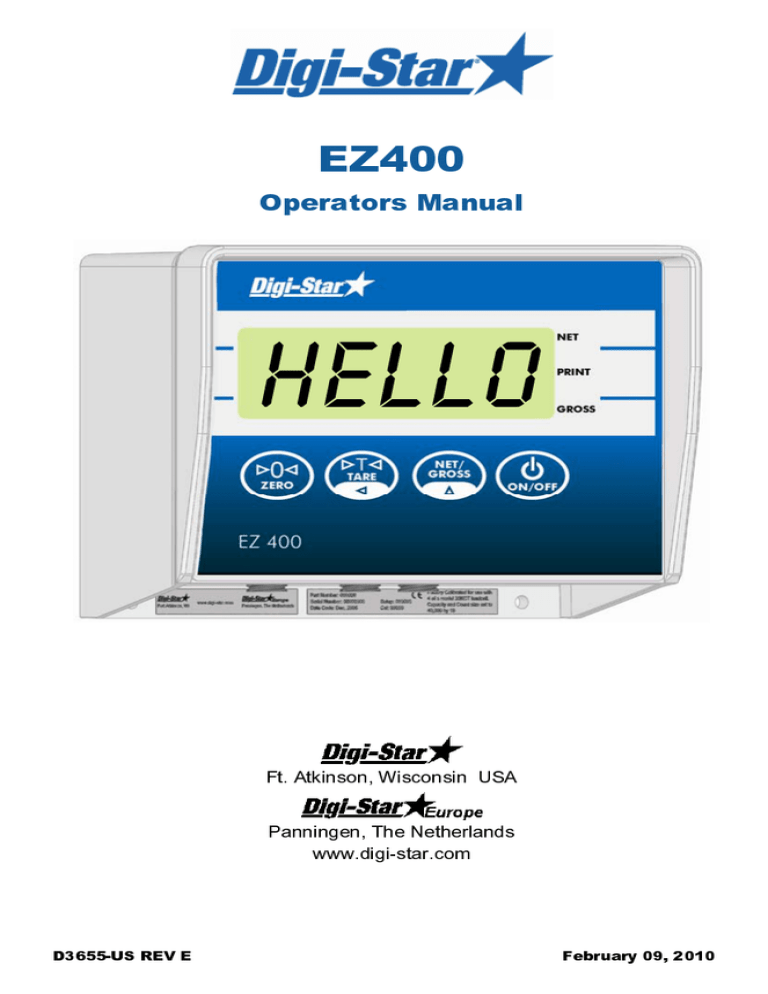

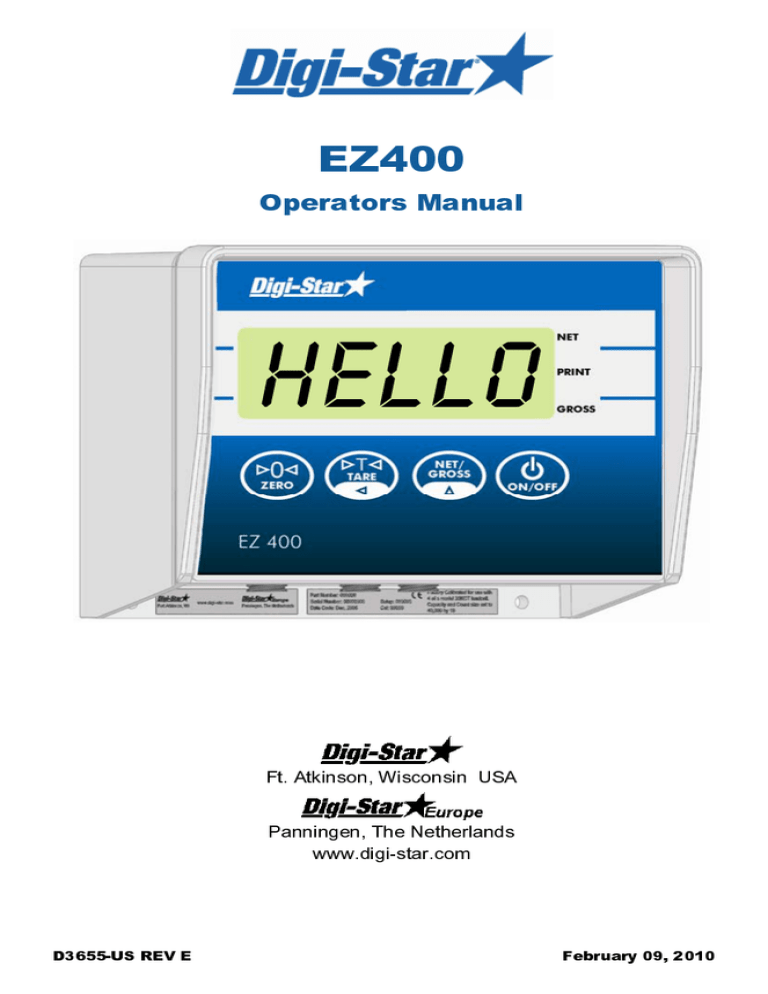

EZ400

Operators Manual

HELLO

Ft. Atkinson, Wisconsin USA

Panningen, The Netherlands

www.digi-star.com

D3655-US REV E

February 09, 2010

EZ400 User’s Manual

D3655-US Rev E

TABLE OF CONTENTS

Table of Contents

TECHNICAL SPECIFICATIONS ..................................................................... 1

SAFETY DURING USE ................................................................................... 2

Cleaning ....................................................................................................... 2

Charging Battery and Welding ..................................................................... 2

INDICATOR OVERVIEW ................................................................................ 3

OPERATION ................................................................................................... 5

Turn on Indicator .......................................................................................... 5

Zero Balance Indicator ................................................................................. 5

Tare and Net/Gross ..................................................................................... 6

Store Data to DDL........................................................................................ 8

Printing Gross Weights ................................................................................ 8

Print Formats ............................................................................................... 9

Changing Indicator ID Name & Clearing Accumulated Weight ................. 10

Turning Off the Indicator ............................................................................ 10

WEIGH METHODS ....................................................................................... 11

General Weigh Method #1 ......................................................................... 11

Slow Weigh Method #2 .............................................................................. 11

Fast Weigh Method #3 ............................................................................... 11

Lock-on Weigh Method #4 ......................................................................... 11

WEIGHING ERRORS ................................................................................... 12

Over-Capacity Limit (OVRCAP)...................................................................... 12

Over Range (+RANGE) .................................................................................. 12

Under Range (-RANGE)................................................................................. 12

Low Battery Indication (LO BAT) ................................................................... 12

