High-Performance Vacuum Insulation Panel in Building Envelope

advertisement

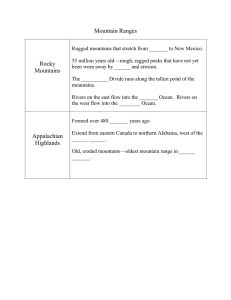

Ontario Building Officials Association(OBOA), 2010 AMTS Technical Committee Meeting, 06 October 2010 Green in Blue Mountains High-Performance Vacuum Insulation Panel in Building Envelope Construction Dr. Phalguni Mukhopadhyaya Senior Research Officer Presentation Outline What is high performance thermal insulation? Vacuum insulation panel – advantages and challenges Various applications Conclusions Green in Blue Mountains 2 Heat Transfer Mechanisms Primary mechanisms • Conduction • Convection • Radiation Influenced by • Air infiltration • Air intrusion • Moisture accumulation Green in Blue Mountains 3 High Performance Thermal Insulation ? Higher thermal resistance Long service life Environmentally friendly Sustainable systems Green in Blue Mountains 4 Thermal Performance Improvement Continues Green in Blue Mountains 5 Basics for High Performance Thermal Insulation 1.4 = 1/R BTU/hr ft2 F Heat flow/temperature difference 1.6 Convection Conduction 1.2 Radiation 1.0 0.8 0.6 0.4 0.2 0 1” 2” 3” Ordinary air spaces CBD – 149; Shirtliffe 1” 2” 3” Air spaces with reflective surface 1” 2” 3” Spaces filled with glass fibres Heat Transfer Across Air Spaces – Contribution by Radiation, Conduction and Convection Green in Blue Mountains 6 Insulation – Components for Heat Transfer Thermal conductivity (W/m.K) 0.03 Air conduction 0.02 Thermal conductivity (W m-1 K-1) R-value per inch 0.040 3.6 0.035 4.1 0.030 4.8 0.025 5.8 0.020 7.2 0.015 9.6 0.010 14.4 0.005 28.9 Radiation 0.01 Solid conduction 0 0 20 60 40 Density (kg/m3) 80 100 Reduce Air Conduction Component – High Thermal Resistance Green in Blue Mountains 7 High Performance Thermal Insulation Closed-cell foam insulation • Blowing agent conductivity Air conductivity Aerogel • Air conductivity (nanopore) < Air conductivity (macropore) Vacuum insulation • Air conductivity Zero Green in Blue Mountains 8 High Performance Thermal Insulation Closed cell foam insulation Green in Blue Mountains Solid polymer matrix Closed cell (Blowing agent) 9 High Performance Thermal Insulation Aerogel: Air conductivity (nanopore) < Air conductivity (macropore) Thermal Conductivity [W/(mK)] 0.028 0.024 0.020 Pore diameter 10 mm 0.016 1 mm 0.1 mm 0.012 0.01 mm 0.001 mm 0.008 Fumed silica/aerogel 0.004 0 1.0E-02 1.0E-01 1.0E+00 1.0E+01 1.0E+02 1.0E+03 1.0E+04 1.0E+05 Green in Blue Mountains Gas pressure (Pa) 10 High Performance Thermal Insulation VIP: Air conductivity component zero Thermal conductivity (W/m.K) 0.03 Air conduction 0.02 Radiation 0.01 Solid conduction 0 0 20 Green in Blue Mountains 60 40 Density (kg/m3) 80 100 11 Vacuum Insulation Panel (VIP) Green in Blue Mountains Source: NRCan 12 Vacuum Insulation Panel (VIP) Green in Blue Mountains 13 Vacuum Insulation Panel (VIP) 499 mm (19.7”) Glass Fibre R63 EPS VIP Green in Blue Mountains Source: NRCan 14 Vacuum Insulation Panel (VIP) Getter/desiccant Core material Multi-layer envelope film Gas barrier/ facer foil Core-bag Pressed silica core with opacifier Green in Blue MountainsSource: IEA/ECBCS Annex 39 15 Vacuum Insulation Panel (VIP) 1. Core Material – imparts mechanical strength and thermal insulating capacity 2. Gas Barrier / Facer Foil – provides air and vapour tight enclosure for core material 3. Getter / Desiccant – adsorbs residual or permeating atmospheric gases or water vapour in the VIP enclosure Green in Blue Mountains 16 Vacuum Insulation Panel (VIP) Inherent advantages • Higher thermal resistance* • Reduced thickness of the component • Recyclable * Any damage in the vacuum system (even a small pinhole) will severely destroy the thermal insulating capacity of VIPs Green in Blue Mountains 17 Vacuum Insulation Panel (VIP) Challenges • Cost (relatively expensive) • Building physics and engineering – Aging and durability – Thermal bridge effects at edges – Condensation Green in Blue Mountains 18 Alternative Core Materials for VIP Precipitated silica, fumed silica, nanogel (silica aerogel) are used as core materials Core materials are expensive Alternative core