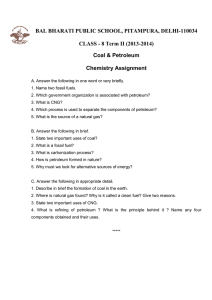

Personal Protective Equipment

advertisement

Health, Safety, Environment and Community Petroleum Management System Personal Protective Equipment PETROLEUM CSG HSEC MANAGEMENT SYSTEM PROCEDURE PERSONAL PROTECTIVE EQUIPMENT Petroleum HSEC Procedure No: PHSE-13-P12 Date: June 14, 2012 Revision: 2.1 Owner: Kim Phillips, Occupational Health and Hygiene Manager Approver: Kristen Ray, Vice President HSEC PHSE-13-P12 Signature On File CONTROLLED DOCUMENT Page 1 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Petroleum Management System Personal Protective Equipment TABLE OF CONTENTS 1.0 PURPOSE.................................................................................................................3 2.0 SCOPE .....................................................................................................................3 3.0 REFERENCES ..........................................................................................................3 4.0 DEFINITIONS ...........................................................................................................4 5.0 PROCEDURE ...........................................................................................................5 5.1 Risk Assessment ..................................................................................................5 5.1.1 Site Risk Assessment ....................................................................................5 5.1.2 Job Risk Assessment.....................................................................................6 5.2 Head Protection ....................................................................................................6 5.3 Eye Protection ......................................................................................................7 5.4 Face Protection ....................................................................................................7 5.5 Hearing Protection ...............................................................................................8 5.6 Protective Clothing...............................................................................................8 5.7 Hand Protection.................................................................................................. 10 5.8 Foot Protection ................................................................................................... 11 5.9 Respiratory Protection ....................................................................................... 11 5.10 Personal Fall Protection................................................................................... 11 5.11 Maintenance...................................................................................................... 12 5.12 Audit and Review.............................................................................................. 12 5.13 Training .............................................................................................................13 6.0 RESPONSIBILITIES ............................................................................................... 14 6.1 Senior Site Manager ........................................................................................... 14 6.2 Local HSE Manager/Supervisor......................................................................... 14 6.3 All Personnel ...................................................................................................... 14 7.0 RECORDS ..............................................................................................................14 8.0 VARIANCES ........................................................................................................... 15 9.0 UPDATES TO THIS DOCUMENT ........................................................................... 15 10.0 ATTACHMENTS ................................................................................................... 15 10.1 Personal Protection Standards ....................................................................... 16 CONTROLLED DOCUMENT PHSE-13-P12 Page 2 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Petroleum Management System Personal Protective Equipment 1.0 PURPOSE This document describes the minimum Personal Protective Equipment (PPE) requirements associated with Petroleum field activities. 2.0 SCOPE This procedure applies to the entire lifecycle of Petroleum activities, processes and products, including exploration and planning, development, operations, closure, marketing and acquisitions and divestments. Partners, suppliers and contractors are encouraged to adopt this procedure. Where there is a conflict between legislation and Petroleum requirements, the more stringent standard prevails while ensuring legal compliance requirements are met. The requirements mandated by this Procedure apply to any work activity that takes place outside of the office. This Procedure does not apply to sites at which activities are entirely office based. 