Implications of Using Lead-Free Solders on X

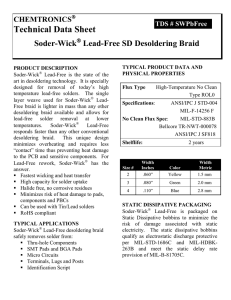

advertisement

Implications of Using Lead-Free Solders on X-ray Inspection of Flip Chips and BGAs David Bernard, Dage Precision Industries Inc. Fremont, CA 94538 e-mail: d.bernard@dage-group.com Abstract All contract manufacturers (CM) of printed wiring boards (PWBs) are having to consider their approach to using leadfree solders to meet current, and future, environmental, legislative and market demands. As these lead-free solders have markedly different operating parameters from those of the tried and tested lead-containing solders, the opportunity for production problems rises. Therefore, the application of appropriate test and inspection procedures now becomes even more important to ensuring product quality and reliability. However, the test and inspection equipment, and methods, used for decades may not now be appropriate for this new challenge. This may be because, at worst, some test parameters are no longer valid with the lead-free solders, or, less seriously, the inspection control settings must be varied to accept revised test responses based on acceptable levels for these new materials. Implementing lead-free solder into production, therefore, raises questions as to the acceptability and adequacy of a company’s existing test methods. This paper discusses the implications of using x-ray inspection on lead-free versions of flip chips and BGAs. Introduction Driven by the concerns for the environmental impact of increasing amounts of lead containing products within waste landfill sites, there is now legislative and commercial pressure on OEMs to implement lead-free solutions within the printed circuit boards (PCBs) of their products. As contract manufacturers (CMs) charged with supplying these OEMs, it is therefore becoming evermore necessary to consider implementing a lead-free strategy within production and to decide what effects this change from traditional lead solders will have on the manufacturing and test and inspection procedures that are used. Japan is already well advanced in converting their PCB manufacturing to using lead-free alternatives and expects to have completed the switch by the end of 2004. In Europe, the European Union has set the date of July 2006 for compliance by all member states, which includes the newest, mainly former Eastern Bloc members, as well as the existing 15 countries. In the US, in contrast, no formal date for a transfer to lead-free production has been raised. Therefore, whilst supply to the home market may not require any switch for the forseeable future, the danger of not implementing lead-free into a CMs manufacturing capability could result in their being excluded from supplying into the ‘lead-free’ markets. It should be noted, however, that although there is a legislative timetable for Europe to be lead-free, there are still many European CMs that have yet to implement this capability. Those CMs that have already changed have been through the extended learning curve that the new process profiles for these leadfree solders require. As such, there is much information available to help new lead-free adopters avoid some of the pitfalls experienced so far. Further information on the European lead-free roadmap together with other useful data based on experience of manufacturers moving to lead-free can be found in the web sites in references 1 and 2. Traditional solders have been of the Tin/Lead (Sn/PB) variety and many decades of experience has been invested into using these materials to the best advantage. This has defined the process windows within which to produce PCBs and also shaped the inspection and testing regimes that have been implemented to ensure quality manufacture. In particular, the reflow temperature profile used within surface mount technology production has been defined around the, typically, 183°C liquidus temperature of these solders. In addition, the visual look of the Sn/Pb solder after reflow has been used by experienced operators to confirm the quality of their solder joints. When using lead-free solders, these fundamental indices are completely changed and therefore the underlying tenets that have been established for so long in PCB manufacture may no longer be valid. Lead-free Solders The most commonly used Sn/Pb solders have consisted of around 63% Sn and 37% Pb. The most commonly used leadfree alternatives are the, so called, SAC alloys which are named after the mixture of tin (Sn), silver (Ag) and copper (Cu) that they contain. Although different solders from different suppliers have varying elemental ratios, the SAC alloys all contain around 97% tin. There are other lead-free solders that are available, with other elemental compositions, but, once again, their main constituent is Sn. So, in general, the lead is being replaced by tin in these new solders. The immediate effect of this change is to dramatically increase the liquidus temperature of these solders to around 215 – 230°C. As a result, the reflow oven temperatures typically used for SMT production must be raised to a much higher level – around 290°C so as to ensure the solder reflow will occur. Such higher temperatures then bring into question the viability of the components used and bare boards themselves. For example, to be lead-free, a standard tin/lead HASL finish would no longer be permitted. Although there is a lead-free HASL finish that comprises of a tin/copper/nickel combination. A silver board finish is often suggested for lead-free