RUN SELF TEST .......................................................................................... 12

MENUS AND CALIBRATION ........................................................................ 13

Changing Options Using Long Form Setup ............................................... 13

SHORT FORM CALIBRATION ..................................................................... 17

Obtain Current Set-up and Calibration Number ........................................ 17

Calibrating Scale For Maximum Accuracy ................................................. 18

Determining New Setup and Calibration Numbers .................................... 18

Enter A New Setup And Calibration Number ............................................. 19

INSTALLATION ............................................................................................. 20

Indicator Mounting ..................................................................................... 20

Optional Ram Mounting ............................................................................. 20

Cable Connection ...................................................................................... 21

Indicator Connection Diagram ................................................................... 21

Bottom Panel Cable Connections .............................................................. 21

Connect Load Cells to J-Box ..................................................................... 22

Load Cell Direction..................................................................................... 22

D3655-US Rev E

EZ400 User’s Manual

Table of Contents

Indicator Calibration ................................................................................... 22

OPTIONAL EQUIPMENT .............................................................................. 23

Data Transfer Options................................................................................ 23

Remote Indicators ...................................................................................... 23

TROUBLESHOOTING .................................................................................. 24

All rights reserved. Reproduction of any part of this manual in any form whatsoever without Digi-Star’s express written permission is

forbidden. The contents of this manual are subject to change without notice. All efforts have been made to assure the accuracy of

the contents of this manual. However, should any errors be detected, Digi-Star would greatly appreciate being informed of them.

The above notwithstanding, Digi-Star can assume no responsibility for errors in this manual or their consequence.

© Copyright! 2009 Digi-Star, Fort Atkinson (U.S.A.).

