3.1.Motoren-englisch - Accu Electric Motors Inc.

advertisement

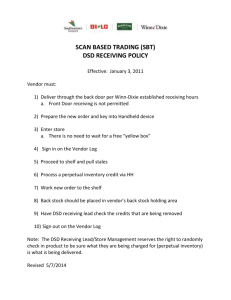

Over 100 years cumulative experience 24 hour rush turnaround / technical support service Established in 1993 The leading independent repairer of servo motors and drives in North America. Visit us on the web: www.servo-repair.com www.servorepair.ca www.ferrocontrol.com www.sandvikrepair.com www.accuelectric.com Scroll down to view your document! For 24/7 repair services : USA: 1 (888) 932 - 9183 Canada: 1 (905) 829 -2505 Emergency After hours: 1 (416) 624 0386 Servicing USA and Canada be in motion be in motion DSD DS DA DST DSL DSD-IPG BPx Motors 7000 8000 9000 10000 10 20 30 40 50 60 70 80 90 100 110 120 ii,52 ii,54 ii,56 ii,58 ii,60 ii,62 ii,64 ii,66 ii,68 ii,70 ii,72 ii,74 ii,76 ii,78 ii,80 ii,82 ii,84 ii,86 ii,88 ii,90 www.baumueller.de ii,98 iii DSD 22 - 100 DS 45 - 200 Dynamic Motors DA 100 - 225 4 6 General Purpose 2 2.02 2.04 2.06 2 2.02 2.04 2.06 2.08 2.08 2.10 2.10 2.12 2.12 2.14 2.14 2.16 2.16 2.18 2.18 2.20 2.20 2.22 2.22 2.24 2.24 2.26 2.26 2.28 2.28 2.30 2.30 2.32 2.32 2.34 2.34 2.36 2.36 2.38 2.38 2.40 2.40 2.42 2.42 2.44 2.44 2.46 2.46 2.48 2.48 2.5 2.50 50 Baumüller supplies intelligent drives for the world´s machines Any company that develops intelligent, future- Our approach is acclaimed throughout almost oriented machine concepts has to increasingly all sectors of machine building. We plan, develop opt for interdisciplinary co-operation – often and manufacture optimized drive and automation beyond corporate boundaries. Maximum perfor- systems for different applications – ranging from mance requires specialization and concentration the one-off machine to the large-scale production of all energies on the respective module. Thus, machine. In addition, we offer entire drive we as a system partner to machine builders systems, from the control cabinet and open-loop do not offer just a drive or a controller. We are control device to converters and motors. In doing always interested in the functioning system as a so, we assist our customers when a system is whole and naturally its optimization by means being commissioned with extensive engineering, of our products and services. Therefore, we as well as support and service. That also applies focus on research conducted at the Baumüller to the actual operation. Laboratories. That is where we develop modern Technical expertise, innovation, flexibility and solutions for drive and automation technology. absolute customer orientation are the distinctive features of our corporate philosophy. This is also reflected in our motto: be in motion. You will find up-to-date information, dates and projects when you visit: www.baumueller.com 2.52 2.52 DST 135 - 315 DSL 56 DSD 45-IPG BPx Baumüller: Your partner High-Torque Motors Linear Servo Motors Gear Motors Planetary Gearing For Automation 10 12 14 16 20 2.54 2.54 2.56 2.56 2.58 2.58 2.60 2.60 2.62 2.62 2.64 2.64 2.66 2.66 2.68 2.68 www.baumueller.com 2.70 2.72 2.74 2.76 2.78 2.78 2.80 2.80 2.82 2.82 2.84 2.84 2.86 2.86 2.88 2.88 2.98 3 2.90 www.baumueller.com 2.98 3 2.90 2.92 2.94 2.96 1 2 3 4 5 7 6 10 20 30 40 50 60 70 80 90 100 110 120 8 9 10 11 12 13 14 15 16 17 18 19 1000 2000 3000 4000 5000 The seven installation sizes for the DSD-range of Baumüller offer a suitable solution for almost every application in the automation. DSD - Dynamic Motors The servo motors for highly dynamic applications with the highest requirements of acceleration capacity and the best start-stop qualities, such as for: packaging machines textile machines plastics machines handling machines special machines small robots 4 4.02 4.04 4.06 4.08 4.10 4.12 4.14 4.16 4.18 4.20 4.22 4.24 4.26 4.28 4.30 4.32 4.34 4.36 4.38 4.40 4.42 4.44 4.46 4.48 4.50 DSD 22 - 100 - Dynamic Motors high torque accuracy high speed almost no cogging effect compact frame size with high power density maximum dynamic response due to excellent torque - inertia ratio smooth housing surface – not easily soiled sleek, uniform housing permanent field synchronous servo motors main connection via terminal box or connector (DSD 22 - 45 only via connector) IP44, other protection type on request (DSD 22 - 36) IP65 non-ventilated, IP54 surface-ventilated with fan (DSD 45 - 100) encoders: resolver 2-pole, SinCos-encoder (optional) more encoders available on request all types optionally with brake The DSD-range is available with air-cooling option. 