infranor polaris-6

advertisement

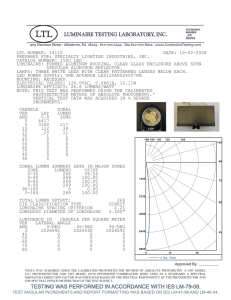

Infranor™ Polaris-6 Polaris, or the pole star, lies less than one degree from the north celestial pole and has served as a stellar beacon leading explorers and navigators to their destination since the beginning of time. Similarly, Infranor has been, and continues to be, a leader in the manufacture of performance floodlighting products and the Infranor Polaris-6 continues this leadership by offering proven reflector technologies in a new architectural shape. Infranor is synonymous with quality and performance and the Infranor Polaris-6 luminaire is no exception. It was developed to exceed market demands for superior performance, precise beam control, and energy efficiency. It is an outstanding choice for all landscape, sign and facade lighting installations. Like all Infranor products, the Polaris-6 boasts a wide variety of precision rectangular beam patterns to fit all of the rectangular elements of our world. No other company has developed as wide an array of precision optical systems to eliminate the shadows left by conventional floodlighting products. Every Infranor Polaris-6 precision flood luminaire meets or exceeds the stringent requirements set forth by UL for wet location use and carries both the UL and ULc labels. All luminaires are fully tested prior to shipment and backed by the protection of a full Sterner/Infranor warranty. Sterner Lighting, through its exclusive Infranor brand, has been manufacturing premier and custom floodlighting products for over 35 years. Infranor is recognized worldwide as the leader and innovator in floodlighting products. The Polaris-6 series continues this time-honored tradition. Table of Contents: Features and Benefits . . Luminaire Construction. Mounting Options . . . . Ordering Matrix . . . . . Ordering Matrix . . . . . Luminaire Specifications Luminaire Beam Patterns Photometry . . . . . . . Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 6 7 8 9 10 11 14 18 2 3 F e at u r e s a n d B e n e f i t s DESIGN FORM An aesthetically pleasing shape helps to accentuate the surrounding architecture and makes this product ideal for landscape, sign, and facade lighting. Our precision die-cast methods allow for sharp distinctive lines and eliminate the need for most external fasteners. The compact design (16.12" W x 9.44" H x 6.37" D) includes integral heat sink fins for cooler operation and longer component life and will operate lamps up to 175W. MOUNTING Heavy Duty Swivel: As a standard feature the Polaris-6 includes the most robust, diecast swivel available in the market today. Regardless of mounting scheme, the innovative swivel design allows for infinite fixture adjustment throughout its aiming angles assuring a clean precise lighting design. Further, the heavy duty swivel contains an oversize wiring compartment for easy installation and eliminates the need for an additional junction box. The Polaris-6 can be conveniently mounted to walls, post tops, base pads, or stanchions. 90˚ 130˚ Swivel (Shown with optional base pad) Fixture Aiming Range Yoke: 95˚ Also available as a yoke mount, the Polaris-6 can be conveniently mounted to walls, base plates or slip fitters (horizontal or vertical). See page 7 for mounting options. 