3.5 m (9’10” to 11’6”) mower conditioner can be tedded by running between the windrows.

The GF 5001 MH and T can also be used to ted two windrows from a 3 m mower.

GF 5001 MH

5.00/16’5’’

4

Pivoting

513/1130

GF 5001 T GF 7001 T

5.00/16’5’’

4

6

Manual

448/986

6.90/22’8’’

Through DIGIDRIVE ® - coupling

Drawbar towed hitch

15 x 6.00 - 6 Ballon

6

655/1444

GF 5001 T/7001 T:

Articulating & Folding frame

- The well designed linkage of the frame articulation joints enables the

GF 5001 T to follow uneven field contours.

- It makes the tedder easy to fold from work to transport and back again while still maintaining the ability to flex vertically.

For low horsepower tractors

The GF 5001 T, with its drawbar hitch, can be used with very low horsepower tractors, even with tractors without a hydraulic 3-point hitch.

Small farms with old or small tractors can also benefit from the advantages of the

GF 5001 T.

Narrow transport

For transport the two outer rotors of the

GF 5001 T are folded towards the rear.

In the transport position the width of the tedder does not exceed 2.80 m (9’2”).

The width is below 3.00 m (9’10’’).

6

Gyrotedders

GF 5801 MH/MHO - GF 6401 MH/MHO

“Top-of-the-line” performance

7

Working widths of 5.75 m

(18’10’’) and 6.40 m (21’) !

• To preserve fodder palatability: these tedders fitted with

6 small diameter rotors are ideally suited to pick up

3 swaths from 2 m (6’7”) and

2.40 m (7’10”) cutting width mowers.

• In addition to being easily operated this tedder’s greater width provides a higher output in the field.

Six small diameter rotors, driven through DIGIDRIVE ® couplings, a stabilized headstock, hydraulic setting to oblique running (MHO version), and the lighting system fitted as standard are a few of the features of these “Top-of-theline” Gyrotedders.

A

B

S P E C I F I C A T I O N S

Working width (DIN) (m/ft)

Number of rotors

Number of tine arms per rotor

Rotor drive

Headstock

Tyres

Oblique position setting

Weight (kg/lbs)

“Pro” tines

- Deflectors A prevent crop build up for improved spreading,

- The uneven strand length B provides improved raking and increased tine service life.

GF 5801 MH GF 5801 MHO GF 6401 MH GF 6401 MHO

5.75 / 18’10’’

6

6.40 / 21’

6

5 6

Through DIGIDRIVE ® -couplings

Pivoting

Balloon 15 x 6.00 - 6 Balloon 15 x 6.00 - 6 /

Mega Balloon 220/50-6 on centre rotors

Manual setting of wheel angle

700/1543

Hydraulic setting of wheel angle

760/1675

Manual setting of wheel angle

835/1841

Hydraulic setting of wheel angle

880/1940

Recognized in official tests!

GF 5801 MHO strong points

,

+ Very even spreading,

+ Good manoeuvrability

+ Stable, even on slopes,

+ Easy pitch angle adjustment, t,

+ Folding and oblique position setting made with one cylinder

,

Tauern and technical advisers of Gumpenstein,

2005).

+ Clarity of the operator

(Source :

“Der fortschrittliche Landwirt”

Hydraulic adjustment for oblique operation

(MHO only)

The machine can be set to right or left oblique running from the driver’s seat by simply operating the hydraulic control valve.

8

The exclusive design of this mechanism

(fitted with 2 bearings, one of which is a taper roller bearing) provides the system with unequalled reliability.

- There is no maintenance or risk of wearinduced play or of the turning shaft seizure.

- Total control is available for tedding at the edges of fields or on steep slopes.

6 small diameter rotors: quality tedding

The articulated frame and 6 small diameter rotors ensure the crop is turned over in its entirety.

- Not only is the crop more evenly spread but the reduced speed at which it is discharged means more gentle handling an reduced nutrient loss in the hay.

