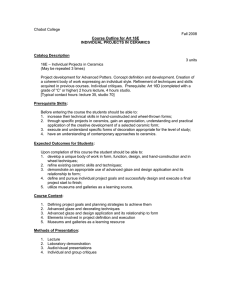

CERAMICS,CJSC

Annex to the summary of the investment proposal

«Creation of large-scale serial production of nanostructured technical ceramics products and ceramic products for medical application»

Innovative company

«NEVZ - CERAMICS», CJSC

2013

1.

Ceramic substrates and packages

1.1 Nomenclature

1.2 Performed works in the direction “Substrates”

1.3 Purchased equipment

Content:

2 . Bioceramics

2.1 Nomenclature

2.2 Performed works in the direction “Bioceramics”

2.3 Purchased equipment

3 . Ceramic insulators

3.1 Nomenclature

3.2 Performed works in the direction “Insulators”

3.3 Purchased equipment

4. Ceramics for protection of vehicles and personnel

4.1 Nomenclature

4.2 Performed works in the direction “Ceramics for protection”

4.3 Purchased equipment

5 . Ceramic elements for stop valves

5.1 Nomenclature

5.2 Performed works in the direction “Ceramic elements for stop valves”

6. Scientific cooperation in the framework of the project

2

Ceramic substrates and packages

Ceramic products developed and manufactured by NEVZ-CERAMICS CJSC for electronics and hydrogen fuel cells market

LED

UHF-devices, Hybrid modules, think and thick film

Alumina oxide (Al

2

O

3

96%) with metallization

Alumina oxide (Al

2

O

3

96%); Polished Alumina

(Al

2

O

3

99,8%)

Solid Oxide Fuel Cells

Fully or partially stabilized zirconia ceramics.

Ceramic products developed and manufactured by NEVZ-CERAMICS CJSC for electronics and hydrogen fuel cells market

Ceramic heat sink

Alumina Oxide (Al

2

O

3

96%), AlN

Packages and substrates

Power semiconductor

HTCC (green ceramic)

AlN with thermo conductivity 180 W/ m К

Future products by NEVZ-CERAMICS CJSC for electronics market

IC’s, Power Devices

LTCC и HTCC

Power Semiconductor Devices (MOSFET),

UHF and other.

3D-structure on ceramics (LTCC board)

AlN, Al

2

O

3 with DBC-metallization

Green LTCC

Russian market of radioelectronics and components

5000

4500

4000

3500

3000

2500

2000

1500

1000

500

0

2013 2019 2025

Forecast of radioelectronics market growth*

8%

6%

15%

5%

5%

18%

24%

19%

Telecommunication equipment

Industrial electronics

Military vehicles

Other

Safety systems

Consumer electronics

Medical electronics

1600

1400

1200

1000

800

600

400

Market

Earning of NC

200

0

2012 fact

2013 2014 2015 2016 2017 2018 2019

Russian market of ceramic substrates form Al2O3, AlN,

LTCC and DBC (not incl. packages for LED, semiconductors and integrated circuits, substrates for fuel cells)

Target segments of substrates and packages application include Σ 34,31 billion rub./61%

Segment Volume, billion rub.

Telecommunication equipment

Industrial electronics

13,33

10,757

Military vehicles 10,23

Other

Safety systems

8,68

4,278

Consumer electronics

Medical electronics

3,41

3,1

Auto electronics 2,945

TOTAL 56,73

Segmentation of Russian market of electronics and components by application fields in 2012**

*The Russian Federation State program “Development of electronics and radioelectronics for 2013-2015”

**Report of market research of electronic components, prepared by “SOVEL” Ltd.

7

NEVZ-CERAMICS CJSC product line for electronics and hydrogen fuel cells market

Al2O3-96% substrates manufactured by slurry casting on the tape

Green HTCC ceramics

AlN substrates with thermal conductivity of

170 W/mK

Polished Al2O3-

99,8% substrates

Substrates with

DBC metallization

Substrates on the base of fully and partly stabilized ZrO2 -

10Sc1CeSZ, 8YSZ,

3YSZ

Leadless packages for semiconductors and integrated circuits

Past 2011 2012 2013 2014 2015 2016 2017 Future

Grinded Al2O3-95% substrates manufactured by pressing

Metallized substrates and packages for

LEDs

Development of own precious metal inks for HTCC and AlN ceramics

Green LTCC ceramics compatible with metallizing inks Ferro and DuPont

Multilead packages for integrated circuits and chip assemblies

8

Performed works in the direction

“Ceramic substrates and packages”

During 2011-2013 NEVZ-CERAMICS CJSC developed and mastered the following:

4 types of ceramic materials: Al2O3 96%, Al2O3 99,8%, AlN and ZrO2;

Technological operations in grinding/polishing, metallizing and combined sintering of metallization and ceramics;

Independent tests of ceramics were performed in the leading Russian and foreign scientific centers.

