Integration of Photovoltaic Distributed Generation in the Power

2012 45th Hawaii International Conference on System Sciences

Integration of Photovoltaic Distributed Generation in the Power Distribution

Grid

Miroslav M. Begovic

I, II, V

Georgia Institute of Technology, Atlanta GA

III, IV

Quanta Technologies, Raleigh, NC

I

I

, Insu Kim

II

, Damir Novosel

III

, Julio Romero Aguero

IV

, Ajeet Rohatgi

V mb50@mail.gatech.edu

IV

II iskim@gatech.edu

julio@quanta-technology.com

V

III

DNovosel@Quanta-Technology.com

ajeet.rohatgi@ece.gatech.edu

Abstract

Numerous North American utilities are integrating growing numbers of investor-owned photovoltaic distributed generation (PV-DG) plants into their distribution systems to comply with state-mandated

Renewable Portfolio Standards (RPS). Given the fact that distribution systems have been designed to be operated in a radial fashion, interconnection of PV-DG may lead to significant impacts on planning and operations that need to be studied to identify mitigation measures and ensure seamless integration. The purpose of this paper is to discuss impacts of PV-DG on power distribution systems planning and operations, including those of steady state and dynamic nature, with emphasis on utility-scale PV-DG. This paper also discusses mitigation measures to address these impacts and presents results of analyses conducted on real distribution feeders and other ramifications of their increased use in distribution networks, especially urban ones.

1.

Introduction

Distributed generation (DG) can be defined as smallscale, dispersed, decentralized, and on-site electric energy systems. Currently, capacities of DGs vary typically in the range of several kW to hundreds of

MW. As more DG penetrates the electric energy systems, more accurate and efficient system analysis algorithms are needed in order to analyze the impact of intermittent DG (e.g., photovoltaic, wind) poses specific challenges given the volatile and uncontrollable nature of its primary resource.

Since DG can change the operation of the distribution system and interfere with its protection and control, electric power utilities are not motivated to interconnect customer owned small generators to their distribution networks. Utilities tend to put non-utility generation under the extensive technical analysis.

Conversely, the regulating authorities tend to act in favor of DG owners and support that the interconnection be as easy and transparent as possible.

The objective of the paper is to discuss some of the issues and challenges faced by the industry due to the growing and rapid proliferation of photovoltaic DG

(PV-DG), including distribution system impacts, energy savings, ecological aspects, and generation cost.

Section 2 discusses the evolution of the PV industry and some of the most recent technology and market developments; section 3 presents an introduction to PV-

DG, sections 4 and 5 discuss potential impacts of PV-

DG on planning and operation of power distribution systems and potential mitigation measures to these issues; and sections 6, 7 and 8 analyze impacts of PV-

DG on generation costs, energy savings and critical peak loading. the DG system on various types of microgrids and distribution networks. The influence of uncertainties can be modeled via suitably optimized Monte Carlo techniques.

Since distribution systems have been designed to be operated in a radial fashion, i.e., to supply unidirectional power flow from substations to loads,

DG interconnection needs to be studied to ensure that its potential impacts are identified and that required mitigation measures are implemented. It is worth noting that some impacts are common to all technologies including conventional ones (e.g., reciprocating engines, small hydro, biomass, etc), however,

2.

Roadmap to Grid Parity for PV

The commercial PV power industry started developing in the 70s. In spite of a 70% reduction of real price of PV modules over 40 years, energy from

PV remains expensive in comparison to conventional generation sources. Furthermore, PV cell efficiencies are still below 20 percent

In the early 80s, changes in politics in the United

States ended substantial funding of solar energy research and, since the nation represented nearly 80% of the global market for solar energy at that time, virtually halted solar energy development around the world [4]. However, in 2008, renewable energy sources including hydropower accounted for more than 9% of

978-0-7695-4525-7/12 $26.00 © 2012 IEEE

DOI 10.1109/HICSS.2012.335

1977

total electricity generation in the United States and

17.7% worldwide. China was the leading nation by renewable generation capacity in 2008 (598 TWh of renewable energy produced that year). A total of 3,584

TWh of renewable energy was produced in the world in

2008, of that only 12 TWh was from solar photovoltaic generators while, for example, 16% (3,288 TWh) of world electric energy was produced from hydroelectric plants. The PV market, however, grew at a rate of ~ 13

% per year during 1982-1996, and further expanded to an average annual growth rate of ~ 40 % during 1996-

2010. In 2008 in the United States, cumulative solar PV net capacity increased by 44% from 2007. The growth rate shows PV is an ongoing shift in electricity generation. PV module shipments increased at an average annual growth rate of 13% since 1982 as one of the most rapidly growing generation resources.

