11 x 17 one sided Installation Guide

advertisement

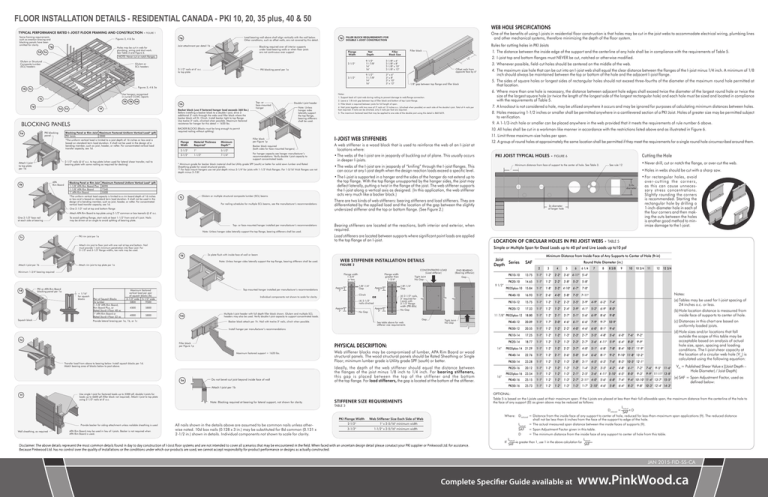

FLOOR INSTALLATION DETAILS - RESIDENTIAL CANADA - PKI 10, 20, 35 plus, 40 & 50 WEB HOLE SPECIFICATIONS TYPICAL PERFORMANCE RATED I-JOIST FLOOR FRAMING AND CONSTRUCTION Some framing requirements such as erection bracing and blocking panels have been omitted for clarity. 1g 1d Load bearing wall above shall align vertically with the wall below. Other conditions, such as offset walls, are not covered by this detail. 1g Figures 3, 4 & 5a Holes may be cut in web for plumbing, wiring and duct work. See Table 3 and Figure 6. 1e Joist attachment per detail 1b FILLER BLOCK REQUIREMENTS FOR DOUBLE I-JOIST CONSTRUCTION 1p Blocking required over all interior supports under load-bearing walls or when floor joists are not continuous over support Flange Width NOTE: Never cut or notch flanges. Glulam or Structural Composite Lumber (SCL) headers Glulam or SCL headers Net Depth 2-1/2" 2-1/2" nails at 6" o.c. to top plate PKI blocking panel per 1a 3-1/2" 1b One of the benefits of using I-joists in residential floor construction is that holes may be cut in the joist webs to accommodate electrical wiring, plumbing lines and other mechanical systems, therefore minimizing the depth of the floor system. FIGURE 1 Filler Block Size 9-1/2" 11-7/8" 14" 16" 2-1/8" x 6" 2-1/8" x 8" 2-1/8" x 10" 2-1/8" x 12" 9-1/2” 11-7/8" 14" 16" 3” x 6” 3" x 8" 3" x 10" 3" x 12" Filler block " 12 Offset nails from opposite face by 6" 1/8" gap between top flange and filler block Figures 3, 4 & 5a 1c Use hangers recognized in current CCMC reports 1j 1h 1p 1a 1n 1k 1m 1h 1f Backer block (use if factored hanger load exceeds 360 lbs.) Before installing a backer block to a double I-joist, drive 3 additional 3" nails through the webs and filler block where the backer block will fit. Clinch. Install backer tight to top flange. Use twelve 3" nails, clinched when possible. Maximum factored resistance for hanger for this detail = 1620 lbs. BLOCKING PANELS PKI blocking panel 1a Blocking Panel or Rim Joist Maximum Factored Uniform Vertical Load* (plf) PKI Joists 3300 *The uniform vertical load is limited to a joist depth of 16 inches or less and is based on standard term load duration. It shall not be used in the design of a bending member, such as joist, header, or rafter. For concentrated vertical load transfer capacity, see 1d. 2-1/2" nails @ 6" o.c. to top plate (when used for lateral shear transfer, nail to bearing plate with same nailing as required for decking) Attach I-joist to top plate per 1b APA Rim Board 1b Blocking Panel or Rim Joist 1-1/8" APA Rim Board Plus 1-1/8" APA Rim Board 1" APA Rim Board Top- or face-mounted hanger Double I-joist header Note: Unless hanger sides laterally support the top flange, bearing stiffeners shall be used. BACKER BLOCKS (Blocks must be long enough to permit required nailing without splitting) Flange Width Material Thickness Required* Minimum Depth** 2-1/2" 1" 5-1/2" 3-1/2" 1-1/2" 7-1/4" Filler block per Figure 1p Backer block required (both sides for face-mounted hangers) For hanger capacity see hanger manufacturer’s recommendations. Verify double I-joist capacity to support concentrated loads. * Minimum grade for backer block material shall be Utility grade SPF (south) or better for solid sawn lumber and Rated Sheathing grade for wood structural panels. ** For face-mount hangers use net joist depth minus 3-1/4" for joists with 1-1/2" thick flanges. For 1-5/16" thick flanges use net depth minus 2-7/8". Maximum Factored Uniform Vertical Load* (plf) 8090 7340 5500 *The uniform vertical load capacity is limited to a rim board depth of 16 inches or less and is based on standard term load duration. It shall not be used in the design of a bending member, such as joist, header, or rafter. For concentrated vertical load transfer capacity, see 1d. Notes: 1. Support back of I-joist web during nailing to prevent damage to web/flange connection. 