130 140 Capacity Torque Acceleration DSD 22 - 100 - Technical Data DSD 22 DSD 28 DSD 36 PN [kW] 0.25 0.52 1.25 nM [min-1] 6000 6000 6000 J [kgcm2] 0.10 0.20 0.44 M0 [Nm] 0.70 1.40 3.30 M0max [Nm] 2.8 5.6 13.2 DSD 22 DSD 28 PN [hp] 0.34 0.70 DSD 45 DSD 56 1.37 DSD 71 DSD 100 5.4 10.1 17 4500 4500 4500 1.9 5.7 16.5 77 5.20 15.5 34.5 89 25 52 100 210 DSD 36 DSD 45 DSD 56 DSD 71 DSD 100 1.68 1.8 7.2 13.5 22.8 4500 nM [min ] 6000 6000 6000 4500 4500 4500 4500 J [lb in2] 0.03 0.07 0.15 0.65 1.9 5.6 26.3 M0 [lbf ft] 0.52 1.03 2.43 3.8 11.4 25.4 65.6 M0max [lbf ft] 2.07 4.13 9.74 18 38 74 155 -1 Subject to alterations. The stated data are maximum values. For details please have a look in the technical documentations. 4.52 4.54 4.56 4.58 4.60 4.62 4.64 4.66 4.68 4.70 4.72 4.74 4.76 4.78 4.80 4.82 4.84 4.86 4.88 4.90 www.baumueller.com 4.98 5 45 40 41 42 43 44 45 56 71 100 132 160 46 47 48 49 50 51 52 53 54 55 56 57 58 59 With a shaft height from 45 to 225 Baumüller offers the largest product range of synchronous and asynchronous motors. DS / DA - Motors The servo motor for dynamic applications with highest requirements of capacity and torque, such as for printing machines packaging machines textile machines plastics machines handling machines special machines general mechanical engineering 6 6.02 6.04 6.06 6.08 6.10 6.12 6.14 6.16 6.18 6.20 6.22 6.24 6.26 6.28 6.30 6.32 6.34 6.36 6.38 6.40 6.42 6.44 6.46 6.48 6.50 DS 45 - 100 - General Purpose (Synchronous) high torque accuracy high speed minimal space required due to compact design virtually wear- and maintenance free due to brushless design permanent field servo motors IP64/65 non-ventilated, IP54 surface-ventilated encoders: resolver 2-pole, SinCos-encoder (optional) other encoders available on request all types optionally with brake The DS-range is also available with air-cooling option. 180 200 225 Capacity Torque Acceleration DS 45 - 100 - Technical Data DS 45 DS 56 DS 71 DS 100 PN [kW] 5.80 11.80 23.56 nM [min-1] 6000 6000 6000 4000 J [kgcm ] 3.4 15.7 50.2 175 M0 [Nm] 3.2 13.2 31.0 84.0 M0max [Nm] 15 32 73 160 DS 45 DS 56 DS 71 DS 100 PN [hp] 1.7 7.8 15.8 31.6 nM [min ] 6000 6000 6000 4000 J [lb in2] 1.16 5.36 17.15 59.80 M0 [lbf ft] 2.4 9.7 22.9 62.0 M0max [lbf ft] 11 24 54 118 1.26 2 -1 Subject to alterations. The stated data are maximum values. For details please have a look in the technical documentations. 6.52 6.54 6.56 6.58 6.60 6.62 6.64 6.66 6.68 6.70 6.72 6.74 6.76 6.78 6.80 6.82 6.84 6.86 6.88 6.90 www.baumueller.com 6.98 7 DS 100 - 200 - General Purpose (Synchronous) high torque accuracy high spped compact and robust design sized with a high level of efficiency permanent field servo motors IP23 internally ventilated, IP54 surface-ventilated, unventilated water-cooled model available (IP54) encoders: resolver 2-pole, SinCos-encoder (optional) other encoders available on request all types optionally with brake The DS-main drives are available as air- and water cooled model. Capacity Torque Acceleration DS 100 - 200 - Technical Data DS 100 DS 132 DS 160 DS 200 PN [kW] 38 92 150 290 nM [min-1] 3000 3000 3000 2700 J [kgcm2] 220 840 2500 7900 M0 [Nm] 320 680 1180 1350 M0max [Nm] 320 680 1180 2120 DS 100 DS 132 DS 160 DS 200 PN [hp] 51 123 201 389 nM [min ] 3000 3000 3000 2700 J [lb in2] 75 287 854 2700 M0 [lbf ft] 236 502 870 996 M0max [lbf ft] 236 502 870 1564 -1 Subject to alterations. The stated data are maximum values. For details please have a look in the technical documentations. 