145˚ Yoke mount luminaire shipped with cord connector and 3' of 16/3 STO-W cord. YOKE 4 Fixture Aiming Range R E C TA N G U L A R B E A M PAT T E R N S For over 35 years, Infranor’s precision rectangular beam patterns have been the choice to illuminate prestigious architecture. Although the Polaris-6 is a new architectual shape, the luminaire utilizes Infranor’s time proven reflector technology. Specifiers may select from eight rectangular beam patterns that provide the highest degree of uniformity on the targeted surface, while minimizing spill light into adjacent properties and the night sky. Further, the efficiencies of rectangular beam patterns often allow for a reduction in the total number of luminaires needed. The optical assembly is manufactured as a unitized body and can be quickly interchanged with other beam patterns to adapt to field conditions. Infranor Rectangular Beam Pattern Typical Round Beam Pattern SEALED SYSTEM Unlike most systems that utilize a two-fastener hinging method, the Infranor Polaris-6 has a die-cast doorframe that attaches securely with four (4) recessed and self-retained stainless steel fasteners. This ensures that the doorframe retains its shape and exerts uniform pressure on the gasket maintaining a watertight seal in all aiming directions. Silicone O-Ring Sealing Gasket (4) #10 Self-Retained Stainless Steel doorframe screws sponge silicone O-ring gasket Sterner engineers have developed a unique gasket system for use in the Polaris-6. As the doorframe presses against the housing, two separate surfaces compress the gasket forming a dual watertight seal against outside contaminants. DIE-CAST housing ACCESSORIES A special reveal has been engineered directly into the doorframe and accepts all door-mounted accessories. This unique design eliminates any chance of light leaks. The doorframe may be removed for maintenance without detaching the shields. See order matrix on pages 8 and 9. four-sided shield Top Shield multi-louver shield Polycarbonate stone guard 5 Barn Door Shield Luminaire construction tempered glass lens Reveal for Mounting options Four self-retained, stainless steel Screws provide Factory secure attachment INstalled Lamp eliminating doorframe distortion and entry of contaminants Quick Disconnect One-Piece Die-Cast Aluminum Housing Optical Assembly Quick Access to Ballast Compartment integral Ballast Easy Access Wire Entrance For Wiring Sealed at Factory Heavy Duty Swivel lamp Options The Polaris-6 accepts both High Pressure Sodium (HPS) and Metal Halide (MH) compact medium base H.I.D. lamps with a maximum wattage of 250W. (250W requires remote ballast box.) HPS lamps are ideal for applications where maximum efficacy and lamp life are required. Metal halide lamps are ideal where “white light” and good color rendering are essential. 6 mounting options Listed below are the heavy duty swivel and yoke mount options — steel construction. Please consult the factory for other mounting options. SWIVEL MOUNT OPTIONS Base Pad Mount: WAll arm Mount: 2.0" IPS Tenon 2.0" IPS Tenon 9 /16" Dia. Holes on 6.0" circle 8.0" SQ. 16.0" 6.25" 7/ 16" Dia. Holes on 6.0" square 4.0" 6.0" SQ. 2.06" Dia. Hole WM PD Dual Post Top Mount: Stanchion Mount: 2.0" IPS Tenon 115˚ 2.0" IPS Tenon 24.0" 40˚ 21.75" 4.0" Fits 2.0" IPS DP 4.5" SQ. ST Fixture Aiming Range with wall arm mount YOKE MOUNT OPTIONS Yoke mount luminaire shipped with cord connector and 3' of 16/3 STO-W cord. Slip Fitter: BAse Plate Mount: 9/ 16" Dia. Holes on 6.0" circle 3/ " 4 3.0" Bolt 3 /4" Bolt 5.83" 3.0" 6.0" SQ SF BP Wall Bracket: 75˚ 8.0" 120˚ 4.06" 3/ 4" 1/ 2" Dia. Holes on 5.0" circle Bolt Fixture Aiming Range with wall bracket WB 7 Fits 2.0" IPS INFRANOR POLARIS-6 ORDERING SEQUENCE Item Sequence: ORDER NUMBER: 1 2 HOUSING LAMP WATTAGE PL6 3 BEAM PATTERN 70MH 100MH 150MH 175MH 250MH 1, 2, 7 SP 2 RN RM RW HPN 3 HPM 2 HPW 2 100HPS 3 150HPS 3 Notes: 1) 2) 3) 4) 4 5 6 7 8 9 10 VOLTAGE BALLAST MODEL STYLE MOUNTING OPTIONS SHIELD OPTIONS GENERAL OPTIONS FINISH 120 208 240 277 347 C SW YK4 FL SC 4 PCL 7 BK BZ WH AL BP SF WB TS 4S EC BD SG 6 N (swivel only) (yoke only) N '250MH' only available with remote ballast. '250MH' not availble in 'SP', 'HPM', 'HPW', and 'BI' distributions. 'HPN' distribution only available in '100HPS' & '150HPS'. 'SC' is only available with the yoke 'YK' version. 