2015 Student EMC Hardware Design Competition

advertisement

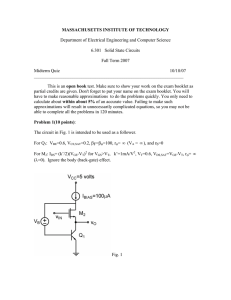

1 2015 Student EMC Hardware Design Competition ∗ University Mislav Mikic∗ , Rebecca Grancaric∗ , Raul Blecic∗† , Adrijan Baric∗ of Zagreb, Faculty of Electrical Engineering and Computing, Unska 3, 10000 Zagreb, Croatia Tel: +385 (0)1 6129547, fax: +385 (0)1 6129653, e-mail: raul.blecic@fer.hr † KU Leuven, ESAT-TELEMIC, Kasteelpark Arenberg 10, 3001 Leuven, Belgium Abstract—A step-down switched-mode power converter based on the regulator MC34063A is designed. Special attention is given to the minimization of its conducted emissions and output voltage ripple. The selection of the components and the design of the printed circuit board (PCB) layout are discussed in detail. The operation of the designed converter is simulated by SPICE simulations. The efficiency, output voltage ripple and conducted emissions of the designed converter are measured. A line impedance stabilization network (LISN) designed on a separate PCB is used for the conducted emission measurements. Index Terms—conducted emissions, electromagnetic interference (EMI), filter design, line impedance stabilization network (LISN), switched-mode power supply (SMPS). I. I NTRODUCTION Switched-mode power converters are used more often than the linear converters, primarily due to their higher efficiency. Linear converters are regulated by a transistor that acts as a variable resistor and dissipates power constantly in order to adjust the output voltage level. The transistor of a switchedmode power converter constantly switches on and off and dissipates power mainly during the transients between the two states. The downside of switched-mode converters is the rich spectrum of their switching waveforms which is a source of conducted and radiated electromagnetic (EM) emissions [1]. The objective of this project is to design, construct and characterize a step-down converter with the conducted emissions in the range of 150 kHz to 30 MHz as low as possible, and the ripple of the output voltage as low as possible. The converter is designed for the input voltages in the range from 6 to 12 V. The output voltage is set to 3.3 V. The output current is set to 330 mA by the load resistor of 10 Ω. The regulator used in the design is MC34063A [2], [3]. Other components required for the converter and for the input and output filters are selected on the basis of circuit analysis as well as the results obtained by SPICE simulations. Printed circuit board (PCB) layout has a considerable effect on the converter characteristics. The layout is designed to minimize the propagation of the noise on the PCB. Finally, after the designed converter is processed and assembled, its efficiency, ripple of the output voltage and conducted emissions are measured. This paper is structured as follows. Section II describes the selection of the components. Section III describes the design of the printed circuit board layout. Section IV defines conducted emissions. Section V shows the results of the measurements. Section VI concludes the paper. II. S CHEMATIC DESIGN The schematic of the designed buck converter is shown in Fig. 1. All components used in the design and their main characteristics are listed in Table I. The selection of the components is described in the following subsection. A. Component Selection 1) External transistor: Selection of an external transistor depends on several factors: its maximum VCE voltage, maximum output current, size and maximum power dissipation. The external transistor is chosen to have a maximum collectoremitter voltage greater than the maximum input voltage (VIN,max = 12 V), and the maximum collector current greater than the maximum allowed current which will flow through the converter. The maximum allowed output current is defined as twice the nominal current to ensure that the converter operates in the continuous mode all the time (IOU T,max = 660 mA). Additionally, to achieve a higher efficiency, a transistor with the VCE voltage drop as low as possible is selected. Since the transistor is used in the Darlington configuration, the total