3.0 REFERENCES This procedure is used in conjunction with: • Petroleum HSE Management System Element 3 – Hazards and Risks • Petroleum Hearing Conservation Procedure • Petroleum Respiratory Protection Procedure CONTROLLED DOCUMENT PHSE-13-P12 Page 3 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Management System Petroleum Personal Protective Equipment 4.0 DEFINITIONS Contractor – A person employed either directly or indirectly by a company contracted to BHP Billiton Petroleum to provide equipment and/or services to a BHP Billiton Petroleum operation. JRA – Job Risk Assessment MSDS – Material Safety Data Sheet New Start – A person that has never been to the site before, or has not been on the site for at least 12 months, or is an infrequent, short duration visitor regardless of when they were last on site. Person in Charge – The senior person on site responsible for overall site activities and operations. PPE – Personal Protective Equipment PTW – Permit to Work Shall or Must – Means a mandatory requirement. Visitor – A person visiting a BHP Billiton Petroleum controlled site who is authorized to do so by the senior-most BHP Billiton Petroleum Site representative. Work Site – Activities associated with petroleum exploration, drilling, construction, production and logistics that have been risk assessed and determined to necessitate the use of PPE. Work sites may include, but are not limited to, areas outside the facility living quarters and office buildings, such as seismic vessels, drilling rigs, construction sites, production facilities, storage terminals and logistics bases. CONTROLLED DOCUMENT PHSE-13-P12 Page 4 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Management System Petroleum Personal Protective Equipment 5.0 PROCEDURE This Procedure outlines the minimum PPE requirements for Petroleum field activities. Depending on the location of the operation, the following standards for PPE design and maintenance shall apply: • Americas (default standard) - ANSI (American National Standards Institute) • Australia – AS/NZ (Australian New Zealand Standards) • UK –British Standards • EN – European Standards • Other standards as applicable 5.1 Risk Assessment 5.1.1 Site Risk Assessment Responsible persons must conduct an initial work-site risk assessment to determine the minimum required PPE. The risk assessment must also determine if hazards exist that require the use of additional specialized PPE. Hazards shall be identified during walkthrough surveys, review of occupational baseline exposures, industry standards, and chemical safety data sheets, making observations of the following basic hazard categories: a) Impact b) Penetration c) Compression d) Chemical e) Heat f) Harmful dusts, mists, fibers, fumes or vapors. g) Light (optical radiation) h) Ionizing and Non-Ionizing Radiation i) Biological Hazards j) Vibration Refer to OSHA 29 CFR Part 1910, Subpart I, Appendix B or an equivalent standard for a work site PPE risk assessment methodology. The PPE risk assessment shall be updated as needed and reviewed every two years. CONTROLLED DOCUMENT PHSE-13-P12 Page 5 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Management System Petroleum Personal Protective Equipment 5.1.2 Job Risk Assessment Prior to each planned work activity at the site, a Job Risk Assessment or JRA shall be conducted to identify job-specific hazards and determine the appropriate PPE to be used. The PPE requirements shall be adequate for the specific tasks being performed. The risk assessment may identify PPE requirements over and above the minimum standards identified in this procedure. Employee provided PPE is not permitted. Unplanned or planned work activities where significant change has occurred must also conduct or revise a previous JRA. Properly fitted PPE is considered the lowest level of control option under the Hierarchy of Controls. It is the last line of defense. 