XIO Family of Remote I/O

XIO Family of Remote BACnet® Input/Output

Devices Mounting & Wiring Instructions

Table of Contents

Introduction ......................................................................................1 Specifications ...................................................................................3 Mounting ..........................................................................................6 Wiring ..............................................................................................8 Wiring Method ...............................................................................11 BACnet Network Wiring ...............................................................12 Setting BACnet Address ................................................................13 HOA Switch LED Operation .........................................................14 Model & Part Numbers ..................................................................15 Regulatory Compliance .................................................................16 Introduction

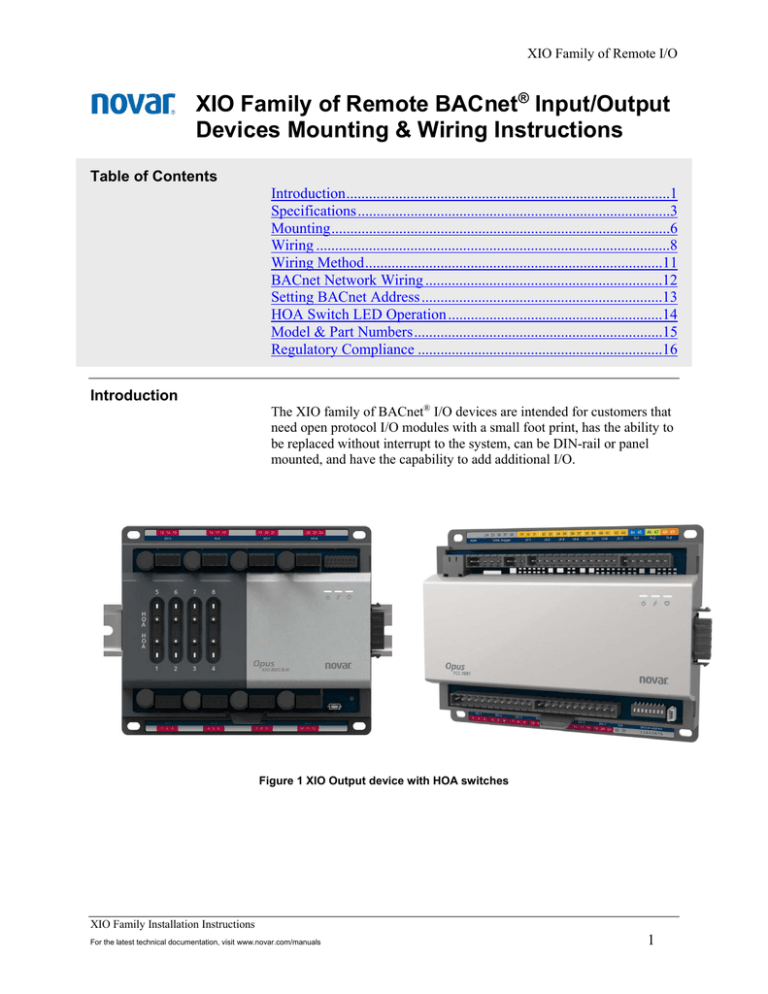

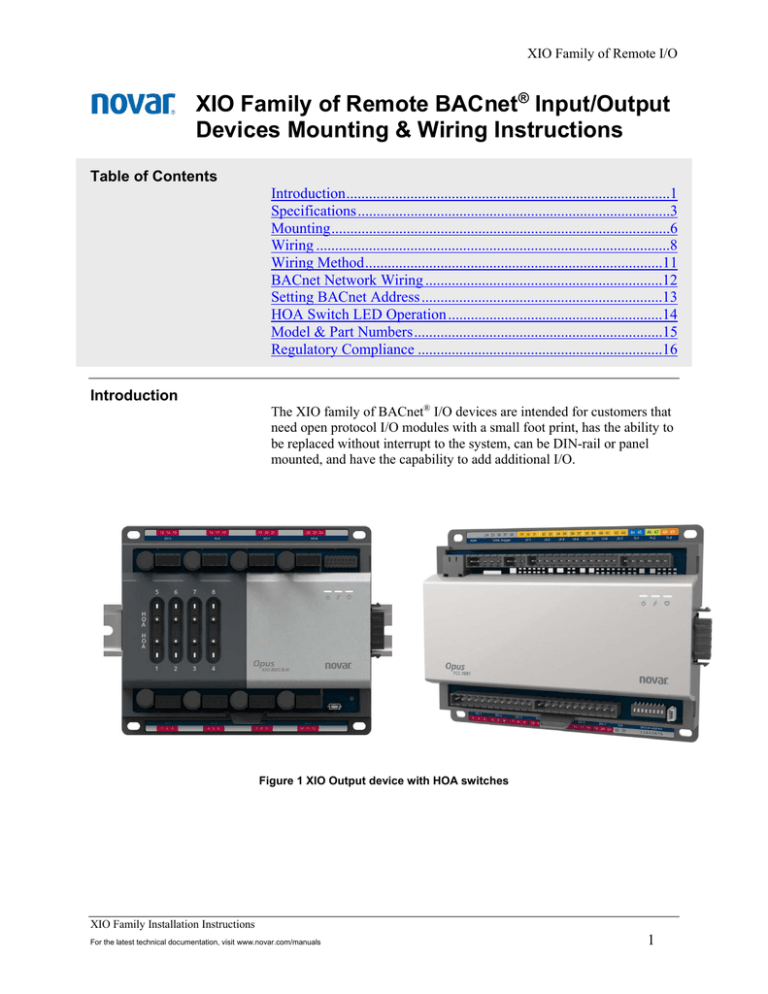

The XIO family of BACnet® I/O devices are intended for customers that

need open protocol I/O modules with a small foot print, has the ability to

be replaced without interrupt to the system, can be DIN-rail or panel

mounted, and have the capability to add additional I/O.

Figure 1 XIO Output device with HOA switches

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

1

XIO Family of Remote I/O

Figure 2 XIO family of Remote BACnet I/O

For reference only

Table 1 XIO Model Types

Model

xio.80

Part

Number

XIO-8U-B

Module Type

8 Universal

Inputs - BACnet

8 Relay Outputs BACnet

8 Relay Outputs BACnet - HOA

4 Universal

Inputs, 4 Relay

Outputs BACnet

Mode

IO Count

Power

Consumption

(VA)

Voltage Input Mode (010VDC)

Current Input Mode (420mA)

Resistance Input Mode

(500-100K Ohms)

Digital/ Pulse Counting

Input Mode (20Hz@50%

duty cycle)