voltage drop can be calculated as: VCE(sat) = VCE(sat),MC34063A + VBE,external , (1) where VCE(sat),MC34063A is the saturation voltage of Darlington-connected transistors integrated inside the MC34063A regulator, and VBE,external is the voltage drop across the external NPN transistor. To minimize VCE(sat) , a transistor with low VBE,external is chosen. The case of the transistor is chosen to ensure that the transistor is capable of withstanding the expected power dissipation. In the worst case scenario, the power dissipation of the external transistor can be calculated as: Pexternal = D · VCE(sat) · IOU T = 0.857 · 2 V · 0.33 A = 0.57 W, (2) where D = 0.857 is the maximum achievable duty cycle of the MC34063A [2], VCE(sat) is the sum of VBE,external (approximated to 0.7 V) and the maximum value of VCE(sat),MC34063A = 1.3 V [2], while the output current is IOU T = 0.33 A. 2) Diode: The most important characteristics of the diode are the blocking voltage, which has to be larger than the maximum input voltage (VIN,max = 12 V), and the forward current which has to be larger than the maximum allowed INPUT FILTER VIN C2 47 µF 10 µF L2 C8 C3 150 µF C4 10 µF 10 µF R1 0.51 Ω U1 VCT CT 1.1 nF VCC TC CII IPK DRC SWC SWITCHING NODE OUTPUT FILTER R2 Q1 SWE 33 Ω GND MC34063A 3.24 kΩ R3 VCE D1 10 µH 680 µH VD VOUT L1 16 kΩ R4 L3 C5 C6 10 µF R5 VOUT,filtered 150 µF C7 47 µF 9.76 kΩ Fig. 1: Schematic of the designed step-down switched-mode power converter. TABLE I: Bill of materials (BOM) for the designed step-down switched-mode power converter. Designator U1 Q1 D1 L1 L2, L3 R1 R2 R3 R4 R5 CT C2, C7 C3, C5 C4, C6, C8 Description MC34063A, regulator BJT, NPN, 30 V, 5.5 A Schottky, 20 V, 2 A Inductor, PWR, 680 µH, 1.3 A 10 µH, Isat = 1.7 A, 100 kHz Resistor, 1 W, 0.51 Ω, 5% Resistor, 33 Ω Resistor, 3.24 kΩ Resistor, 0.1%, 16 kΩ Resistor, 0.1%, 9.76 kΩ Cap, MLCC, 1100 pF, 50 V Cap, 47 µF, 35 V, ALU ELEC Cap, Alu Elec, 150 µF, 35 V Cap, MLCC, 10 µF, 25 V 3) Output inductor: The output stage of the buck converter consists of an inductor and a set of capacitors. The output stage stores and delivers energy to the load, and smooths out the switch node voltage to produce a constant output voltage. The current ripple is a direct function of the output inductor. The current ripple creates an output voltage ripple on the impedance of the output capacitors. The minimum value of the output inductor can be calculated as [2]: Case Style SOIC-8 SOT-223 SOD-123F 12.3 x 12.3 x 10 mm3 6.2 x 5.9 x 4.5 mm3 2512 0603 0603 0805 0805 0603 Radial, 6.3mm Radial, 6.3mm 0805 L1,min VIN,max − VCE(sat) − VOU T · ton,max Iripple,pp,max 12 − 2 − 3.3 · 0.857 · 25 · 10−6 = 0.66 = 217 µH, (3) = where Iripple,pp,max is the maximum allowed ripple current Iripple,pp,max = 0.66 A in the continuous mode, and ton,max is the worst case on-time at the switching frequency of 40 kHz. Since the objective is to design a converter with the ripple of the output voltage as low as possible, the inductor with higher value than the minimum calculated value is chosen (L1 = 680 µH). The selected inductor is packaged in a shielded case to minimize the coupling to other parts of the circuit [6]. 4) Output capacitors: The ripple current creates a voltage drop on the impedance of the output capacitance. To reduce the ripple of the output voltage and the conducted emissions, the ripple current has to be minimized (by selecting a large value of the output inductance, as discussed in the previous subsection), and the impedance of the output capacitance has to be reduced. The output voltage ripple is a function of the output capacitance and the equivalent series resistance (ESR) of the output capacitor. The output voltage ripple peak-to-peak output current (IOU T,max = 660 mA). Additionally, the forward voltage VD has to be as small as possible to minimize power dissipation. A Schottky diode is chosen because of its lower voltage drop. Additionally, the reverse recovery transients due to minority carrier injection and stored charge can be neglected for Schottky diodes up to several MHz [4]. The capacitance of the diode in the off-state and the inductance of the input decoupling network form a resonant circuit [5]. The resonance presents an additional source of EM interference from the switched-mode power converters. Additionally, the overshoots of the currents and voltages in the resonance can damage the devices, while the additional losses related to the resonance reduce the efficiency. The slew-rate control circuit is designed to limit the high-frequency spectrum of the switching waveforms, and to limit the excitation of this resonance. 