HSK-M

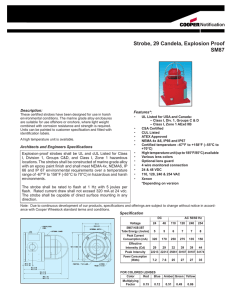

advertisement