EZ400 User’s Manual

D3655-US Rev E

TECHNICAL SPECIFICATIONS

Technical Specifications

SIZE

7.33” long x 5.25” high x 3.38” wide (186mm x

133mm x 85mm)

DISPLAY RESOLUTION

.01, .02, .05, .1, .2, .5, 1, 2, 5, 10, 20, 50, 100

WEIGHT

2 lbs (.91 Kg)

DISPLAY UPDATE RATE

Selectable: 1, 2, 3, 4 times/sec.

HELP MESSAGES

Context sensitive help messages in 10

languages

Long messages are scrolled

MAX. DISPLAY RESOLUTION

Adjustable to 40,000 counts max.

TRANSDUCER EXCITATION

8 volts D.C. Nominal

Capable of driving eight 350 Ohms transducers

Short circuit proof

ATC

Auto Temperature Compensation of the internal

circuitry for high accuracy weighing

measurements

TRANSDUCER SIGNAL

Compatible with transducers having full scale

indicator transfer characteristics greater than

0.25 mv/v

“AUTO RANGE”

(Selectable) To increase display counts

at weight values of 300 and 600 display counts.

CONNECTOR

AMP plastic weather resistant circular

connector. Gold contacts.

POWER REQUIREMENTS

10.5 to 16.0 V.D.C.

160 mA nominal with four 350Ω L.C.

ZERO TRACKING

Selectable, On/Off

SPAN ACCURACY

±(.1% + .005%/ °F) or (.1% + 0.009% °C) full scale ± 1

output count

MOTION DETECTION

Selectable, On/Off

ZERO ACCURACY

(.005%/ °F.) or (0.009% °C) full scale ±1 output count

for 0.5 mv/v transducer

ENVIRONMENTAL ENCLOSURE

IP65, IEC 529

WEIGH ALGORITHM

4 internally selectable digital filters to optimize

performance

(General, Slow, Fast and Lock-on)

NON-VOLATILE MEMORY

EEPROM for balance

OPERATING TEMP

-29°C to 60°C

-20°F to 140°F

SET UP AND CALIBRATION

Via front panel

GROSS RANGE

999,999 max.display

LOW BATTERY WARNING

Enabled at 10.5V nominal

POUND/KILOGRAM

Selectable

DISPLAY

STD EZ 6 Digit LCD 1.0. high

D3655-US Rev E

EZ400 User’s Manual

1

SAFETY DURING USE

Safety During Use

Caution

Cleaning

Do not use running water (high pressure cleaners, hoses) to clean the

indicator.

Charging Battery and Welding

Disconnect all cables from the weighing indicator before charging the

battery or welding on the machine. If cables are left connected, the

weighing indicator and connected load cells could be damaged.

Scale Indicator

Disconnect

all cords

2

EZ400 User’s Manual

D3655-US Rev E

Indicator Overview

INDICATOR OVERVIEW

5

1

2

3

4

Note: See page 20 for installation instructions.

1

– press and hold for 3 seconds to zero balance indicator.

2

– temporary zero (Net Mode) (Standard EZ400).

- Optional: (EZ400 with serial port)

temporary zero (Net Mode)

printer records to memory or prints displayed weight

3

– toggles between Net and Gross weights.

4

– turns indicator on/off. Press while on runs self test.

5

Display Window – Displays current actions.

D3655-US Rev E

EZ400 User’s Manual

3

Indicator Overview

Bottom Panel

6

9

7

8

6 - Power Cord Connection – +12 VDC.

7 -Load Cell Connection – Connect cable from the J-Box.

8 -Serial/J905 – Optional, to communicate with computer and other digital

Input/Output devices.

9

- Remote Port – Optional, for remote display

Pin

1

2

3

4

5

6

7

8

4

J905 Connector Signals

+5VDC

Com #1 Out (Tx) - Computer

Com #1 In (Rx) - DDL & Computer

Com #2 Out (Tx) - Printer

+12 VDC

Gnd – Available for any Com device

Com #2 In (Rx)

Ground

EZ400 User’s Manual

D3655-US Rev E

Operation

OPERATION

Turn on Indicator

1.

HELLO

Press

.

1

Zero Balance Indicator

1. Press

1

1

0

2

for 3 seconds to zero

balance indicator.

2. Flashing arrow points to gross next

to the display window, indicator

ready to weigh.

D3655-US Rev E

EZ400 User’s Manual

5

Operation

Tare and Net/Gross

Tare is a temporary zero (Net Weight)

to display total weight (Gross Weight)

Press

.