NEVZ-CERAMICS, CJSC is the only company in Russia and among CIS-countries that is ready to start production of AlN-ceramics, a substitute of BeO-ceramics. The quality of this ceramics is confirmed by independent tests results performed by the leading European institute Fraunhofer IKTS

(Dresden), Nanoindustry Center of Nizhny Novgorod and Laboratory of physical and chemical properties of solids in the Institute of General Physics.

Comparative properties of AlN-ceramics produced by the leading world manufacturers based on values of thermal conductivity:

Property

Thermal conductivity

(20

С), W/М*К

NEVZ,

Russia

180

MARUWA,

Japan

Fraunhofer,

Germany

180 159

CermTec,

Germany

170

LEATEC,

Taiwan

170

Clec group,

China

140

9

Independent test results of AlN ceramics manufactured by CJSC "NEVZ-

CERAMICS"

CJSC "NEVZ-CERAMICS" the only company in Russia and the CIS, which ready to start production of the aluminum nitride ceramics (AlN) which is an alternative to beryllium ceramic (BeO), the quality of which is confirmed by independent test results:

Fraunhofer IKTS, Germany Nizhny Novgorod center of nanoindustry ,

Russia

General Physics Institute RAS, Russia

Performed works in the direction

“Ceramic substrates and packages”

NEVZ-CERAMICS, CJSC is the only company in Eastern Europe and among CIS-countries that manufactures substrates from fully stabilized ZrO2 (10SclCeSZ) applicable in the solid oxide fuel cells (SOFC).

Comparative properties of SOFC produced by the leading world manufacturers based on energy density:

Producer

Product status

SOFC on the base of

NEVZ substrates

R&D

Versa Power

R&D

SOFCPower test

IKTS test

Staxera commercial

Max. power

Energy density

N/A

270 mW/sm

8 stacks 50kW

300 mW/sm

N/A 8 stacks 6kW

278 mW/sm > 220 mW/sm

2 stacks 1,8kW

182 mW/sm

Fuel utilization N/A 68 % 45 % > 75 % > 75 %

Voltage-current characteristics of the stack Structure of 10Sc1CeSZ ceramics

Equipment purchased for ceramic substrates and packages production

Substrates Casting line :

«KEKO»(Slovenia) Hight – temperature kilns for ceramics sintering in various gase atmospheres

BIOCERAMICS

«NEVZ – CERAMICS», CJSC mastereD production of ceramic items for medical application ( endoprothesis, implants, inmplantation systems and elements of the systems) based on Al

2

O

3

- and ZrO ceramics. Products with bioactive coating of nanostructured hydroxyapatite can be successfully applied in surgical treatment of injury of human locomotor system, dentistry and maxillofacial surgery.

13

Size and structure of “Bioceramics” market

Hip joint implants, spinal implants

The global market of bioceramics estimates 2,3 billion USA$.

Annual growth is 7-12 %.

There are more than 50 manufacturers of hip joint implants in the world.

In September 2011 there are 21 companies in the Russian market.

The main customers of hip joint implants are clinics of traumatology and orthopedics.

In Russia about 200 medical treatment facilities buy the hip joint implants. About 10 clinics buy more than 1000 hip joint implants per year. Assessment of endoprosthesis market in Russia, mln. rub.

Dental ceramic products

In 2010 the dental market of all implants (including non ceramics) estimated

3,2 billion USA$.

In 2011 the Russian market of implantology is estimated in 60 million USA$.

According to the customs statistics during 2011 there the import dental ceramic implants expressed in monetary terms estimated 3,37 million USA$, including:

- 2,00 million USA$ are ZrO2 products;

- 1,37 million USA$ are Al2O3 products.