2 value can be calculated as follows [7]: Vripple,pp = Iripple,pp + Iripple,pp · ESR. 8 · COU T · f becomes greater than 330 mV, the current limit circuitry provides an additional current path to charge the timing capacitor CT . This causes it to rapidly reach the upper oscillator threshold, thereby shortening the time of the output switch conduction and thus reducing the amount of energy stored in the inductor [3]. The value of R1 is calculated by: (4) To achieve low output voltage ripple, it is desirable to use capacitors with low ESR. In this project, two parallel connected capacitors are used. The first one is an aluminum electrolytic capacitor which provides high output capacitance (C5 = 150 µF), and the other one is a ceramic capacitor with low ESR (C6 = 10 µF). 5) Input capacitors: The objective, when selecting the input capacitors, is to reduce the ripple voltage amplitude seen at the input of the module. This reduces the ripple current to a level which can be handled by bulk capacitors. Ceramic capacitors placed at the input of the regulator reduce the ripple voltage. The ESR of aluminum electrolytic and most tantalum capacitors is too high to allow for effective ripple reduction. Large input ripple voltage can cause large ripple current to flow in the bulk capacitors, causing excessive power dissipation in the ESR parasitic [8]. In this project, two parallel connected capacitors are placed at the input. Low ESR ceramic capacitor (C4 = 10 µF) is placed in parallel with aluminum electrolytic bulk capacitor (C3 = 150 µF). These two capacitors are placed close to the regulator MC34063A. 6) Timing capacitor: The external timing capacitor CT defines the switching frequency. The relation used to select its value is [2]: CT = 4.0 · 10−5 [F/s] · ton , R1 = 330 mV/IOU T,max = 330 mV/660 mA = 0.5 Ω. (7) 9) Slew rate control: To control the transistor base current and voltage waveforms, the resistors R2 and R3 are placed to the base of the external transistor. Resistor R2 is placed in series between the base of the transistor and the MC34063A output pin 2. Their purpose is to limit the turn-on time of the external transistor. The resistor R3 is connected to the base of the transistor and to the ground. It is a pull-down resistor to define the turn-off time of the external transistor. The values of the resistors R2 = 33 Ω and R3 = 3.24 kΩ are optimized based on the SPICE simulations. 10) Compensation network: MC34063A is a hysteretic regulator meaning that it does not require a compensation network of the feedback loop [9]. 11) Filter design: Two low-pass LC filters are added to the board, one at the input and one at the output. The input and output filters are designed based on the guidelines given in [10]. The inductor is chosen to be Lf = L2 = L3 = 10 nH, while the capacitor is calculated by: 2 1 10|Att|dB /40 . (8) Cf = Lf 2πfs (5) where ton is the on-time of the converter. The actual value of the timing capacitor CT = 1.1 nF is adjusted based on the measurements of the designed converter to set the switching frequency to 40 kHz. 7) Feedback loop: Two resistors are required to form a voltage divider which is used to set the desired output voltage. One of the resistors is placed between the MC34063A pin number 5 and the output node, and the other one is placed between the same pin and the ground. The relation that links these two resistor values is [2]: R4 , (6) VOU T = 1.25 · 1 + R5 For the desired attenuation level of |Att|dB = 30, the value of Cf = 50 µF is obtained and the electrolytic capacitors C2 = C7 = 47 µF are chosen. B. SPICE Simulations The simulation domain consists of the model of MC34063A, external transistor, diode, and passive components. It is used to analyze the operation of the designed converter. 