Estimated potential growth may transform PV into a

$100 billion industry.

Crystalline silicon (Si) has been the most popular technology for manufacturing PV cells and panels for more than half a century and is largely the reason for its impressive growth in recent times. Crystalline Si is currently facing strong competition from other materials because of its higher manufacturing cost, but it still represents about 90 percent share of the PV market. Significant innovations are taking place in the all areas of (Si) PV cell manufacturing to increase cell efficiencies and lower their cost. Rapid growth of PV installed capacity is expected to continue worldwide and the consequences of the changing generation portfolios will require careful rethinking of planning, operational and many other practices of the electric utilities.

Productions PV cell efficiencies are still below 20 percent. The scale of the PV market, however, grew at a rate of ~ 13 % per year during 1982-1996, and further expanded to an average annual growth rate of ~ 40 % during 1996-2010. Crystalline Si increased its share of the marketplace from 68 % to 90 % in 1990-

2007.Current module prices are about $1.30/W with residential balance of system (BOS) cost of~$2.50/W.

This results in an installed system cost of ~ $4/W and levelized cost of electricity (LCOE) of ~15 ¢/kWh in

Phoenix AZ type of location (regarding solar flux).

Further installed price decrease are needed (to approximately $3/W) to reach LCOE of 10 ¢/kWh, which is viewed as grid parity in the U.S for residential applications. Installed system price needs to be even lower for grid parity in lower insolation regions.

Figure 1 displays the learning curve for PV: whenever the amount of installed PV in the world is doubled, the price of PV modules decreases by approximately 20%. In 1975 PV modules were $ 80/W with cumulative installed capacity of 0.4 MW while presently there is ~18 GW of installed capacity and module prices are approaching $2/W. Extrapolation of this curve (linearly in the log-log domain) suggests that module price could drop to $1/W when the installed PV capacity reaches 100 GW. That would correspond to the cost of electricity of 10 ¢/kWh. If the growth trend of PV continues into the future then the PV module prices could reach $1/W by 2015.

Due to a variety of conditions (recent shortage of polycrystalline Si, wafers and inverters), growth of PV industry capacity is expected to temporarily outpace the demand (according to some forecast from early 2011, the projections for shipment capacity are exceeding 23

GW p

while the demand was estimated to be less than 16

GW p

) [5]. If these forecasts turn out correct, there will be severe pressures on more than 100 module suppliers which currently operate around the world.

Figure 1: Learning curve for the PV industry [4]

Some boost for PV is expected in spite of the unfavorable economic conditions in the last few years, considering recent catastrophic events in Japan and ripples of the news which quickly spread around the world about the triple (possibly larger) nuclear reactor meltdowns at TEPCO’s Fukushima Daiichi power plant which were seriously damaged by tsunami following the catastrophic earthquake in March of 2011. In June of 2011, the German government has announced its intention to permanently shut down its 17 nuclear reactors by 2022 at the expected cost of $40 billion, not counting a possible litigation with plant owners and other unforeseen consequences of that decision.

German government has at the same time announced its increasing commitment to renewable generation technologies as part of the plan to partially offset the loss of generation created by that decision. The French government, which relies on nuclear energy for nearly

80 percent of its electricity generation, is also considering a 5 percent reduction of its nuclear resources, while the Italian government has announced a freeze in all new nuclear initiatives while other governments are contemplating similar measures.

1978

While those decisions are not equivalent to promotion of renewable, they will create energy shortages that will partly be possible to balance with increased proliferation of all renewable technologies, including photovoltaics. Figure 2 shows a roadmap for LCOE to quantify the need for technology development [5]. In

Figure 2, LCOE contours are plotted as a function of module price and efficiency for a location in Phoenix,

AZ. As an example, 18% to 20% efficient modules at a price of $1.00 to $1.25/W can produce electricity at ~10

¢/kWh. This assumes a BOS cost of $2/W for 20% efficient modules, resulting in an installed system cost of $3.0. Figure 2 also shows that the price of a 10% efficient module needs to be ~ 60 ¢/kW in order to produce electricity at 10 ¢/kWh and a less than 8% efficient module cannot attain grid parity even if it is free unless significant successes are achieved in reducing the BOS cost.

Figure 2: Relationship between module cost, efficiency and the cost of electricity [5].