2. Leave a 1/8-inch gap between top of filler block and bottom of top I-joist flange. 3. Filler block is required between joists for full length of span. 4. Nail joists together with two rows of 3" nails at 12 inches o.c. (clinched when possible) on each side of the double I-joist. Total of 4 nails per foot required. if nails can be clinched, only 2 nails per foot are required. 5. The maximum factored load that may be applied to one side of the double joist using this detail is 860 lbf/ft. 1j Glulam or multiple structural composite lumber (SCL) beams For nailing schedules for multiple SCL beams, see the manufacturer‘s recommendations One 2-1/2" nail at top and bottom flange I-JOIST WEB STIFFENERS A web stiffener is a wood block that is used to reinforce the web of an I-joist at locations where: •The webs of the I-joist are in jeopardy of buckling out of plane. This usually occurs in deeper I-joists. •The webs of the I-joist are in jeopardy of “knifing” through the I-joist flanges. This can occur at any I-joist depth when the design reaction loads exceed a specific level. •The I-joist is supported in a hanger and the sides of the hanger do not extend up to the top flange. With the top flange unsupported by the hanger sides, the joist may deflect laterally, putting a twist in the flange of the joist. The web stiffener supports the I-joist along a vertical axis as designed. (In this application, the web stiffener acts very much like a backer block.) There are two kinds of web stiffeners: bearing stiffeners and load stiffeners. They are differentiated by the applied load and the location of the gap between the slightly undersized stiffener and the top or bottom flange. (See Figure 2.) Rules for cutting holes in PKI Joists 1. The distance between the inside edge of the support and the centerline of any hole shall be in compliance with the requirements of Table 5. 2. I-joist top and bottom flanges must NEVER be cut, notched or otherwise modified. 3. Whenever possible, field-cut holes should be centered on the middle of the web. 4. The maximum size hole that can be cut into an I-joist web shall equal the clear distance between the flanges of the I-joist minus 1/4 inch. A minimum of 1/8 inch should always be maintained between the top or bottom of the hole and the adjacent I-joist flange. 5. The sides of square holes or longest sides of rectangular holes should not exceed three-fourths of the diameter of the maximum round hole permitted at that location. 6. Where more than one hole is necessary, the distance between adjacent hole edges shall exceed twice the diameter of the largest round hole or twice the size of the largest square hole (or twice the length of the longest side of the l­ongest rectangular hole) and each hole must be sized and located in compliance with the requirements of Table 5. 7. A knockout is not considered a hole, may be utilized anywhere it occurs and may be ignored for purposes of calculating minimum distances between holes. 8. Holes measuring 1-1/2 inches or smaller shall be permitted anywhere in a cantilevered section of a PKI Joist. Holes of greater size may be permitted subject to verification. 9. A 1-1/2-inch hole or smaller can be placed anywhere in the web provided that it meets the requirements of rule number 6 above. 10. All holes shall be cut in a workman-like manner in accordance with the restrictions listed above and as illustrated in Figure 6. 