- The models GF 5801 MH / MHO meet all the criteria required to produce highly nutritious forage.

Anti-drift stabiliser: for even spreading

Safe transport

The anti-drift stabiliser enables regular crop deposit for a homogeneous drying process.

- This device minimises the “wallowing” that would normally occur when a tedder is operated at high speed or in dense crops.

- The tedder tracks smoothly in line with the centre of the tractor. Normal turning and pivoting of the headstock is not affected.

- As standard.

- With a very narrow width the GF

5801MH / MHO models are also very compact in transport. with a width of less than 2.40 m (7’10”).

- In addition, a lighting and signalling system is fitted as standard to increase safety on roads.

9

Gyrotedders

GF 7601 MH/MHO - GF 8501 MH/MHO

Machines that combine high output with ease of operation…

The GF 6401 and GF 7601

Gyrotedders combine high output with ease of operation. Operating widths are

7.60 m (24’11’’) and 8.50

m (27’11’’), respectively with 8 small diameter rotors.

Ideally suited to pick up

3 swaths from mowers

& mower conditioners with a 3 m (9’10”) width.

These Gyrotedders have a number of features that increase productivity including: hydraulic folding and unfolding, automatic transport lock of the headstock and rotor sections, transport functions controlled from the tractor,

DIGIDRIVE ® multiple finger couplings, etc.

“Anti-Drift” stabiliser: regular windrows for even drying

The GF 6401 and 7601 gyrotedders are fitted with an anti-draft stabiliser with adjustable setting.

- prevents them from drifting off course at high speed or in very dense crops,

- they stay perfectly in line with the tractor and the pivoting headstock’s manoeuvrability is not affected when turning.

Larger ground contact area

The central carrying rotors are fitted as standard with reinforced wheel columns and Megaballoon wheels

S P E C I F I C A T I O N S

Working width (DIN) (m/ft)

Number of rotor

Number of tine arms per rotor

Rotor drive

Headstock

Tyres

Setting to oblique running

Weight (kg/lbs)

GF 7601 MH GF 7601 MHO GF 8501 MH GF 8501 MHO

By setting wheel angle manually

1020/2249

7.60/24’11’’

8

5

8.50/27’11’’

8

6

Through DIGIDRIVE ® -couplings

Pivoting

15 x 6.00-6 Balloon and 220/50-6 Mega Balloon on central rotors

By setting wheel angle hydraulically

1020/2249

By setting wheel angle manually

1100

By setting wheel angle hydraulically

1170

Ideal for cutting widths of around 3 m (9’10”)

Fitted with 8 rotors of small diameter each

Gyrotedders enable tedding 3 swaths of a 3 m (9’10’’) disc mower. Quick and easy adjustment of the rotor angle allows for accurate adjustment and clean pick-up of all types of forage and in any terrain conditions.

MHO version: an exclusive mechanism for adjusting for oblique operation

- The wheel shafts are coupled to a hydraulic controlled linkage.

- Setting them for oblique operation to the left or right is controlled from the driver’s seat.

- This mechanism, exclusive to Kuhn, is very reliable and is fitted with 2 bearings on each wheel shaft. No maintenance is required.

Minimum transport width and standard lighting system

Despite their size, the GF 7601 and

GF 8501 are less than 3 m (9’10”) in width for transport and storage.

- Due to their compact dimensions and small overhang, these units can be used with low horsepower tractors.

- All controls are operated from the tractor cab.

- Furthermore, a full lighting and signalling system is included as standard equipment.

Highly efficient tines

- Tine deflectors A prevent crop wrapping for improved crop injection, more efficient raking and increased tine service life.

A

B

10

Gyrotedders

GF 6401 T - GF 8501 T - GF 8501 TO - GF 10601 TO

Semi-mounted, ultra-wide tedders

11 The tractor power available on the farm will no longer be determining for large width tedding. The GF 6401

T/GF 8501 T/GF 8501 TO and GF 10601 TO Gyrotedders present the ideal solution to this lift problem.