because of its bonding properties with the copper pads. Organic solderable protector (OSP) and gold board finishes may also be considered for lead-free applications. There is also the question of the susceptibility of the components to this additional temperature as well as the finish on the component legs (reference 2). Finally, the look of these solders after reflow is not the same as that seen in Tin/Lead meaning the ‘experience’ gained in this area is no longer helpful in determining problems. In other words, using leadfree is not just simply a question of changing to a higher temperature profile within the reflow oven; board type, finish and component choice all have to be considered. The implication of using lead-free solders, therefore, is that a new ‘learning-curve’ has to be climbed with necessary experimentation and testing to validate these new processes. However, is the test and inspection equipment typically used for process control still valid for these new materials? It has already been mentioned that the look and behavior of leadfree solders is different to that of Tin/Lead. Therefore, with optical inspection techniques, questions must be asked as to the efficacy of their light sources, software algorithms, etc., for inspecting lead-free materials. In a similar vein, will existing and new x-ray systems be able to cope? With the dramatic increase in the use of BGA and CSP components this question becomes more ever more important as only xrays can inspect where optical systems cannot. To ensure that x-ray inspection remains valid for lead-free applications and understanding of the technique is required. X-ray Inspection Two dimensional (2-D) x-ray inspection systems, system most commonly used within the PCB industry, are basically x-ray shadow micrographs (see figure 1). The technique demands that an x-ray light source (called an x-ray tube) produces x-rays, within which the sample is bathed. The differing materials within the sample absorb more, or less, of the x-ray radiation depending on their density and atomic number and cast a shadow of that material at the detector. The denser the material, then the darker the shadow. In this way, solder and copper tracks appear dark compared with the laminated circuit board in a PCB, for example. The detector converts the incident x-rays into optical images for the operator to view. The closer the sample is moved to the x-ray tube then the larger the shadow becomes and this is how magnification is achieved. Figure 1: Basic 2-D x-ray system configuration The quality of the x-ray radiation produced by the x-ray tube, and its effectiveness as discriminating the different materials within a sample to produce a useful analytical image, are defined by the tube settings used. These settings are called the x-ray tube accelerating voltage, or kV, and the tube power and are used to set the tube at appropriate levels so as to get a good contrast image at the detector. The accelerating potential is the applied voltage between the anode and cathode of the x-ray tube that makes electrons, produced at the cathode, strike the target anode, creating xrays. The tube power is calculated from the product of the accelerating potential and the filament current within the cathode used to produce the electrons. The more power then the brighter the x-ray source. However, there are technical limitations on the maximum power that the tubes can achieve (see references 3 and 4). The kV is also a measure of the penetrating power of the xrays. The higher the kV used then the more penetrating are the resultant x-rays. This means that higher kVs need to be used to image dense, or thick but relatively less dense, objects. At lower kVs, only thin and less dense samples can be inspected. Otherwise, the x-rays have insufficient penetrating power to travel through the sample and strike the detector, so creating the image. The interaction between penetrating radiation and matter, such as x-rays passing through a sample under test, is not a simple relationship and is based on a number of factors. Further detailed information on this matter can be found in reference 5. However, the important consideration, as far as imaging lead-free solders, is that absorption of the radiation increases with atomic number and density of the material that is present. Table 1 shows the differences in the atomic number (Z) and the density between the different elements contained within lead and lead-free solders. Lead has a very high Z value and this is being replaced in the lead-free materials mainly with additional quantities of tin that has a much lower Z value as well as a lower density. Therefore, the effect of imaging lead-free solders using the same tube parameters that would currently be used for traditional lead solders may result in the image being overexposed. This is because the lower Z / less dense materials in the lead-free material will absorb the x-rays less, allowing more to pass through to the detector and potentially saturate it. Element Lead Tin Silver Copper Symbol Pb Sn Ag Cu Atomic Number (Z) 82 50 47 29 Atomic Mass (amu) 207.2 118.71 107.8682 63.546 maintained during PCB manufacture. As can be seen in the x-ray images below (images 1 – 8) of lead-free examples of BGA and CSP investigations, there is sufficient contrast and resolution to be able to clearly identify the faults that may occur. Many of these x-ray images come from the results of the SMART Group Lead-Free Hands on Experience that was held during Nepcon UK 2003 and were produced