Analog Output Mode (010VDC)

Form C Relay Outputs

8 Programmable I/O

(Can be individually

programmed as

Universal Inputs and/or

Analog Outputs)

10

8 Outputs

10

Form C Relay Outputs with

HOA switches

Universal Inputs, Analog

Outputs and Form C Relay

Outputs

8 Outputs

10

4 Outputs, 4

Programmable I/O (Can

be individually

programmed as

Universal Inputs and/or

Analog Outputs)

4 Outputs, 4

Programmable I/O (Can

be individually

programmed as

Universal Inputs and/or

Analog Outputs)

8 Inputs

10

xio.08

XIO-8DO-B

xio.08H

XIO-8DO-B-H

xio.44

XIO-4U4DO-B

xio.44H

XIO-4U4DOB-H

4 Universal

Inputs, 4 Relay

Outputs BACnet - HOA

Universal Inputs, Analog

Outputs and Form C Relay

Outputs with HOA

switches

xio.80CT

XIO-8CTI-B

8 Current

Transformer

Inputs - BACnet

CT inputs (AC Current 05Amps)

10

4

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

2

XIO Family of Remote I/O

Specifications

Figure 3 xio.80/xio.80CT Models

Physical Dimensions (xio.80/xio.80CT Models)

Width:

Height:

Depth:

Model Name

xio.80

xio.8CT

5.64 inches (143mm)

5.53 inches (141mm)

1.84 inches (47mm)

Weight

0.70 lbs (319g)

0.69 lbs (303g)

Figure 4 xio.08/xio.08H/xio.44/xio.44H Models

Physical Dimensions (xio.08/xio.o8H/xio.44/xio.44H Models)

Width:

Height:

Depth:

6.64 inches (169mm)

5.53 inches (141mm)

1.98 inches (50mm)

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

3

XIO Family of Remote I/O

Model Name

xio.08

xio.08H

xio.44

xio.44H

Weight

1.03 lbs (468g)

1.08 lbs (488g)

0.91 lbs (415g)

0.93 lbs (424g)

Operating Environment (all models)

Humidity:

Operating Temp:

Storage Temp:

5% to 95% Relative Humidity, non-condensing

-40°F to 158°F (-40° to 70°C)

-40°F to 158°F (-40° to 70°C)

Environmental/Electrical Operating Limits (xio.80CT Model)

Max. Current per Input

(Amps)

2.5

5

5

Max Number of

CT Inputs in use

8

4

8

Max. Ambient

Temperature

158°F (70°C)

158°F (70°C)

140°F (60°C)

Environmental/Electrical Operating Limits (xio.08/xio.08H Models)

