LED Lighting

Emergency LED Products

The Philips Bodine BSL Driver Family

ELI-S-20 Emergency Lighting Micro Inverter

ELI-S-100 Dimming Inverter

Philips Bodine emergency LED drivers answer the call for

LED Technology

From torch lighting to

porch lighting, T12 to

T5 HO, filament to LED,

technology evolves.

So do we.

LED technology is a new frontier. For most in the lighting

industry there is a very real learning curve as we explore the

intricacies, applications, limitations and potential of this amazing light source. Despite the curve, use of LED lighting for

general lighting purposes is growing. As with other types of

lighting, LED lighting must meet the life safety code requirements for emergency illumination. LED fixtures serving as

emergency units must, therefore, provide at least 90 minutes

of emergency lighting. Philips Bodine emergency LED drivers

and emergency lighting inver ters allow these fixtures to meet

or exceed code.

As with other types of lighting, LED lighting must meet the life

safety code requirements for emergency illumination.

2

LED brochure

emergency lighting in LED applications.

Terminology

Array: A configuration of one

or more (usually many more)

LEDs connected to the same

power source.

Emergency LED Driver: A device

that uses electronic circuitry to convert

energy stored in a battery into the DC voltage and current necessary to drive the LED load within the

parameters established by life safety

codes.

Integral-Base Lamp:

A lamp in which the driver

is built into the base. Because

the lamp driver is built into the

base, an emergency LED driver

cannot be wired in between it

and the lamp/LED/LED array. A unit

with an integral base must, therefore, be

driven in emergency mode by an inverter

product, such as the Philips Bodine ELIS-20 Emergency Lighting Micro Inverter.

LEDs in Parallel: In parallel devices, all

of the (+) terminals are connected and

all of the (-) terminals are connected.

All devices have the same voltage across

them and draw as much current as

their internal resistance allows. If all the

devices are exactly the same, the current

through each will be equal and the total

current draw from the power supply will

be that individual current multiplied by

the number of devices or parallel legs

connected. When LEDs are wired in parallel, each LED or group of LEDs will have

the same voltage demand from the driver

and draw an equal amount of current.

LEDs in a Series: The (+) terminal of one

LED is connected to the (-) terminal of the

next. When LEDs are wired in series, the

voltage necessary to run them is the sum

of the individual LED voltage drop and the

current is the same in all LEDs.

LED: Light-emitting diode. A semiconductor device (diode) that emits visible light when electricity is applied.

LED Driver: A device that converts line

voltage into the DC voltage and

current necessary to drive

the LED load.

Light Engine: A configuration of LEDs,

often series and parallel, that cannot

be divided by changing the wiring

between the LEDs. Thus, a power

source drives the whole unit or

nothing at all.

LED brochure

3

Choosing the Best Emergency LED Driver

Selecting Emergency Drivers:

OEM Solutions for Factory Installation

Although we recommend that you send us your fixture or request a sample driver from

us to test in your fixture, there are two critical pieces of information that will help you

select the best emergency LED driver for your project.

The leader in

emergency lighting

technology delivers

LED Array Voltage.

Wiring Specifics.

What’s the LED array voltage you’re using? For best

results, this voltage should be in the midrange of the

output voltage for our products. For example, the

Philips Bodine BSL23C has an output range of 3.0

to 20 VDC. If your LED array voltage is around 12.0

VDC, BSL23C could be a good option. If your array

voltage is 18 VDC, however, the match would be less

ideal, though it still may work.

How are the LEDs wired? Are the LEDs in a series

or parallel? Is the wiring accessible? When LEDs are

wired in series, the voltage necessary to run them

is the sum of the individual LED voltage drop and

the current is the same in all LEDs. If they’re wired

in parallel, each LED or group of LEDs will have the

same voltage demand from the driver and each will

draw an equal amount of current. Thus, the summed

currents in the parallel configuration may quickly

exceed our capability or result in dramatically lower

lumen output than expected. In terms of wiring

accessibility, wiring that is accessible gives you the

option of connecting as few or as many LEDs as appropriate to the emergency driver.

again with emergency

LED drivers.

4

LED brochure

Philips Emergency Lighting offers

emergency drivers for LED lighting

applications. These drivers permit LED

fixtures to serve as code-compliant

emergency lighting units.

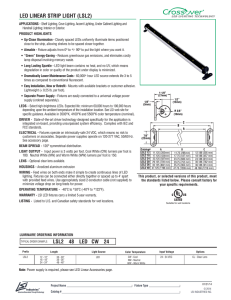

NON-REGULATED

REGULATED *

Philips Emergency Lighting Driver Portfolio

Model

Output

Voltage

(VDC)

Typical

Output

Current

(mA)

Typical

Output

Power

Dimensions

Features or Applications

BSL17C (conduit)

BSL17 (non-conduit)

45 - 130

100 - 200

7.0 W

12” x 2.4” x 1.5”

Multiple mounting configurations;

Ideal for LED downlight applications;

Universal input

UL Component Recognized

for factory installation only;

CSA Certified

BSL17C-C2* * (conduit)

BSL17-C2* * (non-conduit)