8 8.02 8.04 8.06 8.08 8.10 8.12 8.14 8.16 8.18 8.20 8.22 8.24 8.26 8.28 8.30 8.32 8.34 8.36 8.38 8.40 8.42 8.44 8.46 8.48 8.50 DA 100 - 225 - General Purpose (Asynchronous) model as asynchronous cage rotor large field weakening range high level of efficiency compact and robust design high torque accuracy IP23 internally ventilated, IP54 surface-ventilated with fan IP54 water-cooled model available encoders: resolver 2-pole, SinCos-encoder (optional) all types optionally with brake The DA-main drives are available as air- and water cooled model. Capacity Torque Acceleration DA 100 - 225 - Technical Data DA 100 DA 132 DA 160 DA 180 DA 225 PN [kW] 15 50 120 200 265 nM [min-1] 3000 3000 3000 3000 3000 J [kgcm2] 340 1200 3460 6760 20630 M0 [Nm] 67 215 573 955 1862 M0max [Nm] 134 344 917 1528 2979 DA 100 PN [hp] nM J M0 M0max DA 132 DA 160 DA 180 DA 225 20 67 161 268 355 [min ] 3000 3000 3000 3000 3000 [lb in2] 116 410 1182 2310 7050 [lbf ft] 49 159 423 704 1373 [lbf ft] 99 254 676 1127 2197 -1 Subject to alterations. The stated data are maximum values. For details please have a look in the technical documentations. 8.52 8.54 8.56 8.58 8.60 8.62 8.64 8.66 8.68 8.70 8.72 8.74 8.76 8.78 8.80 8.82 8.84 8.86 8.88 8.90 www.baumueller.com 8.98 9 13500 11500 12000 12500 13000 13100 13200 13300 13400 13500 13505 13510 13515 13520 13525 Baumüller offers the DST-range up to 13500 Nm torque and herewith provides the maximum dynamic in the direct drive technology. DST High-Torque Motors The high-torque synchronous motors for application with maximum torque requirements, such as for: plastics machines rotary tables or swivel axis printing machines machine tools woodworking machines special machines 10 10.02 10.04 10.06 10.08 10.10 10.12 10.14 10.16 10.18 10.20 10.22 10.24 10.26 10.28 10.30 10.32 10.34 10.36 10.38 10.40 10.42 10.44 10.46 10.48 10.50 DST 135 - 315 - Powerful High-Torque Motors appropriate for demanding direct drive technology high torques at low speeds low noise heat dissipation at source due to water cooling compact and robust design smooth housing surface – not easily soiled permanent field servo motors degree of protection IP54 encoders: resolver 2-pole, SinCos-encoder (opt.) other encoders available on request The DST-high-torque motors are available as water-cooled model 13600 13700 13800 Capacity Torque Acceleration DST 135 - 315 - Technical Data DST 135 DST 200 DST 315 PN [kW] 30.5 71 175 nM [min-1] 750 450 300 J [kgm ] 0.28 1.3 11.6 M0 [Nm] 845 3450 13500 M0max [Nm] 845 3450 13500 DST 135 DST 200 DST 315 PN [hp] 40.9 95.2 234.7 2 nM -1 [min ] 750 450 300 J [lb ft2] 6.64 30.8 275.3 M0 [lbf ft] 623 2545 9957 M0max [lbf ft] 623 2545 9957 Subject to alterations. The stated data are maximum values. For details please have a look in the technical documentations. 10.52 10.54 10.56 10.58 10.60 10.62 10.64 10.66 10.68 10.70 10.72 10.74 10.76 10.78 10.80 10.82 10.84 10.86 10.88 10.90 www.baumueller.com 10.98 11 2 3 4 5 6 7 49 50 51 52 53 54 55 56 2000 3000 4000 2000 3000 4000 167 250 333 With its two variants the DSL 56 ensures optimal linear motions. As a roller screw assembly for high forces and high velocities or as a ball screw assembly in simple applications for low-cost linear drives. DSL 56 - Three-Phase Synchronous Linear Actuator Compactness, dynamic response and high levels of torque, effectively implemented in a linear motion – these are the features of the DSL 56. With its integrated screw assembly the DSL 56 converts rotary motion to linear motion. The link between Baumüller servo motors and an integrated screw assembly is ideally suited for applications with maximum demands in terms of force and dynamic response, in a compact design. There are two models available: the roller screw assembly for high forces and high velocities or the lower-cost ball screw assembly for simpler applications. Consequently, the DSL 56 optimally meets the requirements of fields of application such as robotics, welding tongs and handling but also in the printing and plastics industries. 