Max. Load Current per

Relay Output (Amps)

2

5

5

Max Number of

Relays in use

8

1

8

Max. Ambient

Temperature

158°F (70°C)

158°F (70°C)

131°F (55°C)

Environmental/Electrical Operating Limits (xio.44/xio.44H Models)

Max. Load Current per

Relay Output (Amps)

2

5

5

Max Number of

Relays in use

4

1

4

Max. Ambient

Temperature

158°F (70°C)

158°F (70°C)

140°F (60°C)

Operating Voltage (all models)

22VAC - 28VAC, 50/60Hz

Power Supply (all models)

Power and universal inputs are classified as NEC Article 725 Class 2

(power limited)

Power Consumption (per model)

Refer to Table 1 XIO Model Types for power consumption per model

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

4

XIO Family of Remote I/O

Input/Output Ratings (Class 2)

Universal Inputs:

Thermistor Mode:

Novar refrigeration 2K, useable range -49 to 102F (-45 to 39C)

PRECON Type 2, 10K, useable range 14 to 212F (-10 to 100C)

PRECON Type 3, 10K, useable range 14 to 212F (-10 to 100C)

Honeywell 20K, useable range 41 to 186.8F (5 to 86C)

Custom Thermistor Table, accuracy = +/2% of reading.

Voltage Mode:

0-10VDC, Input impedance > 5Kohms, Accuracy = +/- 2% of full scale

Current Mode:

4-20mA, Input impedance approximately 523 ohms (+/-10%), Accuracy

= +/-1% of span. Input supports current loop devices having a loop

compliance of 10V or less.

Resistance Mode:

500 – 100K Ohms, Accuracy +/- 2% of reading over 1K - 100K Ohm

range.

Digital/Pulse Counting Mode:

Open circuit voltage = 3.35VDC (+/-10%), Dry contact wetting current >

4mA, Maximum pulse counting frequency = 20Hz @ 50% duty cycle.

Total Input Impedance >10K ohms

Analog Output Mode:

Minimum output range = 0.1 to 10.5VDC Accuracy = Not less than +/2% of span Resolution = Not less than 100mV Load Impedance > 2000

ohms

Relay Outputs:

Fused 250 VAC, 5 AMPS, SPDT (Single Pole Double Throw). Each

output has normally closed and normally open contacts.

NOTE: Use Cooper Bussmann type S500-5A or similar.

NOTE: See Environmental/Electrical Operating Limits for more

information

Current Transformer Inputs:

Range = 0- 5A, Accuracy = +/-5% of span.

Resolution = 100mA

LEDs (all models)

Indicates power (steady on)

Indicates BACnet connectivity (blinks with communications)

Indicates module health status (continuous blink = good health)

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

5

XIO Family of Remote I/O

LEDs (models with HOA switches)

LEDS are on solid when relay coil is in its energized state (actual output

state depends on wiring configuration)

Safety and Precautions

Observe all national and local electrical codes during installation

Mounting

The XIO device may be mounted in any orientation on a panel or a DINrail but must be in a position that allows clearance for wiring or

servicing.

WARNING!

Electrical Shock Hazard! Can cause severe injury, death or

property damage. Disconnect power supply and load power sources

before beginning wiring or making wiring connections to prevent

electrical shock or equipment damage.

Din Rail Mounting

Table 2 Din Rail Mounting

Step

Procedure

1

Holding the device with its top tilted in towards the DIN rail, hook the

top ridge of the DIN rail channel on the back of the controller onto

the top of the DIN rail.

Gently press down on the bottom half of the XIO device to allow the

DIN latch to engage under the DIN rail bottom edge.

2

DIN Latch Release

Figure 5 XIO device DIN Latch Release

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

6

XIO Family of Remote I/O

Din Rail Un-Mounting

Table 3 DIN Rail Un-Mounting

Step

1

2

3

4

Procedure

Remove all wiring connectors from the device to expose DIN latch

release

Pull down DIN latch release with one hand to release the fastener

from the DIN rail.

Lift the bottom of the controller away from the DIN rail with your

other hand.

Unhook the top ridge of the DIN rail channel on the back of the

controller from the top of the DIN rail.

NOTE!

Use caution when pulling the DIN latch release! Over extending the

DIN latch release can damage the resistance spring of the mechanism.

Panel Mounting

Figure 6 xio.80/xio.80CT Modules Mounting Hole Dimensions

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

7

XIO Family of Remote I/O

Figure 7 xio.08/xio.o8H/xio.44/xio.44H Modules Mounting Hole Dimensions

Table 4 Panel Mounting

Step

1

2

Procedure

Position the base of the product level against the panel wall and mark

the wall to show the location of the corner holes.