on Dage x-ray inspection systems. At this event, the same PCB with four different finishes had components placed and reflowed, either by vapour phase or convection, using a SAC (tin./silver/copper) lead-free solder. Further information and results of using these different combinations can be found in reference 6. Conclusion No. of Protons 82 50 47 29 No. of Neutrons 125 69 61 35 11.34 7.31 10.5 8.96 Density (g/cm3) Table 1: Comparison of fundamental properties of elements used in lead and lead-free solders To compensate for this effect, it may be necessary to decrease the tube kV and/or the power values that have been used previously for x-ray inspection of the lead version. This will ensure that suitably contrasted images are still available for making analysis. However, these changes, if indeed are needed at all, are likely to be small in quantity. Values of around 5 – 15 kV less accelerating voltage than for the equivalent lead soldered board may be the typical adjustment necessary. The tube power might need to be decreased by 0.25W but this will be dependent on the x-ray system being used because of the variation in tube efficiency, capability and brightness from manufacturer to manufacturer. Whilst it may be necessary to adjust the x-ray tube parameters for lead-free application, most modern xray systems have the ability to make comprehensive contrast adjustments to the captured x-ray images – see reference3. Therefore, the changes in contrast that using lead-free solders might cause compared to previous lead versions may be able to be adjusted electronically without the need to change the tube parameters and so simplifying the need to change test and inspection procedures as lead-free processes are adopted. Results The key requirements of x-ray inspection of PCBs, lead-free or otherwise, is that opens, bridges, shorts, voids, etc. can be seen such that process and production quality control can be Changing to a lead-free process requires a consideration of the implications that these new materials have on PCB manufacture and test / inspection because of their differing properties to what has been the convention for tin/lead solders for so many years. The lead-free learning curve has to be climbed requiring trials to be made and errors will occur. However, as far as x-ray inspection is concerned then existing and future x-ray equipment will be able to see these faults under lead-free BGA and CSPs as well as within the rest of the SMT components. All that may be necessary is the adjustment of certain x-ray tube parameters to ensure the best image contrast is available to allow for easy analysis. References (1) www.lead-free.org; www.smartgroup.org; www.leadfreesoldering.com (2) Report MATC (A) 141: Code of Practice for the Use of Electronic Components and PCBs in Lead-Free Processing, by M. Wickham, A. Brewin, L. Zou & C.P. Hunt, United Kingdom National Physical Laboratory available from www.npl.co.uk (3) X-ray tube selection criteria for BGA / CSP X-ray inspection, D. Bernard, published in The Proceedings of SMTA International Conference, Chicago, September 2002 (4) Selection Criteria for X-ray Inspection Systems for BGA and CSP Solder Joint Analysis, D. Bernard, published in The Proceedings of Nepcon Shanghai 2003 (5) www.ndt−ed.org/EducationResources/CommunityCollege/ Radiography/Physics/radmatinteraction.htm (6) For the results of the SMART Group Lead-Free Hands On Experience held during Nepcon UK, June 2003 see www.smartgroup.org/ev_leadfree3.asp Image 1: Oblique x-ray view of lead-free BGA with leadfree solder (SAC) after convection reflow, on a silver-finish board. The balls shown with a ‘tear-drop’ shape are caused by the deliberate inclusion of a reflow indicator. In this way, good reflow characteristics are clearly indicated by the unique ball shape and allow easy identification of good process validation under x-ray inspection. Image 2: Oblique x-ray view of lead-free BGA with leadfree solder (SAC) after convection reflow, on an OSP finish board. The variable solder ball shape compared to image 1 suggests the process used needs to be reviewed. Image 3: Oblique x-ray view of lead-free BGA with leadfree solder (SAC)after vapour phase reflow, on a gold-finish board. The bridge between two solder balls is clearly visible indicating the need to rework this part. Image 4: Voiding within solder balls of a lead-free BGA using lead-free solder. This level of voiding is excessive and suggests that the reflow temperature profile used should be modified. Image 5: Oblique x-ray view of lead-free flip chip. The variation in the joint shapes clearly differentiates between open (circular) and reflowed joints (‘hourglass’ shaped). These solder balls are ~ 190 microns in diameter. Image 6: X-ray inspection remains valid for all SMT components and not just BGA and CSP devices as shown in this and images 7 and 8. In this image of a lead-free board, there is voiding under the component that may potentially cause problems as well as voiding in the BGA solder balls. The insides of components are also visible under x-ray inspection. Image 7: Oblique x-ray view of lead-free, pin-in-hole reflow using lead-free (SAC) solder on an OSP-finish board. The barrels are completely filled with solder but there is evidence of voiding within the solder. Image 8: Oblique x-ray view of lead-free, pin-in-hole reflow using lead-free (SAC) solder on a lead-free HASLfinish board (tin/copper/nickel finish). The barrels are not completely filled with solder and therefore may require rework.