1) Design of slew-rate control circuit: The values of R2 and R3 are optimized to ensure that the turn-on and turn-off times of the transistor are low enough so that the high-frequency spectrum of the switching voltage is reduced (R2 = 33 Ω and R3 = 3.24 kΩ). 2) Analysis of the operation at low input voltages: The simulations are performed to analyze the operation of the designed converter when the input voltage is small. The analysis is performed as follows. The rate of charging the output inductor is proportional to the voltage on the inductor when the transistor is on: VIN − VCE(sat) − VOU T dIL1 = . (9) dt on L1 The discharging rate is proportional to the voltage on the output inductor when the transistor is off: dIL1 VOU T + VD =− . (10) dt of f L1 where VOU T is the output voltage, R4 is the resistor connected to output voltage node and R5 the resistor connected to ground. One of the values can be chosen arbitrarily and then the other one is calculated by (6). If the chosen value is too low, then a high current will flow through the resistors and power dissipation will be too large. On the other hand, if the value is too large, then the circuit is susceptible to noise. The selected value of R4 is 16 kΩ, while R5 is 9.76 kΩ. The tolerance of the selected resistors is 0.1% to ensure accurate voltage division. 8) Current limiting resistor: Current limiting is accomplished by monitoring the voltage drop across the external sense resistor R1 . The voltage drop developed across this resistor is monitored by the Ipk sense pin. When the voltage 3 0.4 5 3 0.2 1 −1 0 IL 0.5 −VD 1 Time, t [ms] VOU T,f iltered 1.5 Current, I [A] Voltage, V [V] 7 Ground plane Capacitor C8 0 2 Switching node (a) Feedback trace Voltage, V [V] 3.5 3.4 Vias 3.3 3.2 3.1 0 0.5 1 Time, t [ms] VOU T,f iltered VOU T 1.5 2 Fig. 3: Gerbers of the top layer of the designed converter. (b) Fig. 2: Simulated characteristic waveforms of the designed converter: (a) inductor current IL , output voltage VOU T and the switching voltage node VD , and (b) output voltage VOU T and filtered output voltage VOU T,f iltered . The switching node (the cathode of the diode) is rich in high-frequency noise components and is a strong source of noise in switched-mode power converters. To minimize the capacitive coupling between the switching node and the noise-sensitive traces, the switching copper area should be minimized [11]. To provide a short return path for the highfrequency currents, the capacitor C8 = 10 µF is placed close to the diode. Also, the switching node is placed far from the input, output and regulator to physically separate the noise source and other components. Special attention is given to the design of the feedback connection (comparator inverting input, CII). The feedback trace is short and it is placed far from the switching node. It is also well shielded by a large number of vias that connect the surrounding ground planes in the top layer and the solid ground plane in the bottom layer. In the case when the input voltage VIN is small (e.g. around 6 V), and since LOU T and VOU T are fixed, the time needed to charge the inductor is much larger than the time needed to discharge it. The increased charging time is a consequence of a large voltage drop on the Darlington-connected transistors, which reduces the voltage drop across the output inductor and increases its charging time significantly. Therefore, several cycles of conduction are needed to charge it, while only one cycle of non-conduction is needed to discharge it as shown in Fig. 2. The output voltage reduces significantly during the cycle of non-conduction and it is the dominant source of the voltage ripple of the designed converter for small input voltages. IV. C ONDUCTED E MISSIONS Conducted emissions are defined as the noise currents that are transferred through the AC power cord and placed on the common power net, where they may radiate more efficiently because of the wires in the installation walls which represent large antennas. That way they can cause interference