4000

1. Weight displayed, press

zero weight.

sets

1

0

2. Pressing

displays zero weight

and flashing arrow on side of

display points to NET.

2

3

6

3. Add more weight.

300

EZ400 User’s Manual

D3655-US Rev E

Operation

4. To know total of original weight of

4000 pounds plus added 300

pounds, press

to show 4300

pounds, flashing arrow points

GROSS.

4300

4

5. Press

300 pounds displayed

flashing arrow points NET.

300

5

D3655-US Rev E

EZ400 User’s Manual

7

Operation

Store Data to DDL

(Serial Option Only)

1. Connect the DDL to the SERIAL

port on the bottom panel. See page

4.

2. Press and hold

to save print

data to the DDL.

2

Printing Gross Weights

Optional serial port must be

installed for printing.

Note:

1

8

1. Press and hold

3 seconds to

send displayed weight to serial port.

Each time this command is executed

the value displayed is added to the

“PRTACC” which is the accumulated

weight. Weight is accumulated until

cleared.

EZ400 User’s Manual

D3655-US Rev E

Operation

Print Formats

Three print formats are available to output PRTACC value and SCALE ID to DDL

or printer.

PRTAC1:

FIELD ID, 4856, GR, 274575, PA, 05FE08, I:44P

PRTAC2:

FIELD ID, 05FE08, I:44P

4856, GR, 274575, PA

Includes following information:

• Scale ID (SCALID)

• Weight

• Weight Tag (Net, Gross, Load/Unload)

• Accumulated Weight

• Print Accumulator Tag

• Date and Time

FIELD3, 5977, LB, ,GR, 3097I9,PA,05FE08, 4:42P

PRTAC3:

Includes above and adds “Unit of Measure” and “Lock-On Status” (for

animal weighing).

See “Setting Options” (page 13) to change print format (PRTFMT).

D3655-US Rev E

EZ400 User’s Manual

9

Operation

Changing Indicator ID Name

& Clearing Accumulated

Weight

5

SCALID

2

1 2

3 4

1. Press and hold

3 seconds.

SCALID is displayed followed by

current ID name.

2. Use

and

to enter new

Scale ID.

3. Press

to view accumulated

weight.

4. Press

to resume weighing.

Or

5. Press

to clear accumulated

weight total.

Turning Off the Indicator

bye

1. Press

until “BYE” is displayed.

1

10

EZ400 User’s Manual

D3655-US Rev E

Weigh Methods

WEIGH METHODS

Select weigh method #1 for general weighing.

General Weigh Method #1

All purpose weigh method for stable loads.

Slow Weigh Method #2

Higher accuracy for weighing stable loads.

Fast Weigh Method #3

Determines new weight quickly when weighing stable loads.

Lock-on Weigh Method #4

Weighing active animals and displays stable accurate weight. Set to “OFF” for

weighing stable weights. Lock-On sensitivity can be adjusted using “LOCKON”

menu.

Once weight displayed, scale “Locks-On” to weight. Weight does not change,

even if motion never stops. Small ‘L’ appears on left side of the display

indicating weight “Locked-On.” Animal’s weight must be greater than 2.5% of

scales “capacity” weight before system “Lock-On.”

Break lock, 50% of displayed weight added or removed from scale. “LockedOn” weight can be “rechecked” by pressing . . This breaks “lock” and scale

recalculates weight.

D3655-US Rev E

EZ400 User’s Manual

11

Weighing Errors

WEIGHING ERRORS

Over-Capacity Limit (OVRCAP)

The display shows the message "OVRCAP" if the weight on the scale system

exceeds the capacity limit. The capacity value is entered in SETUP to warn of

overloading the scale system.

Over Range (+RANGE)

The display shows the message "+RANGE" if the weight on the scale system

exceeds the maximum weight measurable by the scale system. The over

range value is always the system’s maximum A/D counts multiplied by the

scaling factor. The actual weight at which over range occurs depends on the

calibration, zero, and display count size.

Under Range (-RANGE)

The display shows the message "-RANGE" if the weight on the scale system is

less than the minimum weight measurable by the scale system. The under

range value is always the system’s minimum A/D counts multiplied by the

scaling factor. The actual weight at which under range occurs will depend on

the; calibration, zero, and display count size.