11. Limit three maximum-size holes per span. 12. A group of round holes at approximately the same location shall be permitted if they meet the requirements for a single round hole circumscribed around them. PKI JOIST TYPICAL HOLES - •Holes in webs should be cut with a sharp saw. 3/4x diameter 2x diameter of larger hole Top- or face-mounted hanger installed per manufacturer‘s recommendations PKI rim joist per 1a 1c Bearing stiffeners are located at the reactions, both interior and exterior, when required. Load stiffeners are located between supports where significant point loads are applied to the top flange of an I-joist. Attach rim joist to floor joist with one nail at top and bottom. Nail must provide 1 inch minimum penetration into floor joist. For 2-1/2" and 3-1/2" flange widths, toe nails may be used. Squash block WEB STIFFENER INSTALLATION DETAILS FIGURE 2 Attach rim joist to top plate per 1a Minimum 1-3/4" bearing required 1d Flange width 1-3/4" or less + 1/16" for squash blocks Pair of Squash Blocks 2x lumber 1-1/8" APA Rim Board, Rim Board Plus, or Rated Sturd-I-Floor 48 oc 1" APA Rim Board or Rated Sturd-I-Floor 32 oc Top-mounted hanger installed per manufacturer‘s recommendations Maximum factored vertical load per pair of squash blocks (lb) 3-1/2" wide 5-1/2" wide 5800 9500 4500 5800 4000 5800 LOCATION OF CIRCULAR HOLES IN PKI JOIST WEBS - TABLE 5 2x plate flush with inside face of wall or beam Note: Unless hanger sides laterally support the top flange, bearing stiffeners shall be used. PKI or APA Rim Board blocking panel per 1a Flange width greater than 1-3/4" 1/8"-1/4" Gap Approx. 2" Clinch Individual components not shown to scale for clarity. Approx. 2" OR (4) 2-1/2" nails clinched 1m Provide lateral bracing per 1a, 1b, or 1c Multiple I-joist header with full depth filler block shown. Glulam and multiple SCL headers may also be used. Verify double I-joist capacity to support concentrated loads. Approx. 2" CONCENTRATED LOAD (Load stiffener) No Gap Backer block attach per 1h. Nail with twelve 3" nails, clinch when possible. Approx. 2" SAF PKI10-10 PKI20-10 END BEARING (Bearing stiffener) Tight Joint No Gap Gap 9 1/2” 1/8"-1/4" Gap See table above for web stiffener size requirements Maximum factored support = 1620 lbs. Transfer load from above to bearing below. Install squash blocks per 1d. Match bearing area of blocks below to post above. 1n Do not bevel-cut joist beyond inside face of wall Web stiffener blocks may be compromised of lumber, APA Rim Board or wood structural panels. The wood structural panels should be Rated Sheathing or Single Floor; minimum lumber grade is Utility grade SPF (south) or better. Ideally, the depth of the web stiffener should equal the distance between the flanges of the joist minus 1/8 inch to 1/4 inch. For bearing stiffeners, this gap is placed bet ween the top of the s tif fener and the bot tom of the top flange. For load stiffeners, the gap is located at the bottom of the stiffener. Attach I-joist per 1b Use single I-joist for factored loads up to 3300 plf, double I-joists for loads up to 6600 plf (filler block not required). Attach I-joist to top plate using 2-1/2" nails at 6" o.c. Note: Blocking required at bearing for lateral support, not shown for clarity. STIFFENER SIZE REQUIREMENTS TABLE 3 PKI Flange Width Provide backer for siding attachment unless nailable sheathing is used Wall sheathing, as required APA Rim Board may be used in lieu of I-joists. Backer is not required when APA Rim Board is used. All nails shown in the details above are assumed to be common nails unless otherwise noted. 10d box nails (0.128 x 3 in.) may be substituted for 8d common (0.131 x 2-1/2 in.) shown in details. Individual components not shown to scale for clarity. Web Stiffener Size Each Side of Web 2-1/2" 1" x 2-5/16" minimum width 3-1/2" 1-1/2" x 2-5/16" minimum width 4 5 6 6 1/4 13.75 1'-1" 1'-2" 2'-2" 3'-6" 4'-11" 5'-4" 14.65 1'-1" 1'-2" 2'-2" 3'-8" 5'-3" 5'-8" PKI35plus-10 15.84 1'-1" 1'-8" 3'-2" 4'-10" 6'-7" 7'-0" 7 8 8 5/8 9 10 10 3/4 2'-6" 4'-0" 5'-8" 7'-5" 7'-11" PKI10-12 15.75 1'-1" 1'-2" 1'-2" 2'-3" 3'-5" 3'-9" 4'-9" 6'-2" 7'-4" PKI20-12 17.33 1'-1" 1'-2" 1'-2" 2'-4" 3'-9" 4'-1" 5'-2" 6'-9" 8'-0" 11 7/8” PKI35plus-12 18.80 1'-1" 1'-2" 2'-1" 3'-7" 5'-1" 5'-6" 6'-9" 8'-6" 9'-8" PKI40-12 20.09 1'-1" 1'-7" 3'-0" 4'-6" 6'-1" 6'-6" 7'-9" 9'-7" 10'-9" PKI50-12 20.55 1'-1" 1'-2" 1'-2" 2'-2" 4'-0" 4'-6" 6'-0" 8'-1" 9'-6" PKI10-14 17.25 1'-1" 1'-2" 1'-2" 1'-3" 2'-3" 2'-7" 3'-5" 4'-8" 5'-6" 6'-0" 7'-6" 9'-2" PKI20-14 18.77 1'-1" 1'-2" 1'-2" 1'-3" 2'-3" 2'-7" 3'-6" 4'-11" 5'-9" 6'-4" 8'-0" 