Critical Considerations in

Workplace Electrical

Safety, 2015 Updates to NFPA 70E

©2015 ESCO Group. All Rights Reserved. ESCO Marketing.

Your Safety Is Our Concern

ESCO Group disclaims liability for any personal injury, property or other damages of any nature whatsoever, whether special, indirect, consequential or compensatory, use of, or reliance on this document. The ESCO Group also makes no guarantee or warranty as to the accuracy or completeness of any information published herein.

Any opinion expressed is the personal opinion of the author, and does not necessarily represent the official position of the NFPA or its Technical Committees.

Use of these materials for training for which compensation is received is prohibited unless authorized by ESCO Group in writing. The purchaser agrees that such materials shall not be rented, leased, loaned, sold, transferred, assigned, copied or used in any form unless authorized by ESCO Group in writing.

Ensuring a Safe Workplace

The National Fire Protection Association (NFPA) has prepared a “standard” for employers to use which addresses electrical safety requirements in the workplace. This standard,

NFPA 70E‐2015, Standard for Electrical Safety in the Workplace, is considered an industry consensus standard as opposed to a federal standard in that it has not yet been fully endorsed as law by OSHA. This consensus standard includes information and guidance

on the following:

1.

Requirements for safe work practices.

2.

Information on hazards:

– Shock

– Arc Flash

3.

Requirements for shock and arc flash boundaries

4.

Requirements for personal protective equipment.

Electrical Hazards

• Electric Shock

• Electrical Arc Flash

• Electrical Arc Blast

Summary of Changes

• “Hazard vs. Risk”

– Normal operation of electric equipment

– Risk assessment to be performed prior to:

• Cutting or drilling into equipment, floors, walls, or structural elements

• Work on a battery system • Arc Flash Risk Assessment

– Incident energy analysis method; or

– arc flash PPE categories,

– Field‐marked equipment labeling requirements revised.

Summary of Changes

• Changes to “task tables”:

– A new task‐based table

– New equipment‐based tables – Hazard/risk category 0 has been removed • Changes to shock protection boundaries:

– Prohibited Approach Boundary was deleted.

– Restricted approach boundary ‐

• designated for conductive articles, and insulated tools.

• Changes to table 130.4(D)(a) Approach Boundaries

• Barricades – Arc Flash Boundary or Limited Approach Boundary

– Whichever is greater.

Summary of Changes

• Program requirements.

– Consider condition of maintenance.

– Field work audits ‐ not to exceed 1 year

• Maintenance Requirements:

– Responsibility for maintenance and documentation of electrical equipment. – New maintenance requirements for test instruments. Summary of Changes

• Changes in Scope of standard:

– Safety‐related maintenance requirements

– Other administrative controls • Changes to definitions:

– qualified person revised to meet OSHA

– energized electrical work permit added

– bare hand work deleted.

• Temporary protective grounding equipment part of job planning. Hazard vs. Risk

• The term “Hazard” replaced with “Risk”.

• Risk Assessment Procedure.

– Identify hazards, – Assess risks,

– Implement controls

• “Hierarchy of Risk Control Methods”.

Hazard vs. Risk

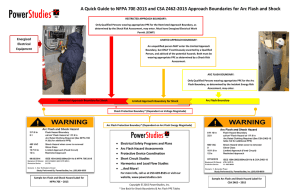

• Shock Risk Assessment: know the voltage.

• Arc Flash Risk Assessment:

– Determine if an arc flash hazard exists.

– Incident Energy Analysis Method or; – Arc Flash PPE Categories Method.

– Determine arc flash boundary and PPE.

Labeling Requirements

(1) Voltage

(2) Arc flash boundary

(3) At least one of the following:

a. Incident energy or arc flash PPE category, but not both!

b. Minimum arc rating of clothing.

c. Site‐specific level of PPE.

Hazard vs. Risk

• Normal Operation allowed:

– Properly Installed (NFPA 70 NEC)

– Properly Maintained (NFPA 70B or manufacturer’s recommendation.

– Doors and covers in place and secured.

– No evidence of impending failure.

Hazard vs. Risk

• Normal operation vs. “increased likelihood of injury..”

• Probability vs. severity

Hazard vs. Risk

• Dress for the arc flash hazard!

< 1.2 cal/cm2

4 to 8 cal/cm2

25 to 40 cal/cm2

Hazard vs. Risk

Cutting or Drilling. • Floors, walls or structure

• Identify location of conductors, cables, and equipment

• Place in electrical safe work condition

• Identify PPE and safe work practices

Task Tables

• Elimination of HRC 0 – How to handle existing labeling

– Best practices

• PPE Categories Method

– Task Table

– Equipment Table

– Arc Flash PPE Category Table

ESCO Electric HRC 0 arc flash protection, circa 2011.

Task Table

Equipment Table

Reproduced with permission from NFPA70E®‐2015, Electrical Safety in the Workplace, ©2014, National Fire Protection Association.

Arc Flash PPE Category Table

Reproduced with permission from NFPA70E®‐2015, Electrical Safety in the Workplace, ©2014, National Fire Protection Association.

Arc Flash PPE Category Table

TABLE 6 ‐ Continued

Reproduced with permission from NFPA70E®‐2015, Electrical Safety in the Workplace, ©2014, National Fire Protection Association.

Shock Protection Boundaries

• Prohibited approach boundary removed.

• Restricted approach boundary:

– No conductive items

– Insulated tools

ESCO Electrician using insulated gloves, tools, and barriers.

Shock Protection Boundaries

Barricades set up at Limited Approach or Arc Flash boundary, if greater. Program Requirements

• Consider Condition of maintenance

• Field work audit frequency – not to exceed 1 year.

QUESTIONS?

Jason Wolf, CSP

3450 3rd St. Marion, IA 52302

(319) 538‐7892

jasonwolf@theescogroup.com

Your Safety Is Our Concern

Thank You!

©2015 ESCO Group. All Rights Reserved. ESCO Marketing.