Lower costs are promoted by higher efficiency cells because variable component of the BOS cost

(installation labor, hardware and land area) increases with lower efficiency due to larger system area. A 15% efficient module with a 0.5%/ºC efficiency degradation coefficient (K

T

) needs to cost $1.17/W in order to produce electricity at 10 ¢/kWh. An 18% efficient module can achieve the same goal at a price of $1.38/W because of lower BOS cost. However, an 18% efficient module (~20% efficient cells) generally has higher open circuit voltage V coefficient K

T

OC

and lower temperature

(

≤

0.4%/ºC) and so one can afford to pay

$1.47/W for the module for grid parity. A 10% efficient

Si module needs to be $0.57/W due to much higher

BOS cost or efficiency premium of $0.90/w.

For cost effectiveness of the installation, module price is also a function of local retail price of electricity and solar flux or insolation. It is important to recognize that the required module price for grid parity is a strong function of module efficiency, temperature coefficient for efficiency degradation, module life, local price of electricity and solar insolation because all these factors influence the total power generated by the module over its life.

Silicon PV technology is benefiting from improved cell efficiencies and lower costs consistent with the goal of attaining grid parity by 2015. The benefits are achieved through innovation in crystal growth and ingot slicing, low-cost technology development for efficiency enhancement and the use of thinner wafers. Model calculations show that 20% screen printed cells on

~170 μm thick wafers produced from $40/kg feedstock

Si can lead to ~$1.20/W modules,

≤

$3.0/W installed system cost and LCOE of ~10 ¢/kWh [5].

3.

Photovoltaic Distributed Generation

Numerous North American utilities are experiencing rapid proliferation of investor-owned solar photovoltaic distributed generation (PV-DG) on their distribution feeders. This is being driven by the need to comply with Renewable Portfolio Standards (RPS) and the availability of incentives for electricity production using renewable resources [1].

PV-DG may be classified as micro, small, medium and utility-scale:

•

Micro-scale PV-DG consists of highly distributed

VA-size single-phase units (e.g., 200 W) such as the ones described in [2].

•

Small-scale PV-DG consists of few kW-size singlephase units (e.g., 5 to 10 kW) such as the ones installed on rooftops of residential households.

•

Medium-scale PV-DG consists of larger kW-size three-phase units (e.g., 100 to 500 kW) such as the ones installed on rooftops of small commercial buildings.

• Utility-scale PV-DG consists of MW-size threephase units that have nominal capacities that are manageable by distribution feeders and substations, e.g., between 500 kW and 10 MW.

PV-DG integration may lead to severe impacts on different areas of distribution systems planning and operations, including effects on active and reactive power flows, voltage profiles (e.g., voltage rise, voltage unbalance), interaction with voltage control and regulation equipment (LTCs, voltage regulators, capacitor banks), equipment maintenance and life cycle, feeder loading, overcurrent and overvoltage protection

(e.g., modification of reach of overcurrent protection devices, Temporary Overvoltage), electric losses, power factor, and power quality. It is worth noting that these impacts are not exclusive of utility-scale PV-DG, they may also be caused by large proliferation of smaller scale PV-DG.

Impact severity is a function of the penetration level and location of PV-DG. Since reverse power flow is

1979

one of the main drivers of PV-DG impacts on distribution feeders, penetration level may be defined on a feeder basis as the ratio of the total installed capacity of PV-DG vs. a predefined feeder demand [3].

A convenient approach is to use the PV-DG system’s

AC ratings ( P

PVAC

) and the annual minimum feeder load at times of maximum PV-DG output ( P

Fmin,PVmax

), e.g., at noon, as shown in (1), where P i,PVAC

is the AC rating of the i -th PV-DG plant in the feeder:

ܲ ൌ

σ

ǡುೇಲ

ಷǡುೇೌೣ

(1)

Using this definition the following penetration levels may be defined:

•

Low penetration:

σ

݇

ଵ

ୀ

ܲ

൏ σ ܲ

•

High penetration:

σ ܲ

ǡ

ǡ

൏ ݇

ܲ

ிǡ௫

݇

ଵ

ଶ

ܲ

ܲ

ிǡ௫

•

Moderate penetration:

ୀ ǡ

ிǡ௫

൏ ݇

ଶ

ܲ

ிǡ௫

A similar definition may be used for determining penetration levels for distribution substations or individual distribution transformers, in that case

P

Fmin,PVmax

must be replaced by P

Submin,PVmax

and

P

Transfmin,PVmax

, respectively. The selection of k

1

and k

2 would depend, among others, on the utility’s distribution planning and operation guidelines and criteria, system characteristics, etc. For instance, if k

1

=

1 and k

2

= 2, then low penetration level does not lead to reverse power flow, moderate penetration causes

“modest” reverse power flow and high penetration produces “severe” reverse power flow at distribution feeder level. A more “conservative” utility with feeders that are more prone to be impacted by PV-DG may prefer to use k

1

= 0.5 and k

2

= 1 to define penetration levels. However, it is worth mentioning that other definitions may also be used, e.g., penetration level on the basis of the percentage of residential customers that adopt the technology, i.e., that install PV-DG systems.