9'-9" PKI35plus-14 21.29 1'-1" 1'-2" 1'-2" 2'-2" 3'-7" 4'-0" 5'-1" 6'-8" 7'-8" 8'-4" 10'-1" 11'-9" 14” 16” 11 12 12 3/4 Notes: 1'-1" Tight Joint No Gap PHYSICAL DESCRIPTION: 3 16.93 1e Filler block per Figure 1p Round Hole Diameter (in.) 2 PKI40-10 (4) 2-1/2" nails, 3" required for I-joists with 3-1/2" flange width (PRI-80s) No Gap Gap Minimum Distance from Inside Face of Any Supports to Center of Hole (ft-in) Joist Series Depth Install hanger per manufacturer‘s recommendations 1f •For rectangular holes, avoid ove r- cu t t in g t h e c o r n e r s, as this can cause unnecessar y stress concentrations. Slightly rounding the corners is recommended. Starting the rectangular hole by drilling a 1-inch-diameter hole in each of the four corners and then making the cuts between the holes is another good method to minimize damage to the I-joist. Simple or Multiple Span for Dead Loads up to 40 psf and Live Loads up to10 psf 1k Attach I-joist per 1b Knockouts are prescored holes often provided by I-joist manufacturers for the contractor’s convenience to install electrical or small plumbing lines. They are typically 1-3/8 to 1-3/4 inches in diameter, and are spaced 12 to 24 inches on center along the length of the I-joist. Where possible, it is preferable to use knockouts instead of field-cutting holes. To avoid splitting flange, start nails at least 1-1/2" from end of I-joist. Nails may be driven at an angle to avoid splitting of bearing plate. Note: Unless hanger sides laterally support the top flange, bearing stiffeners shall be used. •Never drill, cut or notch the flange, or over-cut the web. See rule 12 Minimum distance from face of support to the center of hole. See Table 3. Attach APA Rim Board to top plate using 2-1/2" common or box toenails @ 6" o.c. One 2-1/2" face nail at each side at bearing Cutting the Hole FIGURE 6 (a)Tables may be used for I-joist spacing of 24 inches o.c. or less. (b)Hole location distance is measured from inside face of supports to center of hole. (c)Distances in this chart are based on uniformly loaded joists. (d)Hole sizes and/or locations that fall outside the scope of this table may be acceptable based on analysis of actual hole size, span, spacing and loading conditions. The I-joist shear capacity at the location of a circular web hole (Vrh) is calculated using the following equation: PKI40-14 22.76 1'-1" 1'-2" 2'-1" 3'-6" 5'-0" 5'-4" 6'-6" 8'-1" 9'-2" 9'-10" 11'-8" 13'-2" PKI50-14 23.28 1'-1" 1'-2" 1'-2" 1'-3" 2'-8" 3'-1" 4'-5" 6'-3" 7'-6" 8'-3" 10'-5" 12'-1" PKI20-16 20.12 1'-1" 1'-2" 1'-2" 1'-3" 1'-3" 1'-4" 2'-2" 3'-5" 4'-2" 4'-8" 6'-1" 7'-2" 7'-6" PKI35plus-16 23.54 1'-1" 1'-2" 1'-2" 1'-3" 2'-1" 2'-5" 3'-6" 4'-11" 5'-10" 6'-5" 8'-0" 9'-3" 9'-9" 11'-11" 13'-8" PKI40-16 25.15 1'-1" 1'-2" 1'-2" 1'-3" 2'-7" 2'-11" 4'-0" PKI50-16 25.73 1'-1" 1'-2" 1'-2" 1'-3" 1'-3" 9'-5" 11'-6" 5'-6" 6'-8" 7'-4" 9'-4" 10'-10" 11'-4" 13'-7" 15'-5" 1'-7" 2'-10" 4'-6" 5'-8" 6'-4" 8'-3" 9'-8" 10'-3" 12'-4" 14'-3" Vrh = Published Shear Value x [(Joist Depth – Hole Diameter) / Joist Depth] (e)SAF = Span Adjustment Factor, used as defined below: OPTIONAL: Table 5 is based on the I-joists used at their maximum span. If the I-joists are placed at less than their full allowable span, the maximum distance from the centerline of the hole to the face of any support (D) as given above may be reduced as follows: Lactual xD Dreduced = SAF Where: Dreduced=Distance from the inside face of any support to center of hole, reduced for less-than-maximum span applications (ft). The reduced distance shall not be less than 6 inches from the face of the support to edge of the hole. Lactual =The actual measured span distance between the inside faces of supports (ft). SAF =S pan Adjustment Factor given in this table. D =The minimum distance from the inside face of any support to center of hole from this table. Lactual Lactual If is greater than 1, use 1 in the above calculation for SAF SAF JAN 2015-FID-SS-CA Complete Specifier Guide available at www.PinkWood.ca