Exergy Analysis of Solar Power Tower Plants

advertisement

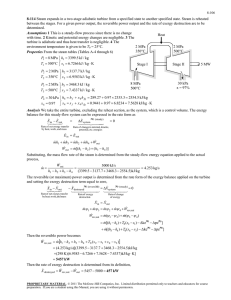

IJISET - International Journal of Innovative Science, Engineering & Technology, Vol. 2 Issue 12, December 2015. www.ijiset.com ISSN 2348 – 7968 Exergy Analysis of Solar Power Tower Plants Satyendra Chaturvedi1 Satyaveer Singh1, Rachiit Garga1 P P P P P Department of Mechanical Engineering IIMT group of institution, Greater Noida Email: sattu8888@gmail.com , satyaveers392@gmail.com , 32TU U32T 32TU U32T Abstract: Establishing the renewable electricity contribution from solar thermal power systems based on energy analysis alone cannot legitimately be complete unless the exergy concept becomes a part of that analysis. This paper presents a theoretical framework for the energy analysis and exergy analysis of the solar power tower system using molten salt as the heat transfer fluid. Both the energy losses and exergy losses in each component and in the overall system are evaluated to identify the causes and locations of the thermodynamic imperfection. Several design parameters including the direct normal irradiation (DNI), the concentration ratio, and the type of power cycle are also tested to evaluate their effects on the energy and exergy performance. The results show that the maximum exergy loss occurs in the receiver system, followed by the heliostat field system, although main energy loss occurs in the power cycle system. The energy and exergy efficiencies of the receiver and the overall system can be increased by increasing the DNI and the concentration ratio, but that increment in the efficiencies varies with the values of DNI and the concentration ratio. It is also found that the overall energy and exergy efficiencies of the solar tower system can be increased to some extent by integrating advanced power cycles including reheat Rankine cycles and supercritical Rankine cycles. Introduction and Methodology Molten-nitrate salt was the working fluid in the solar receiver. This distinguishes it from other power tower technologies. Liquid salt at 550°F (288°C) is pumped from a ‘cold’ storage tank through the receiver, where it is heated to 1050°F (565°C), and then on to a ‘hot’ tank for storage. When power is needed from the plant, hot salt is pumped to a steam generating system that produces superheated steam for the turbine/ generator. From the steam generator, the salt is returned to the cold tank where it is stored and eventually reheated in the receiver. Figure is a schematic diagram of the primary flow paths. Determining the optimum storage size to meet power-dispatch requirements is an important part of the system design process. ( Molten Salt Power tower System) The heliostat field that surrounds the tower is laid out to optimize the annual performance of the plant. 571 IJISET - International Journal of Innovative Science, Engineering & Technology, Vol. 2 Issue 12, December 2015. www.ijiset.com ISSN 2348 – 7968 The field and the receiver are also sized depending on the needs of the utility. In a typical installation, solar energy collection occurs at a rate that exceeds the maximum heat rate required to provide steam to the turbine. Consequently, the thermal storage system can be charged at the same time that the plant is producing Power at full capacity. With a solar multiple of ~3, a molten-salt plant located in a high-insolation region can be designed for an annual capacity factor of ~70%. Consequently, power towers could potentially operate at full power for 70% of the year without the need for a back-up fuel source. By varying the size of the solar field, solar receiver, and size of the thermal storage, plants can be designed with annual capacity factors ranging between 20 to 70% . (The Solar Tower Plant in Operation) Schematic diagram of a solar tower power plant and t-s diagram Dig 1 Test procedure 572 IJISET - International Journal of Innovative Science, Engineering & Technology, Vol. 2 Issue 12, December 2015. www.ijiset.com ISSN 2348 – 7968 The exergy 𝜑𝜑̇ associated with solar irradiation on the heliostat mirror surface 𝑄̇ can be expressed as 𝜑𝜑̇ = 𝑄̇ (1𝑇𝑜 )…………………………………………………….. (1) 𝑇∗ 𝜑𝜑̇ Exergy associated with the solar irradiation on the heliostat mirror surface 𝑄̇ Energy associated with the solar irradiation on the heliostat mirror surface 𝑻𝑻o Ambient Temperature 𝑻𝑻 * Apparent sun temp. as an exergy source and taken to be 4500 K R R Useful exergy absorbed by the flowing molten salt is 𝜑𝜑𝑟𝑟𝑒𝑒c,ab𝑠𝑠 = 𝑚𝑚𝑚𝑚𝑠𝑠 ( (ℎ𝑏𝑏 − ℎ𝑎𝑎 ) − 𝑇𝑇0( 𝑠𝑠𝑏𝑏 – 𝑠𝑠𝑎𝑎) )……………………………………….(2) 𝜑𝜑𝑟𝑟𝑒𝑒c,ab𝑠𝑠 = 𝑚𝑚𝑚𝑚𝑠𝑠 𝑐𝑐𝑝𝑝𝑚𝑚𝑠𝑠 (( 𝑇𝑇𝑏𝑏 – 𝑇𝑇𝑎𝑎) − Tb 𝑇𝑇0𝑙𝑙𝑛𝑛 ))……………………………………….