with other devices. The frequency range of conducted emissions is from 150 kHz to 30 MHz. CISPR 22 class B conducted emission limits and given in Table II [12] and in Fig. 4 [12]. For consistent results, conducted EMI tests are performed using a passive device called a line impedance stabilization network (LISN). The LISN is inserted in series between the system power source and converter power inputs (in our case, LISN is inserted in series between the converter output and the load). The purpose of the capacitors C3 and C4 and the inductors L1 and L2 is to divert external noise and to prevent III. L AYOUT C ONSIDERATIONS The designed printed circuit board (PCB) is a 1.5-mm thick, 2-layer board on the FR-4 substrate. The thickness of the copper layer is 35 µm. The dimensions of the PCB are 46 mm x 71 mm. The top layer of the designed PCB is shown in Fig. 3. Proper layout design can greatly reduce the emissions. The return path of high-frequency currents should be as close as possible to the noise source to minimize the propagation of the noise across the board. The return paths are minimized by a solid ground plane in the bottom layer connected by a large number of vias to the ground planes in the top layer. Additionally, all the components are chosen in a small-size SMD packages to reduce their parasitic inductances. 4 TABLE II: CISPR 22 conducted emission limits for class B digital devices [12]. Frequency (MHz) 0.15 0.5 0.5 - 5 5 - 30 dB µV QP (AV) 66 (56) 56 (46) 56 (46) 60 (50) Measured with LISN 66 Voltage (dBµV) µV QP (AV) 1995 (631) 631 (199.5) 631 (199.5) 1000 (316) Fig. 6: Gerbers of the top layer of the designed LISN. 60 (QP) 56 TABLE III: Bill of materials (BOM) for LISN. 50 46 (AV) f 150 kHz 500 kHz 5 MHz 30 MHz Fig. 4: CISPR 22 conducted emission limits for class B digital devices [12]. Designator C1, C2 C3, C4 R1, R2 L1, L2 X1, X2 X3, X4 Description MLCC, 0.1 µF, 100 V, 5%, X7R MLCC, 1 µF, 100 V, 10%, X7S 1 kΩ 56 µH, Irms = 2.4 A, 10 MHz Terminal block SMA, end launch Case Style 1206 0805 0805 12.3 x 12.3 x 6 mm3 3.5 mm pitch SMA V. M EASUREMENTS The measurements of the efficiency, output voltage ripple and conducted emissions of the designed converter are shown in this section. that noise from flowing through the measurement device and contaminating the test data. The purpose of the capacitors C1 and C2 is to prevent any DC from overloading the input of the test receiver. The resistors R1 and R2 act as static charge paths to discharge the capacitors C1 and C2 in the event that the 50-Ω resistors are removed. One 50-Ω resistor is the input impedance of the test receiver (spectrum analyzer or EMI reciever), while the other one is a 50-Ω dummy load. The schematic of a LISN is shown in Fig. 5 [12]. A. Time-domain measurements The time-domain measurements are performed for the input voltages in the range from 6 to 12 V with the 1-V step. A 10-Ω resistor is connected to the output of the converter. The input current IIN , the input voltage VIN , the output voltage VOU T and the ripple of the output voltage VOU T,pp are measured. From the measurements, the input power, output power, loss and efficiency are calculated as: The LISN is designed on a separate PCB. The top layer is shown in Fig. 6. The bottom layer is a solid ground plane. The BOM for the LISN is given in Table III. LISN IP Phase L1 Product under test IN C1 IP Neutral L2 IN C3 C2 C4 R1 50 Ω R2 PIN = POU T = PLOSS = η = VIN · IIN 2 VOU T RLOAD PIN − POU T POU T . PIN (11) (12) (13) (14) The measured and calculated results are given in Table IV. The calculated efficiency is shown in Fig. 7, while the measured time-domain waveforms of the ripple of the output voltage for VIN = 6 V and for VIN = 12 V are shown in Fig. 8. The characteristic waveforms for VIN = 6 V and for To VIN = 12 V are shown in Fig. 9 and Fig. 11, respectively. ac power The characteristic waveforms at the turn-on and turn-off of the net external transistor for VIN = 6 V are shown in Fig. 10. 