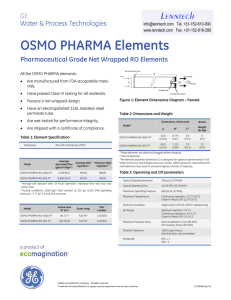

Series 100, 200, 300, 400, 500, 600, 700 , 800

advertisement