12 12.02 12.04 12.06 12.08 12.10 12.12 12.14 12.16 12.18 12.20 12.22 12.24 12.26 12.28 12.30 12.32 12.34 12.36 12.38 12.40 12.42 12.44 12.46 12.48 12.50 DSL 56 - Linear-Servo Drives drive-shaft support for high radial forces alternatively ball screw, respectively planetary screw assembly spindle drive can be replaced without motor disassembly brake assembly without changing total length high dynamics and maximum force due to servo technology multiple ways of installation according to IEC34-7 – IM 3689 / IM 9389 encoder system standard resolver 2-pole (other encoder type on request) aluminum case degree of protection IP54 all types optionally with brake The DSL linear-servo drive is available as air-cooled model 2000 3000 4000 Capacity Force Acceleration DSL 56 - Technical Data threaded spindle drive 21x5 nM [min-1] ball screw 32x5 DSL 56 M DSL 56 M DSL 56 M DSL 56 M 2000 3000 4000 2000 F0 [kN] 6.0 6.0 6.0 6.0 F0max [kN] 20 20 20 7.0 vN [mm/s] 167 250 333 167 threaded spindle drive 21x5 ball screw 32x5 DSL 56 M DSL 56 M DSL 56 M DSL 56 M nM [min ] 2000 3000 4000 2000 F0 [lbf] 1349 1349 1349 1349 F0max [lbf] 4496 4496 4496 1574 vN [in/s] 6.55 9.84 13.1 6.55 -1 rated torque brake: 15 Nm, lifetime: >10m double strokes, stroke: 155 mm, allowed radial load: >200 N Subject to alterations. The stated data are maximum values. For details please have a look in the technical documentations. 12.52 12.54 12.56 12.58 12.60 12.62 12.64 12.66 12.68 12.70 12.72 12.74 12.76 12.78 12.80 12.82 12.84 12.86 12.88 12.90 www.baumueller.com 12.98 13 8 1 2 3 4 5 6 7 10 20 30 40 50 60 70 80 90 100 110 120 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 1000 2000 3000 4000 5000 The new geared motor from Baumüller, the DSD 45-IPG, is distinguished by its high torque and excellent dynamic response qualities. Offering transmission ratios of i=4 and i=8, the DSD 45-IPG is a compact and dynamic motor that meets the highest torque requirements. DSD 45-IPG Three-Phase Synchronous Geared Motor Thanks to the integrated planetary gearing, the DSD 45-IPG is ideal for high torque applications that require a high dynamic response. The DSD has an overload capacity that is up to 40% greater than in comparable servomotors in the DS series. With these qualities, the DSD 45-IPG is the perfect candidate for handling, robotics and packaging applications. In spite of the transmission ratios of i=4 and i=8, the motor fully retains its dynamic characteristics. The extremely compact DSD 45-IPG paves the way for optimal space utilization. Several axes can, for example, be placed side by side in a space-saving manner. Depending on the application, Sincos encoders or brakes can be combined with the gearing. 14 14.02 14.04 14.06 14.08 14.10 14.12 14.14 14.16 14.18 14.20 14.22 14.24 14.26 14.28 14.30 14.32 14.34 14.36 14.38 14.40 14.42 14.44 14.46 14.48 14.50 DSD 45-IPG - Geared Motors The concept offers: Features of the integreated planetary gearing include: high output torque high dynamic response low circumferential backlash (< 3´) low moment of inertia high stability compact frame size high efficiency (98%) sleek, uniform housing transmission ratios i = 4 und i = 8 smooth housing surface – not easily soiled low noise level (< 65 dBA) optimized transmission stepping any required mounting position high protection type IP65 lifetime lubrication encoder system standard resolver 2-pole (other encoder type on request) all types optionally with brake The DSD 45-IPG is available as air-cooled model 130 140 Capacity Torque Acceleration DSD 45-IPG - Technical Data Motor / Gear DSD 45-IPG4 DSD 45-IPG8 PN [kW] 1.22 1.37 1.22 1.37 nM [min-1] 750 1125 375 562 J [kgcm ] 0.12 0.12 0.23 0.23 M0 [Nm] 20.4 20.4 40.8 40.8 M0max [Nm] 98 98 108 108 PN [hp] 1.64 1.84 1.64 nM [min ] 750 1125 375 562 J [lb in2] 0.041 0.041 0.079 0.079 M0 [lbf ft] 15.05 15.05 30.1 30.1 M0max [lbf ft] 72.3 72.3 79.7 79.7 2 DSD 45-IPG4 -1 DSD 45-IPG8 1.84 Subject to alterations. The stated data are maximum values. For details please have a look in the technical documentations. 14.52 14.54 14.56 14.58 14.60 14.62 14.64 14.66 14.68 14.70 14.72 14.74 14.76 14.78 14.80 14.82 14.84 14.86 14.88 14.90 www.baumueller.com 14.98 15 1 2 3 3 10 20 30 40 50 60 70 80 90 100 110 120 4 5 6 7 8 9 10 11 12 13 14 The three models standard, economy und high performance of the Baumüller planetary gearings provide compact and economical drive solutions at the highest technology level. BPx - Baumüller Planetary Gearing Range In connection with our standard DS/DSD servo drives, the BPx – planetary gear range is optimally suitable for applications that require maximum standards of torque and dynamics. In combination with a high number of transmission ratio gradings, almost any possible combination of motor