Assessment of dental implants market in Russia, mln. rub.

Customers of dental implants: Dental technical laboratories, Dental clinics, Milling centers

Leading world manufacturers: Nobel Biocare, Sax IBS (Германия), SIRONA Dental Systems (Germany),

Bettini SPA, BIOMET 3i, Wieland, Astra Tech, Bicon Dental Implants, BioHorizons.

Application

Modern joint replacement technologies

Surgical treatment of the spine disorders

Treatment of the bone tissue pathologies

CAD/CAM technologies for stomatology

Product

Hip joint implant with ceramic friction pair

Knee joint implant

System of spine ventral stabilization

Spinal interbody fixators

Implants – Cavity filling granules

Materials and implants for stomatology

The works performed in «Bioceramics»

Spinal implants

There is NO ceramic equivalent to the product worldwide!!!

Development of design and technological documentation on manufacturing interbody endoprosthesis of porous ceramics; plates and screws of dense ceramics;

Toxicological research of ceramics, positive results obtained;

Pre – clinical studies on biomannikin, positive results obtained;

Development of the program on clinical studies; The program has been accepted by the Ethics Committee;

3 successfully carried out operations on installation

of a spinal implant to the patient at the

FSBI «NIITO» Ministry of Health of Russia

in 2013

( Novosibirsk Research Institute Traumatology and Orthopeadics)

Serial production : 2 semester of 2013.

Cooperation with leading medical organizations and centers

The works performed in «Bioceramics»

Hip joint endoprosthesis

Development and manufacturing of the composition of nanostructured composite ceramic material, mechanical and strength characteristics of which meet the requirements to a hip joint friction pair: bending strength over 900 mPa;

Carrying of toxicological research of composite ceramic material according to ISO 10993, that approved nontoxicity of the developed composition;

Carrying of the research in cooperation with the research laboratory of Central Institute of

Traumatology and Orthopeadics (CITO, Moscow):

- Ceramic hip joint friction pair held the simulation wear tests according to GOST (

National State Standard) P52640 over a period of 20 years of exploitation;

- Ceramic hip joint friction pair held the tests according to ISO 7206 – 10 on static pressure over 2 tonnes;

Samples of endoprosthesis are submitted for match (sizer) technological tests to Russian accredited research laboratory. Termination of the tests – august 2013.

Serial production: 2 semester 2014.

17

The works performed in «Bioceramics»

Ceramic zirconium dioxide blanks for dental restorations

Research works on indicating major characteristics of the material of the product;

Toxicological research of the developed material according to IS0 10993 positive results obtained;

Development of laboratory technological regulations providing high stability performance of ceramic blocks;

Development of ceramic samples of ceramic blocks;

Preliminary engineering and medical tests. Positive results obtained

State registration, receipt of registration certificate authorizing the treatment of medical products in the territory of the Russian Federation

- Serial production: 2 semester 2013

18

Equipment purchased for bioceramics production

Niro Atomizer Granulator Isostaic press «Frey»

Gasostatic press EPSI

Multi-purpose grinding machine for complex surfaces Multigrind AF

Injection – molding machine «Allrounder

Golden Edition 270C»

(ARBURG , Germany)

19

CERAMIC INSULATORS

JSC «NEVZ – CERAMICS » manufactures multi – purpose ceramic insulators( for vacuum arcquenching chambers (VAQC) packages for power semiconductor devices, electric – optical converters (EOC), and is planning to produce ceramic tubes and other ceramic item fro different industries.

Ceramic insulators for vacuum arcquenching chambers

Insulators for packages for power semiconductor device s

Insulators for electric – optical converters

20

Size and structure of “Ceramic insulators” market

Analysis of the main market parameters for the basic product:

Production: in 2011 the world production volume of ceramic insulators and products from technical ceramics was estimated at least 4 billion rubles 9according to the consumption rates of the world leaders).

Import: according to the customs statistics during the 4Q of

2010 and 3Q of 2011 the total import of ceramic insulators

(insulators, rings, rollers, tubes, plugs, etc.) was more than 5 million USA$. The main exporter-states are: China, Germany,

Japan, Netherlands.

