Paper - Nanyang Technological University

advertisement

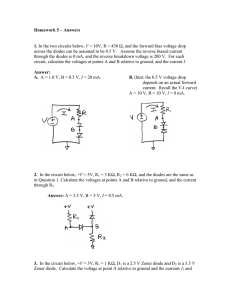

A 76% Efficiency Boost Converter with 220mV Self-Startup and 2nW Quiescent Power for High Resistance Thermo-Electric Energy Harvesting 1 Abhik Das1, 2, Yuan Gao2, Tony Tae-Hyoung Kim1 Nanyang Technological University, Singapore, 2Institute of Microelectronics, Singapore Abhik2@e.ntu.edu.sg Abstract— With the emergence of thin-film thermo-electric generators (TEG), power density and sustainability of energy harvesting sources have improved. These novel power sources however exhibit high internal electrical resistances. Conventional state-of-the-art boost converters encounter low efficiency and potential startup failures when harvesting energy from such sources. This paper presents a highly efficient boost converter for thermo-electric energy harvesting systems based on a novel Power-on-Reset (PoR) driven startup circuit. It utilizes the feedback between TEG, the boost converter, and the PoR circuit, converting a reset signal edge into a train of pulses. The proposed startup circuit is automatically disabled once startup operation is completed, and consumes the quiescent power of 2nW in steadystate. The proposed boost converter has a self-startup TEG voltage of 220mV and a peak power conversion efficiency of 76% with a minimum input for operation being 85mV. startup circuits report completely electrical startup techniques to harvest from limited DC power sources [4-10]. However, TEG such as TGP-751 possesses high internal electrical resistance (ESR) between 240 - 350Ω. Higher ESR limits the current and power available from the power source due to the higher voltage drops across it. The limited available power and voltage makes battery-less self-startup even more difficult, affecting the operations of the previously reported circuits [3-10]. In this paper, we propose a PoR-based startup circuit with self-control of the duration and frequency of the PoR pulses during startup. The pulses are initiated due to the I. INTRODUCTION Thermal energy is one of the most ubiquitous sources, desirable for implantable and wearable devices. Various renewable energy harvesters powered from light, vibration, thermal, or bio-fuel sources are available depending on system power dissipation, physical size, and reliability [1-2]. Such energy sources replace batteries, provide long-lasting operation for sub-mW applications, and eliminate the difficulty in recharging and replacing it. Thermo-electric generators (TEG) can manifest as temperature difference (∆T) under any environmental conditions, making it more desirable. Improved TEG elements such as MPG-D751 which uses compounds of Bi, Sb, Te and Se, achieve smaller device area with increased power density (100W/mm2), compared to conventional bulk-material-based TEGs (2W/mm2) at ∆T of less than 10 °C, which enables system miniaturization. Electrically, a TEG can be modelled as an ideal voltage source in series with internal resistance (ESR). The physical dimensions of a TEG and the temperature difference between human body and ambient are limited. Therefore, battery-less startup from low voltages and power is challenging. One of the major factors limiting the electrical startup is the threshold voltage of MOSFETs. Advanced CMOS technology can overcome this limitation at the cost of higher leakage power. As an alternative solution, a startup circuit with the startup voltage of 35 mV is reported [3]. However, it uses a MEMS switch to aid the turn-on action at ultra-low voltage. In addition, the efficiency can vary due to the uncertainty of the MEMS switch after startup. Several other battery-less self- 978-1-4673-7472-9/15/$31.00 ©2015 IEEE Fig. 1. Proposed harvester system architecture. Fig. 2. Timing waveforms of operating sequences. 