5.2 Head Protection Hard hats, or safety helmets, which meet the requirements listed in Section 10.1, shall be worn in all designated work areas. Hard hats shall be made of plastic or other nonmetallic/non-conductive materials and designed to hold chin straps. When working at heights the use of chin straps shall be considered in the JRA. Metal hard hats do not meet the standards for electrical resistance and therefore shall not be permitted. Hard hats shall be inspected per Section 5.11. A hard hat shall be replaced immediately if it becomes brittle, cracked or is otherwise damaged. Suspensions and shells shall be replaced per the manufacturer’s recommendation. All new starts and visitors shall wear a specialty color hard hat when entering the work site to distinguish them from experienced workers. Where required, these hats shall be worn for a minimum of 3 rotational cycles (or 3 months, whichever is longer) to ensure greater visibility during the orientation period and allow experienced site personnel to provide additional support. In extreme cold, full head insulation or suitable liners for hard hats may be worn. These shall be made of material consistent with the Flame Resistant Clothing requirements noted in this procedure. CONTROLLED DOCUMENT PHSE-13-P12 Page 6 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Petroleum Management System Personal Protective Equipment 5.3 Eye Protection Safety glasses, with side impact protection, or goggles shall be worn in all designated work areas as outlined in the site risk assessment. Glasses and prescription glasses shall be designed and constructed to meet the requirements listed in Section 10.1. Where regular prescription glasses are required to be worn, these must be ANSI approved, or equivalent, or be worn with overprotection such as goggles. Detachable side shields must only be used for site visitors whose prescription glasses otherwise meet established standards. Both clear and tinted lenses shall be made available and must have ultraviolet protective coated lenses. Tinted lenses shall not be used indoors or other areas of reduced ambient light. Personnel have responsibility to maintain eye protection in a safe condition. Antifogging compounds for safety glasses/ lenses shall be available and used to maintain clear vision when work conditions are impacted by fogging. Contact lenses are permitted, but their use shall not interfere with or be compromised by the work activity. Contact lenses do not provide eye protection and the wearer may have increased risk of eye injury from exposure to dusts and chemical vapors. Eye protection shall be worn in addition to the contact lenses. Personnel working with chemicals, degreasers, detergents, or equipment that contains a hazardous or pressurized liquid or gas (e.g. wet cell batteries), where exposure is identified as a risk, shall wear non-vented, splash resistant goggles. Special lenses are required when oxygen fuel cutting. Splash resistant goggles are required when working with chemicals or in dusty conditions 5.4 Face Protection During work activities that involve grinding, chipping, and buffing, or where material could separate and become a projectile, a face shield shall be worn in conjunction with either safety glasses or goggles. Face shield shall be designed and constructed to meet the requirements listed in Section 10.1. For exposure to hot or corrosive materials, a face shield shall be worn over the goggles. CONTROLLED DOCUMENT PHSE-13-P12 Page 7 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Petroleum Management System Personal Protective Equipment A welding hood, with non-glass visor, shall be worn over standard safety glasses when welding. Personnel engaged in sandblasting, water blasting or spray painting shall wear eye protection under the face shield or air supplied hood to protect the eyes and face from known hazards. 5.5 Hearing Protection Hearing protection shall be worn in all designated high noise areas or other demarcated area. Hearing protection shall meet the requirements of the Petroleum Hearing Conservation Procedure. A quantitative noise survey shall be completed around all machinery and equipment located at the site to document sound level readings and identify areas that require hearing protection. The assessment shall include both permanent and temporary equipment. Signs shall be posted at each work location where continuous noise levels are at 80 dB(A) or greater over an 8 hour time-weighted average. Various forms of hearing protections shall be made available, such as disposable/ reusable ear plugs or hard hat mounted ear protectors, and shall be worn in posted areas. Hearing protection shall also be worn during operations that generate noise in excess of 80 dB(A). 