Export: there is no export of ceramic insulators for arch chutes and image converters. The only importers of ceramic insulators in small scale are state-members of CIS

The main application areas for ceramic insulators:

- ceramic insulators for commutation devices in energy

(insulators for arch chutes),

0

- Ceramic insulators for image converters (vacuum photoelectronic devices),

- Ceramic insulators for nuclear industry, that are used as thermoinsulation material and eclectically insulating material in active zone of reactor,

- Other products from technical ceramics for different industries

(tubes, plugs, rollers, etc.).

Needs assessments in Russia, million rubles

2012 2013 2014 2015 2016

21

The works performed in «Insulators» production

The company performed R&D works:

The production technology for ceramic ring insulators (on the base of nanostractured ceramics) is developed;

The production technology for Al2O3 - 99,8% (VK100-2);

The production technology for large-sized and long ceramic elements is developed by using method of thermoplastic slurries casting.

A new technological line for ceramic insulators production is put into operation.

NEVZ-CERAMICS, CJSC develops and manufactures products for the leading customer in power industry and electric engineering:

22

The modern equipment for technical ceramics production available at NEVZ-CERAMICS,CJSC

The equipment of the leading European producers is assembled and put into operation

Niro A/S Spray dryer

Isostatic press PI-80Z

(Dorst,Germany)

PressTPA-50 (Dorst, Germany)

Sintering in gas kilns Wistra1,2

(Germany)

Hydrogen-oxygen station

(Teledyne, USA)

23

The modern equipment for technical ceramics production available at NEVZ-

CERAMICS,CJSC

Tunnel kiln

For sintering ceramic products

Wistra 3 (Germany)

Grinding

Glazing by МР-400 equipment (Germany)

Galvanics

Burning of glaze in electric kiln GMQ 4030-15 NM

24

CERAMICS FOR PROTECTION VEHICLES AND

PERSONNEL

During last 2 years JSC «NEVZ-Ceramics» has initiated development and mastering of the production of the expanded product range of

"ceramics for protection“ on the basis of aluminum oxide. Ceramics based on silicon carbide, boron carbide and alumina radar-absorbent ceramics are under development and mastering stage.

25

Size and structure of “Ceramics for protection” market

In 2011 the global production run was about

1,2 billion USA$

The annual average growth of ceramics for protection consumption is expected at a rate of 17% for the period 2012-2017

Due to the absence of big ceramics for protection manufacturers the import in

Russia is about 70%. The main exporterstates of ceramics for protection in Russia are Germany, India, Israel, China.

Application fields of ceramics for protection:

Production of protection means for military and civil land, naval and air vehicles (panels for protection)

Production of protection means for personnel (vests for protection, mantelets, etc.)

Needs assessments in Russia, thousands rubles

Purpose

(application field)

Protection for personnel assets

Protection for light land vehicles

BMP / BMD, BM

(Fighting vehicles)

Protection for air vehicles fighting helicopters

Protection for naval vehicles, frigates and corvettes

Ceramics for protection

The works performed in protective ceramics production

Within 3 years there have been held no less than 20 of bench and field tests on evaluation of the bullet resistance of armor plates for vehicles protection in range of calibers of weapons 7.62 mm, 12.7 mm, 14.5 mm., the test have also been carried out at the main accredited testing centers of the Russian Defense Ministry and the Russian Ministry of

Internal Affairs and also at foreign testing centers: «Banc National D’Epreve des Armes et

Munitions» (France) and Industrieanlagen-Betriebsgesellschaft (IABG) ( Germany).

Armor ceramics produced by NEVZ – CERAMICS, CJSC has successfully passed series of tests and confirmed ballistic properties in the ceramic-composite armor elements for 3, 5,

5a, 6 and 6a protection levels of the leading domestic manufacturers of bullet proof vests

(JSC "Research Institute of Steel", JSC “CIRASA”, JSC SPE "CLASS", JSC RP

"ARMOKOM-Center", JSC "Techinkom", SPA “Special materials“), which confirms the possibility of its application personnel assets protection against automatic rifles.

28

“Protection of personnel”

Development and test results of armor panels.

Caliber 7,62 mm, 2009 – 2010

“Protection of personnel”

Development and test results of armor panels.

Caliber 7,62 mm, 2012

Test samples of armor double-curve panel for body-proof vest of 6A protective level according

GOST P-50744-95

Test report of Siberian branch of FKU NPO “STiS”,

Russian Ministry of Internal Affaires

Firing after freezing under -50 C

Panel front

Panel back.

