Section 16. Wire Management

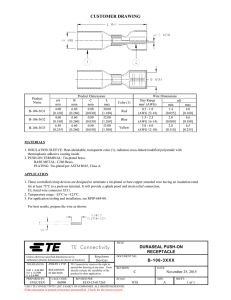

advertisement