The use of a semi-mounted design allows these tedders to be operated with tractors as small as 37 kW (50 hp).

Though large in size these tedders are easy to handle and can achieve an impressive work rate. The

GF 10601 TO can tedd up to 12 ha (30 acres) per hour with a working width of 10.60 m (34’9”).

As far as transport is concerned, this is carried out easily, thanks in particular to the integral folding of the outer sections.

S P E C I F I C A T I O N S

Working width (DIN) (m/ft)

Number of rotors

Number of tine arms per rotor

Rotor drive

Hitch

Tyres on rotor wheels

Tyres on transport wheels

Oblique position setting

Weight (kg/lbs)

Transport

- The wide track of the rear transport wheels using high floatation tires

(ultra-high floatation on the GF 10601

TO) provide these tedders with excellent stability and transportability.

- In addition to the compact folding capability for transport, a lighting and signalling system is fitted as standard equipment.

GF 6401 T GF 8501 T GF 8501 TO GF 10601 TO

6.40/21’

6

6

8.50/27’11”

8

6

Through DIGIDRIVE ® -couplings

10.60/34’9”

10

6

Semi-mounted – 2 points on lower drawbar

Balloon 15 x 6.00 – 6 / Mega Balloon 220/50-6 on central rotors

145 x 13

1100/2425

Manual

195/65 R 15

1350/2976

Hydraulic

1470/3240

26 x 12.00-12

1890/4166

Oblique tedding keeps hay in the field

For tedding along the edge of a field and to avoid any risk of throwing any crop out of the field or onto a fence oblique tedding is provided. Simply operating the hydraulics and an electric switch in the tractor cab enables all the wheels to be turned to the left and to the right on the GF 8501 TO and GF 10601 TO

Gyrotedders.

“Mega Balloon” tyres for high floatation

The two central rotors are each equipped with reinforced wheel columns and

Mega-Balloon tyres.

- The weight distribution of the central section of the frame is then easily carried and ground pressure is reduced.

- This also improves the operation of the semi-mounted Gyrotedders over irregular ground.

Thorough, even, tedding

The articulated frame and small diameter rotors ensure the crop is turned over in its entirety.

- Not only is the crop more evenly spread, but the reduced speed at which it is discharged means more gentle handling and reduced nutrient loss in the hay.

- Semi-mounted Kuhn Gyrotedders meet all the criteria required to produce highly nutritious forage.

12

KUHN Gyrotedders 1001 series

Strong points that all Gyrotedders have in common

13 D I G I D R I V E

®

THE ONE AND ONLY

A KUHN exclusive system multiple finger couplings

The rotors of all “1001” series Gyrotedders are driven with the exclusive DIGIDRIVE ® system, developed and patented by KUHN.

- The Digidrive ® coupling consists of two multiple finger couplings made from forged, case-hardened, heat treated steel.

This design and construction is extremely wear resistant and provides a phenomenally long life.

- The smooth power transmission of the

Digidrive ® system provides constant velocity and power transmission under field operations. As the Digidrive ® system remains engaged even when folded for transport (exception, GF 5001T) rotors are always in perfect line making proper alignment unnecessary when unfolding the tedder for operation.

- The key feature of the Digidrive ® system is the ability to fold up to an angle of nearly

180° without damage even if the PTO is inadvertently engaged. In addition, the system provides substantially reduced transport widths and storage requirements.

Benefit from the reliability and comforts offered by a renowned manufacturer for harvesting crops

Kuhn’s experience to assist farmers

Small rotors = Great results

Improved raking to fully collect the forage on the soil

Small diameter rotors

- The rotor articulation range and floating swivel hitch of the KUHN Gyrotedders allow the tedder to faithfully follow the ground contours and thus fully turn over the forage.

- The tedder tines skim the surface, lift the crop while minimising ground contact which could damage plant roots and contaminate hay with soil.

