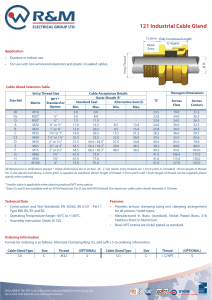

Industrial Application

advertisement