1. HOUSING PD WM DP 5 ST 5) 6) 7) 8) N NS 8 'DP' option automatically doubles the fixture quantity unless otherwise specified. 'SG' not available with 'EC'. 'PCL' option not available with '250MH' remote box version. Please supply metal color chip or supply RAL# for any 'NS' finish. 2. LAMP WATTAGE HALIDE (70MH) (100MH) (150MH) (175MH) (250MH)* (PL6) SODIUM (100HPS) (150HPS) ED17 ED17 ED17 ED17 ED28 B17 B17 (* '250MH' only available with remote ballast.) (* '250MH' not available with 'SP', 'HPM', 'HPW', 'BI', & 'PCL' options.) 3. BEAM PATTERN (SP)* (RN) (HPM)* (HPW)* (RM) (HPN)** (RW) (* 'SP', 'HPM', 'HPW', & 'BI' not available in '250MH'.) (** 'HPN' only available in 'HPS'.) (SP=spot, BI=bi-polar, R=rectangular,HP=high-point, N=narrow, M=medium, W=wide.) 5. BALLAST 4. VOLTAGE (120) (240) (208) (277) (347) (C)* Core & Coil (* Core & coil ballast is high-power factor and rated for -20°F (-28.9°C).) (*’250MH’ uses remote ballast box.) 6. MODEL STYLE (YK) Yoke (SW) Swivel 10.07" 6.34" 16.12" 9.44" 9.44" 14.75" Fits 2.00" pipe (2.38 O.D.) EPA: 1.47 9.45" 6.34" 16.12" 10.23" 0.81" for 3/4" mounting bolt by others WT: 25 LBS. EPA: 1.47 8 WT: 23 LBS. 2.00" PL6 7. SWIVEL MoUNTING OPTIONS (PD) (DP) (ST) Stanchion Mount Base Pad (Anchors supplied by others.) 0.56” (4) 2.06” I.D. (’DP’ option automatically doubles the fixture quantity unless otherwise specified.) Dual Post-Top Mount (Anchors supplied by others.) 2.00” IPS tenon 6.00” dia bolt circle 0.44” (4) 28.12” 24.00” 21.75” 4.50” 16.00” All components steel welded construction 4.00” All components steel welded construction (For concrete pour) (2.00” sch. 40 steel pipe) 4.00” 2.00" IPS tenon (2) 4.50” 6.00” 14.38” 3.00” 2.00” IPS tenon 2.38” O.D. (WM) Wall Mount 11.00” All components steel welded construction 8.00” 6.00” 6.00” 4.00” 8.00” Fits 2.00” IPS 6.25” 0.25” (N) Not Required All components steel welded construction 7. YOKE MoUNTING OPTIONS (BP) Base Plate (WB) Wall Bracket (Anchors supplied by others.) (Anchors supplied by others.) 0.56” (4) 6.00" dia. bolt circle 1.81” 1.16” (SF) Slip Fitter 3.44” Can be mounted to 2.00" pipe (max) with U-bolts (U-bolts by others). 3/8” locking bolt 3.13” 3/4" mounting hardware 3.00” 1.38” 3.50” 5/8" pivot bolt 5.63” Cast ductile iron wall bracket and horizontal sector 0.38” Cast ductile iron surface base 0.56" (4) 3.50” 4.50” 1.50” 3/4" mounting hardware Removable pipe plug for installing water-tite connector (supplied) 3/4" mounting hardware 1.50” 6.00” To fit 2.00" (2.38"O.D.) pipe tenon x 4.00" long (min.) Removable splice inspection cover Cast tenzalloy fitter 8.00” 5.50” 1/2"set screws Water-tite Connector Removable hole plug for sideyoke mounting (N) Not Required 8. SHIELD OPTIONS (TS) Top Shield (Standard shield finish is black unless otherwise specified.) 15.79" 4.25" (EC) Egg Crate 8.12" 15.79" 4.25" 8.12" (BD) Barn Door 15.79" 4.25" 8.12" (SG)* Polycarbonate Stone Guard 15.79" (4S) Four Sided (N) Not Required 6.56" 1.94" 8.12" (*’SG’ not available with ‘EC’.) 9. GENERAL OPTIONS (FL) Fuse Luminaire (PCL)* Eye Dot Photocell (SC) Safety Cable (N) Not Required (* 'PCL' not available in '250MH'.) 10. FINISH (BK) Black (BZ) (AL) Natural Aluminum (NS)* Non-Standard Dark Bronze 9 (WH) White (*Please supply metal color chip or supply RAL# for any ‘NS’ finish.) INFRANOR POLARIS-6 FIXTURE DIMENSIONS & details SWIVEL YOKE EPA: FIXTURE WEIGHT: 16.12" EPA: FIXTURE WEIGHT: 1.47 25 LBS. 10.07" 6.34" 16.12" 9.44" 1.47 23 LBS. 9.45" 6.34" 9.44" 14.75" 10.23" Fits 2.00" pipe (2.38" O.D.) 0.81" for 3/4" mounting bolt (supplied by others) 15.00" 14.50" 6.62" Remote ballast box detail (250MH only) 5.60" 2.00" 4.00" (4) clearance holes for 3/8" anchors (supplied by others) 15.75" INFRANOR POLARIS-6 WRITTEN SPECIFICATIONS HOUSING The luminaire housing shall be one-piece die-cast aluminum with integral cooling fins for heat dissipation. The