Chipless RFID pH Sensor for Food

Spoilage Monitoring

ECE 4600 – Group Design Project Proposal

Group #5

John Baldwin

Marvin Bataller

Christian Espino

Project Supervisor:

Dr. G. Bridges

Date of Submittal:

October 1, 2012

1. INTRODUCTION

Food quality is an important manufacturing requirement for consumer health and safety.

Current methods to monitor the quality of food during the transit and storage process are to use

temperature sensors, enzyme sensors, or gas sensors. Such sensors, however, have significant

drawbacks, which include low sensing accuracy in moist environments, high operating

temperatures, complicated fabrication processes, and several design constraints which prohibit a

wireless integration [1]. These factors reduce the cost-effectiveness and feasibility of their use in

commercial applications.

An alternative technique used to manage food quality is to monitor the change of pH

levels of the product. pH is essentially the measurement of the hydrogen ion concentration and is

usually expressed in the logarithmic scale [2]. A pH sensor commonly consists of two electrodes

which provide a linear potential response over a wide range of pH values [3]. During the food

spoilage process, the pH profile changes due to the growth and metabolic actions of microbes [1].

The pH level can therefore provide an accurate indication of the freshness of the product.

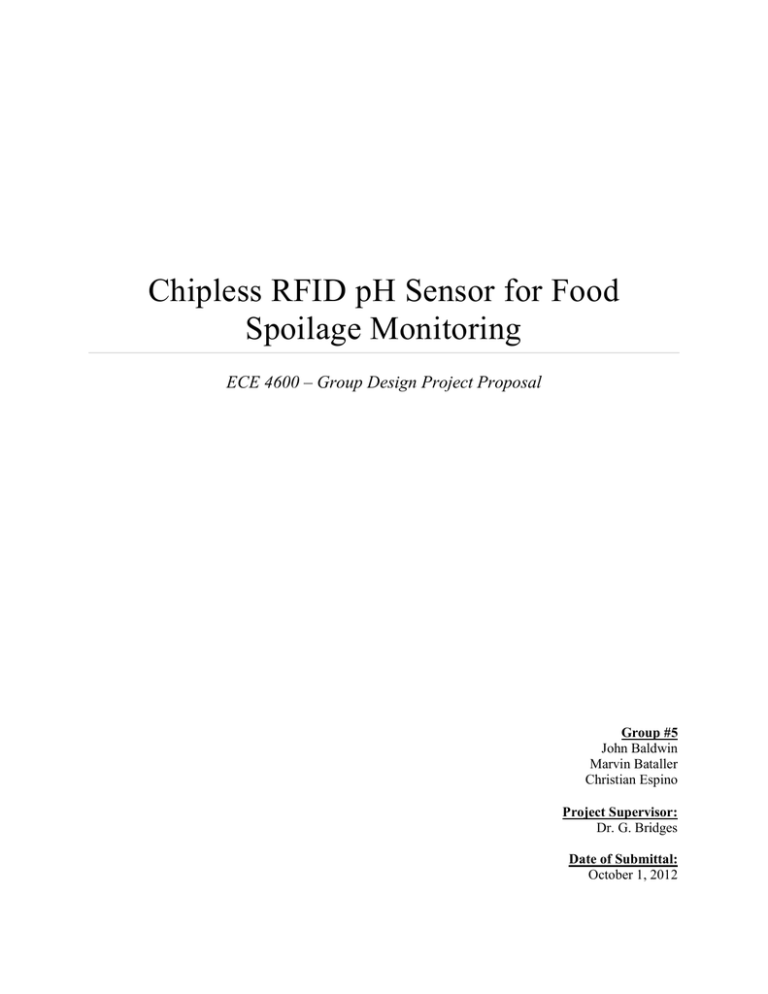

The objective of this project is to design and fabricate a pH sensing device which can be

embedded into packaged material. The device will have three main components, which will

include the pH detector, two resonator circuits, and the transceiver. Furthermore, the device will

also be magnetically coupled to an external source, where the resonant frequency of one of the

resonator circuits will be proportional to the pH of the material. The change of pH will vary the

potential across a set of electrodes integrated into the resonator circuit. The response of the

device will be measured by a network analyzer. Furthermore, existing Radio Frequency

Identification (RFID) concepts will be incorporated into the design for a wireless passive device

approach. This passive wireless design will be an efficient method of measuring food quality as

it can be embedded directly into packaged materials.

1

2. SPECIFICATIONS

The pH sensing device will operate in a 4-7 pH range environment and have a ± 0.3 pH

accuracy. To determine the accuracy, the output of the sensor will be compared to a commercial

pH sensor. The device will also operate in a high moisture environment in an ambient

temperature between 2 – 30 °C. Since this device will be designed to be embedded into packaged

materials such as 2L carton of milk, the maximum length, width, and thickness will be 15.0cm,

10.0cm, and 0.250cm respectively. The device will be comprised of a pH detector, two resonator

circuits, and a transceiver as shown in figure 1.

The pH detector will use an iridium oxide electrode in tandem with a silver chloride

reference electrode. The hydrogen ion concentration will induce a change in voltage across the

electrodes of approximately 60mV/pH [3]. The induced voltage will be used to bias a variable

capacitor, also known as a varactor, which will be integrated into the resonator component.

The resonator component will consist of a reference and sensing circuit, and will each be

modelled as an RLC circuit shown in figure 2. The resonant frequency of an RLC circuit can be

calculated by

where

is the resonant frequency in Radians/Second, L is the

inductance in Henrys, and C is the capacitance in Farads. Both the reference and sensing circuits

will be designed to resonate at a frequency of approximately 2.4 GHz. The sensing resonator,

however, will have a varactor integrated into the circuit which will vary the resonant frequency

by approximately ± 0.1 GHz. To achieve the highest sensitivity in the change of reverse bias

voltage across the varactor, a characteristic capacitance curve slope that is greatest between 100

to 500 mV will be selected.