It is worth noting that conventional DG output is relatively constant and controllable, therefore most of its impacts can be investigated through steady state analyses. Due to the intermittency of its primary resource due to clouding phenomena, PV-DG impacts also need to be analyzed by means of dynamic studies.

Given the complexity of these studies, impacts and mitigation measures are more difficult to identify, and utilities and distribution planners are generally are less prepared to deal with them. Moreover, many existing utility interconnection standards and planning guidelines need to be revisited to ensure that all these aspects are appropriately taken into account.

Section 4 of this paper discusses impacts of PV-DG on power distribution systems and measures to mitigate them, with emphasis on utility-scale PV-DG. In order to capture a wide range of possible phenomena and impacts, the results of analysis performed for a variety of scenarios on real distribution feeders are presented and discussed. These scenarios cover different penetration levels and location of PV-DG and various feeder loading conditions.

4. PV-DG Impacts on Distribution Systems

Some of the most common impacts driven by PV-

DG integration on distribution systems are:

•

Reverse power flow: high penetration levels of PV-

DG can lead to reverse active power flow at feeder and substation transformer level. This condition may affect overcurrent protection coordination and the operation of line voltage regulators, particularly of those set to forward operation mode and/or Line

Drop Compensation (LDC) [1]. Furthermore, reverse power flow at substation transformer level may affect voltages and loading limits of some transformers [6].

• Voltage rise: PV-DG integration modifies feeder voltage profiles and may lead to significant voltage rise particularly at locations close to PV-DG plant sites. This can cause violations on utility planning limits and industry standards, cause complaints from customers, and cause the operation of overvoltage protection systems of PV-DG plants.

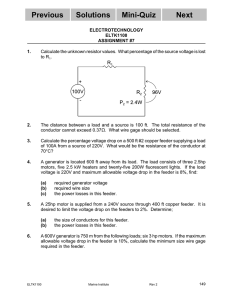

Figure 3 shows an example of steady-state voltage rise at four PV-DG plant sites (base case represents no PV-DG generation). Since the magnitude of voltage rise is, among others, a function of PV-DG output, in this case the voltage profiles follow the typical bell-shape of PV-DG output. Voltage rise is a limitation for integration when large PV-DG units are connected at the end of long, lightlyloaded feeders.

•

Voltage fluctuations: PV-DG intermittency can have significant impacts on feeder voltages. This is more noticeable on feeders with low short-circuit power levels, i.e., with low stiffness factor, and on

PV-DG plants located far from distribution substations. Figures 4 and 5 show examples of PV-

DG intermittency. Figure 4 shows the output profiles of a real PV-DG plant for the month of

August of 2010. This plot shows that significant

1980

variations for this PV-DG plant. Evidently these customers. The severity of these voltage fluctuations and power quality issues can be

90

80

70

60

50

40

30

20

10

0 that adopt the technology).

1.05

1.04

1.03

1.02

1.01

1.00

0.99

0.98

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Hour

PV1-Base

PV1-Connected

PV2-Base

PV2-Connected

PV3-Base PV4-Base

PV4-Connected

1.60

1.40

1.20

1.00

0.80

0.60

0.40

0.20

0.00

0.0

0.5

P (MW)

Fir

1.0

1.5

2.0

0% 50% 100%

• penetration level es increase: Low and decrease the magnitude o f feeder currents, proportional to the square o f line current) and

Hour

Figure 4. PV-DG output intermi ittency

•

Voltage and current unbalance: l large penetration

PV-DG, on the other side, may cause reverse power flow and increase the magnitude of

PV-DG installed on rooftops of residential households) may offset feeder cur rrents and lead to significant voltage and current unbalance (e.g., phase A of a three-phase lateral may experience different penetration levels of PV-DG (penetration

Figure 7 for various penetrat tion levels, e.g., for

100% penetration, losses (wi ith respect to base overall effect on feeder losses can be evaluated by calculating average instead of i nstantaneous losses.