237 VIN VOUT L1 VOUT L1 VTEG VIN P4 VD>VST(INV1) L1 M1 P1 CLK1 Z C1 Node charging (HIGH=VIN) ST=Switching Threshold Node discharging (LOW=0) (a) r I2 VIN VD<VST(INV1) L1 M1 CLK1 Z M2 (a) N1 C1 220 mV CLK1 (b) 0V 220 mV PoR CPOUT CLK1 CP 0V CLK1' Y VIN BC C PoR P4 X INV1 L1 CLK1 D Y X Fig. 3. (a) Auxiliary Booster, (b) Main Booster. M1 N4 D Y X Fig. 5. PoR circuit operation: (a) CLK1 'HIGH' phase, (b) CLK1 'LOW' phase. LOAD CLK2 COUT M1 LOAD COU T CLK1 I1 (b) M3 VIN r BCC The proposed energy harvesting system is illustrated in Fig. 1. It consists of four main blocks; namely, Boost Converter Core (BCC), Starter, Pulse Generator for Steady-state (PGS) and Decision Switch (DS). DS and PGS form the Control Unit for steady-state operation. The Starter consists of Power-on-Reset (PoR) and Charge Pump (CP). BCC has two sub-blocks, Auxiliary Booster (AB) and Main Booster (MB). The AB block is comprised of a NMOS (M1), a diode-connected PMOS (M3), an inductor (L1) and a capacitor (COUT). Although conventional PoR does not produce oscillating waveforms, the proposed PoR block automatically generates a chain of pulses based on feedback action and the available finite ESR of TEG at the falling edge before resetting completely. The PoR-generated CLK1 drives CP and M1. The peak amplitude of CLK1 at low voltages is lesser than M1’s threshold voltage. CLK1 is therefore used to boost VIN to a higher voltage CPOUT (Fig. 2) using CP, which powers PGS and MB (M2 replaces M1 to form MB) in CP mode to boost VOUT (when VOUT<0.45V). The schematics of AB and MB are depicted in Fig. 3 (a) and 3 (b), respectively. If the CP mode still persists after CLK1 settling at 0V, VOUT will be eventually discharged. To avoid this, once VOUT is charged to a preset voltage of 0.45 V, DS will switch the power supply of PGS from CPOUT to VOUT for normal operation (VOUT mode). PoR is a reset circuit that is incorporated to detect power applied to a chip and generate a reset impulse response for the chip. The proposed PoR (Fig. 4) is designed to improvise the ideal characteristics observed in PoR discussed in [10]. At the beginning of startup, all the nodes inside the PoR circuit are at 0 V. VIN charges the on-chip capacitor C1 through the VTEG PROPOSED HARVESTER ARCHITECTURE AND OPERATIONS II. transistors P4 and N4. Before the node D is charged beyond the switching threshold of INV1 (ST_INV), Y follows VDD and the node X remains LOW. M1’s gate driven by CLK1 has the same polarity as Y and follows VDD. With the rise of VDD, M1 is turned on weakly and the conduction current I1 (Fig. 5(a)) charges L1. When D is rises beyond ST_INV, Y starts falling and M1 is turned off. The decrease of conduction current (I2 in Fig. 5(b)) leads to smaller voltage drop across r. This increases the VIN level, which increases the ST of the inverters in PoR. If the voltage level at D (VD) is still lower than the instantaneous ST_INV, CLK1 becomes HIGH again. Therefore, the action of Y propagating to CLK1, which varies the voltage drop across r, results in an oscillating nature of CLK1 (Fig. 6), and continues until VD becomes greater than ST_INV1 during the off-state of M1. This disables Starter and M1 that minimizes the quiescent power in both. The frequency of CLK1 is proportional to VIN and the size of N1, and inversely proportional to r. The pulse duration and the number of pulses increase with VIN and r. While they decrease with BCC difference in the voltage drops across the ESR at different circuit conditions. The proposed startup circuit is automatically disabled after startup to minimize the power and leakage. P3 Z N3 P2 X N2 P1 C1 Ch arging N4 D D Y N1 Ideal PoR C1 Idea l PoR Beh avio r t=0 220 