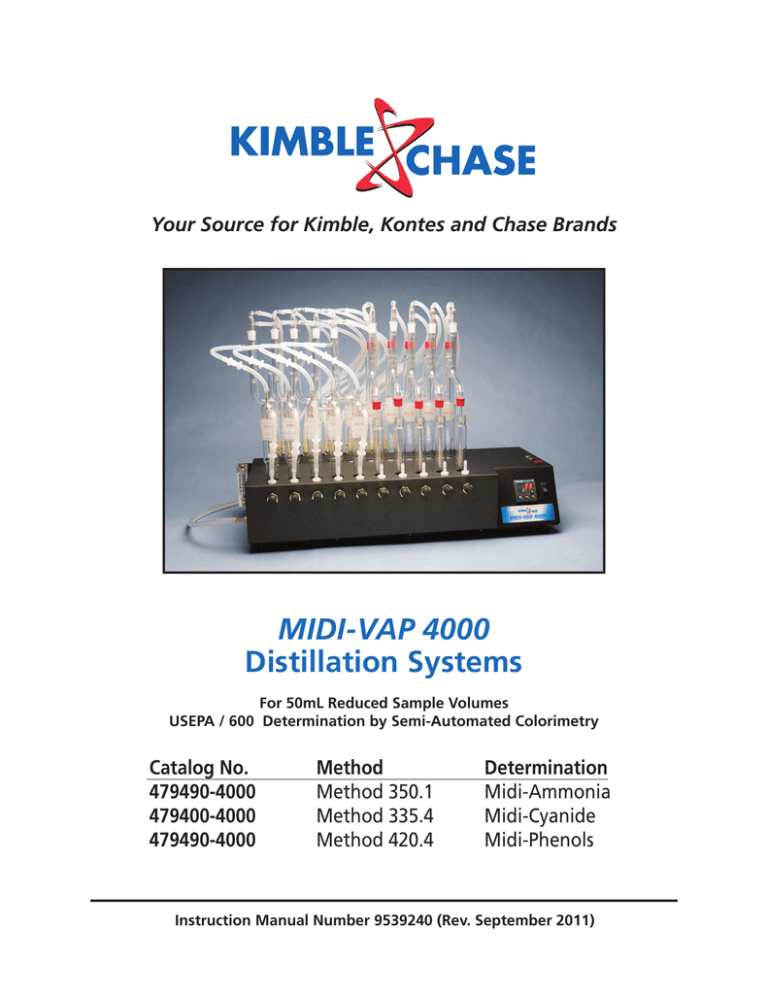

Midi-Vap 4000 Distillation Systems

advertisement