- Fast drying thanks to the efficient turning over

14

The large pitch angle ensures that the forage is fully turned over and mixed for improved drying process

Small rotors: drying time reduced by 33% - Source: Chamber of Agriculture Weser - Ems (Germany)

No tools required to adjust tedding to the type of forage

From a sharp angle of approach that thoroughly disperses heavy long wet forages, to a shallow angle of approach that meets the requirements of a dryer, more delicate crop, Kuhn Gyrotedders can be swiftly adapted.

Adjustment is provided through the combination of setting the rotor height and angle. All adjustments are made without the need for the removal/installation of bolts, pins, or spacers.

Fully equipped

Most of the wide Kuhn Gyrotedders are fitted with standard equipment that includes an anti-drift stabiliser, tine deflectors, Mega Balloon wheels on the central rotors, a spare rotor wheel, and a lighting and signalling system.

High quality tines for maximum service life

- The 4 large diameter coil tines used on

Kuhn Gyrotedders must meet extremely stringent quality standards. In addition to heat treatment, Kuhn tines undergo an additional special process which substantially increases resistance to fatigue.

- The test requirement of Kuhn tines is to withstand a minimum of at least

180,000 full flex cycles on a test bench.

All genuine KUHN tines bear the KUHN stamp.

Top of the range equipment for increased user-friendliness

15

The best combinations of Kuhn Gyrotedders and KUHN GMD mowers and FC mower-conditioners

Recommended combinations Swaths from GMD Disc mower in standard configuration or FC with swath deflectors open

GF 3701

Swaths from GMD Disc mower with swath reduction kits or FC with swath deflectors closed

GF 4201 GF 5001

1.60 m GMD 400

Swaths from front mounted

GMD Disc mower or FC mower-conditioner

GF 5801

2.00 m GMD 500

2.40 m

2.80 m

3.10 m

GMD 600 GII

GMD 602 GII

GMD 700 GII

GMD 702 GII

GMD 702 F

GMD 283 TG

GMD 800 GII

GMD 801 - GMD 802

GMD 802 F

GMD 313 TG

3.50 m GMD 902

4.00 m GMD 4010

4.40 m GMD 4410

8.80 m GMD 883

DISC MOWERS

GYROTEDDERS

MOWER-CONDITIONERS

2.00 m FC 202

2.40 m FC 243

3,70 m 4,20 m 5,00 m 5,75 m

2.50 m FC 250

2.80 m

FC 283

FC 280 F

3.00 m

FC 313

FC 303

FC 313 F

3.50 m FC 353

4.00 m ALTERNA 400

5.00 m ALTERNA 500

8.13 m FC 813

8.80 m FC 883

How to properly match a tedder to a mower or mower-conditioner

Choose the appropriate width and avoid running over the crop. Refer to the above table to select the correct tedder width to match your mower or mower-conditioner. Find a tedder size that will maximise productivity while eliminating double coverage and avoid running over swaths.

1.60 m GMD 400

2.00 m GMD 500

2.40 m

GMD 600 GII

GMD 602 GII

2.80 m

3.10 m

GMD 700 GII

GMD 702 GII

GMD 702 F

GMD 283 TG

GMD 800 GII

GMD 801 - GMD 802

GMD 802 F

GMD 313 TG

3.50 m GMD 902

4.00 m GMD 4010

4.40 m

8.80 m

GMD 4410

GMD 883

DISC MOWER

GYROTEDDERS

MOWER-CONDITIONERS

2.00 m FC 202

GF 6401 GF 7001 GF 7601 GF 8501 GF 10601

6,40 m 6,90 m 7,60 m 8,50 m 10,60 m

2.40 m FC 243

2.50 m FC 250

2.80 m

FC 283

FC 280 F

3.00 m

FC 313

FC 303

FC 313 F

3.50 m FC 353

4.00 m ALTERNA 400

5.00 m ALTERNA 500

8.13 m FC 813

8.80 m FC 883

16

KUHN Gyrotedders

All along the drying process

17 1. Fast drying

With up to 30-35 % humidity, crops loose sugar and proteins due to plant breathing and micro-organisms.

