Section 16475 - Overcurrent Protective Devices

advertisement

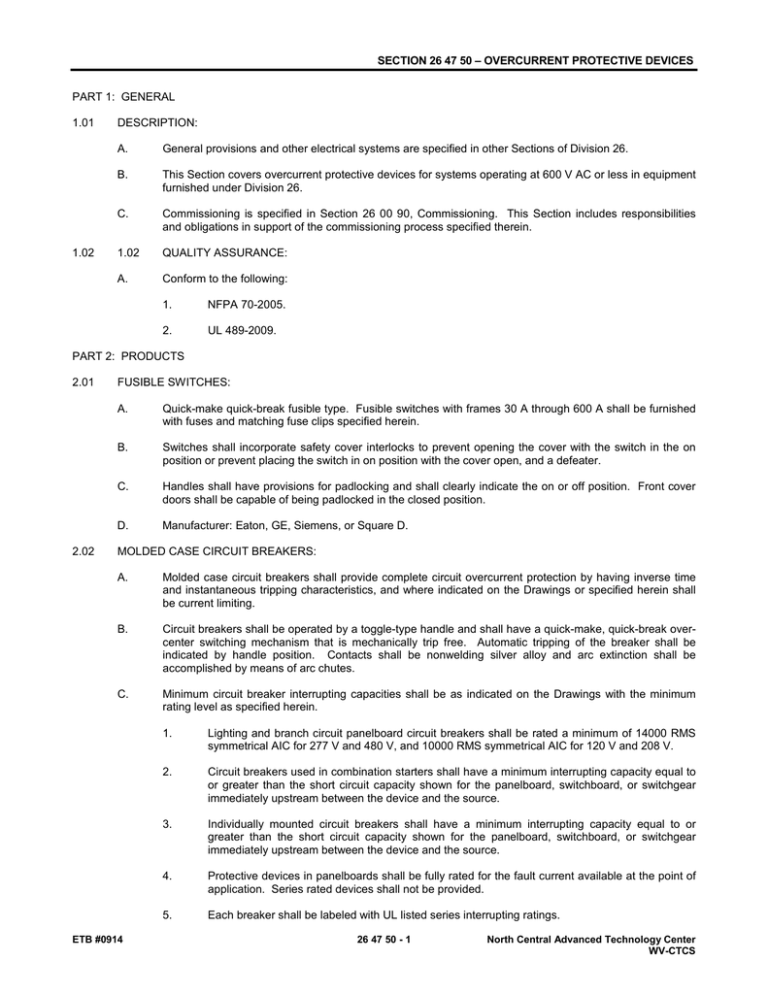

SECTION 26 47 50 – OVERCURRENT PROTECTIVE DEVICES PART 1: GENERAL 1.01 1.02 DESCRIPTION: A. General provisions and other electrical systems are specified in other Sections of Division 26. B. This Section covers overcurrent protective devices for systems operating at 600 V AC or less in equipment furnished under Division 26. C. Commissioning is specified in Section 26 00 90, Commissioning. This Section includes responsibilities and obligations in support of the commissioning process specified therein. 1.02 QUALITY ASSURANCE: A. Conform to the following: 1. NFPA 70-2005. 2. UL 489-2009. PART 2: PRODUCTS 2.01 2.02 FUSIBLE SWITCHES: A. Quick-make quick-break fusible type. Fusible switches with frames 30 A through 600 A shall be furnished with fuses and matching fuse clips specified herein. B. Switches shall incorporate safety cover interlocks to prevent opening the cover with the switch in the on position or prevent placing the switch in on position with the cover open, and a defeater. C. Handles shall have provisions for padlocking and shall clearly indicate the on or off position. Front cover doors shall be capable of being padlocked in the closed position. D. Manufacturer: Eaton, GE, Siemens, or Square D. MOLDED CASE CIRCUIT BREAKERS: A. Molded case circuit breakers shall provide complete circuit overcurrent protection by having inverse time and instantaneous tripping characteristics, and where indicated on the Drawings or specified herein shall be current limiting. B. Circuit breakers shall be operated by a toggle-type handle and shall have a quick-make, quick-break overcenter switching mechanism that is mechanically trip free. Automatic tripping of the breaker shall be indicated by handle position. Contacts shall be nonwelding silver alloy and arc extinction shall be accomplished by means of arc chutes. C. Minimum circuit breaker interrupting capacities shall be as indicated on the Drawings with the minimum rating level as specified herein. ETB #0914 1. Lighting and branch circuit panelboard circuit breakers shall be rated a minimum of 14000 RMS symmetrical AIC for 277 V and 480 V, and 10000 RMS symmetrical AIC for 120 V and 208 V. 2. Circuit breakers used in combination starters shall have a minimum interrupting capacity equal to or greater than the short circuit capacity shown for the panelboard, switchboard, or switchgear immediately upstream between the device and the source. 3. Individually mounted circuit breakers shall have a minimum interrupting capacity equal to or greater than the short circuit capacity shown for the panelboard, switchboard, or switchgear immediately upstream between the device and the source. 4. Protective devices in panelboards shall be fully rated for the fault current available at the point of application. Series rated devices shall not be provided. 5. Each breaker shall be labeled with UL listed series interrupting ratings. 26 47 50 - 1 North Central Advanced Technology Center WV-CTCS SECTION 26 47 50 – OVERCURRENT PROTECTIVE DEVICES D. Individually mounted circuit breakers shall incorporate hinged covers with external operating handles. Devices shall be removable from the front. E. Breakers with frames 600 A and larger shall include solid state trip complete with built-in current transformers, solid state trip unit and shunt trip. Breakers shall have trip ratings as indicated on the Drawings. Trip units shall have adjustable short time setting with a fixed instantaneous override for circuit protection. Main breakers shall be provided with additional short delay trip time adjustment for increased system coordination. Where indicated on the Drawings, or specified herein, breakers shall have built-in ground fault protection with adjustable pick-up rating not exceeding 1200 A. Ground fault time delay shall be adjustable 0.1 s to 0.5 s. Breakers shall have a neutral ground fault current transformer for 4-wire systems. F. Insulated Case Circuit Breakers: G. 1. Breakers shall be UL listed, insulated case type, minimum AIC as indicated on the Drawings. Breakers shall be stationary, draw-out, 100% equipment rated units, with pad-lock function. Breakers shall be listed for series rating of 150000 RMS symmetrical AIC minimum with Class L fuses applied on the line side. 