Technical Handbook

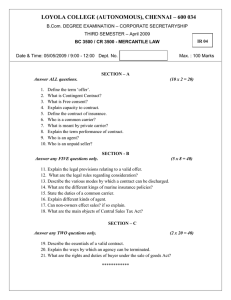

advertisement