•

Total Harmonic Distortion (T HD) increase: large penetration levels of PV-DG may lead to THD increase. This is becoming a n important subject

1981

given the fact that additional power electronicsinterfaced equipment is expected to be connected to the distribution grid, e.g., Plug-in Electric

Vehicles and Distributed Energy Storage (DES).

Therefore, interaction among all these equipment plus the presence of capacitor banks on the distribution system may lead to other harmonic related issues such as resonance. Figure 8 shows the THD values for different feeder locations and

100% penetration of PV-DG.

•

Interaction with voltage-controlled capacitor banks,

LTCs, and line voltage regulators: Voltage rise and voltage fluctuations may cause an increase in the tap changes LTCs and line voltage regulators, and cause switching of voltage-controlled capacitor banks. This in turn can cause additional voltage and reactive power flow fluctuations, affect power quality, equipment maintenance frequency and lifecycle, and impact the implementation of advanced

Volt-VAr Optimization (VVO) schemes such as

Conservation Voltage Reduction (CVR).

40

30

5. Mitigation Measures

The severity of the steady-state and dynamic issues

20

10

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 caused by PV-DG integration is estimated via impact studies. The objective of these studies is to determine economically feasible mitigation measures that alleviate the impacts and facilitate integration of PV-DG plants.

Mitigation measures are a function of the nature of the

Hour

BASE

40%

10%

50%

20%

60%

100%

30%

70%

80% 90%

Figure 7. Feeder losses as a function of PV-DG penetration level

0.05

0.0

0.05

for two real distribution feeders

Harmonic Spectrum at source

[3] 0.0290617

Harmonic Spectrum at mid point impacts identified during the studies (steady state, dynamic or both) and applicable regulation, policies and standards. Alternatives for mitigating PV-DG impacts can be classified as conventional and smart grid approaches. Conventional approaches include the utilization of existing technologies, examples of this are:

•

Set line voltage regulators and LTCs to cogeneration or bidirectional operation modes, and modify or customize their control settings (e.g., reference voltage) to account for the voltage rise

0.0

and load offset (e.g., for Line Drop Compensation applications) introduced by PV-DG plants

•

Modify control settings of capacitor banks, relocate existing capacitor banks, and install controls on

[83] 0.00442317

Harmonic Spectrum at end point

0.05

fixed capacitor banks

•

Rebalance feeder loads to mitigate steady state high voltage, voltage and current unbalance, and reduce voltage fluctuations

•

Use express or dedicated feeders for independent interconnection of utility-scale PV-DG plants.

•

0.0

[3] 0.0409815

Figure 8. THD for 100% PV-DG penetration level and different feeder locations. THD from top to bottom is 4.35% (feeder gateway), 4.85% (feeder midpoint) and 7.45% (feeder end).

Overcurrent and overvoltage protection: Potential impacts of PV-DG on protection systems include reach modification of overcurrent protection devices such as reclosers and relays, and

Considerations such as express feeder voltage and annual energy losses are important for selecting the length of express feeders and the maximum capacity of PV-DG plants to be interconnected by it.

Smart grid approaches make use of new technologies

Temporary Overvoltage (TOV) due to ungrounded system operation during accidental islanding and novel operational methodologies, examples of this are: conditions. Overall overcurrent protection coordination may also be affected.

• Operate PV-DG plants at fixed non-unity leading power factor (absorbing VArs within inverter

1982

limits) or under a power factor schedule

• Implement dynamic volt-VAr compensation schemes using either PV-DG inverters or Flexible

AC Distribution Systems (FACDS) such as distribution Static Synchronous Compensator

(STATCOM), commercially known as D-VAr [7]

•

Use DES to level out and “firm” PV-DG output during intermittency conditions and mitigate voltage fluctuations

• Using Direct Transfer Trip schemes (DTT) or grounding banks to prevent ungrounded system operation and TOV during accidental islanding of

PV-DG

•

Use directional protection to prevent overcurrent protection miss-operation.

•

Use GPS-based synchrophasor measurement technology to detect islanding.

Figure 9 show the simulation results of operating

PV-DG plants at fixed non-unity leading power factor for the same plants as Figure 3. The results show that the steady-state voltage increase at the PV-DG plant sites is alleviated by this mitigation measure.