50 Ω B. Conducted emissions measurements Conducted emissions are measured in the frequency range R from 150 kHz to 30 MHz [13]. An R&S ESRP EMI Test Receiver is used for the measurements. The parameters of the receiver used in the measurements are set according to CISPR 16 [14] and are given in Table V. The conducted Green wire Fig. 5: The schematic of a line impedance stabilization network (LISN) [12]. 5 TABLE IV: Time-domain measurements as a function of the input voltage. VIN [V] (meas) 6 7 8 9 10 11 12 IIN [A] (meas) 0.28 0.24 0.20 0.18 0.16 0.14 0.13 VOU T [V] (meas) 3.263 3.278 3.279 3.282 3.281 3.291 3.286 RLOAD [Ω] (nominal) 10 10 10 10 10 10 10 PIN [W] (calc) 1.680 1.680 1.600 1.620 1.600 1.540 1.560 POU T [W] (calc) 1.065 1.075 1.075 1.077 1.077 1.083 1.080 72 8 68 66 64 VOU T,f iltered VOU T,pp [mV] (meas) 41.5 19.8 16.4 19.2 24.0 8.0 33.6 VIN −VD VCT 4 2 0 7 8 9 10 Input voltage, VIN [V] 11 −2 0 12 Fig. 7: Measured efficiency as a function of the input voltage. 0.1 0.2 0.3 Time, t [ms] 0.4 0.5 Fig. 9: Characteristic waveforms measured at VIN = 6 V. 3.32 8 3.3 6 Voltage, V [V] Output voltage ripple, Vripple [V] Efficiency, η [%] (calc) 63.38 63.96 67.20 66.49 67.28 70.33 69.22 6 Voltage, V [V] Efficiency, η[%] 70 62 6 PLOSS [W] (calc) 0.615 0.605 0.525 0.543 0.523 0.457 0.480 3.28 3.26 3.24 3.22 0 VIN = 6 V, Vpp = 41.5 mV VIN = 12 V, Vpp = 33.6 mV 0.5 1 4 2 0 1.5 −2 0 Time, t [ms] Fig. 8: Output voltage ripple measured at VIN = 6 V and VIN = 12 V. VOU T,f iltered 1 2 3 4 Time, t [µs] VIN 5 −VD 6 VCT 7 Fig. 10: Characteristic waveforms measured at VIN = 6 V, zoomed to capture the turn-on and turn-off waveforms of the external transistor. Weakly-excited resonance [5] can be seen at the moment when the transistor turns on. emissions are measured at the output of the converter. LISN is connected between the output of the converter and the 10-Ω load resistor. The measurements performed using a peak detector are well below the specified limits [13]. The measurement setup is shown in Fig. 14, while the designed converter during measurements is shown in Fig. 15. The metallic enclosure covers the converter during the measurements of the conducted emissions. Fig. 12 shows measured conducted emissions. Additional measurements in the frequency range from 9 kHz to 500 kHz are performed to capture the switching frequency and the higher harmonics in more detail and they are shown in Fig. 13. VOU T,f iltered Voltage, V [V] 12 VIN −VD VC T 8 4 0 0 0.1 0.2 0.3 Time, t [ms] 0.4 0.5 Fig. 11: Characteristic waveforms measured at VIN = 12 V. 6 TABLE V: Parameters of the EMI Receiver according to CISPR 16 [14] used in the measurements. Frequency Range 9 kHz - 150 kHz 150 kHz - 30 MHz Resolution Bandwidth (RBW) CISPR - 200 Hz CISPR - 9 kHz Video Bandwith (VBW) 200 Hz 200 Hz Detector auto peak (max hold) auto peak (max hold) Sweep points 1000 1000 Conducted EMI, [dBµV] Metallic enclosure DC source Measured Conducted EMI CISPR 22, Class B, Quasi-Peak Detector CISPR 22, Class B, Average Detector 80 60 40 20 0 150 1000 Frequency, f [kHz] 10000 30000 Conducted EMI, [dBµV] Fig. 12: Conducted emissions in the frequency range from 150 kHz to 30 MHz (according to the CISPR 22 Class B [13]) measured at the output of the designed converter. The input voltage is set to VIN = 6 V. 80 Designed converter Oscilloscope EMI receiver Fig. 14: Measuring conducted emissions of the designed converter. Measured Conducted EMI CISPR 22, Class B, Quasi-Peak Detector CISPR 22, Class B, Average Detector 60 Load (10 Ω) 40 20 0 9 43 86 129172 Frequency, f [kHz] To EMI reveiver 500 LISN 50-Ω termination Designed converter Fig. 13: Conducted emissions in the frequency range from 9 kHz to 500 kHz measured at the output of the designed converter. The input voltage is set to VIN = 6 V. The spectrum shows the switching frequency of 43 kHz and higher harmonics. Fig. 15: Measuring conducted emissions - close-up of the designed converter. 