Low Battery Indication (LO BAT)

If the supply voltage drops below the (10.5 Volts), the message RECHARGE

BATTERY - TURNING OFF” and LO BAT” will periodically show on the display to alert

the operator of the low battery condition.

“

“

RUN SELF TEST

1

12

1. Press

then

during

normal system operation to start

self-test.

EZ400 User’s Manual

D3655-US Rev E

MENUS AND CALIBRATION

Menus and Calibration

The Indicator has optional settings that allow flexibility in the way that the scale

is used and data is collected.

Changing Options Using Long Form Setup

Enter Long Form Setup by holding

and

Press

to select menu 1, 2, 3 or 4.

for three seconds.

Press

to advance to desired parameter.

Press

to select proper setting.

Press

to save setting and advance to next parameter.

Hold

and press

to return to indicator operation.

Default settings from the factory vary with options and due to customer

preferences.

SETTING

[display]

OPTIONS [displayed]

BOLD=DEFAULT

DESCRIPTION

MENU 1. BASIC FEATURES IN MOST INDICATORS

LANGUAGE

(langag)

DISPLAY RATE

(0 rate)

ZERO TRACK

(ztrack)

English

Dutch

French

German

Italian

Portuguese

Spanish

Danish

Hungarian

Spanish

[ENGLSH)

[NEDERL]

[FRANCS]

[DEUTSH]

(ITAL]

(PORT]

(ESPAN]

(DANSK]

(MAGYAR]

(VESTA]

Select language to be displayed.

I,2,3,4

Update display times per second.

ON/OFF

If ON -zero track adjust balance for

buildup of snow & mud.

WEIGH METHOD

I=General,

(W mthd)

2=Fast,

3=Slow,

Select weigh method

4=Lock-On

D3655-US Rev E

EZ400 User’s Manual

13

Menus and Calibration

SETTING

[display]

LOCK-ON

(

OPTIONS [displayed]

BOLD=DEFAULT

I-7 , 8, 9

LOCKON)

SCALE ID SETUP

(scalid)

LOCK-N-HOLD

(

LKNHLD)

(

AUTOFF)

(

LSTORE)

(

LSSEND)

AUTO OFF

NEW EZ

On/OFF

I5, 30, 45, 60,

OFF

LOCK-ON-STORE

LOCK-ON-STORE

SEND

1 PRESS ZERO

DESCRIPTION

Use the lowest setting that still

allows the system to lock on

consistently. A low value allows the

system to be more sensitive to

animal motion. A high value allows

the scale to lock on faster.

Identity of scale (truck id or Mixer

number).

Weight is held until next animal is

weighed.

Indicator automatically shut OFF

after specified time of inactivity.

For animal weighing only.

For animal weighing only.

If ON -press and hold Zero key to

Zero/Balance scale.

MENU 2. CLOCK, PRINTER, COMMUNICATIONS & ESTIMATED

WEIGHT FEATURES

TIME FORMAT

24 HR

Select time format -AM/PM or 24

(time f)

hour

AM/PM

(I zero)

1 TIME

(time)

DATE FORMAT

(date f)

DATE

(date)

TARE AUTO

PRINT

ON/OFF

XX:XX:XX

1-mm-dd

2-mm/dd/yy

3-mm/dd/yyyy

4-dd-mm

5-dd/mm/yy

6-dd/mm/yyyy

7-ddmoyy

8-ddmoyyyy.

Enter XXXXXX

(Il prt)

14

Select date format

Select key changes date -function

key chooses mm/dd/yy .

ON/OFF

If ON -tare auto-prints displayed

weight.

ON/OFF

If ON -indicator data prints on one

line.

(tareap)

ONE LINE PRINT

Select key changes time, function

key chooses hh:mm:ss.

EZ400 User’s Manual

D3655-US Rev E

Menus and Calibration

SETTING

[display]

(

SCOREM)

AUTO PRINT

(aprint)

(COM IN)

OPTIONS [displayed]

BOLD=DEFAULT

I,2,3,4,5,6,

DOWNLD,

EZ CMD, EZ2CMD

AUTO

(prtfmt)

WTONLY

DOWNLD

DT+TM

ID+TM

IDWTTM

ANIMAL

3200-A

3200-B

32-TMR

DATCHI

FDINFO

WTRCTM

EIDINF

EID

EIDVID

PRTAC2

PRTAC3

(CI DLY)

OFF, .I0, .25, .50, .75, I-5

C2 DLY)

OFF, .I0, .25, .50, .75, I-5

(prtacc)

(tarprt)

ESTIMATED

WEIGHT

Select alternate & comma (CSV)

formats.