and gear allow an optimal adaptation of customized application. Three models are available: gear models in the so-called HP (= High Performance) version are available for highest torques and speeds for applications with standard requirements the model BPS is a gear solution of a high technology level the model range BPE (= Economy) is used for basic applications 16 16.02 16.04 16.06 16.08 16.10 16.12 16.14 16.16 16.18 16.20 16.22 16.24 16.26 16.28 16.30 16.32 16.34 16.36 16.38 16.40 16.42 16.44 16.46 16.48 16.50 The feature of the BPx range are: low circumferential backlash (< 3‘) In connection with our standard motor ranges DS and DSD the concept offers: high stability high driving torque high efficiency (98%) high dynamics great choice of gear ratios low total moment of inertia low noise level (< 65 dBA) compact design high quality (ISO 9001) high protection type IP65 any required mounting position lifetime lubrication BPF HP High Performance Range BPx HP For highest torque speeds, depending on requirement as standard or flange model. The patented system for venting in the gear prolonges the lifetime of the mechanical components. The gears of the BPx range have an optimal connection to the motor shaft due to a special clamping piece. Therewith the BPS HP concentricity is optimised, the noise is minimised and assembly errors are excluded. 130 140 Capacity Torque Acceleration BPx HP - Technical Data BPx 36 HP M0 [Nm] ninput max [min-1] i BPx 45 HP BPx 56 HP BPx 71 HP 110 220 520 1000 10000 8000 7000 6000 4 - 64 4 - 64 4 - 64 4 - 64 BPx 36 HP BPx 45 HP BPx 56 HP BPx 71 HP M0 [lbf ft] 81 162 384 738 ninput max [min ] 10000 8000 7000 6000 4 - 64 4 - 64 4 - 64 4 - 64 i -1 Subject to alterations. The stated data are maximum values. For details please have a look in the technical documentations. 16.52 16.54 16.56 16.58 16.60 16.62 16.64 16.66 16.68 16.70 16.72 16.74 16.76 16.78 16.80 16.82 16.84 16.86 16.88 16.90 www.baumueller.com 16.98 17 BP X FS HP type code BPx: HP High Performance Standard Range BPS FS Frame Size X S SA F E EA EF Standard gears for connection to standard flangeand shaft extension of the DS and DSD motor ranges by Baumüller. BP = Standard = Standard Angle = Flange = Economy = Economy Angle = Economy Flange Baumüller Planetary Also available as angular gear for applications with interference contour. BPS BPSA Capacity Torque Acceleration BPS - Technical Data BPS 36 M0 [Nm] ninput max [min-1] i M0 [lbf ft] ninput max [min ] i -1 BPS 45 BPS 56 BPS 71 BPS 100 77 120 260 910 1800 14000 10000 8500 6500 6000 3 - 100 3 - 100 3 - 100 3 - 100 3 - 100 BPS 36 BPS 45 BPS 56 BPS 71 BPS 100 57 89 192 671 1328 14000 10000 8500 6500 6000 3 - 100 3 - 100 3 - 100 3 - 100 3 - 100 Subject to alterations. The stated data are maximum values. For details please have a look in the technical documentations. 18 18.02 18.04 18.06 18.08 18.10 18.12 18.14 18.16 18.18 18.20 18.22 18.24 18.26 18.28 18.30 18.32 18.34 18.36 18.38 18.40 18.42 18.44 18.46 18.48 18.50 Economy Range BPE The so-called economy-version (standard or angle) is available for basic applications with low torque and low speed requirements. BPE BPEA BPEF Capacity Torque Acceleration BPE - Technical Data BPE 20 M0 [Nm] ninput max [min-1] i M0 [lbf ft] ninput max [min ] i -1 BPE 30 BPE 40 BPE 45 BPE 56 BPE 60 BPE 80 20 44 130 130 260 260 800 18000 13000 7000 7000 6500 6500 6500 3 - 512 3 - 512 3 - 512 3 - 512 3 - 512 3 - 512 3 - 512 BPE 20 BPE 30 BPE 40 BPE 45 BPE 56 BPE 60 BPE 80 14.8 32.5 95.9 95.9 192 192 590 18000 13000 7000 7000 6500 6500 6500 3 - 512 3 - 512 3 - 512 3 - 512 3 - 512 3 - 512 3 - 512 Subject to alterations. The stated data are maximum values. For details please have a look in the technical documentations. 