5.6 Protective Clothing The wearing of Flame Resistant Clothing is required for all personnel and visitors when: • Located on a production facility with hydrocarbon-containing process equipment and working in PPE required areas. • Loading/ unloading or transferring hydrocarbons where vapors are present in the atmosphere that present a flash fire potential. • Repairing active hydrocarbon piping, tankage or equipment that is outside the production facility and the potential for a flash fire has not been completely eliminated. • Performing hot work activities on active hydrocarbon equipment and piping (hot tapping). • Working on hydrocarbon piping or other related equipment that is below grade or defined as a confined space, and the potential for a flash fire has not been completely eliminated. • Performing high voltage switching operations and maintenance. CONTROLLED DOCUMENT PHSE-13-P12 Page 8 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Petroleum Management System Personal Protective Equipment • An employee or supervisor identifies a site-specific job and/ or area with potential exposure to flash fire/ arc burn injuries, such as through an electrical circuit. • Specified by local regulation or policy. Flame Resistant Clothing (FRC) shall comply with the following requirements: • Flame Resistant Clothing material shall comply with NFPA 2112 and be tested to ASTM F 1930 (or equivalent standard). All Flame Resistant Clothing and non-Flame Resistant Clothing shall be worn and maintained accordingly: • Personnel shall wear Flame Resistant Clothing as the outer-most garments except when other personal protective clothing is required (e.g. Chemical resistant suits, welder’s leather, personal flotation devices, increased visibility vests). • Personnel should not wear synthetic blends such as nylon, polyester, rayon, polyethylene, etc under the protective clothing. Only natural fibers such as cottons or wools are recommended to be worn underneath FRC. • Only long sleeved FRC shall be worn in designated Flame Resistant Clothing areas/ jobs. FRC shall be worn in such a manner as to completely cover the torso, arms and legs (sleeves rolled down and body fully zipped or buttoned up). • Clothing should be laundered, repaired and taken out-of-service per the manufacturer’s recommendations. • Where there is a risk of exposure to heat stress, FRC should be constructed of 3M Nomex® IIIA 4.5 oz or Milliken Amplitude® 6oz material. Light colors are recommended, such as Gray, Khaki/Tan, and Light Blue. These selections can reduce the impacts that lead to heat illness. • Where there is risk of exposure to extreme cold, insulated work suits or parkas may be worn. When FRC is required, winter clothing can be worn underneath the Flame Resistant Clothing layer. • Rain gear worn over Flame Resistant Clothing can negate the effectiveness of the protective layer, especially if the material would melt in a flash fire. Where the working conditions require FRC then Flame Resistant rainwear is also required and must comply with the ASTM F2733 standard. High Visibility and Reflective Stripes • When working in the vicinity of light vehicle traffic and mobile equipment, work clothing worn on site must be made from or have applied high visibility material and deflective strips that conform to the requirements listed in Section 10.1. • Hi-Vis class 1 vests must be used over existing work clothing to increase visibility where work clothing does not meet the Hi-Vis standard. CONTROLLED DOCUMENT PHSE-13-P12 Page 9 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Petroleum Management System Personal Protective Equipment 5.7 Hand Protection All personnel shall wear suitable hand protection (gloves) on the work site that comply with the requirements listed in Section 10.1. Exceptions to this requirement, such as performing tasks that require additional finger dexterity, shall be approved by a supervisor and captured on a JRA or through the Permit to Work system. The selection of hand protection shall be based on the following: • the specific task being performed • conditions present • duration of exposure • potential hazards identified • performance characteristics of the glove material The use of fit for purpose protective gloves is mandatory when: • welding • oxygen fuel cutting • grinding • blasting • working with chemicals • performing specific electrical functions • using hand tools Personnel shall use hand protection when performing work that exposes the hands to any of, but not limited to, the following: • absorption of harmful substances • cuts or lacerations, abrasions • punctures • vibration • burns (chemical or thermal) • harmful extremes in temperature Leather gloves, or other suitable material, are required when rigging or handling materials. Gloves shall be free of holes and defects. CONTROLLED DOCUMENT PHSE-13-P12 Page 10 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Management System Petroleum Personal Protective Equipment 5.8 Foot Protection Safety-toed boots are required in all designated work areas outside the site office. Footwear shall meet the requirements listed in Section 10.1. Protective footwear shall have leather or rubber uppers that extend above the ankle, an oil resistant sole, and a distinctive heel (raised 3/8 to ½ inch across the entire heel) for climbing stairs and ladders. Site specific risk assessments shall determine whether lace-up or pull-on footwear is used by persons on site. Chemical resistant foot protection is required when handling or working with hazardous or corrosive materials. 