PROCEDURE: BUILDING ENTRY Safety glasses with side shields

advertisement

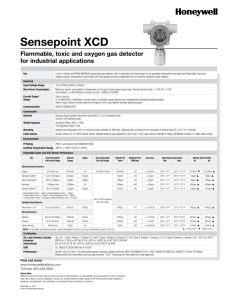

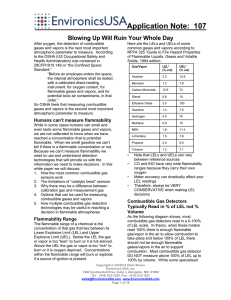

PROCEDURE: RISK RANKING: BUILDING ENTRY MEDIUM HAZARD ASSESSMENT: HAZARD 1. Flammable vapors / LEL. POTENTIAL EFFECTS CONTROL 1. Vapors may ignite 1. Personal or portable and cause flash fire. 2. Worker could 2. O2 deficiency. 3. Not performing the building entry procedure. experience oxygen deprivation and become unconscious. 3. Possibility of coming into contact with hazardous product. monitor to be used to determine if flammable vapors or LEL are present. 2. Personal or portable monitor to be used to determine if 02 levels are at acceptable limits. 3. Post warning sign or this procedure at entrance to buildings not equipped with fixed H2S or LEL detection. SAFETY EQUIPMENT: Safety glasses with side shields, hard hat, steel toe boots, FR clothing, personal H2S monitor or 4-way monitor, communication (cell/radio), SCBA or SABA (if required). PROCEDURE: 1. Prior to entering location, ensure ALL personal protective equipment is being worn and is applicable to the hazards and atmosphere in which you are working. 2. When arriving to location, check wind direction. If possible, park up wind at least 25 meters (80 ft) from the building. 3. Ensure the portable monitor calibration is current and the unit is in the “ON” position. 4. Approach building slowly. Look and listen for irregularities (i.e. vent lines hissing.) PROCEDURE: BUILDING ENTRY ‐ 1 ‐ Date of Preparation: June 29, 2004 Date of Revision: June 29, 2004 PROCEDURE: BUILDING ENTRY 5. If operator does not notice anything out of the ordinary, stand clear of and slowly open the building door (B.C. open the door porthole), then insert the monitor to the inside of the building for 30 seconds, (if monitor alarms, leave to gas free area). Go to step # 8. 6. If no alarm sounds after 30 seconds has elapsed, check monitor for acceptable limits (Maximum concentration for H2S is 10 PPM). (Maximum concentration for explosive gas is 20% LEL). (Minimum Oxygen deficiency level is 19.5% 02). 7. If no hazardous condition exists, carry on with normal daily routine. 8. Should personal monitor reach any of the alarm points. .immediately vacate the building. 10 PPM H2S and >, leave area, notify back-up personnel and don SCBA. Go to building and check again for H2S (if > 100 PPM,summon standby person). lif >10% LEL, leave area with doors/windows open, recheck concentration, determine source and isolate if < 19.5% 02 entry to building is permitted only with SABA or SCBA breathing equipment worn Back up man to be present under these circumstances. . . - 9. Once standby person arrives, together don SCBA and one operator can go into building and determine cause of gas concentration, while other operator watches from safe distance. 10.Once leak is determined, rectify problem, confirm the acceptable limits in the building and carry on with normal daily routine. 11.Operator is to perform pre-entry testing every time they enter a building that has the possibility of presenting them to exposure of a hazardous product / gas, and must document the pre-entry findings at a minimum of once per month and should be able to make those findings available upon request. This information must then be kept on file. Failure to comply with this section of the procedure could result in fines levied against Haltech Testing Inc. should the WCB / OH&S check on an operator. Buildings with fixed gas and fire detection do not apply. PROCEDURE: BUILDING ENTRY ‐ 2 ‐ Date of Preparation: June 29, 2004 Date of Revision: June 29, 2004