perimeter of the casting shall incorporate a channel designed to retain a silicone O-ring gasket, providing a compression seal to the doorframe assembly. The luminaire housing, including the wire entrance, shall be completely sealed from the outside environment. LENS & DOORFRAME The luminaire lens shall be clear tempered glass, 0.188" thick, thermal and impact resistant. Lens shall be set into a die-cast aluminum doorframe, gasketed and retained by four continuous galvanized steel clips around the lens perimeter for uniform pressure and watertight seal. Doorframe shall be one-piece die-cast aluminum and secured to the housing with four #10 recesessd and self-retained stainless steel screws. The exterior shall contain four cored holes for securing external shielding accessories. The inner perimeter of the door casting shall incorporate a cchannel, designed to compress the O-ring gasket in the housing at two points, providing a “dual seal” to prevent the entrance of contaminants and moisture. HEAVY DUTY SWIVEL The swivel shall be a two-piece die-cast aluminum assembly, designed to mount directly to a 2" pipe tenon (2.38" O.D.). Swivel shall incorporate two access panels in the side for wire access to the cULus recognized splice compartment. Swivel shall mount to the luminaire housing with two diecast hubs for additional mounting support and locking capability to withstand the toughest of environmental conditions and shall allow for infinite aiming positions within its aiming range. YOKE The luminaire yoke shall be of formed aluminum 0.25" thick and 2.00" wide. Yoke shall allow for infinite aiming positions within its aiming range. Yoke version shall be equipped with a watertight connector and 3' of 16/3 STO-W cord. REFLECTOR The luminaire reflector module shall be of a high purity anodized or patterned specular aluminum in a choice of forms to provide a wide selection of constricted, rectangular, high-proportioned beam patterns. All reflector units (spot to be spun aluminum) shall be backed by an aluminum extrusion for stability and repeatability of distribution. ELECTRICAL MODULE Luminaire shall be cULus listed for use in wet locations and manufactured from UL recognized electrical components. Electrical assembly is easily accessible through the reflector module. Each high power factor ballast is capable of starting temperatures down to -20°F (-28.9°C) and shall be CWA. The socket shall be a mogul-based porcelain socket with a 4KV rating. LAMP Luminaire shall accept the following lamps: 70MH, 100MH, 150MH, 175MH, 250MH, (remote, ED28) ED17 100HPS, 150HPS B17 To obtain the highest level of lighting quality, it is recommended to replace lamps before reaching predicted lamp life per manufacturer’s and IES guidelines. It is also recommended to group re-lamp to maintain uniformity and performance. REMOTE MOUNTED BALLAST BOX (250MH) Ballast shall be housed in a cast aluminum housing with heat dissipating fins and supplied with (2) watertight connectors. Ballast box shall have a cast aluminum cover and is secured with (6) plated steel fasteners. Ballast shall be capable of mounting at a distance of 200 ft. (based on 10-gauge wire and 1% voltage drop). The cast aluminum alloy shall contain less than 2/10 of 1% copper for resistance to corrosion including marine applications. FINISH Finished parts are washed in a multistage phosphate processing system and finished with a polyester urethane powder coat paint. Standard colors are dark bronze, black, white, and natural aluminum. Contact factory for nonstandard colors. In the interest of continuous product improvement, Sterner Lighting reserves the right to change specifications without notice. Lamp and electrical specifications/availability subject to change by manufacturer without notice. 