Eye Protection

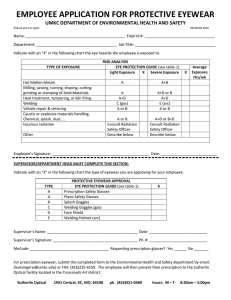

advertisement

Slide 1 Eye Protection Welcome to the training session about protecting your eyes at work. Slide 2 Session Objectives You will be able to: • Identify potential eye hazards • Prevent eye injuries with protective eyewear • Use, maintain, and inspect proper protective eyewear • Use appropriate first aid for emergencies © Blue Tuna Documentation By the end of the training session, you will be able to: Identify the potential work areas and activities that could cause injury to your eyes. Understand how to prevent those injuries. Use, maintain, and inspect protective eyewear. Use appropriate first aid for emergencies. Slide 3 Eye Injury Statistics • Each day, more than 2,000 workers suffer eye injuries • Annually, 62,000 eye injuries result in lost workdays • Eye protection can reduce the number and severity of eye injuries in 90% of accidents © Blue Tuna Documentation According to Prevent Blindness America, a national nonprofit organization, each day of the calendar year results in another 2,000 workers suffering a serious eye injury. Annually, about 100,000 of these eye injuries result in temporary or permanent vision loss. Approximately 62,000 of those eye injuries are severe enough that the injured worker misses at least one day of work. According to some experts, eye protection can reduce the number and severity of eye injuries in 90% of accidents. Note: Statistics listed on this slide can be referenced to Prevent Blindness America (www.preventblindness.org). Slide 4 Eye Hazards • Flying objects • Harmful dust particles • Chemical splashing or spraying • High-intensity heat or light • Welding, brazing, torch cutting • Direct or reflected sunlight © Blue Tuna Documentation Eye Hazards depend on the type of work you do, but here are some main categories: Flying objects Harmful dust particles Chemical splashing or spraying High-intensity heat or light Welding, brazing, torch cutting Direct or reflected sunlight Slide 5 Flying Object Hazard and Protection • Hazard—flying objects cause lens damage • Fragments, chips, particles, sand, dirt • Work processes • Chipping, grinding, masonry work • Eye protection • Glasses with side protection, goggles, or face shield for severe exposure © Blue Tuna Documentation Most flying objects pose impact hazards to the eyes. According to the federal Bureau of Labor Statistics, 70% of serious eye injuries are caused by flying or falling objects, and 60% of those objects are smaller than the head of a pin. Flying objects that can create an impact hazard include: Fragments, large chips, particles, sand, and dirt. Can anyone name some other flying objects specific to our facility that could get into your eyes? Jobs or work processes that might create some of these flying objects include: Chipping, grinding, masonry work, woodworking, sawing, drilling, chiseling, riveting, and sanding. Can anyone name some jobs or work processes at our facility that could create flying objects, chips, etc.? Are there activities you do at home that could create flying objects? If we are going to talk about the hazards, we also have to discuss how to protect our eyes. For most jobs, approved safety glasses with side protection are adequate to protect against flying objects. For jobs with large numbers of flying objects, goggles would be required. Wear a face shield over the goggles if your face needs protection from flying objects. Slide 6 Dust Hazard and Protection • Hazard—walking into floating particles causes irritation, redness, and abrasion • Wood dust, foam dust, soot • Work process • Woodworking, buffing, cleaning • Eye protection • Goggles for tight seal around the eyes © Blue Tuna Documentation Dusts usually include items that do not fly at you; rather, they will usually float around or slowly fall toward the ground. Often dust can get in your eyes if you just walk through an area with a dust hazard. This can cause eye irritation, redness, excessive tearing, and abrasions (scratches) to the lens. Besides wood dust, foam dust, and soot, can anyone name some specific dustlike items from our facility that could get in your eyes? Jobs or work processes that create dust hazards include: Woodworking, buffing materials, and cleaning with air wands or brooms. Can anyone name specific jobs at our facility that can create dust hazards? Use eyewear to protect your eyes from dust hazards. Because dust can easily float behind normal safety glasses and still get in your eyes, goggles or some type of safety glasses that create a seal around the eyes are required. The more hazardous the dust, the tighter to the face the safety eyewear needs to be. Slide 7 Chemical Hazard and Protection • Hazard—splash, spray, or mist causes burning, pain, or blurriness • Acids, caustics, solvents • Work process • Handling or processing a chemical • Eye protection • Goggles • Face shield over goggles for severe exposure © Blue Tuna Documentation All chemicals can cause injury if they make contact with your eyes. Common ways of contact are splashes, spray, or mist. Acids and caustics will severely burn your eyes. Degreasing chemicals, such as solvents, can damage your eyes in many ways depending on the type of solvent. Many processes and activities at work involve the handling or use of chemicals. Can you think of any? Anytime you handle, use, mix, or otherwise process chemicals creates potential exposure to the eyes. Appropriate protective eyewear can effectively prevent injury to the eyes. If you are working with any liquid chemical that could potentially splash onto your face and eyes, or that is misted or sprayed, you must wear chemical-resistant goggles, at a minimum. If working with dangerous chemicals such as acids or in situations with severe exposure, you must wear a face shield over the goggles. Ask trainees to name the chemicals and work processes used in their work areas that are potential eye hazards. Slide 8 Heat Hazard and Protection • Hazard—Steam, hot liquid, hot air, or flame cause pain, eyelid burns, and