PRTAC1

(zerout)

(

Select scoreboard output mode 1/sec 2-2/sec 3-3/sec 4-every

conversion 5-display rate 6-display

weight change 7-send status 1/sec,

8-send status1/5sec, 9-Reserved &

I0-send EID 1/2 sec.

If ON -pressing keys auto-prints

weight values.

Com port interface selections

DOWNLD for Data Down Loader,

EZ CMD = Original EZ Commands,

EZ2CMD = EZII Escape

Commands.

I

ON/OFF

PRINT FORMAT

DESCRIPTION

Choose the number of seconds

the printer will delay before

advancing to the next print line.

Choose the number of seconds

the printer will delay before

advancing to the next print line.

Tare

Allows operator to adjust Gross

weight of scale by changing the

zero/balance.

ESTWT

MENU 3. SCALE CALIBRATION SETTINGS

DISPLAY COUNT .0I,.02,.05,.I,.2,.5,I,2,5,I0,20, Count set too small, readings

unstable and indicator not accurate

50,I00

COUNT

AUTO-RANGE

Scale increases display count size

ON/OFF

for weights over 300 again at 600

ARANGE

lbs/kgs.

(

)

(

)

(

0,I,2,3,4,5,6,7,8,9

)

D3655-US Rev E

EZ400 User’s Manual

15

SETTING

[display]

DISPLAY UNIT

OPTIONS [displayed]

BOLD=DEFAULT

Menus and Calibration

DESCRIPTION

(lb-kg)

.0I,.02,.05,.I,.2,.5,I,2,5,I0,20,

50,I00

Select display count size of weigh

values.

(cap)

LB/KG

Display pounds -lb or kilograms -kg

CAPACITY

WM1 ADJUST 1

(wmaI-I)

WM1 ADJUST 2

(wmaI-2)

WM1 ADJUST 3

(wmaI-3)

WM2 ADJUST 1

(wma2-I)

WM2 ADJUST 2

(wma2-2)

WM2 ADJUST 3

(wma2-3)

Enter MAXIMUM weight

measurable on scale.

0=OFF Use values less than WMA

1-1 for quick weight response.

Enter weight to activate quick

weight response.

Increase number to smooth

weighing

0=OFF Use values less than

WMA2-1 for quick weight

response.

Enter weight activate quick weight

response.

MENU 4 – NOT USED

16

EZ400 User’s Manual

D3655-US Rev E

SHORT FORM CALIBRATION

Short Form Calibration

The Short Form Setup & Calibration procedure allows you to change “SETUP”

and “CAL” numbers of indicator.

Do not attempt to calibrate scale if indicator is not reading stable weights.

Calibration procedure will not fix instability, inconsistencies, or flashing

"RANGE" messages.

Obtain Current Set-up and Calibration Number

Write down current SETUP and CAL

numbers of your EZ 400 indicator.

These numbers are displayed during

Self Test.

To run self test with indicator ON:

1. Press

then

to start Self

Test.

1

2. Press

to “pause” the Self-Test

while numbers are displayed.

3. Press

again to allow self-test

to complete normally.

SETUP # _______________

CAL # ________________

SETUP NUMBER

Following is a list of functions that are controlled by the “SETUP” number:

Weigh Method (

)

Gain

Display Units (

)

Scale Capacity

Display Counts (

)

3

2

1

W MTHD

LB-KG

COUNT

D3655-US Rev E

EZ400 User’s Manual

17

Short Form Calibration

Calibrating Scale For Maximum Accuracy

To accurately calibrate scale, you need a large amount of weight that

has a known value. For best results you should have at least as much weight

as largest load you plan to weigh.

Note:

Determining New Setup and

Calibration Numbers

1. Press

to Zero-Balance. See

page 5.

2. Put KNOWN WEIGHT on scale

platform and write down WEIGHT

DISPLAY.

Perform following equation to find

ACCURATE CAL #.

1

The setup number does not change.