15 - 50

100 - 270

7.0 W

12” x 2.4” x 1.5”

Class 2; Multiple mounting configurations; Ideal for use with Fortimo DLM

and SLM modules; Universal input

UL Component Recognized

for factory installation only;

CSA Certified

BSL10 Cold-Pak

24 - 52

200 - 400

10.0 W

8.97” x 3.5” x 2.9”

+ battery

Easier to install; Output Class 2

Compliant; Cold temperature

(-4 F to +131 F); Universal input

UL Component Recognized

for factory installation only;

Output Class 2 Compliant

20 - 50

50 - 130

125 - 200

400 - 1000

150 - 400

100 - 160

20.0 W

16.6” x 2.8” x 2.85”

+ battery

High output provides 20W constant

output power; BSL20LV is class 2;

Universal input

UL Component Recognized

for factory installation only

BSL722 (non-conduit)

28 - 33

700

23.1 W

9.4” x 2.2” x 1.05”

+ battery

Drives two LED arrays in parallel;

Universal input

UL Component Recognized

for factory installation only;

CSA Certified

BSL722 Cold (non-conduit)

28 - 33

700

23.1 W

9.4” x 2.2” x 1.05”

+ battery

Designed for but not restricted to

cold temperatures (-4 F to +140 F);

Drives two LED arrays in parallel;

Universal input

UL Component Recognized

for factory installation only;

CSA Certified

BSL23C (conduit)

BSL23 (non-conduit)

3 - 20

225 - 410

4.5 W

9.4” x 2.4” x 1.5”

Multiple mounting configurations;

Ideal for downlight and steplight

applications

UL Component Recognized

for factory installation only

BSL26C (conduit)

BSL26 (non-conduit)

3 - 30

120 - 265

5.1 W

9.4” x 2.4” x 1.5”

Multiple mounting configurations;

Ideal for downlight applications;

LVLE compliant

UL Component Recognized

for factory installation only;

CSA Certified

Designed for linear strip fixtures;

Class 2; Metal and polycarbonate

case options available; Universal

input

UL Component Recognized

for U.S.

BSL20LV

BSL20MV

BSL20HV

Listing

BSL310C (metal case with conduit)

BSL310M (metal case no conduit)

BSL310* * * (polycarbonate case no conduit)

10 - 50

200 - 400

10.0 W

BSL310C / BSL310M

15.34” x 2.25” x 1.16”

BSL310

14.5” x 2.25” x 1.18”

BSL310DF (metal case with conduit)

BSL310CP (metal case with conduit)

10 - 50

200 - 400

10.0 W

15.34” x 2.25” x 1.16”

Designed for linear strip fixtures;

Class 2; BSL310DF has dual flex conduit; BSL310CP is compatible with

Cree LMH Modules; Universal input

UL Component Recognized

for U.S.

BSL310C-CAN (metal case with conduit)

BSL310M-CAN (metal case no conduit)

BSL310-CAN (polycarbonate case no conduit)

10 - 36

300 - 400

10.0 W

BSL310C / BSL310M

15.34” x 2.25” x 1.16”

BSL310

14.5” x 2.25” x 1.18”

Designed for linear strip fixtures;

Class 2; Metal and polycarbonate

case options available; Universal input

Suitable for factory installation in Canada and U.S.;

cUL Component Recognized

*Regulated power output over 90 minutes.

** The BSL17C-C2 and BSL17-C2 are UL Classified for use with specific Philips Fortimo DLM (downlight module) and SLM (spotlight module) products. The designation of UL Classified for use with

specific Fortimo DLMs and SLMs means that the BSL17C-C2/BSL17-C2 may be factory installed without additional UL testing in Fortimo fixtures for which an emergency option has been filed.

***The BSL310 is field installable exclusively with the Philips EvoKit LED retrofit. It cannot be field installed without the EvoKit. For more information, please contact PEL Sales at 800.223.5728 or

Tech Support at 888.263.4638.

Philips Bodine BSL products provide 90 minutes of emergency illumination in compliance with emergency codes. See the Life Safety Code® 7.9.2.1 (2012).

All BSL products above are UL Component Recognized for factory installation only.

The lone exception is the BSL310 paired with the EvoKit.

LED brochure

5

UL Listed for Factory or Field Installation.

ELI-S-20

Emergency Lighting Micro Inverter

The Philips Bodine 25W ELI-S-20 emergency lighting micro inverter transforms

LED and fluorescent fixtures into code-compliant emergency lighting.

It is the ideal emergency backup for the

Edison-base (screw-base) LED lamps that

are commonly replacing CFLs in retrofit

applications and is a superior choice for office,

retail, hospitality and other similar spaces.

ELI-S-20 allows fixtures to be on, off,

switched or dimmed. It supports 100% of

AC rated output throughout its 90-minute

runtime so fixtures operate at full brightness

during emergency operation. The device

provides power to the input side of the

fixture, including the ballast, and is designed

for use with indoor applications.

The ELI-S-20 features an LED-friendly

sinusoidal (sine) waveform rather than square

waveform output. Sinusoidal waveform

is characterized by very low harmonic

distortion and by clean power similar to that

produced by utility-supplied electricity, making

the ELI-S-20 well suited for even the most

sensitive LED lighting.