The transceiver will be comprised of two antennas which will be required to handle the

reception and transmission of a frequency sweep in the 2 to 3 GHz range. The antenna will be

designed to be cross-polarized to minimize the interference between the input and output signals.

Circular disk monopole antennas will be used in the design due to large bandwidth requirements

and its simplistic design [4]. The transmitted signal of the pH sensor will be designed to be

distinguishable at a distance of at least 5cm.

The specifications of the device are summarized in Table 1 on the following page.

.

2

Table 1: Specifications

SPECIFICATIONS

pH Operating Range

4 – 7 pH

pH Sensing Accuracy

± 0.3 pH

Operating Environment

High Moisture

Operating Temperature

2 – 30 °C

Maximum Device Dimensions:

Length

15.0 cm

Width

10.0 cm

Thickness

0.250 cm

Reference Resonator

Fixed Frequency at 2.4 GHz

Sensing Resonator

Variable Frequency at 2.4 ± 0.100 GHz

Voltage Sensitivity Range

100 to 500 mV

Antennas

2 UWB Circular Monopole @2-3GHz Cross Polarized

Minimum Interrogation Distance

5.0 cm

Fluid Proximity Distance to Tag

0.2 cm

Rx

Tx

E-field

Network

Analyzer

Resonator

Circuit

RLC

Model

Rx

Tx

Electrodes

E-field

Figure 2: RLC Model of the

Resonator with Variable

Capacitor and Electrodes

Figure 1: Operating Principle of the

Chipless RFID System

3

3. TASKS AND MILESTONES

Table 2 shows the milestones and the tasks to complete this project, as well as how the

work will be distributed among each group member. The timeline for each task is indicated in the

Gantt chart on the following page.

Table 2. Milestones, Tasks, and Division of Work

MILESTONES AND TASKS

ASSIGNED INDIVIDUAL(S)

1. Preliminary Work

Research Chipless RFID

Research pH Sensing

Ansoft Programming Review

Christian, John, Marvin

Christian, John, Marvin

Christian, John, Marvin

2. Materials

Gather Materials List and Pricing

Order Materials

Christian, John

Marvin

3. Replicate Existing Chipless RFID Systems

Simulate System in Ansoft

Build Chipless RFID System

Test Chipless RFID System

John, Marvin

Christian, John

Christian, John, Marvin

4. Simulate and Design Chipless pH Sensor

pH Sensing Circuit

Transceiver

Resonators

Build Chipless pH Sensor

Christian

Marvin

John

Christian, John, Marvin

5. Testing and Optimization

Monitor pH of Milk

Optimize Design

Christian, Marvin

John, Marvin

6. Administrative Work

Project Proposal

Informal Oral Progress Report

Formal Written Progress Report

Formal Oral Progress Report

Project Title

Final Report

Project Presentation

Christian, John, Marvin

Christian, John, Marvin

Christian, John, Marvin

Christian, John, Marvin

Christian, John, Marvin

Christian, John, Marvin

Christian, John, Marvin

4

4. GANTT CHART

5

5. BUDGET

The materials and cost required for this project is shown in Table 2. The total cost of the

project is estimated to be $510.57.

Table 2: Budget

ITEM

UNIT

UNIT

COST

TOTAL

COST

1.

Varactor – BB152-115 NXP

5

0.50

$2.50

2.

Rogers RT/Duroid 5880 Glass Microfiber Reinforced

1

$216.09

$216.09

1

$162.00

$162.00

1

$60.00

$60.00

PTFE Composite Material (.062”x12”x18”)

3.

Iridium Oxide Wire - 99.8% Metal Basis

(5cm length x 0.5mm dia.)

4.

Silver Oxide Wire – 99.9% Metal Basis

(1m length x 1.0mm dia.)

5.

SMA Jack Flange Mount to PCB

2

$22.41

$22.41

6.

2% Milk (2L)

1

$2.57

$2.57

7.

ADSV 2.2 Software 1

1

$0.00

$0.00

8.

HFSS Software 1

1

$0.00

$0.00

9.

Network Analyzer - HP 8753E 1

1

$0.00

$0.00

10. Impedance Analyzer - HP Agilent 4290A 1

1

$0.00

$0.00

11. Commercial pH Sensor – Exstik II 1

1

$0.00

$0.00

12. Estimated Shipping and Brokerage Fees

-

1

-

$45.00

Provided by the Electrical and Computer Engineering

Department

GRAND

TOTAL:

6

$510.57

6. REFERENCES

[1] W. Huang, S. Deb, Y. Seo, S. Rao, M. Chiao, J.C. Chiao. “A Passive Radio-Frequency pHSensing Tag for Wireless Food-Quality Monitoring”. IEEE Sensors Journal. Vol. 12, pp.

487-495. March 2012.

[2] R. Petrucci, W. Hardwood, F. Herring, J. Madura. General Chemistry. Upper Saddle River,

New Jersey: Pearson Prentice Hall, 2007, pp. 670.

[3] S. Bhadra. “Electrode Potential-Based Coupled Coil Sensor for Remote pH Monitoring”,

IEEE Sensors Journal. Vol. 11, pp. 2813-2819. November 2011.

[4] S. Preradovic and N. Karmakar. “Chipless Millimeter Wave Identification (MMID) Tag at

30 GHz,” in Microwave Conference (EuMC), 2011, pp. 123-126.

7