18

EZ400 User’s Manual

D3655-US Rev E

Short Form Calibration

Enter A New Setup And

Calibration Number

1

4

3

1

1. Press and hold

then press

for 3 seconds to enter short

form calibration.

2. The display will flash “SETUP” and

then display the 6-digit setup

number with the right digit

flashing.

3. Press

several times to

increment digit to it proper value.

4. Press

to advance digit left.

Repeat steps 3 and 4 for each digit as

required.

7 5

D3655-US Rev E

5. Press

to enter new setup

number and display calibration

number.

6. Repeat steps 3 and 4 to modify

the calibration number.

7. Press

to enter new

calibration number and display will

go back to normal.

8. Verify the accuracy of scale.

EZ400 User’s Manual

19

Installation

INSTALLATION

Indicator Mounting

RAIL MOUNT

KEY

A

B

C

D

E

F

G

WING MOUNT

WEDGE MOUNT

STANDARD

PART NUMBER

DESCRIPTION

403769

BRACKET – STR TOP MOUNT

403980

BRACKET – ROBO MOUNTING

403770

BRACKET – WING MOUNT

405069

U-BOLT, 1/4-20 X 3.25 ZP

403771

MODIFIED PLASTIC WEDGE MOUNT

405124

WEDGE MOUNT BRACKET, INCLUDES UBOLTS & NUTS

405084

NUT, 1/4-20 TOP LOCKING FLANGE

Optional Ram Mounting

RAM MOUNT

U-BOLT BASE

TWIST LOCK

STANDARD

SUCTION CUP

KEY PART NUMBER

DESCRIPTION

A

403180

RAM MOUNT

B

403179

MOUNT BASE-1" BALL U-BOLT

C

404230

RAM SUCTION CUP W/TWIST LOCK

20

EZ400 User’s Manual

D3655-US Rev E

Installation

Cable Connection

Scale Indicator

Power Cord

Remote Indicator

(Optional)

Pin To 12VDC Power Supply

1 Red

+Terminal

2 Black

-Terminal

3 Orange Alarm Out

4 Blue Remote Input

See J-Box

Connections

Indicator Connection Diagram

J-Box Connection

Remote Port

(Optional)

Power Cord

Connection

Serial/J905

(Optional)

Bottom Panel Cable Connections

D3655-US Rev E

EZ400 User’s Manual

21

Installation

Connect Load Cells to J-Box

Connect load cell

wires to terminal

blocks. See Wire

Color Key

J-Box Illustrated for 4

Load Cell Installation

Wire Color Key

Color

Description

1

White

Signal +

2

Green

Signal -

3

Red

Excitation +

4

Black

Excitation -

5

Shield

Shield

Tighten Nuts

J-Box Cable

Load Cell Cable

Connect to Indicator

bottom Panel.

J-Box Connections

Load Cell Direction

Observe direction of arrow when installing load cell.

Indicator Calibration

If you connect an indicator to a different weighing implement, the calibration

and setup number may need to change. Refer to calibration procedures (see

pages 17-19) or contact your Digi-Star representative for assistance.

22

EZ400 User’s Manual

D3655-US Rev E

Optional Equipment

OPTIONAL EQUIPMENT

Data Transfer Options

Kit Data Down Loader

Allows transfer of data from indicator

to PC. (Optional Serial/J905 port must

already be installed in indicator)

Remote Indicators

RD440 small remote display

RD2400V backlit remote display with

1.7” high numbers

RD2400V backlit remote display

w/transmitter and installed receiver

RD4000 remote display

D3655-US Rev E

EZ400 User’s Manual

23

Troubleshooting

TROUBLESHOOTING

FLOW CHART

START

YES

Is the reading on the

Indicator stable?

Does the indicator come on?

If your display is unstable, or

flashes “±RANGE” disconnect

the j-box cord from Indicator.

Is display still unstable?

NO

YES

Put your weight on each

NO

load cell. Does the indicator

respond to your weight?

Check all J-Box

and Load Cell

YES

cables for cuts

or pinched/flat

spots.

Are the readings

all positive? If not

Load Cell is

upside down.

Does the scale weigh you

approx. the same over all

Load Cells? (Weight will

not be accurate)

: Take them

apart and clean connections.