Voltage Profile PV-DG - Minimum Case (mitigation)

1.05

simulations is 1.04 PU. The results show how dynamic volt-VAr compensation outperforms power factor mitigation. The highest voltage with no mitigation exceeds 1.52 p.u. (curve b), with power factor mitigation is limited to 1.05 p.u. (curve c), and while with volt-VAr compensation is limited to 1.4 p.u.

(curve d).

6. PV-DG Impacts on Generation Costs

In the following sections, an installation involving various PV-DG capacities distributed across the feeder is investigated from the standpoint of ecological and economic effectiveness. While some simplifying assumptions are being made (mostly due to the lack of actual data), the conclusions drawn are not impacted by those simplifications.

Solar radiation

No mitigation

1.04

1.03

1.02

1.01

PF mitigation

1.00

0.99

Dynamic volt-VAr mitigation

0.98

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Hour

PV1-Base PV2-Base PV3-Base PV4-Base

PV1-Connected PV2-Connected PV3-Connected PV4-Connected

Figure 9. Voltage rise at PV-DG plant sites (mitigation case using fixed non-unity leading power factor of 0.97)

However, in some cases the utilization of a fixed non-unity leading power factor does not mitigate voltage fluctuations or voltage violations during rapid

PV-DG output fluctuations caused by intermittency

(incident solar radiation fluctuation due to clouding).

Such situation may require implementing a dynamic volt-VAr compensation scheme using PV-DG inverters, this schemes dynamically modifies the inverters reactive power output, i.e., the plant power factor, to keep voltages within predefined limits. Figure 10 shows solar radiation (top curve) and a comparison of three cases, b) no mitigation, c) mitigation using fixed nonunity leading power factor, and d) mitigation using dynamic volt-VAr compensation scheme using PV-DG inverters. The maximum voltage limit in these

0 250 500 750 1000 1250 1500 1750 2000

Time (seconds)

Figure 10. Dynamic voltage fluctuations at PV-DG plant site: a) solar radiation, b) no mitigation, c) mitigation using fixed nonunity leading power factor of 0.97, and d) mitigation using dynamic volt-VAr compensation scheme using PV-DG inverters

A load profile varies in time in accordance with the customer type (residential, commercial, agricultural and pumping, industrial, and large industrial customers).

The load profiles used in this analysis are obtained from actual utility data [11]. To account statistically for a variety of types of loads, reactive power consumption is generated randomly while the power factor is kept over

0.85. It is assumed that all the individual customer loads have nearly identical load profiles at the feeder.

Feeder peak demand is assumed to be 3.49 MW applied to the IEEE 123 test feeder. The characteristics of different load profiles are analyzed in Figures 11 and

12. Figure 11 presents the load duration curves of total active power of each load type. It shows that large

1983

industrial type loads exceed the active power load profile most often, while residential type loads are least likely to exceed it. Figure 12 presents the probability curves of total active power of each load type.

4000

Large Industrial

3500

3000

Agricultural and Pumping

Industrial

Commercial

Residential

2500

2000

1500

1000

500

0 % 10 % 20 % 30 % 40 % 50 % 60 % 70 % 80 % 90 % 100%

Percentage of time that power exceeds curve[%]

Figure 11. Duration curves of annual 3-phase active power of each load type in 2010

Interaction between DG utilization and load profile will affect the total energy costs. For the utility, the benefit of using DG is avoided energy production near peak levels and reduction in transmission and distribution losses. Reducing the effective feeder load in the distribution networks where it is installed also reduces the transmission and distribution losses.

The total energy savings can be translated into the total generation cost savings. Assumed costs for base, intermediate, peak power generation are shown in Table

1. The generation cost curve in 100 kW blocks is shown in Figure 13.

0.35

0.3

0.25

Residential

Commercial

Industrial

Agricultural and Pumping

Large Industrial

0.2

0.15

0.1

0.05

0

1000 1500 2000

Power in kW

2500 3000 3500

Figure 12. Probability curves of annual 3-phase active power of each load type in 2010

35

30

25

20

15

10

5

550

500

450

400

350

Large Industrial

Agriculture and Pumping

Industrial

Commercial

Residential

300

250

200

150

100

50

0 % 10 % 20 % 30 % 40 % 50 % 60 % 70 % 80 % 90 % 100%

Figure 13. The generation cost curve in 100 kW blocks of each load type in 2010

According to the assumed cost rate for base, intermediate, and peak power generation, the projected annual generation costs are calculated. The elements in the following tables are obtained using the following formula where P i is the active power produced in hour i of the year and CP i

is the cost of avoided generation at the same time:

C

Annual

Generation

=

8760

¦

P i

×

C

P i i

=

1

The validation of the PV system output in the Atlanta area was obtained using the System Advisor Model

(SAM) from NREL to compare the performance of the

340 kW system on Georgia Tech campus with its modeled forecast. The results, shown in Figure 14, show a good agreement between the actual and forecasted data.

