1 Introduction

advertisement

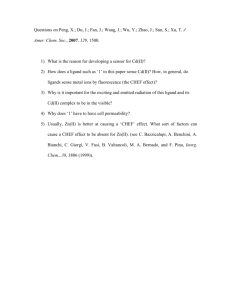

Introduction

1 Introduction

The catalytic polymerisation of olefins by well-defined organometallic catalysts has

traditionally been the exclusive field of the early transition metals (groups 3 – 5).

Metallocene catalysts (with a ligand set based on two η5-cyclopentadienyl moieties),

which often contain a group 4 metal in its highest oxidation state, can achieve

tremendous activities. These catalysts can readily be fine-tuned by ligand

modifications and continue to be a subject of research, both in academia and in

industry.1

Early transition metal catalysts are usually hard Lewis acids which implies formation

of strong complexes with hard Lewis bases. Olefins, however, are relatively weakly

bound since they are soft Lewis bases, binding through their π-cloud to the metal.

The combination of a hard Lewis acidic active site and a soft substrate makes these

catalysts extremely sensitive to the presence of polar molecules (containing e.g. O or

N) in the reaction medium (either as impurities, or as part of the substrate).

Therefore, they are often designated ‘oxophilic’. Polymerisation may be inhibited

because the olefin has to complete for the metal centre with Lewis bases in the

reaction medium. In the case of a hard Lewis base, coordination may even lead to

irreversible poisoning of the catalyst. In addition, early transition metal catalysts

contain highly polar Mδ+–Cδ– bonds, which are vulnerable to protonolysis (e.g. by

adventitious H2O in the medium). As a consequence, polymerisations with these

catalysts often require the use of a large excess of cocatalyst to scavenge impurities

from the reaction medium.

An associated disadvantage of the early transition metal catalysts is that they cannot

be employed for the copolymerisation of monomers with polar functionalities. The late

transition metals (groups 9 – 11) are much less oxophilic and coordination of polar

molecules is often readily reversible. The increased heteroatom tolerance allows

polymerisations to be run at lower cocatalyst concentrations. The late metals also

offer much better chances for copolymerisation of ethene or propene with

comonomers containing polar functionalities.2 The reduced oxophilicity of the late

transition metals is illustrated by the SHOP (Shell Higher Olefin Process) system for

oligomerisation of ethene, which utilises a homogeneous Ni(II) catalyst in an alcoholic

solvent.3-11 Heteroatom tolerance also enables the alternating copolymerisation of

ethene

and

carbon

monoxide

by

Pd(II)

catalysts.12

Nevertheless,

homopolymerisation of simple olefins by late transition metals has been largely

unknown for a long time, although polyethene formation had occasionally been

observed with certain SHOP catalysts.6,10,11,13,14 The failure of most Ni catalysts to

polymerise ethene to high molecular weight polyethene is related to the fact that β-H

elimination is fast, resulting in the formation of dimers15 or oligomers at most.

1.1 Late transition metals

A major breakthrough was accomplished in 1995 when Brookhart introduced Ni(II)

and Pd(II) catalysts based on α-diimine ligands with o-substituted aromatic Nsubstituents. In the presence of methylalumoxane (MAO), these compounds are

active in the polymerisation of ethene and α-olefins.

1

Chapter 1

Ar

N Ar

N

M

Br

Br

M = Ni, Pd, Ar = 2,6-iPr2C6H3

Figure 1.1

In principle, the transfer of a β-H atom from the growing polymer chain to the metal

center alone does not necessarily lead to chain termination: simple dissociation of the

olefinic polymer resulting from β-H-elimination is significantly endothermic. If the

coordinated olefinic polymer remains coordinated to the metal centre, reinsertion will

take place enabling further chain growth (Scheme 1.1). However, the olefinic polymer

can be displaced from the metal by associative coordination of a new monomer

molecule. Brookhart recognised that chain termination can thus be retarded by

blocking associative displacement of the chain through well-positioned steric

hindrance applied by the ancillary ligand.

In the Ni and Pd catalysts, the aryl rings of the ligand are forced into an orientation

perpendicular to the diimine backbone. The o-substituents effectively shield the axial

positions of the square coordination plane, thus preventing associative displacement

of the coordinated polyolefin chain by the monomer. This retardation of chain transfer

with respect to chain growth, enables the formation of high molecular weight

polymers. If aryl groups with sterically less demanding o-substituents are employed,

the catalysts produce oligomers (α-olefins).16,17 Besides their influence on the ratio of

rate of chain transfer to the rate of chain growth, the large aryl substituents also

hamper the formation of inactive [(diimine)2M] complexes.18,19

P

N

P

N

M

P

β-H elim.

M

N

N

M

reinsertion

N

H

N

C2H4

C2H4

N

N

P

+

M

M

N

H

H

N

P

Scheme 1.1 Associative chain displacement. M = Ni, Pd, P = growing polymer chain

Since Brookhart’s original findings, the use of appropriate steric protection on the

ancillary ligand to block associative chain displacement has led to many new Ni and

Pd polymerisation and oligomerisation catalysts. Many of these contain an α-diimine

2

Introduction

as the key ligand structure,18,20-26 although other neutral (N,N)-,27,28 (N,O)-,29 (P,O)30,31

(P,P)-,32-35 and (P,N)-ligands36-43 have yielded active systems as well.