5.9 Respiratory Protection At each Petroleum operational unit Respiratory protection devices shall meet the requirements outlined in the Petroleum Respiratory Protection Procedure and shall be worn in all designated areas, or during identified tasks as outlined by the JRA. The following work environments must be addressed in the Respiratory Protection Program: • For firefighting or confined space entry, or when there is a risk of insufficient oxygen. • For protection against H2S or other hazardous atmospheres. • For protection against hazardous dusts, mists, vapors, gases or particulates. 5.10 Personal Fall Protection Personal fall protection shall be worn in all designated areas and as required by the job risk assessment and Permit to Work. Fall protection shall be worn where there is a risk of falling from a height of 2 meters or more, or to gain access to within 2 meters of an open edge where there is the potential to fall 2 meters or more, or as detailed by the JRA. Where there is a conflict between legislation and Petroleum requirements, the more stringent standard prevails while ensuring legal compliance requirements are met. Fall protection shall conform to the requirements set out under Petroleum Fatal Risk Control 7 – Working at Heights. CONTROLLED DOCUMENT PHSE-13-P12 Page 11 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Petroleum Management System Personal Protective Equipment The components of the personal fall protection system include: • • • • • An engineered and appropriately rated anchor point. Automatic and/or self locking connecting mechanisms. A lanyard with deceleration capability.(Must prevent personnel from striking the ground) A full body harness. All connectors shall be at least double-locking to prevent roll out. All fall protection equipment shall be inspected before each use and maintained according to the manufacturer’s recommendations. A register of fall protection equipment shall be maintained, including records of inspections for new and replacement equipment. 5.11 Maintenance All PPE shall be maintained and stored in accordance with the manufacturer’s specifications. All PPE shall be inspected by the wearer prior to use, with regular inspections performed by competent personnel on a recurring schedule where required by regulation. Inspection logs must be maintained where required by local regulation. 5.12 Audit and Review Each Petroleum operational unit must monitor compliance with PPE requirements including the following elements: • • • • The schedule for PPE compliance auditing should take into account infrequent activities. Observations are conducted by HSEC and line supervision. Provide positive reinforcement for correct use of PPE and coaching for people where incorrect use is observed. PPE compliance must include these observations: o Personnel observed are wearing required PPE o PPE in use is appropriate for the exposure and adequately fitted / worn correctly PPE compliance is calculated as a percentage of the number of correct observations versus the total number of observations. Site PPE compliance is the average of all observations on site over the defined period. The PPE procedure must be reviewed on a recurring basis to verify compliance and identify areas for improvement. The schedule for reviewing this procedure shall be at least every three years. CONTROLLED DOCUMENT PHSE-13-P12 Page 12 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Management System Petroleum Personal Protective Equipment 5.13 Training Requirements to wear PPE shall be reviewed during site HSE inductions. All employees, and contractors required to wear PPE shall be trained to know the following: • When PPE is required? • Which PPE is required? • How to properly wear, remove and adjust the PPE. • The limitations of the PPE. • Proper care, maintenance and disposal of PPE. Personnel shall demonstrate an understanding of the training and show their ability to use PPE properly before being allowed to perform work. Retraining is required if: • There are changes at the work site that impacts the previous training. • There are changes to the PPE used at the work site. • Inadequacies in the individual’s knowledge or use of the PPE are identified.. An accredited trainer shall be used for training on specialized PPE, such as fall arrest equipment. CONTROLLED DOCUMENT PHSE-13-P12 Page 13 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Petroleum Management System Personal Protective Equipment 6.0 RESPONSIBILITIES 6.1 Senior Site Manager The responsibility for ensuring compliance with