50

45

GTAC PV SIM

SAM

40

0

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Figure 14. Comparison of SAM and GTAC PV simulation program at the 90° azimuth (facing east) and 15° tilt angle

1984

Table 1. Levelized cost data for generation [12]

Base

Power

Intermedia te Power

Peak

Power

Capacity

(kW)

0~1500

1500~3000

3000~

Fuel

Coal,

Nuclear

IGCC,

GCC

Gas turbine

Generation Cost

($/MWh)

Coal: 78$ ~ 144 $

Nuclear: 107$ ~ 138$

IGCC: 110$ ~ 141$

GCC: 74$ ~ 102$

Gas Peak: 225$ ~ 342$

7. PV-DG Impacts on Energy Savings

The main objective of PV installation is to boost the energy savings. Figure 15 shows annual estimated monthly PV generation output of an assumed PV system in the Atlanta area in the United States. It is assumed that the total PV capacity is equal to 40 % of the peak load demand. Figure 16 presents the impact of

PV on feeder load demand. Penetration levels from 0-

40% are assumed.

1600 300

Total Demand

PV Output Generation(40%)

1400

250

1200

200

1000

800

600

400

200

150

100

50 etc.). In addition to CO

2

reduction, it can also cause water footprint reduction through avoided thermoelectric and hydroelectric generation, fuel reduction, such as coal, petroleum, and natural gas in the thermal power generation. Energy savings and replacement values using alternative energy generation are shown in Table 2.

If shaving of peak load levels is the main objective, it is possible to orient the PV system more westward, thereby boosting the PV output at the peak load times at the expense of some reduction of the overall production of energy. Assuming that a feeder has 3,000 kW critical peak loads, if the total critical load reductions are 1000 kW in the presence of a 10% PV generation with 100 hours/year, then the avoided generation cost at peak rate is 21,280 [$/year] per feeder. Table 3 presents this potential impact of the cost for the critical peak load on each penetration level. Figure 17 shows the annual total generation cost curves of each penetration level.

Table 2. Energy savings and replacement values on a IEEE test distribution feeder considering alternative energy generation

PV

Penetr.

Rate

Energy CO

2

Energy

Savings

Reduction

Thermoelectr.

Site Water

Water

Hydroelect

.

Weighd

Total Site

10% 538.12 339.0 0.3 25.5 0.9

20% 1070.95 689.0 0.6 50.8 1.8

30% 1598.49 1028.3 1.0

40% 2119.77 1364.0 1.3

75.8 2.6

100.5 3.5

PV

Penetr.

Rate

Coal Petrol

Fuel

Natural Gas Other

Gases

Biomass

2200

2000

1800

1600

0

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Figure 15. Annual PV generation and load demand on a typical distribution feeder.

3400

0

3200

3000

2800

2600

2400

0%

10%

15%

20%

25%

30%

35%

40%

1400

00:00 06:00 12:00 18:00 00:00

Figure 16. The effect of PV generation on a typical day of the year

(horizontal axis represents time of the 244 th

day of the yr)

In addition, the PV output energy savings are providing the opportunity to create the avoided carbon footprint of peak generators by not using the more ecologically impactful technologies (coal, natural gas,

Table 3. Potential impact for the critical peak load

Penetration

Level

Reduced

Peak

Load

Reduction Hour

Avoided

Generation

Load(kW) in 100kW Cost($/year)

0% 3557.87 0 0 $0

The total energy savings can be also translated into the total generation cost savings. It is known that different generation technologies are used for persistent, low inertia and low cost generation at the base load level (coal, nuclear), while more expensive and much more dynamic power plants are used to follow sometimes rapidly changing loads at the peak level (gas turbines). The cost differences between different generation technologies contribute to higher cost of generation during peaks loading conditions. The difference may be 10-20 times higher than the cost of

1985

generation at base load. According to the typical cost rate for base, intermediate, and peak power generation, the projected annual generation costs are presented in

Table 4.

550

500

450

400

350

300

0%

10%

Peak with respect to operational aspects in distribution networks, as well as energy savings, ecological, and generation cost. In addition, this study addresses potential cost impacts on critical peak load.