2. Gentle crop handling

With less than 40 % humidity, crop becomes delicate and prone to leaf loss, especially for leguminous plants.

3. Even drying of the whole crop

For silage making and baling, the differences in moisture level causes uneven fermentation. For hay, a 15% humidity level must be reached to prevent its warming up and mould from developing. The protein digestibility of “warm” crop is reduced.

4. At any time

Through limited exposure to sun and rain, the crop’s value is preserved, preventing in particular the loss in vitamin A, which improves cow fertility, udder development, milk production and the strength of newly born calves.

Approach the swath along the centre line of the rotor

When a swath is lying on the ground, the part with most moisture and which is most compact is located along the centre and close to the ground. Tedding too high can leave 30 to

60 cm (12 to 24”) of crop untedded. If the swath is approached along the centre line of a rotor, at the point where the tines are closest to the ground, this ensures that crop is entirely lifted.

Set the rotor angle

Depending on the nature of the crop and stubble height the various settings for rotor angle enable the KUHN Gyrotedder to be set to properly turn over the entire crop. It is not subject to leaf loses due to overly aggressive tedding or excessive speed, nor “lumps” being formed as a result of being thrown too close to the ground.

Fine tuning of the rotor angle

Fine-tuning of the rotor angle and tine height is performed using the top link on fully mounted tedders or the adjustment crank on trailed tedders. Tines should be set to skim the ground without scraping it.

Using the Gyrotedder gently for the last pass

(reduced PTO speed and relatively high groundspeed) limits leaf loss.

Making night windrows

Crop dries approximately 8 hours a day.

During the night, its moisture content increases again with the humidity in the air. In case of important dew, drying becomes even more difficult.

The Kuhn advantage: Making night windrows with the 2-speed reduction gearbox reduces the amount of crop exposed to humidity.

2-speed reduction gearbox for making night windrows

Is available as optional equipment, for making small windrows in order to limit the exposure of crop to dew and rain.

TECHNICAL SPECIFICATIONS

Hitch

GF 3701 GF 4201 MH GF 5001 MH GF 5001 T GF 5801 MH GF 5801 MHO

3-point Towed drawbar

3-point

Category

Headstock [3 point]

Wheels adjustable in height without use of tools with 15 x 6.00 - 6 balloon tyres

Fixed

1 and 2

Pivoting

Standard

-

-

2

Pivoting

Number of rotors

Number of tine arms per rotor

Rotors driven through exclusive DIGIDRIVE

Weight (kg/lbs)

Drive with torque limiter

Manual positioning of outer rotors

® system

4

4

4

6

4

6

4

6

6

5

6

5

Standard

4.00 /13’1” 4.65 /15’3” 5.40 /17’11” 5.40 /17’11” 6.00 /19’8” 6.00 /19’8” Total extended width (m/ft)

DIN working width (m/ft)

Width in transport position (m/ft)

Power requirement at PTO – kW / hp (from)

3.70/12’2’’ 4.20/13’9’’ 5.00/16’5’’ 5.00/16’5’’ 5.75/18’10’’ 5.75/18’10’’

2.17 (7’3”) 2.50 (8’2”) 2.85 (9’4”) 2.80 (9’2”) 2.40 (7’11”) 2.40 (7’11”)

11/15 15/20 15/20 15/20 20/27 20/27

327/720 452/995 513/1129 448/986 700/1573 760/1675

Standard

Manual 180° pivoting for directing tines inwards

Folding towards the rear

Optional equipment

Hydraulic vertical folding

2-speed reduction gearbox

Oblique running (left / right) by setting wheel angle

Wheel deflector

Anti-drift stabiliser

Manual

-

Optional equipment

Optional equipment

Hydraulic

Standard

Standard

Lighting and signalling Optional equipment Standard

Tractor hydraulic equipment 1 single acting outlet 1 double acting outlet

For GF 22 N/P & GF 440 T and GF 6301MH through to GF 10601 TO Gyrotedders – please refer to the individual brochures for these tedder lines.