18.52 18.54 18.56 18.58 18.60 18.62 18.64 18.66 18.68 18.70 18.72 18.74 18.76 18.78 18.80 18.82 18.84 18.86 18.88 18.90 www.baumueller.com 18.98 19 Planning Project management Development hardware & software engineering Control cabinet design Installation Commissioning Expansion of existing systems Technical support worldwide Training Service Maintenance 362 363 364 365 Retrofit 349 350 351 352 353 354 355 356 357 18 19 20 21 22 23 24 358 359 360 361 1 2 3 4 5 6 7 You can always reach us via our service hotline, 24/7: +49 (0) 911 5432 133. Automation solutions by Baumüller Co-operation with development partners, who contribute to the entire solution in a system-oriented way, is a pre-condition if you want to concentrate on your own competencies in the field of machine building. If your automation partner supports you during the realization of your system concept, you receive the development, project management and the optimal adaptation of a drive solution from one source. As an innovative system partner of the capital goods industry, the Baumüller Group is the competent solution provider for automation, electronic and drive technology and control technique during the entire lifetime of a system. It goes without saying that in addition to our complete package consisting of engineering, installation, commissioning and services, we offer customer service with perfect coverage – namely anywhere in the world and at any time. We are the partner for your success. 20 20.02 20.04 20.06 20.08 20.10 20.12 20.14 20.16 20.18 20.20 20.22 20.24 20.26 20.28 20.30 20.32 20.34 20.36 20.38 20.40 20.42 20.44 20.46 20.48 20.50 Planning Together with you we design an economical and technological future-oriented system. Project management Our project leaders ensure the implementation of turnkey equipment. Development Irrespective of the industry, various motion and control functions occur from time to time in slightly adapted forms. Cam disk Cam controller Baumüller displays these frequently occuring, Winder standardized functionalities in function modules that can easily and quickly be integrated in the system, followed by an adaptation to individual Register control Electronic gear unit Dancer controller Cross cutter needs. 362 363 364 365 PLC Industry solutions We know the conditions of your industry and speak the language of your customers. From printing machines with high demand on sychnronization of the drives, via control-intensive applications in the plastics industry to the requirements in conveyor technology, assembling and storage systems, we implement system concepts of the most diverse application specifications. Hardware and software engineering From the dimensioning via cabling to air conditioning of your control cabinets, we design your hardware taking account of all design and manufacturing options that are technologically innovative, user-oriented and as economical as possible. 20.52 20.54 20.56 20.58 20.60 20.62 20.64 20.66 20.68 20.70 20.72 20.74 20.76 20.78 20.80 20.82 20.84 20.86 20.88 20.90 www.baumueller.com 20.98 21 Control cabinet design and wiring We implement individual and user-oriented solutions from sheet metal production to completely wired control cabinet. Our strengths are special designs and special production in small to medium series. Installation / Commissioning You construct the mechanics of your system, we install the electronics. Whether inhouse or worldwide at your customers site – with our software solutions and drive technologies we set your machine ideas in motion. For the worldwide installation and commissioning of your systems, we always take account of the respective country-specific standards. 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 3 4 5 6 7 8 9 10 11 12 13 14 15 Expansion of existing systems Innovative and customer-specific products require state-of-the-art production methods and machine functions. Using an adaptation or expansion of your existing machine architecture, you quickly achieve an increased flexibility and availability of your systems – while allowing you to estimate your expenses and manage your investments. Technical support worldwide Whether it is remote diagnosis and remote maintenance using telecommunication or the Internet, through our 24-hour hotline or our contact partners at branch offices onsite in more than 40 location worldwide – the experts from Baumüller provide full explanations to all your questions concerning drive and automation solutions. 