mV 0V Fig. 6. Waveforms showing variations of PoR internal nodes Fig. 4. Circuit Schematic of Proposed PoR 238 III. MEASUREMENT RESULTS N, C1 affects only the start-time. During phase (a), M1 is weakly conductive operating in the sub-threshold region where Vx drops to enable the conduction current (I1) during this short interval. Because of the inductor's nature to resist a change across it, Vx will rise again. At this point, as explained in phase (b), M1 reaches sub-threshold saturation condition, and the current through L stops rising and decreases with a small slope (VCLK >4UT). When CLK1 becomes '0', the current though M1 is cut-off, forcing Vx to shoot sharply and turn M3 on, during which L discharges all its charges to COUT. UT is the thermal voltage. Dickson's CP and the measured CPOUT waveform are shown in Fig. 7 and Fig. 8, respectively. Note that CPOUT will eventually decay if no switching from the CP mode to the VOUT mode occurs during steady-state due to the absence of pulses in CLK1. Therefore, the system switches its control from the CP mode to the VOUT mode during this instant. Selection between the CP mode and the VOUT mode is made by DS (Fig. 9). DS comprises a multiplexer (MUX) and a detector (DET). When the DET output (X) is at 0 (until VOUT<450mV), MUX selects the CP mode. When VOUT>450mV, the VOUT mode is selected by MUX. After this, X1 follows VOUT. PGS consists of a controlled ring oscillator (Fig. 10) followed by a frequency divider and a gate buffer for driving M2 with the clock CLK2 in steady-state (VOUT mode). The proposed harvester system is implemented in a 65-nm CMOS process. The harvester module contains TE-CORE7 [11] which contains the standalone Thermo-Generator Package, TGP-751. For simplified measurements, a controlled power supply with a series resistor (r) is used to emulate the target TEG. For characterization and measurements of MPGD751 with the designed circuit, the power management circuit inside the module was disconnected from MPG-D751. MPGD751 exhibits an electrical resistance of between 240 - 350Ω. The characteristics of Micropelt’s TEG (MPG-D751) is shown in Fig. 11. Characterization and measurements of the proposed harvester with TEG has been executed after disabling the module's boost converter. Fig. 11. TEG V-I Characteristics. CPOUT VIN CLK1 MUX CLK1' VOUT CPOUT 0/1 X1 (a) DET CP PGS DS Fig. 7. CP Schematic VOUT CLK1 CPOUT DET Core VOUT 220mV VIN 500mV Discharged Startup time 10.5ms X VTEG 220mV 220mV DET Fig. 9. DS Schematic Fig. 8. CPOUT waveform (b) Steady-state VOUT Ring Osc. Core CLK1 VDD VDD D-F/F Vgs CLK2 VDD 1.3V IN Q Q’ CLK1 reset Self- generated Pulse-train VTEG OUT Buffer Vgs (a) Fig. 12. Measured Start-up transient at VTEG=220mV; r= 350Ω. (b) Fig. 10 (a). Ring Oscillator schematic for steady-state, (b) Frequency Divider 239 The startup operation at VTEG of 220 mV and r = 350Ω is demonstrated in Fig. 12 (a). The exploded view of CLK1 pulses is highlighted in Fig. 12 (b). The resetting of CLK1 and accordingly the Starter enhances the voltage gain further. The PoR pulses reset after a finite period and VOUT settles at 1.3 V. As shown in Fig. 13, at r = 70Ω, the minimum startup voltage of 170 mV was obtained. At lower values of r (070Ω), the startup voltage is inversely proportional to r. At higher values of r (70 - 450Ω), however, the higher voltage drop reduces the available VIN. After startup operation is completed, it can harvest energy from the minimum voltage of 85 mV boosting VOUT to 550 mV. VOUT settles where the power loss in HS is equal the harvested power. The peak efficiency at r = 350Ω is 76% at the input of 180 mV as shown in Fig. 14. The quiescent power of Starter and M1 together is 4nW, is 0.4% of the input power at 90 mV. The