NO PENETRATION

Panel front

“Protection of personnel”

Development and test results of armor panels.

Caliber 7,62 mm, 2013

Test samples of armor double-curve panel from NEVZ ceramics for body-proof vest of 6A protective level according

GOST P-50744-95 developed in collaboration with a foreign partner that is specialized in R&D for personnel protection.

Protection level: 6A class, GOST 50744P+ballistic inset of 1 class, GOST 50744P

Protection area: 7,65 dm2

Mass: 3,059 kg

Relative density: 0,40 kg/dm2 Panel back.

No penetration

Test samples of armor double-curve panel from

NEVZ ceramics for body-proof vest of 5A protective level according GOST P-50744-95 developed in collaboration with a foreign partner that is specialized in

R&D for personnel protection.

Panel front

Panel back. No penetration

Protection level: 5A class, GOST 50744P+ballistic inset of 1 class, GOST 50744P

Protection area: 8,6 dm2

Mass: 3,028 kg

Relative density: 0,35 kg/dm2

Armor ceramics field tests results

Light armor vehicle protection (14,5 mm caliber bullets)

Date: 6 – 10 of June, 2011

Location: test center of the Russian Ministry of Defense

Test object: Armed vehicle with additional bullet-proof protection panels on the base of armor ceramics. Additional protection panels are installed on the side views, frontal view and turret of the armed vehicle.

Scope of tests:

68 shots are made into the armored vehicle, including 13 shots in front projection, 25 sots in right side and 30 shots in left side.

31

Armor ceramics field tests results

Light armor vehicle protection (14,5 mm caliber bullets)

Development of armor protection:

“Russian machines”, JSC and “Military industrial company” Ltd.

Armor ceramics: “NEVZ-Soyuz”, HJSC

Test results of firing into the side projection

View from inside

On the inside of the hull armor damage is not fixed

Test results of firing into the top manhole

Imitation of winter operation conditions (- 52 о С)

Before test After test

Test center «Banc National d'Epreuve»

(St. Etienne, France)

Panel front

Tests of ceramic-composite panels according to STANAG 4569 АЕР55, Level 3

(bullet AP8, WC-core), 2013

Panels - made from ceramic rollers 29*18 mm, backup layer - steel 8 mm,

Ammunition - AP8 bullet 7,62 mm

Core - WC

Results: 12 shots, NO PENETRATION OF THE BACKUP

LAYER

Backup layer.

NO penetration

Panel back

33

Panel front

Test center «Banc National d'Epreuve»

(St. Etienne, France)

Panels - made from ceramic rollers 29*18 mm, backup layer - steel 8 mm,

Ammunition - FSP 20 mm

Result: 3 shots, NO PENETRATION OF THE

BACKUP LAYER

Backup layer.

NO penetration

Panel back

34

Equipment purchased for protective ceramics production

Press KOMAGE (Germany)

Hot pressing complex HPW400

(FCT, Germany)

Automatic press ЕРМ-120 (China),

2 items.

Granulator DORST D-100

(Germany)

PressTPA-50 (Dorst,

Germany)

Rotary press Courtoy R53

(Belgium)

Kiln REIDHAMER

(Germany)

CERAMIC ELEMENTS FOR STOP VALVES

«NEVZ – CERAMICS», CJSC masters production of ceramic valve units featuring thermal strength, thermal shock resistance and hydro- and abrasive damages, and also resistance to aggressive effects of environment. Ceramic valve units are designed for integration into control stop valves produced in large scale by

Russian manufacturers.

36

Size and structure of “Stop valves” market

•

According to the researches there is no production of ceramic stop valves in Russia;

•

According to the report of Scientific and Industrial

Valve Manufacturers Association in 2010 the import of valves in Russia was 1128,9 million USA$. The production volume of steel valves by domestic manufacturers was 1258,6 million USA$;

•

Consumption of all types of valves in oil and gas industry is about 24% 9597 million USA$) of the total market;

•

The forecast volume the most expensive high-quality steel valves, that are planned to be replaced by ceramic production of HC JSC NEVZ-Soyuz, will be

46,5 million $;

•

If 50% of the customers who import now the expensive steel valves use Russian ceramic valves, the consumption volume of ceramic valves in Russia will reach 23,2 million USA$ or 720,8 million rubles.