10 Luminaire bea m patterns lamp beam M Ax C D beam angle 50% field angle 10% pat t e r n Va lu e s m ax c d ( I n D e g r e e s ) m ax c d ( I n D e g r e e s ) ies type V xH V xH V xH 100W MH SP 98,880 06x14 13x21 1x2 ED-17 RN 11,240 12x81 60x107 4x6 100W lamp rated RM 6,790 24x81 128x115 6x6 9,000 lumens RW 3,160 59x96 133x144 7x7 HPM 4,800 41x85 420x138 6x7 HPW 3,010 86x90 125x146 6x7 150W MH SP 107,700 06x14 15x24 1x2 Rated 11,500 lumens RN 13,900 12x92 36x108 2x6 RM 9,200 20x82 114x108 6x6 RW 4,490 47x92 125x141 6x7 HPM 5,420 48x84 122x139 6x7 HPW 3,210 110x97 132x146 6x7 175W MH SP 109,440 05x17 14x26 1x2 ED-17 RN 17,481 12x81 60x107 4x6 Rated 14,000 lumens RM 10,566 24x81 128x115 6x6 RW 4,920 59x96 133x144 7x7 HPM 5,772 54x89 124x143 6x7 HPW 3,809 99x109 128x151 6x7 250W MH RN 25,851 09x81 49x108 4x6 ED-28 RM 12,239 27x83 117x120 6x6 Rated 20,000 lumens RW 6,383 57x93 125x139 6x7 150W HPS SP 71,640 09x26 14x45 1x3 ED-17, BD-17 RN 29,535 08x75 24x98 2x5 RM 15,003 22x76 115x104 6x6 For 100W HPS max RW 6,333 49x85 126x139 6x7 candela, multiply HPN 8,992 36x82 122x138 6x7 values by 0.5938 HPM 6,306 59x96 125x145 6x7 HPW 4,629 99x90 128x148 6x7 For 70W MH max candela multiply values by 0.6111 11 l i g h t i n g i l l u s t r at i o n s SIGNAGE Good sign lighting design is accomplished by minimizing spill light while maximizing uniformity. Luminaires should be unobtrusive and easy to maintain. The Infranor Polaris-6 product, with its rectangular beam pattern, is the ideal luminaire for meeting these requirements for signs of all sizes. This application uses one RM beam pattern to highlight the wording and provide an even illumination over the surface of the sign. FOLIAGE Foliage illumination is typically used to create drama and highlight the color of the foliage. The Infranor Polaris-6 luminaire, with its wide array of available distributions, provides a solution to all foliage lighting applications and is constructed of materials that can endure the elements present in a harsh environment. Additionally, the Polaris-6 is a completely sealed system that keeps out any contaminants. This application uses the HPW beam pattern to provide depth to the foliage and to highlight the body of the trees. 12 BUILDING FAC ADES Building and facade lighting can be used to create patterns of illumination, to provide a uniform wash of the facade, or to highlight sculptures and other architectural features. The plethora of beam patterns available with the Polaris-6 product addresses the variety of installation challenges and provides solutions to all architectural lighting needs. This application uses the RN reflector option at a short setback to highlight the building facade. FL AGPOLE AND MONUMENT LIGHTING Flagpole and monument lighting should provide an efficient and uniform solution that minimizes the excessive spill light into the nighttime sky. The Polaris-6, with its excellent beam control, is ideal for this type of lighting design. This application uses two SP beam patterns and locates the luminaire at a short setback to make the cross glow from top to bottom while emphasizing the cross arm. 13 photometric Distribution: 175W MH L a mp I n f r a NOR S P Values based on 14,000 initial lumens. ITL Report #36824.IES V E RT I C A L D E G R E E S 18 CANDELAS 12 109440 10% MAX CANDELA 82080 6 54720 0 27360 50% MAX CANDELA -90˚ -6 90˚ H O R I Z O N TA L D I S T R I B U T I O N -12 -18 -18 -12 -6 I n f r a NOR R N 0 6 12 18 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s ITL Report #35456 V E RT I C A L D E G R E E S 90 CANDELAS 60 17481 10 % M A X C A N D E L A 13110.79 30 8740.3 0 4370.21 50% MAX CANDELA -90˚ -30 90˚ H O R I Z O N TA L D I S T R I B U T I O N -60 -90 -90 -60 -30 I n f r a NOR R M 0 30 60 90 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s ITL Report #35457 V E RT I C A L D E G R E E S 90 CANDELAS 60 