Continuously decreasing prices and increasing efficiencies of the PV modules and BOS and favorable analyses of large level integrations of renewable generation into distribution networks offer opportunities for peak load reduction, as well as reduction of electric utilities carbon and water footprints. When the combined impact of these factors is taken into account, grid parity may be reached sooner than some analysts are predicting.

250

200

150

100

Critical Peak Load (100 Hours/Year)

50

1000 1500 2000 2500 3000 3500

Power in kW

Figure 17. Annual generation cost curve for penetration levels

Table 4. Total annual generation costs of each penetration level

Penetration

Rate

Total

Consumed

Energy

Energy

Savings

Projected

Generation

Cost

Cost

Savings

MWh/yr MWh/yr $/yr $/yr

A A 0% A N % B B 0% B N %

0% 10419.06 0 $1,262,919 0

$1,199,792 $63,126

20% 9348.11 $1,138,441 $124,478

30% 8820.57 $1,076,766 $186,153

40% 8299.29 $1,016,124 $246,794

The results shown in Table 4 do not take into account the cost of PV generators installed on a feeder. The third column represents energy savings through local

PV production at penetration levels equal to percentages of the peak load (first column). The cost savings accounting for types of avoided generation technologies are shown in the last two columns. It is assumed that such generation may be the result of green energy incentive programs or individual customer initiative. If the cost of PV is taken into account, it would allow calculating the break even times for economic recovery of the investment. As those costs are rapidly declining at the present time, it is reasonable to assume that PV technology will reach grid parity at some time between 2013 and 2017 in the most developed countries.

8. Conclusions

This paper provides a viewpoint of technological and economic snapshot of the current PV technology with a view of achieving grid parity in the near future, and presents a discussion of the impact of PV generation

9. Acknowlegement

The authors gratefully acknowledge support of

National Science Foundation under grant #0836046 which was used for part of the work presented herein.

10. References

[1] J. Romero Agüero, S. Steffel, “Integration Challenges of

Photovoltaic Distributed Generation on Power Distribution

Systems”, Proceedings of IEEE PES 2011 General Meeting,

Detroit, MI, July 2011.

[2] http://www.petrasolar.com/downloads/SunWave-UP-Series.pdf

[3] M. Ropp, J. Newmiller, C. Whitaker, B. Norris, “Review of potential problems and utility concerns arising from high penetration levels of photovoltaics in distribution systems”,

33rd IEEE Photovoltaic Specialists Conference 2008 , San

Diego, CA

[4] Rohatgi.A., Ristow.A., Das.A., Ramanathan.S., Road to Cost th

Effective Silicon PV, 18 I-PVSEC, Jan 2009.

[5] Kim, P., Polivarapu, H., “Solar Photovoltaic Industry: 2011

Outlook – FIT cuts in key markets point to over-supply,”

Deutsche Bank, January 5, 2011.

[6] L.M. Cipcigan, P.C. Taylor, Investigation of the reverse power flow requirements of high penetrations of small-scale embedded generation, IET Renewable Power Generation , pp. 160-166, No.

3, Vol. 1, Sep. 2007.

[7] http://www.amsc.com/products/transmissiongrid/reactivepower-AC-transmission.html

[8] G.M Masters, Renewable and Efficient Electric Power Systems,

Wiley, 2004

[9] T.A. Short, Electric Power Distribution Handbook , CRC Press,

2003

[10] Miroslav M. Begovic, Insu Kim,” Distributed Renewable PV

Generation in Urban Distribution Networks”, Proceedings 2011

IEEE PSCE , March 2011, Phoenix, AZ.

[11] http://www.sce.com/AboutSCE/Regulatory/loadprofiles/2010lo adprofiles.htm

[12] “Levelized Cost of Energy Analysis, Version 3.0”, Lazard, pp.

2, February 2009. Begovic, M., Pregelj, A., Rohatgi, A., “Fouryear performance assessment of the 342 kW PV system at

Georgia Tech”, Photovoltaic Specialists Conference, 2000 .

Conference Record of the Twenty-Eighth IEEE 15-22 Sept.

2000 Page(s):1575 – 1578

[13] Seth Borin, Joy Wang, and Valerie Thomas, “City of Atlanta

Greenhouse Gas Emissions Inventory”, pp. 9, March 2009.

P.

Torcellini, N. Long, and R. Judkoff, “Consumptive Water Use for U.S. Power Production”, NREL, pp. 5, December 2003.

“Annual Energy Review 2009”, U.S. Energy Information

Administration, pp. 230, August 2010

1986