quiescent power and the efficiency are measured at VTEG of 220 mV and the input resistance of 350Ω after the circuit has acquired steady-state. At VIN > 550 mV, the increased leakage in M1 and Starter degrades the quiescent power. TABLE I compares this work with other state-of-the-art works. The test chip micrograph with area 0.146µm2 is shown in Fig. 15. Table I: Comparison chart with state-of-the-art work QP (%) Min. VTEG (mV) 150 (240-350)Ω TEG’s range of r 0 100 200 r (Ω) 300 3 2 20 0 QP (%) Efficiency (%) 4 40 1 0 100 200 300 VTEG (mV) 400 3.97 -- Min. VIN (mV) -- -- 30 -- 85 40 330 50 380 220 (170)* Peak Eff. (%) 61# 80 73 81† 76†† Process (nm) 130 -- 65 130 65 Start-up mech. Trfr. Typical r (Ω) 5 1 2 PoR L.T CP -- 6.2 -- 3 PoR Up to 450††† CONCLUSION P. Glynne-Jones, and N. M. White (2001). Self-powered systems: A review of energy sources. Sensor Review, 21, 91-97. [2] R. J. M. Vullers et. al., "Energy Harvesting for Auto nomous Wireless Sensor Networks", IEEE SOLID-STATE CIRCUITS MAGAZINE, PP. 29-38, Spring 2010. [3] Y. K. Ramadass and A. P. Chandrakasan, “A Batteryless Thermoelectric Energy-Harvesting Interface Circuit with 35mV Startup Voltage,” IEEE ISSCC Dig. Tech. Papers, pp. 486-487, Feb 2010. [4] P. Chen et al., “A 95-mV Startup Step-Up converter with VTH-Tuned Oscillator by Fixed-Charge Programming and Capacitor Pass-On Scheme,” IEEE ISSCC Dig. Tech. Papers, pp. 216-217, Feb. 2011. [5] H-Y. Tang et. al., "A Fully Electrical Startup Battery-less Boost Converter withz 50mV Input Voltage for Thermoelectric Energy Harvesting,” Symp. on VLSI Circuits, pp. 196-197, June 2012. [6] J-P. Im et al., "A 40mV Transformer-Reuse Self-Startup Boost Converter with MPPT Control for Thermoelectric Energy Harvesting," IEEE ISSCC Dig. Tech. Papers, pp. 104-106, Feb. 2012. [7] K. Kadirvel, et al., “A 330nA Energy-harvesting Charger with battery Management for Solar and Thermoelectric Energy Harvesting,” IEEE ISSCC, pp. 106-107, Feb. 2012. [8] A. Shrivastava, et al, "A 1.2µW SIMO Energy Harvesting and Power Management Unit with Constant Peak Inductor Current Control Achieving 83-92% Efficiency Across Wide Input and Output Voltages” Symp. on VLSI Circuits, pp. 1-2, June 2014. [9] S. Bandopadhyay, et. Al., “A 1.1 nW Energy-Harvesting System with 544 pW Quiescent Power for Next-Generation Implants,” IEEE J. Solid State Circuits, vol. 49, no. 12, pp. 2812-2824. Dec. 2014. [10] C. Carvalho and N. Paulino, “Start-up circuit for low-power indoor light energy harvesting applications,” E.L., May 2013, vol. 49, no. 10. [11] Micropelt GmbH, TE-CORE7, Preliminary Datasheet. 5 Peak Efficiency= 75.9 % -- Start-up volt. (mV) [1] Fig. 13. Measured Start-up Voltages with r. 60 -- This Work 0.4 (4nW)** REFERENCES 400 80 [8] IV. 190 170 [5] A highly efficient boost converter using a Power-on-Reset based Starter is presented. By utilizing the differences in voltage drop across the electrical series resistance of TEG for different circuit conditions, the PoR can generate pulses at ultra-low voltage and power. Since the resistance itself is the key to the oscillating nature of the proposed PoR, it can achieve the self-startup operation with high internal resistance up to 450Ω. The PoR-based Starter implements three functions such as providing pulses, disabling Starter after a finite time period, and assisting CP to step-up its output voltage. Startup voltage of 170mV obtained @r=70Ω 210 [7] **@85mV, Quiescent power in Starter (2nW) + M1 (2nW) =4nW; *170mV startup @r=70Ω; #@300mV; ††@180mV input; 1Transformer; 2 LC Tank Oscillator; 3CP+Boost; †@0.4V for boost converter; †††Circuit can operate @r>450Ω with reduced efficiency 250 230 [6] 0 500 Fig. 14. Measured Efficiency and QP with VTEG. Fig. 15. Test chip micrograph. 240