materials can reduce the cost of VIP Green in Blue Mountains 19 Vacuum Guarded Hot Plate (VGHP) Green in Blue Mountains Vacuum enclosure Cold plates Fixed end Stand Main guarded heater VGHP Operation 20 Thermal Characteristics of Core Materials Thermal Characteristics vs. Pore Pressure 3.6 0.040 4.8 0.030 0.025 0.020 0.015 0.010 0.005 7.2 14.4 R-value Per Inch 0.035 Atmospheric pressure Thermal conductivity (W/m.K) (Mineral Oxide Fibre Board) 28.8 0 1 10 Green in Blue Mountains 100 1000 10,000 Pressure (Pa) – Log scale 100,000 1,000,000 21 Thermal Characteristics of Core Materials 3.6 0.030 Open-cell polystyrene Precipitated silica 4.8 0.025 0.020 0.015 0.010 0.005 7.2 R-value Per Inch 0.035 Nanogel (Barrier Ultra-R) Open-cell polyurethane Atmospheric pressure Thermal conductivity (W/m.K) 0.040 14.4 28.8 0 1 10 100 10,000 100,000 Pressure (Pa) – Log scale Source: http://www.glacierbay.com/vacpanelinfo.asp Green in Blue Mountains 1,000 22 Alternative Nano-Porous Core Materials Pore Structure Analysis – Scanning Electron Microscopic Mineral Oxide Fibre Board (MOFB) Green in Blue Mountains High Density Glass Fibre (HDGF) 23 Alternative Nano-Porous Core Materials Thermal Characteristics of MOFB and HDGF 3.6 0.030 0.025 0.020 0.015 0.010 4.8 7.2 R-value Per Inch 0.035 Atmospheric pressure Thermal conductivity (W/m.K) 0.040 14.4 Mineral oxide fibre board High density glass fibre 0.005 28.8 0 1 10 Green in Blue Mountains 100 1,000 10,000 100,000 1,000,000 Pressure (Pa) – Log scale 24 Alternative Nano-Porous Core Materials Particle Size Analysis – Output from Particle Analyzer Particle Size Distribution Pumice Green in Blue Mountains Particle Size Distribution Zeolite 25 Alternative Nano-Porous Core Materials Thermal Characteristics of Pumice and Zeolite Powders 1.8 0.080 Pumice Powder 0.060 0.050 0.040 0.030 0.020 0.010 0.000 Zeolite Powder 0.070 2.1 0.060 2.4 0.050 2.9 0.040 3.6 0.030 4.8 0.020 7.2 0.010 14.4 R-value Per Inch 0.070 Thermal Conductivity (W/m.K) Thermal Conductivity (W/m.K) 0.080 0.000 1 10 100 1000 10000 Pressure (Pa) - Log Scale Green in Blue Mountains 100000 1000000 1 10 100 1000 10000 100000 1000000 Pressure (Pa) - Log Scale 26 Alternative Nano-Porous Core Materials Basic Hypothesis of Fibre-Powder Composite Fibres Powder particle Pores (a) Fibrous pore structures Green in Blue Mountains (b) Fibrous pore structures packed with particles 27 Alternative Nano-Porous Core Materials Basic Hypothesis of Fibre-Powder Composite 25 mm Powder Green in Blue Mountains Fibreboard 3.5 mm 3.5 mm 3.5 mm 3.5 mm 3.5 mm 3.5 mm 3.5 mm 28 Alternative Nano-Porous Core Materials Comparison of Thermal Characteristics – New/Alternative Core Materials vs. Nanogel and Precipitated Silica 1.8 0.07 High density glass fibre – Pumice powder composite 2.1 0.06 Precipitated Silica Nanogel Mineral oxide fibre – Zeolite powder composite 2.4 0.05 0.04 0.03 0.02 0.01 2.9 3.6 4.8 7.2 R-value Per Inch Mineral oxide fibre – Pumice powder composite Atmospheric pressure Thermal conductivity (W/m.K) 0.08 14.4 0 1 10 100 1,000 10,000 Pressure (Pa) – Log scale Green in Blue Mountains 100,000 1,000,000 29 Alternative Nano-Porous Core Materials New Vacuum Packaging Facility at NRC-IRC Chamber Green in Blue Mountains VIP specimen 30 Vacuum Insulation Panel Challenges • Building physics and engineering – Aging and durability – Thermal bridge effects at edges – Condensation Green in Blue Mountains 31 Aging and Durability Manufacturing Properties of core materials Handling and exposure Green in Blue Mountains Source: IEA/ECBCS Annex 39 32 Thermal Bridge Use large panels Overlap panels Fill gaps at edges with insulating materials Green in Blue Mountains Warm side Cold side Source: IEA/ECBCS Annex 39 33 Condensation VIP is an absolute vapour barrier Avoid damp construction materials Consequences of vacuum failure Green in Blue Mountains 34 Various Applications Green in Blue Mountains Source: IEA/ECBCS Annex 39 35 Various Applications Wall Floor Green in Blue Mountains Ceiling Wall Source: IEA/ECBCS Annex 39 36 Apartment and Office Block (Europe) Façade Renovation Vertical Lath Green in Blue Mountains