22 22.02 22.04 22.06 22.08 22.10 22.12 22.14 22.16 22.18 22.20 22.22 22.24 22.26 22.28 22.30 22.32 22.34 22.36 22.38 22.40 22.42 22.44 22.46 22.48 22.50 Training Only with well-trained employees can you quickly respond to a problem. We offer training onsite and in our training center. On the basics of electrical drive engineering, on maintenance of switching stations, controllers and drives, and on selective troubleshooting in the broader range of printing technology and drive engineering. In co-operation with you, we create a flexible training program that is specifically tailored to the training needs of your employees. Service The correct repair and spare parts must instantly be available to immediately remedy a failure of your system. In co-operation with you, we develop an extensive service plan and make a technically sound and cost-optimized selection of components that you should keep on hand. We ensure the functional state of your stock of spare parts and deliver components that are missing in an emergency – day and night via express. 16 17 18 19 Maintenance A professionally maintained machine means safety. Safety for the production and safety for your employees. We are your partner for all maintenance of electrics, drive repairs and motor repairs. We recognise in advance any possible causes of failure and increase the availability of your machine – without lost output. Retrofit We retrofit existing systems with up-to-date drive systems, control cabinets and user interfaces, so that your system can execute a failure-free, state-ofthe-art production. With a retrofit of your existing machine architecture, you are able to achieve higher system flexibility and availability in a very short time. 22.52 22.54 22.56 22.58 22.60 22.62 22.64 22.66 22.68 22.70 22.72 22.74 22.76 22.78 22.80 22.82 22.84 22.86 22.88 22.90 www.baumueller.com 22.98 23 Drive Center National The Netherlands Baumüller Benelux B.V. Platinastraat 141 NL-2718 SR Zoetermeer T: +31 (0) 79 3614 - 290 F: +31 (0) 79 3614 - 339 Darmstadt Baumüller Nürnberg GmbH Waldstraße 1 D-64347 Griesheim T: +49 (0) 6155 84 30 - 00 F: +49 (0) 6155 84 30 - 20 Australia / Sydney Baumüller Australia Pty. Ltd. Sydney Office 19 Baker Street, Botany NSW 2019, Sydney T: +61 2 83350 - 100 F: +61 2 83350 - 169 Baumüller Brno s.r.o Skalice nad Svitavou 72, CZ-67901 Skalice nad Svitavou T: +420 516 499 - 111 F: +420 516 499 - 117 Linear motors Baumüller Kamenz GmbH Nordstraße 57, D-01917 Kamenz T: +49 (0) 3578 3406 - 0 F: +49 (0) 3578 3406 - 50 Representatives International Brazil NC Service Indústria e Comércio Ltda. Av. Tamboré, 1217 Baruerí-SP, BR-06460-000 T: +55 (0) 11 4195 - 0502 F: +55 (0) 11 4195 - 2479 Austria Baumüller Austria Ges.mbH Im Bäckerfeld 17, A-4060 Leonding T: +43 (0) 732 67 44 14 - 0 F: +43 (0) 732 67 44 14 - 32 China Beijing Yanghai Automation Technology Co., Ltd. Room 1008, No.7, Huaqing Business Building, Iluaqing Garden, Wudaokou, Haidian District, Beijing 100083, P.R.C. T: +86 (0) 10 8286 7980 F: +86 (0) 10 8286 7987 England Baumüller (UK) Ltd. 14 Redlands Centre, GB-Coulsdon, Surrey CR5 2HT T: +44 (0) 208 - 763 2990 F: +44 (0) 208 - 763 2959 France Baumüller France S.à.r.l. Zone de la Malnoue 39, Avenue de l´Europe, F-77184 Emerainville T: +33 1 6461 - 6622 F: +33 1 6461 - 6006 France Baumüller France S.à.r.l. (Strasbourg) 9 rue de la Durance, F-67100 Strasbourg T: +33 (0) 3 88 40 12 51 F: +33 (0) 3 88 40 07 24 128 173 Electronics Baumüller Nürnberg GmbH Ostendstraße 80-90, D-90482 Nürnberg T: +49 (0) 911 5432 - 293 F: +49 (0) 911 5432 - 328 Sheet metal forming Baumüller Dravinja d.o.o. Delavska cesta 10, SI-3210 Slovenske-Konjice T: +386 3 75723 - 00 F: +386 3 75723 - 32 / 33 Denmark Robotek EL & Teknik A/S Blokken 31, Postbox 30, DK-3460 Birkerød T: +45 4484 7360 F: +45 4484 4177 Systems Baumüller Anlagen-Systemtechnik GmbH & Co. KG Ostendstraße 84, D-90482 Nürnberg T: +49 (0) 911 54408 - 0 F: +49 (0) 911 54408 - 749 Services Baumüller Reparaturwerk GmbH & Co. KG Andernacher Straße 19, D-90411 Nürnberg T: +49 (0) 911 9552 - 0 F: +49 (0) 911 9552 - 999 Korea BOMAC SYSTEMS 712 Yucheon Factophia 196 Anyang-7 dong, Mananku, Anyangsi, Kyungkido 430-017, Korea T: +82 31 467 - 2030 F: +82 31 467 - 2033 Italy Baumüller Italia s.r.l., Viale Italia 12, I-20094 Corsico (Mi), T: +39 02 45100 - 181 F: +39 02 45100 - 426 Small