•

There are no statistics of ceramic valves export from

Russia.

Needs assessments in Russia, million rubles

It is considered only high-quality valves, and the indictors were forecasted taking into account that 50% of the customers who import now the expensive steel valves will use Russian ceramic valves. The forecasted annual average growth of import is 50%

(according to the reports of Industrial Valve Manufacturers

Association).

37

Application

Stop and control valve units for oil and gas, chemical, nuclear and other industries

Product

Sealing rings

Ball valve

Throttle

Fitting

The works performed in production of

«ceramic elements for stop valves»

- Development of tailored composition of ceramic composites for stop valves based on Aluminum Oxide and Zirconium Dioxide

(ZrO

2

+Al

2

O

3

);

Conclusion of a contract with Fraunhofer IKTS ( Germany) on development of the technology of production of ceramic elements for stop valves by injection molding;

Partial manufacturing of tooling for pilot production;

39

Test results of throttles performed by petroleum refiner companies

In the framework of partnership Agreement between NEVZ-CERAMICS, CJSC and RUST-

95, CJSC there have been performed tests of throttles made from ceramics for Moscow petroleum refiner-plant

40

Test results of ceramic fittings by RGO “Technovek”, CJSC

In April, 2012 in the framework of cooperation between NEVZ-

Soyuz, HJSC and RGO

Technovek, CJSC there have been performed erosive tests of fittings caused by free jet blast.

41

R&D work results of ceramic ball DN 50 production in the framework of cooperation with

PTPA, JSC

In 2012 in the framework of cooperation between NEVZ-

CERAMICS, CJSC and PTPA, JSC there have been produced the first test samples of ceramic balls DN for stop valves DN 50. The test samples are under finishing and preparation for testing.

42

Laboratory and analytical equipment purchased for ceramics production

Apparatus for simultaneous thermal analysis STA 449 F3

Scanning electron microscope JSM-6010

Differential scaninng calorimeter DSC 204

Particle size analyzer by sedimentation and centrifugation with X-ray detector BI-XDC

Serial X-ray fluorescence spectrometer

Thermal measurement device LFA 446

Tensile testing machines

Instron with two columns of 3360serial

43

SCIENTIFIC COOPERATION IN THE

FRAMEWORK OF THE PROJECT

Noncommercial Partnership “Siberian Ceramics”

Date of establishment - 2009

Non-commercial Partnership “Siberian ceramics” was established at the initiative of CJSC NEVZ-CERAMICS with the support of Plenipotentiary of the President of the Russian

Federation in Siberian Federal Region and Novosibirsk

Oblast Administration

NP “Siberian Ceramics” structure:

SB RAS Academic organizations Institute for Theoretical and Applied Mechanics SB RAS, Institute of

Solid Chemistry and Mechanical Chemistry SB RAS, Institute for Inorganic Chemistry SB RAS, Institute of

Hydrodynamics SB RAS, Institute of Strength Physics and Material Science SB RAS.

Siberian Region Institutes of Higher Education – National Research Tomsk Polytechnic University, National

Research Novosibirsk State University, Novosibirsk State Technical University, Novosibirsk State Medical University.

Medical profile organizations – Novosibirsk Scientific Research Institution Traumatology and

Orthopedics of RosMedTechnologies, Tomsk Military Medical Institute of Russian Federation Ministry of

Defence, Close JSC «Siberian Scientific Research and Testing Center of Medical Equipment»

45

Scientific cooperation with foreign ceramic manufacturers

Fraunhofer, IKTS, Germany

The major institute in Europe, that makes researches in the field of nanoceramics, particulary alumina, carbide, zirconium and nitride.

Сerel, Poland

Development and production of zirconium ceramics

Institute of science and technology for ceramics (ISTEC), Italy

Developmnet in the field of nanostructured ceramics ( porous and pressed)

Neoker, S.L., Spain

Development and production of nanofibers

FCT System, Germany

Research works on boron carbide armour ceramics under hot pressing using the «Spark-plazma» system

Saint Gobain IndustrieKeramik GmbH, Germany

Technology and industrial production of armour plates of various configurations based on silicon and boron carbides

46