10 5 6 6 10 % M A X C A N D E L A 7924.7 30 5283 0 2641.5 50% MAX CANDELA -90˚ -30 90˚ H O R I Z O N TA L D I S T R I B U T I O N -60 -90 -90 -60 -30 I n f r a NOR R W 0 30 60 90 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s ITL Report #35577 V E RT I C A L D E G R E E S 90 CANDELAS 60 4920 10% MAX CANDELA 3689.8 30 2460 0 1230 50% MAX CANDELA -90˚ -30 H O R I Z O N TA L D I S T R I B U T I O N -60 -90 -90 -60 -30 90˚ 0 30 60 90 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s Photometric distributions illustrated above are based on a 175W MH lamp. For other lamping options, please consult the applications department at Sterner Lighting. 14 I n f r a NOR HPM ITL Report #36818 V E RT I C A L D E G R E E S 90 CANDELAS 60 5772 10 % M A X C A N D E L A 4329 30 2886 0 1443 50% MAX CANDELA -90˚ -30 90˚ H O R I Z O N TA L D I S T R I B U T I O N -60 -90 -90 -60 -30 0 I n f r a NOR HP W 30 60 90 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s ITL Report #36821 V E RT I C A L D E G R E E S 90 CANDELAS 60 3809 10 % M A X C A N D E L A 2 8 5 6. 7 5 30 19 0 4 . 5 0 952.25 50% MAX CANDELA -90˚ -30 H O R I Z O N TA L D I S T R I B U T I O N -60 -90 -90 -60 -30 90˚ 0 30 60 90 HOR I ZO N ta l D e g r e e s VERTICAL DISTRIBUTION Photometric distributions illustrated above are based on a 175W MH lamp. For other lamping options, please consult the applications department at Sterner Lighting. 15 photometric Distribution: 150W HP S L A MP I n f r a NOR S P Values based on 16,000 initial lumens. ITL Report #36826 V E RT I C A L D E G R E E S 27 CANDELAS 18 71640 10% MAX CANDELA 53730 9 35820 0 17910 50% MAX CANDELA -90˚ -10 90˚ H O R I Z O N TA L D I S T R I B U T I O N -19 -28 -28 -19 -10 I n f r a NOR R N 0 9 18 27 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s ITL Report #35453 V E RT I C A L D E G R E E S 72 CANDELAS 48 29535 10% MAX CANDELA 2 2 1 5 1. 2 5 24 14 7 6 7. 5 0 7383.75 50% MAX CANDELA -90˚ -24 90˚ H O R I Z O N TA L D I S T R I B U T I O N -48 -72 -72 -48 -24 I n f r a NOR R M 0 24 48 72 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s ITL Report #35454 V E RT I C A L D E G R E E S 90 CANDELAS 60 15 0 0 3 10% MAX CANDELA 112 5 2 . 2 5 30 75 0 1. 5 0 3 75 0. 7 5 50% MAX CANDELA -90˚ -30 90˚ H O R I Z O N TA L D I S T R I B U T I O N -60 -90 -90 -60 -30 I n f r a NOR R W 0 30 60 90 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s ITL Report #35576 V E RT I C A L D E G R E E S 90 CANDELAS 60 6333 10% MAX CANDELA 4 74 9. 7 5 30 3 16 6 . 5 0 15 8 3 . 2 5 50% MAX CANDELA -90˚ -30 H O R I Z O N TA L D I S T R I B U T I O N -60 -90 -90 -60 -30 90˚ 0 30 60 90 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s Photometric distributions illustrated above are based on a 150W HPS lamp. For 100W HPS multiply candela values by 0.5938. 16 I n f r a NOR HP N ITL Report #36817 V E RT I C A L D E G R E E S 90 CANDELAS 60 8 99 2 10% MAX CANDELA 6 74 4 30 4 496 0 2248 50% MAX CANDELA -90˚ -30 90˚ H O R I Z O N TA L D I S T R I B U T I O N -60 -90 -90 -60 -30 0 I n f r a NOR HP M 30 60 90 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s ITL Report #36820 V E RT I C A L D E G R E E S 90 CANDELAS 60 6306 10% MAX CANDELA 4 72 9. 5 30 315 3 0 15 76. 5 50% MAX CANDELA -90˚ -30 90˚ H O R I Z O N TA L D I S T R I B U T I O N -60 -90 -90 -60 -30 0 I n f r a NOR HP W 30 60 90 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s ITL Report #36823 V E RT I C A L D E G R E E S 90 CANDELAS 60 4629 10% MAX CANDELA 3 4 7 1. 7 5 30 2 3 14. 5 0 115 7. 2 5 50% MAX CANDELA -90˚ -30 90˚ H O R I Z O N TA L D I S T R I B U T I O N -60 -90 -90 -60 -30 InfraNOR BI 0 30 60 90 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s ITL Report #36919 V E RT I C A L D E G R E E S 90 CANDELAS 60 3702 10% MAX CANDELA 2776.5 30 1851 0 925.5 50% MAX CANDELA -90˚ -30 H O R I Z O N TA L D I S T R I B U T I O N -60 -90 -90 -60 -30 90˚ 0 30 60 90 VERTICAL DISTRIBUTION HOR I ZO N ta l D e g r e e s Photometric distributions illustrated above are based on a 150W HPS lamp. For 100W HPS multiply candela values by 0.5938. 