The XIO I/O device mounts using four screws inserted through the

corners of the base. Fasten securely with four No. 6 or No. 8

machine or sheet metal screws.

Wiring

A removable terminal block is used to make all wiring connections to the

XIO device. Attach all wiring to the appropriate terminal blocks. All

wiring must comply with applicable electrical codes and ordinances, or

as specified in installation wiring diagrams (reference Wiring Method

section).

Users have the option to connect devices via daisy chain (using the

supplied removable terminal block) or connect devices via the bus

connectors (on the right (female) and left (male) side of the device).

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

8

XIO Family of Remote I/O

NOTE!

Bussed installation of XIO Remote I/O is limited to a maximum of

five (5) modules

NOTE!

The RCC-1081 can also connect to the XIO power and

communication bus (edge) connectors, not to exceed a maximum of

five (5) modules on 1 bus.

NOTE!

If the bus connector method is being used, then the supplied 5position terminal block cannot be used when attaching additional XIO

devices.

Terminal Block Wiring

Figure 8 XIO Devices linked via Daisy Chain

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

9

XIO Family of Remote I/O

+A

SH

-B

AC1

AC2

Figure 9 XIO Devices linked via Bus Connector

Figure 10 Terminal Label/PIN configuration for the XIO-8U-B

Figure 11 Terminal Label/PIN configuration for the XIO-8CTI-B

Figure 12 Terminal Label/PIN configuration for the XIO-8DO-B and XIO-8DO-B-H

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

10

XIO Family of Remote I/O

Figure 13 Terminal Label/PIN configuration for the XIO-4U4DO-B and

XIO-4U4BDO-B-H

WARNING!

Electrical Shock Hazard! Can cause severe injury, death or

property damage. Disconnect power supply and load power sources

before beginning wiring or making wiring connections to prevent

electrical shock or equipment damage.

NOTE!

For multiple controllers operating from a single transformer, the same

wire of the transformer secondary must be connected to the same

power input terminal in each controller.

The total power draw for all modules sharing the same transformer

must not exceed 100VA.

Wiring Method

Each terminal block can accommodate the following gauges of wire:

— Single wire: from 22 AWG to 14 AWG solid or stranded

— Multiple wires: up to two 18 AWG stranded

NOTE!

When attaching two or more wires to the same terminal, other than 14

AWG (2.0 sq mm), be sure to twist them together. Deviation from this

rule can result in improper electrical contact.

Table 5 Preparing wiring for terminal blocks

Step

1

Procedure

Strip 1/2 in. (13 mm) from wires to be attached at one terminal.

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

11

XIO Family of Remote I/O

½”

2

3

Cut a single wire to 3/16 in. (5 mm). Insert the wire in the required

terminal location and tighten the screw.

If two or more wires are being inserted into one terminal location,

twist the wires together a minimum of three turns before inserting

them.

4

Cut the twisted end of the wires to 3/16 in. (5 mm) before inserting

them into the terminal and tightening the screw.

5

Pull on each wire in all terminals to check for good mechanical

connection.

BACnet Network

Wiring

A two-conductor shielded cable (reference Novar Part Numbers in Table

7) should be used to make the BACnet MS/TP Network Communications

connections from the Opus Executive Controller to the terminals on the

left side of the XIO device.

The BACnet network should originate from the main Opus Executive

Controller and connect to the XIO device with the supplied 5 position

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

12

XIO Family of Remote I/O

terminal block. Multiple devices can be connected via daisy chain wiring

or bussed devices. Stubs or branches off the BACnet network are not

allowed.

In order to guarantee the network performance of each BACnet segment,

the BACnet network segments from the Opus Executive Controller

should contain only XIO device modules or other Novar approved

BACnet MS/TP devices.

NOTE!

Bussed installation of XIO Remote I/O is limited to a maximum of

five (5) modules

NOTE!

Network termination and/or biasing resistors should NOT be applied

to any Opus BACnet installation.

NOTE!

The baud rate for the XIO devices is fixed with 38400 baud.

NOTE!

Do not exceed the maximum recommended length (1200 M / 4000 ft.)

for any BACnet segment.

Setting BACnet

Address

Every XIO device comes from the factory set to a BACnet address of 0.

Each controller must be assigned a unique BACnet MAC address

(ranging from 4 through 254) in order for the Opus xcm Executive

Controller to be able to identify and communicate with it.

NOTE!

Address zero (0) cannot be used for controllers

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

13

XIO Family of Remote I/O

Users must set the unique BACnet MAC address for the XIO device

using the eight (8) DIP switches on the front of the module.

