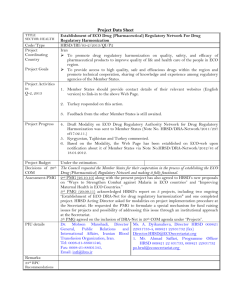

Standards and Preferences

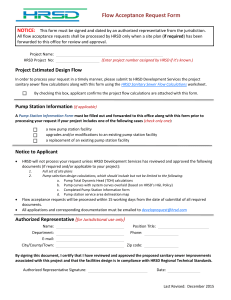

advertisement