2. Breakers shall be equipped with integral solid state programmer with adjustable current, adjustable long-time delay, adjustable short-time delay, adjustable instantaneous pick-up, adjustable ground fault pick-up, adjustable ground fault delay, and overload, short circuit, and ground fault trip indication targets. Ground fault trip range shall be approximately 25% to 100% of nominal breaker rating, up to a maximum of 1200 A. Remotely Operated Circuit Breakers: 1. H. ETB #0914 All remotely operated branch circuit breakers shall provide overload and short circuit protection suitable for the location in the electrical system, as defined in the panelboard schedules. Remotely operated power switching devices shall have the following: a. Integral branch circuit overcurrent protection as required by the NFPA 70. All circuit breakers shall have a UL Listed interrupting rating sufficient for the application or UL Listed series connected ratings for the maximum available fault current at that point in the system. Submittals reflecting the use of relays or contactors to perform remote switching must show evidence in writing that the relays withstand the available fault current. b. UL Listed SWD ratings for 15A and 20A 1-, 2- and 3-pole branch devices, HID ratings, and HACR ratings. c. Handle operator that shall mechanically open the power switching device contacts when moved to the OFF position and disable the contacts from being remotely closed. d. Manual override switch to enable or disable the remote operation of the device and allow breaker handle to fully control the On/Off state of the breaker. Override must fully disengage remote operation of the breaker mechanism. Device utilizing ‘one-shot’ or ‘temporary’ overrides will not be accepted. e. Visible flag that clearly indicates the status of the circuit breaker contacts with the panel trim installed. Flag shall indicate: ON, OFF, and TRIPPED circuit breaker states. The visible flag shall be mechanical in nature, directly tied to the circuit breaker mechanism, and shall be provided in addition to any status indicator supplied by the system electronics. f. Switching endurance rating of 200,000 open/close/open remote operations. Switching devices with lower ratings may be judged to be acceptable, but must be provided with 100% spare switching devices for each circuit to ensure an equivalent total number of operations. Manufacturer: Eaton, GE, Siemens, or Square D. 26 47 50 - 2 North Central Advanced Technology Center WV-CTCS SECTION 26 47 50 – OVERCURRENT PROTECTIVE DEVICES 2.03 2.04 FUSES: A. Fuses in devices through 600 A capacity: UL Class RK1 current limiting, dual element, time-delay type with Class R fuse clips for motor branch circuits and transformer feeders, and UL Class J current limiting, quick acting type for other applications. B. Fuses in devices greater than 600 A capacity: UL Class L, time-delay, current limiting type. C. Fuses shall be voltage rated for the system in which they are installed. D. Manufacturer: Bussmann, Edison Fusegear, Ferraz Shawmut, GE, or Littelfuse. SPECIAL FUSES: A. Fuses in control circuits and special applications shall be of type and size for duty for the specific application. PART 3: EXECUTION 3.01 INSTALLATION: A. 3.02 3.03 3.04 FUSIBLE SWITCHES: A. Install fuses in fusible switches. B. Provide fuses in fusible switches serving packaged air conditioning units and elevators in accordance with manufacturers’ recommendations and nameplate requirements. CIRCUIT BREAKERS: A. Fasten circuit breakers without causing mechanical stresses, twisting or misalignment being exerted by clamps, supports, or cabling. B. Install fuses in circuit breakers with fuse protection. SPARE FUSES: A. 3.05 Install overcurrent protective devices as indicated on the Drawings or specified herein, in accordance with manufacturer's written instructions. Provide 3 spare fuses of each size, UL class, and voltage rating and turn over to the Owner. Obtain a receipt for same. FUSE STORAGE: A. Furnish a galvanized sheet metal cabinet with hinged door and latch in the main electrical service room to contain spare fuses. To the back side of the door attach a type written list of spare fuses itemized to show quantity, amperage, class and catalogue order number. END OF SECTION 26 47 50 ETB #0914 26 47 50 - 3 North Central Advanced Technology Center WV-CTCS