To set the BACnet address of an XIO device using the DIP switches:

Find an unused address on the MS/TP network to which the controller

connects.

Locate the DIP switch bank on the front of the Controller that is labeled

MAC Address.

With the XIO device powered down, set the DIP switches for the

BACnet address you want. Add the value of DIP switches set to OFF

(down) position to determine the MAC address (see Table 6). Example:

if only DIP switches 1, 3, 5, and 7 are in the OFF (down) position the

BACnet address would be 85 (1 + 4 + 16 + 64 = 85).

Table 6 DIP Switch Values for MS/TP MAC Address

DIP

VALUE (when in

OFF position)

1

2

3

4

5

6

7

8

1

2

4

8

16

32

64

128

HOA Switch LED

Operation

For output modules equipped with HOA switches, the LED will rapidly

blink on and off if the HOA is in either the Hand (H), or Off (O)

positions to notify that the device is not operating in automatic control.

When the switch is in the Auto (A) position, the LED will be

continuously on or off, to match the status of the output relay coil.

In Opus software, the position of the HOA switches can be read while

viewing the points folder of the XIO device. Therefore, if the device is

overridden, you have a method of seeing that in the software. If needed,

alarms can be set up whenever loads are put into override.

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

14

XIO Family of Remote I/O

Model & Part

Numbers

Table 7 Novar Part Numbers

Part No.

XIO-8U-B

XIO-8DO-B

XIO-8DO-B-H

XIO-4U4DO-B

XIO-4U4DO-B-H

XIO-8CTI-B

709031000

730090000

770067000

Product Description

8 Universal Inputs - BACnet

8 Relay Outputs - BACnet

8 Relay Outputs - BACnet - HOA

4 Universal Inputs, 4 Relay Outputs - BACnet

4 Universal Inputs, 4 Relay Outputs - BACnet - HOA

8 Current Transformer Inputs - BACnet

Two-conductor shielded cable, RS-485 (1000 foot reel)

24-VAC Transformer (40 VA)

24-VAC Transformer(100VA)

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

15

XIO Family of Remote I/O

Regulatory

Compliance

This device has been tested and found to be in compliance with the

requirements set forth in UL 60730, Automatic Electrical Controls for

Household and Similar Use, and is recognized by Underwriters

Laboratories, Inc., for installations in the United States.

This device has been tested and found to be in compliance with the

requirements set forth in C22.2, No. 24-93, Temperature-Indicating and

Regulating Equipment, and is recognized by Underwriters Laboratories,

Inc., for installations in Canada.

This device has been tested and found to be in compliance with the

requirements set forth in C-Tick.

Federal

Communications

Commission (FCC)

This device complies with Part 15 of the FCC Rules. The product meets

emissions requirements for product specific standards EN

55022/FCC/IC, Class B. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2)

This device must accept any interference received, including interference

that may cause undesired operation.

NOTE!

This device has been tested and found to comply with the limits

established for Class B digital devices. It may be used in a residential

environment and is intended to be used in a commercial environment.

CAUTION!

Any changes or modifications not expressly approved by Novar could

void your authority to operate this equipment.

Canadian

Department of

Comms (DOC)

NOTE!

This Class B digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numerique de la Classe B respecte toutes les exigencies

du Reglement sur le material broilleur du Canada.

Waste Electrical &

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

16

XIO Family of Remote I/O

Electronic Equip

NOTE!

Customers are advised to dispose of this product at the end of its

useful life according to applicable local laws, regulations, and

procedures.

Conformité

Européenne (CE)

NOTE!

EMC requirements - CE (European Union) conformity with the

appropriate IEC standards referenced in UL 60730.

LVD requirements - CE (European Union) conformity with UL 60730

which is aligned with IEC 60730.

Opus® is a Registered Trademark of Honeywell International

BACnet® is a registered trademark of American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE)

The material in this document is for information purposes only. The content and the product it describes are subject to change

without notice. Novar makes no representations or warranties with respect to this document. In no event shall Novar be liable for

technical or editorial omissions or mistakes in this document, nor shall it be liable for any damages, direct or incidental, arising out of

or related to the use of this document. No part of this document may be reproduced in any form or by any means without prior

written permission from Novar.

Copyright © 2016 by Honeywell International, Inc. All Rights Reserved.

Novar

6060 Rockside Woods Blvd.,

Cleveland, OH 44131

Phone: 1.800.348.1235

www.novar.com

XIO Family Installation Instructions

For the latest technical documentation, visit www.novar.com/manuals

17