7 VI. C ONCLUSION [13] IEC CISPR22, “Information Technology Equipment - Radio Disturbance Characteristics - Limits and methods of measurement,” 2006. A step-down switched-mode power converter is designed, analyzed and characterized. The design is based on the regulator MC34063A. The selection of the components and the design of the PCB layout are discussed. The operation of the converter is analyzed by SPICE simulations. The ripple of the output voltage for small values of the input voltage is a consequence of a large difference between the charging time and the discharging time of the output inductor. The difference is a consequence of a large voltage drop on the Darlington-connected transistors, which reduces the voltage drop across the output inductor and increases its charging time significantly. This is the dominant source of the ripple of the output voltage of the designed converter for small input voltages around 6 V. The ripple of the output voltage measured at the input voltage of 6 V is 41.5 mV. The conducted emissions are measured by a LISN designed on a separate PCB. The measured conducted emissions at the input voltage of 6 V and using a peak detector are well below the limits given by the regulations. The 4th harmonic at 172 kHz is less than 20 dBµV. [14] IEC CISPR16, “Specification for radio disturbance and immunity measuring apparatus and methods,” 2004. Mislav Mikic was born in Slavonski Brod, Croatia, in 1991. He received the Mag.-Ing. degree in electrical engineering from the University of Zagreb, Zagreb, Croatia, in 2015. Currently, he is an embedded software engineer at the IEL d.o.o Zagreb. His work include programming microntrollers. The topic of his Master’s thesis was design of switching DC-DC converters with respect to electromagnetic compatibility. Rebecca Grancaric was born in Zadar, Croatia, in 1993. She received the Bacc.Ing. degree in electrical engineering from the University of Zagreb, Zagreb, Croatia, in 2015. Currently, she is a first year graduate student at the University of Zagreb. The topic of her undergraduate thesis was characterization of step-down switched-mode power converter focusing on electromagnetic compatibility. R EFERENCES [1] D. M. Robert W. Erickson, Fundamentals of Power Electronics. Kluwer Academic Publishers, New York, Boston, Dordrecht, London, Moscow, 2004. [2] MC34063A, MC33063A, SC34063A, SC33063A, NCV33063A - 1.5 A, Step-Up/Down/Inverting Switching Regulators, ON Semiconductor, 2010. [3] J. Alberkrack, AN920/D - Theory and Applications of the MC34063 and µA78S40 Switching Regulator Control Circuit, ON Semiconductor, 2002. [4] ON Semiconductor, 1N5817/D - Axial Lead Rectifiers, ON Semiconductor, 2006. [5] A. Bhargava, D. Pommerenke, K. Kam, F. Centola, and C. W. Lam, “DCDC Buck Converter EMI Reduction Using PCB Layout Modification,” IEEE Trans. Electromagn. Compat., vol. 53, no. 3, pp. 806–813, Aug. 2011. [6] Texas Instruments, AN-2155 Layout Tips for EMI Reduction in DC / DC Converters, Texas Instruments, 2013. [7] ——, SLVA630A Output Ripple Voltage for Buck Switching Regulator, Texas Instruments, 2015. [8] J. Arrigo, Input and Output Capacitor Selection, Texas Instruments, 2006. [9] S. Maniktala, Technical Note TN-203, Microsemi, 2012. [10] A. Martin, AN-2162 Simple Success With Conducted EMI from DC-DC Converters, Texas Instruments, 2013. [11] H. J. Zhang, Application Note 136 - PCB Layout Considerations for Non-Isolated Switching Power Suplies, Linear Technology, 2012. [12] C. R. Paul, Introduction to Electromagnetic Compatibility. John Wilwy & Sons, Inc., Hoboken, New Yesey, 2006. Raul Blecic was born in Rijeka, Croatia, in 1986. He received the Dipl.-Ing. degree in electrical engineering from the University of Zagreb, Zagreb, Croatia, in 2009. Currently, he is a double degree PhD student at the University of Zagreb and KU Leuven, Belgium. His research interests include electromagnetic compatibility of integrated circuits, integrated circuit design and modelling of microwave structures and components. Adrijan Baric received the Dipl.-Ing. and M.Sc. degrees in electrical engineering from the University of Zagreb, Zagreb, Croatia, in 1982 and 1985, respectively, and the Ph.D. degree in electronics from the Dublin City University, Dublin, Ireland, in 1995. Since 1984, he has been with the University of Zagreb, where he is currently a Professor. His research interests include semiconductor device modeling, integrated circuit design, interconnect modeling and electromagnetic compatibility. 8