- Atlas Copco

advertisement

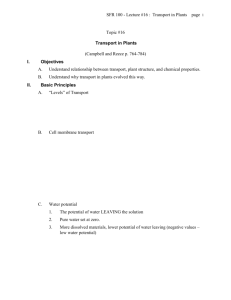

Atlas Copco Railway Air Systems Oil-free Scroll Compressor SFR 2-14 7 2 6 4 5 1 3 8 1 Optimized cooling fan to obtain a fully balanced compressor for smooth running 5 Heavy duty air intake filter for efficient operation in dusty environments 2 Railway approved IP55 AC or DC motor with start and operating capabilities between -40°C and +50 ºC 6 Direct drive concept for lean dimensions, low weight, short service time and high reliability 3 Integrated vibration dampers for minimum transfer of vibrations to and from the compressor 7 High efficiency, totally enclosed fan-cooled (TEFC), IP 55, class F electric railway motor for continuous trouble-free operation with greased for life bearings 4 Top quality oil-free scroll elements with patented superflow for high performance and extended lifetime even in the worst ambient conditions 8 The Full Feature version includes an integrated filter and membrane dryer which removes condensate water and vapor from the compressed air to protect your piping network and brake system from freezing, corrosion and staining Features and Benefits Space-Saving Design Minimized space requirements with single side access for maintenance and installation �Optional air dryer, filters and control cubicle can all be integrated in a very compact compressor package � Enduring Performance The compressor is designed, built and tested to meet the toughest conditions in railway applications (extreme climatic conditions, high humidity and vibrations) �Built in accordance with relevant international standards for railway applications �Proven technology used in many applications worldwide � AC_Railway_sfr_datasheet_2014_0903.indd 1 Oil-Free Compressor Environmentally friendly oil-free scroll �Less maintenance � Reliability & Durability Minimum amount of moving parts Corrosive resistant materials �Long service interval �Direct drive concept � � Easy Installation Plug and play system �Easy to access main connections � Low Noise System without Pulsations Very low noise level without any need of a noise canopy No pulsations from reciprocating masses, neither into your piping system nor to the car body: only a smooth constant air flow sound from this continuous-flow unit � � Full Feature Version and Still Low Weight A complete packaged unit including filter and membrane dryer to achieve an outlet air quality up to 1.2.0 according to ISO 8573-1 �Full feature oil-free unit and still a low total weight � Power and Control Quick Connectors For fail-proof quick connection of power and control lines � 03/09/14 15:58 Manifold For easy installation of all required safety and measuring devices on a single manifold Full-Feature version A completely packaged unit including an aftercooler, filter and membrane dryer to achieve an outlet air quality up to 1.2.0 according ISO 8573-1 Control cubicle To be able to control the unit as stand-alone unit without expensive system integration Different drives Alternative drives like pulley or DC available on request Control voltage connector To easily connect the control voltage lines Motor voltage connector To easily connect the power voltage lines Different approvals CE, ASME, SQL Control pressure switch To regulate the compressor according to air demand by measuring the pressure in the system dP-switch inlet filter For remote signaling in case the inlet filter is clogged Customized frame To easily integrate the complete package into the available space envelop in, under or on top of the railway vehicle Technical Specifications Compressor type Capacity Shaft power Maximum pressure Sound pressure level l/s l/min cfm kW hp bar(e) psig dB(A) 50 Hz version SFR 2-50 SFR 4-50 SFR 5-50 SFR 7-50 SFR 12-50 3.4 5.5 7.9 10.5 25.0 205 330 475 630 1500 7.2 11.7 16.7 22.2 53.0 2.2 3.7 5.5 6.5 12.0 3.0 5.0 7.5 8.8 16.3 10 10 10 10 10 145 145 145 145 145 57 58 62 66 69 60 Hz version SFR 2-60 SFR 4-60 SFR 7-60 3.4 5.5 13.6 205 330 815 7.2 11.7 28.8 2.2 3.7 7.5 3.0 5.0 10.0 10 10 10 145 145 145 57 58 67 Inverter version SFR 7i SFR 10i SFR 11i SFR 14i 14.2 20.8 23.3 28.3 850 1250 1400 1700 30.0 44.1 49.4 60.0 8.0 10.0 11.0 14.0 10.9 13.5 15.0 19.0 10 10 10 10 145 145 145 145 66 69 70 71 Unit performance measured at a standard unit (before dryer) according to ISO1217 Ed. 03, Annex C-1996 Reference conditions: Absolute inlet pressure 1 bar (14.5 psig) Intake air temperature 20°C (68°F) Mean noise level measured according to ISO 2151/Pneurop/Cagi PN8NTC2 at 4.6 meter free field 2935 0979 41 – Printed in Belgium – Subject to alteration without prior notice. Never use compressed air as breathing air without prior purification in accordance with local legislation and standards. Options www.atlascopco.com AC_Railway_sfr_datasheet_2014_0903.indd 2 03/09/14 15:58