Concrete Vertical Lath VIP Foam Panel Plaster After Source: IEA/ECBCS Annex 39 37 Office Building (Europe) Insulated Prefabricated Concrete Elements Green in Blue Mountains Source: IEA/ECBCS Annex 39 38 Prefabricated Wall Elements Coping stone Lath Anchor Polyurethane foam Vacuum insulation Vapour stop Concrete ca. 27 cm Green in Blue Mountains Source: IEA/ECBCS Annex 39 39 Semi-detached House (Europe) Façade Renovation Before Green in Blue Mountains After Source: IEA/ECBCS Annex 39 40 Semi-detached House Cross-section of Insulated Wall Green in Blue Mountains 56 mm Wall Vapour barrier Vacuum insulation (15 mm) Polystyrene (35 mm) PVC rail Reinforcing plaster (3 mm) Synthetic resin plaster (3 mm) Source: IEA/ECBCS Annex 39 41 Semi-detached House Green in Blue Mountains Installation Source: IEA/ECBCS Annex 39 42 Performance Assessment Green in Blue Mountains Source: IEA/ECBCS Annex 39 43 Terraced House (Europe) Building Envelope Renovation Green in Blue Mountains Source: IEA/ECBCS Annex 39 44 Terraced House Cross-section of Insulated Wall 9.2 Green in Blue Mountains Brick wall (340 mm) Separating layer (10 mm) Vacuum insulation (30 mm) Compressible foam tape Lath of laminated wood (40/30) Hespen-profile (12 x 40 mm) Vacuum insulation (15 mm) Soft grain board painted with bitumen (22 mm) Fermacell board HD (15 mm) Source: IEA/ECBCS Annex 39 45 Performance Assessment 2002 Green in Blue Mountains Green in Blue Mountains Source: IEA/ECBCS Annex 39 2003 46 Net Zero Energy Super E House (Japan) Source: Chris Mattock MRAIC, Habitat Design Plus Consulting Ltd. Green in Blue Mountains 47 Flat Roof Assembly TYPICAL FLAT ROOF Metal roof Roofing paper 12.5 mm plywood sheathing shaped 38x184 @ 610mm o.c. Fibreglass bracket 150 mm Rock wool (R22) Roofing paper 12.5 mm plywood sheathing 241 mmI-joist @610mm o.c. 241 mm Icynene A.B. (R34.2) 21 mm VIP (R43) 19x89 strapping @610mm o.c. 12.5mm drywall ceiling Paint finish Source: Chris Mattock MRAIC, Habitat Design Plus Consulting Ltd. Green in Blue Mountains 48 Harmony House Equilibrium Project (Canada) RSI 1.06 R 6 triple glazed windows Source: Chris Mattock MRAIC, Habitat Design Plus Consulting Ltd. Green in Blue Mountains 49 Wall Assembly www.harmony-house.ca Source: Chris Mattock MRAIC, Habitat Design Plus Consulting Ltd. Green in Blue Mountains 50 Upcoming Northern Canada Project Green in Blue Mountains House in Yukon 51 Conclusions High performance thermal insulation can be used in various components of the exterior building envelopes. Vacuum Insulation Panel (VIP) offers a great new opportunity for the thermal insulation industry in Canada. NRC-IRC is in the forefront of VIP technology research and application. Green in Blue Mountains 52 Parting Shot Green in Blue Mountains 53 Parting Remarks All the forces in the world are not so powerful as an idea whose time has come. Green in Blue Mountains Victor Hugo 54 Insulation and Building Materials Laboratory (IBML) Measurement Focus Areas Heat flow metre – thermal conductivity Vacuum guarded hot plate – thermal conductivity Guarded hot plate – thermal conductivity to Innovation Thermal and moisture performance assessment of insulation and building materials National thermal measurement calibration laboratory Research support to CCMC and CCC Development of standard test methods Analytical techniques for thermal and moisture transport process Maintain and enhance unique hygrothermal material property database Research on innovative building materials Pressure plate apparatus – desorption isotherm Green in Blue Mountains Air permeability apparatus – air permeability Partial immersion – water absorption coefficient Sorption / desorption measurement – sorption / desorption isotherm Constant temperature and humidity chambers – water vapour diffusion 55 Thank You Natural Resources Canada (NRCan) Canada Mortgage and Housing Corporation (CMHC) Kingspan Insulated Panels Yukon Housing Yukon Cold Climate Innovation Centre Panasonic Canada Energy Solutions Centre Yukon College Green in Blue Mountains 56 Upcoming International VIP Conference Green in Blue Mountains 57 www.nrc-cnrc.gc.ca/irc