(3) Ta Result and discussion Properties of state points in power cycle Table 1. State point Temperature in ͦC Pressure in kPa 1 45.8 10 2s 45.9 3150 2 46.0 3150 3 236.6 3150 4s 238.7 12,600 4 239.0 12,600 5 552.0 12,600 573 IJISET - International Journal of Innovative Science, Engineering & Technology, Vol. 2 Issue 12, December 2015. www.ijiset.com ISSN 2348 – 7968 6s 327.4 3150 6 353.5 3150 7s 45.8 10 7 45.8 10 8 - - 9 - - Exergy analysis of the base case solar tower system Table 2. Subsystem Received(kw) Delivered(kw) Heliostat field 7478.8 5609.1 Centralreceiver 5609.1 3111.7 SGSS 3111.7 2793.5 Power cycle 2793.5 2080.6 Over all 7478.8 1830.9 Loss(kw) 1869.7 2497.4 318.2 712.9 5647.9 Efficiency(%) 75.00 55.48 89.77 74.48 24.48 From the preceding section, it is known the present analysis is based on the energy balance and exergy balance of each subsystem. The analysis for the SGSS heat exchangers and the Rankine power cycle depends only on the thermodynamics properties of molten salt and steam at each state as shown in fig. 1, which is well developed and self-evident. The analysis for the central receiver is based on a thermal model, which is modified from a validated model developed by Li et al. to validate the modification; the present model was used to calculate the thermal performance of the sandia National Laboratories molten salt electric experiment based on the parameters provided. The calculate energy efficiency of the receiver is 87.77%, which agrees well with the predicted value of 87.73% from Li`s work, and the experimental average efficiency of 87.5% from Bergan’s experiments. Therefore the calculated results of the paper are reasonable, which are useful for guiding the design and operation of solar power tower plants. 574 IJISET - International Journal of Innovative Science, Engineering & Technology, Vol. 2 Issue 12, December 2015. www.ijiset.com ISSN 2348 – 7968 The results of the exergy analysis of the base case system are listed in table 2. The results of the exergy analysis show a distinct behavior. The total exergy efficiency of the hole system is 24.5%, while the subsystem exergy efficiencies are 75%, 55.5%, 89.8% and 74.5% for the heliostat field, central receiver, SGSS and the power cycle, respectively. The power cycle subsystem has relatively large exergy efficiency (74.5%), and the corresponding percentage exergy loss is as small as 12.6%, although main exergy loss occurs there. On the contrary, although the central receiver has a large energy efficiency and a small energy loss percentage (9.7%). It has the largest percentage exergy loss (44.2%). Followed by 33.1% in the heliostat field subsystem. This is because the fact the solar isolation is the energy of very high quality and great irreversibility’s occur when the high quality isolation is absorbed to the thermal energy with the temperature of about 700-900 K, as a result, the energy loss in the central receiver has high quality, containing a lot of exergy. References “Exergy and energy analysis of solar power tower plant” Xu, Zhifeng Wang, Xin Li, Feihu sun Laboratory of solar thermal energy and photovoltaic system, institute of electrical engineering. Chinese academy of science, Beijing 100190,chaina. [1] S. K. Tyagi, S. Wang, M. K. Singhal, S. C. Kaushik and S. R. Park, “Exergy Analysis and Parametric Study of Con-centrating Type Solar Collectors,” International Journal of Thermal Science, Vol. 46, 2007, pp. 1304-1310. [2] C. Xu, Z. Wang, X. Li and F. Sun, “Energy and Exergy Analysis of Solar Power Tower Plants,” Applied Thermal Engineering, Vol. 31, No. 17- 18, 2011, pp. 3904-3913. [3] V. S. Reddy, S. C. Kaushik and S. K. Tyagi, “Exergetic Analysis and Performance Evaluation of Parabolic Dish Stirling Engine Solar Power Plant,” International Journalof Energy Research, 2012. [4] I. Dincer and M. A. Rosen, “Exergy, Energy, Environ-ment and Sustainable Development,” Elsevier, 2007. 575 IJISET - International Journal of Innovative Science, Engineering & Technology, Vol. 2 Issue 12, December 2015. www.ijiset.com ISSN 2348 – 7968 [5] G. Glatzmaier, “Summary Report for Concentrating Solar Power Thermal Storage Workshop,” NREL/ TP-5500[6] S. C. Kaushik, V. S. Reddy and S. K. Tyagi, “Energy and Exergy Analyses of Thermal Power Plants: A Review,” [7] F. Cavallaro, “Fuzzy TOPSIS Approach for Assessing Thermal Energy Storage in Concentrated Solar Power (CSP) Systems,” Applied Energy, Vol. 87, No. 2, 2010, pp. 496-503. [8] S. Flueckiger, Z. Yang and S. V. Garimella, “An Inte- grated Thermal and Mechanical Investigation of Mol- ten-Salt Thermocline Energy Storage,” Vol. 88, No. 6, 2011, pp. 2098-2105. [9] R. Petela, “Exergy Analysis of the Solar Cylindrical Pa-rabolic Cooker,” Solar Energy, Vol. 79, No. 3, 2005, pp. 221-233. 576