(Rust or paint should be wire

brushed.) Then reconnect and

tighten securely.

Replace battery

(weak battery may test good if

tested with no load on battery)

Make sure

red wire is connected to (+)

positive side and black wire is

connected to (-) negative side.

When using a multimeter to

check for voltage, measure

between pin 1 (pos) and pin 2

(neg). Meter should read

between 10.5 and 14.5 volts

DC if using a tractor power

cord, black wire is positive and

white wire is negative.

Try another

Indicator. (Even a different

model or set-up should come

on.)

Poor Connection

YES

Bad Battery:

Bad Power Cord:

Your Indicator is probably

defective. Try another

Indicator to verify.

Be aware of electrical

interference that might

affect Indicator, such as

mobile phones, CB

radios, radio towers,

electrical motors, etc.

Make sure Load Cell

cables are not attached to

hydraulic lines or

reservoir.

Note:

NO

Bad Indicator:

Remove the cover from your J-Box

YES

Is there moisture inside the box?

Your Indicator is probably not set-up

and calibrated correctly. Check the

decal on the bottom of Indicator. It

shows what type of Load Cells the

Indicator was calibrated to. By

pressing the on key while the

Indicator is already on, you will get

the Indicator’s “Set-up” and “Cal”

numbers. See if they compare to the

set-up and calibration numbers on

the Indicator. Contact Dealer for

further information.

Fix or replace the J-Box

NO

YES

NO

Look for loose connections.

Watch your Indicator display

while moving the wires and

pressing on the circuit board

inside the J-Box. You will see

if there is a loose connection

or bad solder joint.

YES

Dry out your J-Box (use a

hairdryer). Check cable

strain reliefs for tightness.

Cables have drip loops. Is

lid gasket damaged?

Did the J-Box have a bad

connection or loose wire?

NO

See next Page

24

EZ400 User’s Manual

D3655-US Rev E

Troubleshooting

FLOW CHART

Continued

1. Disconnect all the Load Cell

wires from the terminal blocks

inside the J-Box (leave the

Indicator on while connecting

and disconnecting the wires, it

will not damage Load Cells or

Indicator if wires are shorted

during this step). Is reading on

Indicator stable?

YES

Hook up the Load Cells to the J-Box one at

a time (only one Load Cell connected at a time).

This will get a reading for each Load Cell. While

performing this test, watch for any other

symptoms such as erratic/unstable display.

Indicator flashing “±RANGE”, negative reading,

etc. If the Indicator reading should ever appear

abnormal with any Load Cell connected then it is

probably bad.

Note:

NO

Replace J-Box

(be aware of electrical

interference that might affect

your scale such as: mobile

phones, CB radios, radio

towers, electric motors, etc.).

3. Connect one Load Cell back into one of the

terminals in the J-Box. (The reading you get for

each Load Cell is dependent on the size and type

of each Load Cell and how much weight is over

each Load Cell. In general, the number should be

positive and stable.)

4. Record the Indicator reading with

the Load Cell connected.

5. Stand or hang your weight over the connected

Load Cell. Record how much the weight

increased with your weight over the Load Cell. (A

scale with only one Load Cell will weigh heavy.)

7. Repeat step 6 for the remaining Load Cells.

Remember to record your readings.

Do not expect the Load Cells to give the same

reading. It is common for Load Cells to have

readings that vary by hundreds, even thousands.

Especially when one is carrying more weight.

D3655-US Rev E

2. Zero balance the Indicator.

(Press “NET/GROSS” then

“ZERO”). Indicator should display

“0”.

If the scale responded to your weight,

that’s verification on the J-Box is OK. If the

scale did not respond, either that Load Cell is

bad or the J-Box is bad. Try the other Load

Cells. If the Indicator still shows no response,

the J-Box is bad. (Replace J-Box)

Note:

6. Disconnect the first Load Cell and reconnect

a second one. Record the Indicator reading.

Stand or hang your weight over the connected

Load Cell. Record how much the weight

increased.

8. Bad Load Cells will have a reading that is

either unstable, makes the indicator flash

“±RANGE” or is more than three times greater

or less than the average of the others. Also the

readings of your weight over each Load Cell

should be similar. (Probably 4 times your actual

weight). Any differences could be an indication

of a bad Load Cell or a structural problem.

EZ400 User’s Manual

25