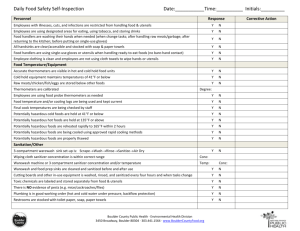

Food Safety Program

advertisement