The micro inverter is UL Listed (25W) and

CSA Certified (20W) unit equipment and

designed for new and retrofit lighting projects.

Product Highlights

• Works with LED and fluorescent fixtures up to 25W

• Is unit equipment

• Supplies 90 minutes of emergency illumination at

full brightness

• Provides power to the input side of connected

lighting loads

• Ideal for but not limited to screw-base LED lamps

ELI-S-20 includes auto select (120/277 VAC) to reduce wiring

• Compatible with Philips 22W TLED linear LED lamps

errors. With the convenient auto select, ELI-S-20 automatically

• Suitable for indoor, dry and damp applications

detects input voltage and sets the output voltage accordingly.

• Features fused output load connections

• AC Input Power Rating: 9.5W;

output voltage 120/277 VAC (auto select), 60 Hz

• Dimensions: 16.6” x 2.8” x 2.85”

• Remote mounting distance: 250 feet maximum

• Warranty: 5 years (not pro-rata)

• UL Listed for 25W / CSA Certified for 20W

Model

ELI-S-20

Wattage

25

Feature

For LED and fluorescent lamps

When an emergency LED driver cannot be used, line

voltage inver ters, such as ELI-S-20 and ELI-S-100, may

be the best solution.

6

LED brochure

UL Listed for Field Installation.

ELI-S-100

The ELI-S-100 provides emergency output power of 100W

maximum and supports the lighting load for a minimum of

90 minutes. While the ELI-S-100 works with both fluorescent

and LED lighting, it offers two important features for LED

applications: dimming capabilities and sinusoidal output.

Emergency Lighting Inverter

Dimming in LED Applications

ELI-S-100’s dimming feature delivers cost-savings, flexibility

and control in LED applications. The dimming capability

allows a higher power fixture to operate at a dimmed

100W maximum emergency-mode lighting level, eliminating reliance on a high power inverter to run the fixture.

Alternately, ELI-S-100 allows a string of multiple fixtures

to be driven in emergency mode at a combined 100W

maximum. For example, four100W LED fixtures may be

connected to one ELI-S-100 and dimmed for emergency

operation to 20% of normal power, with each LED fixture

supplying 20W of output power (20W x 4 = 80W).*

Two models are available: ELI-S-100-120V and ELI-S-100-277V.

Product Highlights

• Compatible with LED and fluorescent fixtures

• Provides emergency output power of 100W maximum

• Features sinusoidal output

• Dimming compatible with 0-10V systems • Includes fused output load connections

• Two versions available: 120V model and 277V model

• Remote mounting distance: 250 ft.

Sinusoidal Output

• Temperature rating: 32° F to 104° F (0° C to 40° C)

The ELI-S-100 features an LED-friendly sinusoidal (sine)

waveform rather than square waveform output. Sinusoidal waveform is characterized by very low harmonic

distortion and by clean power similar to that produced by

utility-supplied electricity.

• Dimensions: 12.562” x 9.812” x 4.675”

(319 mm x 249 mm x 119 mm)

• Weight: 25 lbs. (11.34 kg) with batteries installed

• Warranty: Unit, 5 years; Battery, 3 years

+7 years pro-rated

• UL Listed/CSA Certified

• Designed for field installation

*Note dimming drivers are less efficient at reduced power.

This inefficiency must be accounted for in the design.

The ELI-S-100 provides a dimming control output of 2-10 volts,

and the emergency-mode dimming voltage is field-settable in

five steps to provide nominally 20%, 40%, 60%, 80% or 100%.

The dimming feature requires a dimming AC driver.

• May be connected to one or multiple fixtures

• Supports emergency lighting for a minimum of

90 minutes

Model

ELI-S-100

Wattage

100

Feature

Offers LED dimming capabilities

LED brochure

7

Proper installation, of course, is critical to emergency operation.

Emergency LED Driver Installation

Note: Emergency LED drivers are UL

Recognized and must be factory installed

with one exception. The BSL310 may be

field installed when paired with

the Philips EvoKit LED retrofit.

The installation of Philips Bodine emergency LED drivers is

similar to that of fluorescent emergency ballasts. Depending

upon the emergency LED driver selected and fixture type,

the emergency driver may be installed inside, on top of or

remote from the fixture.

When an emergency LED driver cannot be used, line

voltage inver ters may be the best solution.

As with Philips Bodine fluorescent emergency ballasts, Philips

Bodine emergency LED drivers do not affect normal fixture

operation and may be used with a switched or unswitched

fixture. If a switched fixture is employed, an unswitched hot lead

must be connected to the emergency driver. In either case, the

emergency driver must be fed from the same branch circuit as

the AC driver. Please see the product specification and instruction

sheets for more information.

Proper installation, of course, is critical to emergency operation.

However, regular code-compliant testing and maintenance must

also be done and are essential to any life safety program.

© 2014 Philips Emergency Lighting

All rights reserved.

Document order number: L0000022 14.5

236 Mt. Pleasant Rd.

Collierville, TN 38017

Sales 800.223.5728

Fax 901.853.5009

www.philips.com/bodine