18

TECHNICAL SPECIFICATIONS

GF 6401

MH

GF 6401

MHO

GF 6401

T

GF 7001

T

GF 7601

MH

GF 7601

MHO

GF 8501

MH

GF 8501

MHO

GF 8501

T

GF 8501

TO

GF 10601

TO

Hitch

Category

Headstock

Height adjustable wheels

Tyres

Wheels with Mega Balloon tyres on central rotors

Number of rotors

Number of tine arms per rotor

DIGIDRIVE ® system

Total extended width (m/ft)

DIN working width (m/ft)

Width in transport position (m/ft)

Height in transport position (m/ft)

Tyre size for integral transport unit

Power requirement at PTO – kW/HP (as from)

Weight (kg/lbs)

Drive with torque limite

2-speed reduction box

Setting to oblique running

(left / right)

Wheel deflector

Tine deflectors

Anti-drift stabiliser

Lighting and signalling

Tractor hydraulic and electric equipment

3-point

3.30/10’10”

850/1874 manual

1 SA* outlet

-

2

Pivoting standard

6.75/22’2”

6.40/21’

900/1980 1100/2420 655/1441 hydraulic standard standard standard

22/30 standard

1 SA*

1 x DA** oulet

6

6 semi-mounted to 2 lower lift arms towed drawbar

3.45/11’4”

145 x 13

-

1 DA** outlet

-

-

-

7.35/24’1”

6.90/22’8”

manual

-

-

-

Optiomal equipment

standard

7.93/26’

7.60/24’11”

2.95/9’8”

2.83/9’3”

1 DA**

5

2 positions

-

2 DA**

3-point

15x6.00-6 balloon

3.20/10’6”

30/40

1 DA**

8

2

Pivoting standard

2 DA**

8.85/29’

8.50/27’11” standard standard semi-mounted to 2 lower lift arms

1 DA** 1 DA** outlet

1 x 2 pin electrical- socket

(supplied)

10.95

10.60/34’9”

1020/2249 1120/2469 1100/2420 1170/2574 1350/2970 1470/3234 1890/4158 standard

Optional equipment hydraulic manual standard hydraulic standard

6 manual

-

3.45/11’4”

195/65 R 15

hydraulic

10

3.95/13’

26x12.00-12

40/55

-

* SA: single acting; **DA: double acting

For information on small and medium sized Kuhn Gyrotedders – please refer to the literature provided for those machines.

Our material is produced in accordance with the European Machinery Directive in the member states of the European Union. In countries outside the E.U., our machinery complies with the safety regulations set by the country concerned. Some safety devices may have been removed from our leaflets in order to clarify the illustration. Under no circumstances should the machine be operated without the necessary safety devices in place (as specified by the assembly instructions and operators manual). We reserve the right to change any designs, specifications or materials listed without further notice. Our models and trademarks are patented in more than one country. Machines and equipment in this leaflet can be covered by at least one patent and/or registered design. Registered trademark(s).

YOUR KUHN DEALER :

KUHN S.A.

- F 67706 Saverne Cedex www.kuhnsa.com - E-mail: info@kuhnsa.com

U.S.A. : KUHN FARM MACHINERY, INC

5390 East Seneca Street

VERNON, NY 13476 - 0840

Phone : (315) 829 2620 - Fax : (315) 829 2270 www.kuhn-usa.com - info@kuhn-usa.com

KUHN FARM MACHINERY PTY. LTD.

7 Manorwood Pl.,

MITCHAM, 3132 VIC,

Fax : 03 9874 3462 www.kuhnsa.com - info@kuhnsa.com

United Kingdom :

KUHN FARM MACHINERY (U.K.) LTD

Stafford Park 7,

TELFORD - SHROPSHIRE TF 3 3 BQ

Phone : TELFORD (01952) 239300/1/2

Fax : (01952) 290091 www.kuhn.co.uk - info@kuhn.co.uk