this procedure rests with the Site Manager (Person in Charge) to ensure that: • All activities at the work site have been risk assessed to determine PPE requirements. • Designated work areas requiring PPE are clearly and correctly marked. • The PPE requirements have been communicated to all employees, visitors and contractors working at the site. • The PPE identified by risk assessment is available on site and properly stored. • Personnel are trained in the selection, maintenance and use of the PPE. 6.2 Local HSE Manager/Supervisor The local HSE Manager/Supervisors are responsible for verifying compliance with this procedure through periodic assessments and reviews. All non-compliances shall be brought to the attention of the Site Manager. 6.3 All Personnel All employees, contractors and visitors are responsible for learning the site PPE requirements, wearing and using the PPE appropriate for a work activity, and complying with the requirements set out in this standard. 7.0 RECORDS The following records shall be maintained: • Records of risk assessments that identify hazards and job risk assessments (JRA’s) for identifying specific PPE requirements. • Records of personnel training. • Signage indicating required PPE. CONTROLLED DOCUMENT PHSE-13-P12 Page 14 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Management System Petroleum Personal Protective Equipment 8.0 VARIANCES Any planned deviations from the requirements of this procedure shall be recorded on Petroleum HSEC Variance Form and submitted to Petroleum HSE Systems Support. Variances to this procedure must be approved by: 1. HSEC Manager/Supervisor 2. Senior Line Manager 3. Vice President HSEC 9.0 UPDATES TO THIS DOCUMENT This is a Petroleum HSE Controlled Document. Requests for updates to Petroleum HSE Controlled Documents shall be documented on the Petroleum HSEC Document Proposal and Review Form and sent to the Petroleum HSE Systems Support email in the GAL. 10.0 ATTACHMENTS 10.1 – Personal Protection Standards CONTROLLED DOCUMENT PHSE-13-P12 Page 15 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Management System Petroleum Personal Protective Equipment 10.1 Personal Protection Standards Protection Type Head Protection Eye/Face Protection International Standard (or Equivalent) Description ANSI Z89.1 Standard For Industrial Head Protection AS/NZ 1800/1801 Occupational Protective Helmets - Selection, Care And Use; Occupational Protective Helmets CSA Z94.1 Industrial Protective Headwear Performance Selection, Care, And Use. ANSI Z87.1 Occupational And Educational Eye And Face Protection Devices CSA Z94.3 Selection, Use And Care Of Protective Eyewear EN166 Personal Eye Protection - Specifications AS/NZS 1336/1337 Recommended Practices For Occupational Eye Protection; Eye Protectors For Industrial Applications Hearing Protection Petroleum Hearing Conservation Procedure. Flame Resistant Clothing NFPA 2112 & ASTM F1930 Flame-Resistant Garments for Protection of Industrial Personnel Against Flash Fire Flame Resistant Raingear ASTM F2733 Specification For Flame Resistant Rainwear For Protection Against Flame Hazards High Visibility Clothing ANSI/ ISEA 1072004 class1/level 2 standard High Visibility Public Safety Vests EN 471 High Visibility Garments CONTROLLED DOCUMENT PHSE-13-P12 Page 16 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1 Health, Safety, Environment and Community Management System Petroleum Personal Protective Equipment Protection Type Flame Resistant High Visibility Clothing Hand Protection Foot Protection International Standard (or Equivalent) Description ASTM F1506 Performance Specification For Flame Resistant Textile Materials For Wearing Apparel For Use By Electrical Workers Exposed To Momentary Electric Arc And Related Thermal Hazards ANSI/ISEA 103 Classification And Performance Requirements For Chemical Protective Clothing ANSI/ISEA 105 Hand Protection Selection Criteria EN 420 Protective Gloves - General Requirements And Test Methods EN 388 Gloves Giving Protection From Mechanical Risks EN 407 Gloves Giving Protection From Thermal Hazards EN 12477 Welding Gloves EN 374 Gloves Giving Protection From Chemicals And Micro-Organisms EN 10819 Mechanical Vibration And Shock EN 60903 Live Working – Gloves Of Insulating Material ASTM F2413-05 Standard Specification For Performance Requirements For Foot Protection EN 345-1 Requirements For Safety Footwear Fitted With Toecaps Designed To Give Protection Against Impact. Respiratory Protection Petroleum Respiratory Protection Procedure Personal Fall Protection Petroleum Fatal Risk Control 7 – Working at Heights. CONTROLLED DOCUMENT PHSE-13-P12 Page 17 of 17 Printed copies of this document are not controlled. To verify this copy is current, check the Petroleum Portal. Rev. 2.1