17 applic ation inform ation I E S - R E C O M M E N D E D I L L U M I N A N C E VA L U E S surface lux surface footc andles footc andles BRIGHT SURROUNDINGS BRIGHT SURROUNDINGS L I G H T S U R FA C E S 150 15 L I G H T S U R FA C E S 500 50 M E D I U M L I G H T S U R FA C E S 200 20 D A R K S U R FA C E S 1000 100 M E D I U M D A R K S U R FA C E S 300 30 D A R K S U R FA C E S 500 50 L I G H T S U R FA C E S 200 20 D A R K S U R FA C E S 500 50 DARK SURROUNDINGS L I G H T S U R FA C E S 50 5 M E D I U M L I G H T S U R FA C E S 100 10 M E D I U M D A R K S U R FA C E S 150 15 D A R K S U R FA C E S 200 20 sign lighting b u i l d i n g fa ç a d e s lux DARK SURROUNDINGS recommended guidelines B E A M PAT T E R N S The rectangular narrow beam pattern (RN) is ideal for lighting facades and signs where long setbacks are necessary or for providing a uniform wash on tall facades with short setbacks. The high proportioned wide beam pattern (HPW) is appropriate for providing an even wash on facades with medium setbacks and is effective in controlling spill light by placing a high proportion of the light above the center beam. The variety of beam spreads making up the spread between SP and HPW provide solutions for all possible lighting needs. SETBACK Luminaire setback can vary depending on the results desired. If a textured surface is being illuminated and the desired effect is to emphasize the texture of the surface, a short setback should be considered to reveal the depth of the texture. If a uniform wash or distribution is required, then a setback of two-thirds to threequarters the height of the structure should be considered. L U M I N A I R E S PA C I N G Depending on the lighting effects desired and the beam pattern used, luminaire spacing should range between one and two times the luminaire setback. With the wide variety of beam patterns available with the Polaris-6, there are many tools to select from for all of your lighting design challenges. As the possibilities of aiming options and solutions for lighting applications are unlimited, the following information serves to provide a general rule of thumb in determining beam spread requirements for applications where even illumination is required. SHIELD OPTIONS Luminaire shield options are available. Shields will affect the published photometric distributions. Please consult the factory for assistance. 18 recommended guidelines (continued) Illustrated in the following application is a 25' high wall and varying luminaire setback positions. Also shown are the recommended rectangular beam patterns suggested for the given luminaire setback ranges. The example below is meant to be a general guideline for selecting the appropriate beam spread for applications requiring an even illumination of the surface. Please consult the factory for assistance in applying these and other beam spreads and for assistance with your lighting design. setback 25' r ec o be m m ed n r te en pa t 0 d 5 10 am 15 20 RN 25 RM HP 30 M RM W , R T E C H N I C A L A S S I S TA N C E Just as there are many stars in the nighttime sky, there are many different solutions available for a successful lighting design. Our experienced staff of application engineers has been involved with the lighting design for applications ranging from simple sign lighting to the lighting of the shuttle launch pad at Cape 19 Canaveral. This same staff of expert application engineers is available to assist with all of your lighting design challenges. Please consult the applications department at Sterner Lighting for assistance with your design.