blurred vision • Work process • Furnace operations, pouring or casting molten metals • Any high-temperature operations • Wear eye protection such as a screen or reflective face shield © Blue Tuna Documentation Working with high temperatures can also be very damaging to the eyes. Steam, hot liquid, hot air, or flame cause pain, eyelid burns, and blurred vision. Some examples of work processes that create such hazards include: Operating a furnace or working with molten metals Any other high-temperature operations When working with hot molten metals that could potentially splash into your eyes, wear goggles with a face shield over the goggles. When working with high temperatures that do not pose a threat of splashing hot materials or flying hot sparks, such as working with a furnace, wear a protective screen or a reflective face shield that will keep the extreme heat away from your eyes. When working with hot sparks, safety glasses are sufficient. However, if exposure to hot sparks increases, goggles must be worn, and if the exposure becomes severe, a face shield must be worn over the goggles. If your facility has any potential heat exposure hazards, be sure to stress the importance of eye protection in these areas. Often, because the work is already hot, workers are reluctant to wear protective eyewear because it makes them even hotter. Slide 9 Welding Hazard and Protection • Hazard—Welder’s flash or flying sparks cause pain, extreme sensitivity, and burns • Work process • Walking unprotected near welding operation • Eye protection • Welder’s face shield • Sunglasses inadequate © Blue Tuna Documentation Welding, brazing, and torch cutting create a number of potential eye hazards. Welder’s flash occurs when the eyes are overexposed to the intense lights of welding operations. This often occurs when welders strike the arc a split second before dropping their face shield or hood over their eyes. The skin or eyes can be burned from the heat or intense light created when welding, brazing, or cutting. Flying sparks could enter and damage the eye. Metal fragments or slag could enter the eye, particularly when welding overhead. Work processes that can produce such hazards include: Welding operations, or walking past or observing welding operations, can cause eye injuries. Always use eye protection when welding A welder’s face shield is the best protection against the intense light from welding. Sunglasses are totally inadequate protection from welding light damage. Slide 10 Sunlight Hazard and Protection • Hazard—direct or reflected sunlight • Retinal burn, blurred vision, pain • Work process • Working outside on any job, working near water • Eye protection • Sunglasses and hat © Blue Tuna Documentation Exposure to direct or reflected sunlight can cause both temporary and permanent eye damage. Exposure can lead to retinal burns, blurred vision, pain, and total loss of eyesight. Work processes that leave a worker exposed to sunlight include: Working outside, especially around water where the sunlight is reflected into the eyes even when looking down Eye protection includes: Sunglasses and a hat Slide 11 Use Proper Protective Eyewear • 90% of occupational eye injuries could have been avoided with proper protective eyewear • Many injured workers believed protective eyewear was not necessary in their particular situation • Follow company rules for eye protection © Blue Tuna Documentation According to OSHA, 90% of occupational eye injuries could have been avoided with proper protective eyewear. Note the use of the word “proper.” Many injured people may have been using eyewear and thought they were adequately protected, but they were not. OSHA also found that many of the injured workers did not think that protective eyewear was necessary in their particular work situation. We want to make sure that all employees know when wearing eye protection is necessary and what type of eye protection should be worn for each potentially hazardous situation. Slide 12 Eyewear Standards • Comply with ANSI Z87.1 • Eye protection equipment will be marked with “Z87” • Sunglasses or prescription glasses usually do not meet the standard © Blue Tuna Documentation The American National Standards Institute has developed manufacturing standards for eye protection. Meeting this standard ensures that the eye protection equipment has met certain impact standards, shatter standards, and chemical-resistant standards. Look at your safety glasses, goggles, or face shield. They must be marked with “Z87” to indicate that they meet the ANSI standard. Normal sunglasses or prescription glasses will not meet this standard. These could potentially shatter or break if impacted by a flying object and cause additional eye injury. Slide 13 Choosing Eye Protection • Fit the protection equipment to the person • Ensure high-quality equipment is used • Ensure good fit and comfort • Lens options © Blue Tuna Documentation Choosing and selecting the right protective eyewear for the type of job and each particular person is very important. Protective eyewear must fit well to protect properly and be comfortable. Improper fit will not provide the required protection and if uncomfortable, employees will continually remove them to make adjustments, or not wear them at all. Once the type of protection (i.e., safety glasses, goggles, face shield) has been selected to protect against the identified hazard, you will want to find equipment that is appropriate to each person working with the identified hazard. Quality eyewear should be selected because it will last longer and protect better. Be sure your eyewear fits well and is comfortable. Without a good fit, the eyewear can’t protect you properly. Without comfort, the eyewear will inevitably be taken off. Lens options include antifog, antiglare, indoor/outdoor lenses, and different colors or shades. Your supervisor will choose the appropriate lens for each job. Consider having a selection of eyewear for employees to evaluate and try on. Some safety vendors will lend a selection of eyewear to try out.