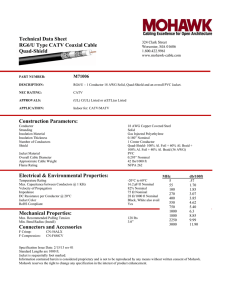

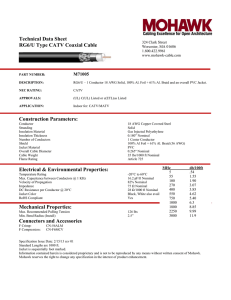

high voltage

advertisement