Benefits CSL541 | Silicone Conformal Coating

advertisement

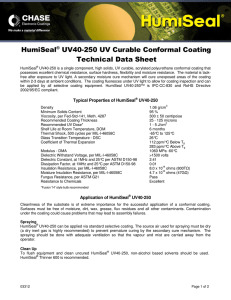

530 | Anti-Graffiti Protective Coating CSL541Si-COAT Conformal Coating | Silicone Conformal Coating Due to the decrease in size of printed circuit boards (PCBs) and increase in packing density, there is a greater risk of shorts, corrosion of conductors and solder joints, dendritic growth and electro migration of metal between conductors. Conformal coatings or thin polymeric films which “conform” to the surface of the printed circuit board (PCB) can improve the long term reliability of the assembly. A conformal coating acts as an electrical insulator. It protects the electronic circuits from the environment including moisture ingress and contaminants such as airborne dust which could lead to corrosive effects and shorts. In addition, the use of conformal coatings protects circuits and components from abrasion and solvents. Stress relief is also provided for the circuit board. Benefits •Resists moisture, vibration, and temperature extremes Why do silicones excel in Conformal Coating applications? Silicone elastomers physical properties that make them ideal conformal coatings include: • easy to use and repair • excellent electrical properties • flexibility, mechanical shock and vibration absorption • resistance to ultra-violet rays, ozone, and weathering • resistance to humidity, moisture, and water repellency • excellent thermal stability •Electrically insulating •UV stable •Non-corrosive •Processing versatility •Easy repairability CSL541 100% Silicone Conformal Coating CSL541 is a one part, moisture cure, room-temperature vulcanizing (RTV) electronic grade 100% silicone conformal coating. CSL541 is designed for use in corrosion-sensitive electronic equipment with no adverse effects. CSL541 remains flexible from -40°C to 200°C (-40°F to 392°F). CSL541 is recognized under the Components Program of Underwriters Laboratories Inc.® CSL541 is primarily used in applications where a conformal coating is required to protect sensitive circuitry. CSL541 can be applied by dipping, spraying or simple flow coating, as well as robotic dispensing. … CSL541 Product Characteristics www.cslsilicones.com 530 | Anti-Graffiti Protective Coating CSL541Si-COAT Conformal Coating | Silicone CSL541 Intended Uses Typical CSL541 coating is a 100% silicone formulation particularly useful for protecting circuitry in severe service environments, while maintaining a low stress environment for components and connections. These severe conditions range from every day temperature and humidity extremes seen in consumer electronics, to the harsher automotive engine compartment applications and the extremes demanded in military or industrial applications. Applications CSL541 Typical Properties‡ • Printed Circuit Board manufacturing Cure System One part RTV/Oxime • General EMS Viscosity [cP] • Electrical assembly Skin Over Time at Standard Conditions2 [min] Flowability Pourable Liquid 4000 20 Cure Time at Standard Conditions - 10mil [hours] 1 1 Features • Recognized under the Components Program of Underwriters Laboratories Inc.® • Neutral cure formulation will not corrode copper, brass or silver • Excellent hydrophobicity • Can be applied by spray, flow and brush techniques 15 Shore A Hardness2 ASTM D2240 [points] Dielectric Strength2 ASTM D149 [V/mil] 720.1 (283.5 kV/cm) Volume Resisitivity ASTM D257 [ohm.cm] 2 >1.4 x 1012 ‡Data is subject to change without notice. These values are not intended for use in preparing specifications. For more complete information, please refer to the current Technical Data Sheets for these products. NOTES 1 Standard Conditions are 25°C (77°F) and 50% relative humidity 2 Cured for 7 days at Standard Conditions1 CSL541 Availability Colors¥ Clear 000 ¥The color chips are only representations of actual colors and should not be considered an exact color match to finished product. CSL541 is available in clear. Custom colors may be available upon request. Complementary Formulations Alternate viscosity formulations are also available. Packaging CSL541 is available in 3.8L (1 US gallon) cans, 19L (5 US gallon) pails and 189L (50 US gallon) drums. Shelf Life and Storage CSL Silicones Inc. 144 Woodlawn Rd. W. Guelph, ON Canada N1H 1B5 +1 519.836.9044 +1 800.265.2753 www.cslsilicones.com CSL541 has a shelf life of twelve months from date of manufacture when stored in the original unopened container in dry, shaded conditions, away from sources of heat or ignition, and stored at or below 90°F (32°C).