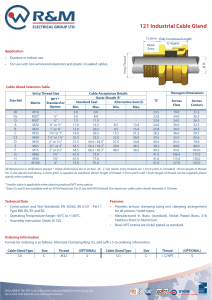

emc 4 cable glands

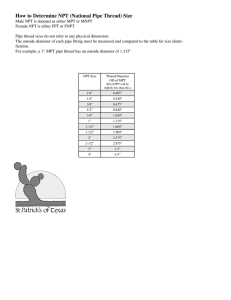

advertisement