motors Baumüller Nürnberg GmbH Werk Bad Gandersheim Flugplatzweg 2, D-37581 Bad Gandersheim T: +49 (0) 5382 9805 - 0 F: +49 (0) 5382 9805 - 55 China Sunary Automatic Technology Limited Company 3rd Floor No.476, Chunxiao Rd., Zhangjiang High-Tech Park Pudong, Shanghai 201203 T: +86 (0) 21 5080 9898 F: +86 (0) 21 5308 7675 Finland Kontram Oy Olarinluoma 12, P.O.Box 88, FI-02201 Espoo, Finland T: +358 9 8866 4500 F: +358 9 8866 4799 India Baumüller KAT India Pvt. Ltd. 4th Floor, Commerce Avenue, Paud Road, IND - 411 038 Pune T: +91 20 25 45 96 82 F: +91 20 25 45 96 84 115 Baumüller Nürnberg GmbH Werk Kitzingen, Floßhafenstraße 2, D-97318 Kitzingen T: +49 (0) 9321 700 80 F: +49 (0) 9321 700 888 USA Baumueller Chicago Corp. 1512 East Algonquin Rd., USA-Arlington Heights, IL 60005 T: +1 847 956 - 7392 F: +1 847 956 - 7925 Drive Center International 84 Motors Baumüller Nürnberg GmbH Ostendstraße 80-90, D-90482 Nürnberg T: +49 (0) 911 5432 - 0 F: +49 (0) 911 5432 - 130 USA Baumueller Hartford Inc. 117 West Dudley Town Road, USA-Bloomfield, CT 06002 T: +1 860 - 243 0232 F: +1 860 - 286 3080 Stuttgart Baumüller Nürnberg GmbH Hahnweidstr. 21 D-73230 Kirchheim / Teck T: +49 (0) 7021 485 57 - 10 F: +49 (0) 7021 485 57 - 77 64 Production Turkey Baumüller MOTOR KONTROL SISTEM SAN. VE TIC. LTD. STI Colak Ismail Sok. No: 31/1, TR-81070 Istanbul-Suadiye T: +90 (0) 216 372 - 2485 F: +90 (0) 216 372 - 7570 Nürnberg / Bavaria Baumüller Nürnberg GmbH Ostendstr. 80-90 D-90482 Nürnberg T: +49 (0) 911 54 32 - 501 F: +49 (0) 911 54 32 - 510 54 Venezuela, Colombia, Ecuador Nimbus International C.A. C.C. Parque Tuy, Local P-18, YV-Ocumare del Tuy, 1209 T: +58 (0) 39 25 1347 F: +58 (0) 39 25 7149 Switzerland Baumüller Schweiz AG (East) Glärnischstrasse 46, CH-9500 Wil T: +41 (0) 71 929 46 - 66 F: +41 (0) 71 929 46 - 67 Hannover Baumüller Nürnberg GmbH Bohlenweg 10 D-30853 Langenhagen T: +49 (0) 511 77 19 68 - 0 F: +49 (0) 511 77 19 68 - 77 42 Sweden Robotek El & Teknik Skårs Led 3, 40313 Göteborg T: +46 (0) 31 703 71 90 F: +46 (0) 31 703 71 01 Switzerland Baumüller Suisse S.A. Rue des Usines 22, CH-2000 Neuchâtel T: +41 (0) 32 7301 - 260 F: +41 (0) 32 7301 - 351 Dresden Baumüller Kamenz GmbH Nordstraße 57 D-01917 Kamenz T: +49 (0) 3578 34 06 - 0 F: +49 (0) 3578 34 06 - 50 40 Russia, Kazakhstan Permanent K&M Wolokolamskoye Chaussee 73, Office 517, Moscow, 125424 T: +7 (095) 9563867 F: +7 (095) 7803429 Spain Baumüller Ibérica S.A. Ausias Marc 13 10 2a, E-08010 Barcelona T: +34 (0) 93 3426 926 F: +34 (0) 93 2701 321 Düsseldorf Baumüller Nürnberg GmbH Jacob-Kaiser-Str. 7 D-47877 Willich-Münchheide T: +49 (0) 2154 4 87 - 0 F: +49 (0) 2154 4 87 - 59 30 Poland Mekelburger Polska Ul. Kóscielna 39 F/3, PL-60537 Poznán, T: / F: +48 (0) 61 8481 520 Baumüller München GmbH Meglingerstraße 58, D-81477 München T: +49 (0) 89 748 898 - 10 F: +49 (0) 89 748 898 - 75 be in motion be in motion 1000 2000 3000 4000 5000 6000 192 Responsible for content: Baumüller Nürnberg GmbH Ostendstraße 80–90 90482 Nürnberg T: +49 (0) 911 5432 - 0 F: +49 (0) 911 5432 - 130 www.baumueller.com Baumüller Anlagen-Systemtechnik GmbH & Co. KG Ostendstraße 84 90482 Nürnberg T: +49 (0) 911 54408 - 0 F: +49 (0) 911 54408 - 719 Baumüller Reparaturwerk GmbH & Co. KG Andernacher Str. 19 90411 Nürnberg T: +49 (0) 911 9552 - 0 F: +49 (0) 911 9552 - 999 ii All data/information and particulars given in this brochure is non-binding customer information, subject to constant further development and continuously updated by our permanent alteration service. Please note that all particulars/figures/information is current data at the date of printing. These particulars are not legally binding for the purpose of measurement, calculation or cost accounting. Prior to using any of the information contained in this brochure as a basis for your own calculations and/or applications, please inform yourself about whether the information you have at your disposal is up to date. Therefore, no liability is assumed for the correctness of the information. ii,02 ii,04 ii,06 ii,08 ii,10 ii,12 ii,14 ii,16 ii,18 ii,20 ii,22 ii,24 ii,26 ii,28 ii,30 ii,32 ii,34 ii,36 ii,38 ii,40 ii,42 2.191.e.04/05.20M ii,44 04/05 ii,46 ii,48 ii,50