The principle of shielding axial positions has also revived the development of

monoanionic ligands for neutral Ni(II) catalysts. Neutral catalysts are expected to

have a higher heteroatom tolerance than the cationic catalysts. Grubbs introduced a

family of catalysts based on sterically hindered salicylaldiminato ligands (Figure

1.2A).44,45 In the presence of B(C6F5)3 or Ni(COD)2 (COD = cis-1,5-cyclooctadiene),

these complexes polymerise ethene with high activity. Many related Ni polymerisation

catalysts with monoanionic (N,O)-ligands have been reported, some of which do not

require a cocatalyst at all (Figure 1.2B,C).19,46-53

With respect to the charge and denticity of the ligand, the Grubbs-type catalysts can

be compared to the SHOP oligomerisation catalysts. Not surprisingly, SHOP-type

Ni(II) (P,O)-chelates equipped with well-positioned steric bulk have now been

reported to produce polyolefins.54,55 Anionic (N,N)-ligands equipped with sterically

demanding groups have also been applied in Ni polymerisation catalysts.56,57

R

Ar

N

O

Ar

Ni

Ph

PPh3

A

Ar = 2,6-iPr2C6H3

R = 9-Anthracenyl

N

O

Ni

Ar

PPh3

Ph

B

Ar = 2,6-iPr2C6H3

N

O

Ni

PPh3

Ph

C

Ar = 2,6-iPr2C6H3

Figure 1.2 Neutral Ni(II) olefin polymerisation catalysts

1.2 Iron-based catalysts

In 1998, the groups of Gibson and Brookhart reported highly active catalysts based

on divalent Fe and Co producing highly linear polyethylene in the presence of MAO

cocatalyst.58,59 The catalyst precursor complexes contain a pyridine-2,6-diimine (PDI)

ligand with sterically demanding aryl groups on the imine nitrogens. In general, the

Fe derivatives are much more active than the Co derivatives. These catalysts again

demonstrate the principle of steric protection of the metal centre. Reduction of the

steric bulk on the nitrogen aryl substituents, converts the polymerisation catalysts into

oligomerisation catalysts.60-64 If the steric bulk is reduced too drastically, however,

inactive [(PDI)2Fe]2+ complexes are formed.65

3

Chapter 1

N

Ar

Cl

N M

Cl

N

Ar

[(PDI]MCl2]

M = Fe, Co, Ar = 2,6iPr2C6H3

Figure 1.3

Several attempts have been made to develop new Fe or Co based catalysts by

modification of the basic structure of the PDI ligand. Instead of aryl substituents, NR2

groups have been introduced in the PDI ligand as steric protection. The

corresponding Fe and Co complexes produce oligomers or low molecular weight

polyethene.66. Related to these derivatives are pyrrolyl-substituted PDI ligands.66,67

Replacement of one or both imine donors by amine functionalities strongly decreases

the activity of the iron complexes.68 Replacement by N-heterocyclic carbene donors

results in loss of activity with cobalt.69 Bis(iminophophoranyl)pyridine ligands have

been

employed

by

Al-Benna

et

al.

to

prepare

the

complexes

[{C5H3N(R2P=NR’)2}MX2] (M = Fe, Co). In spite of their structural similarity to the PDI

ligand, the Fe and Co complexes showed only low (Fe) to moderate (Co) activity in

ethene polymerisation in the presence of MAO.70 Variation of the central donor by

changing the pyridine for thiophene, furan, carbazole, pyrimidine or triazine moieties

also leads to significantly less active catalysts.67,71 If the pyridine donor is replaced by

the anionic pyrrolato group, the ligand coordinates to Fe(II) in bidentate mode,

forming bis(ligand)Fe complexes which are inactive upon activation with MAO.72 In

general, any modification of the basic PDI ligand structure leads to loss of activity.

Attempts to develop alternative olefin polymerisation catalysts based on Fe have met

with very limited success. In the patent literature examples have appeared of Fe(II)

precatalysts with tridentate monoanionic ligands (Figure 1.4A–C). Their activities

however, are very much lower than those achieved by the Gibson/Brookhart

system.73 Phosphinimide Fe(III) complexes (Figure 1.4D) have been found to form

modestly active systems with MAO under rather demanding conditions.74

PPh2

Me2Si

Cl

N

Fe

N

Cl

Me2Si

PPh2

A

NMe2

NAr

Cl

Fe

NAr

B

Fe

Cl

Br

Cl

Br

NMe2

C

P(tBu)3

Cl

Fe

N

N

Br

Fe

Br

P(tBu)3

D

Figure 1.4

It appears that design of new polymerisation catalysts based on Fe or Co is less

straightforward than in the case of Ni or Pd. One of the main reasons is that for the

former systems there is still uncertainty about the nature active species (see section

1.6). Possibly, the electron configuration on the metal forms a special combination

4

Introduction

with the electronic structure of the ligand. It may well be that the known redox-activity

of the PDI ligand contributes to the success of the PDI/Fe- or PDI/Co-combination.75

1.3 Activation of precatalysts

As seen from the examples in the preceding sections, active olefin polymerisation

catalysts are now available for a range of late as well as early transition metals. In

many cases, the actual active catalyst species is not isolated and used as a welldefined organometallic complex, but is generated in situ from a catalyst precursor or

precatalyst (that itself is not active) and a cocatalyst. In order to discuss the nature

and properties of the active catalyst species, the various methods used to generate

such active species are briefly reviewed.

1.3.1 Activation by alumoxanes

Many transition metal precatalysts can be activated by MAO (MethylAlumOxane)

cocatalyst.76-78 The composition and structure of MAO are not well-understood, and

therefore MAO is often represented by the formula [AlOMe]n. MAO is obtained by

controlled hydrolysis of AlMe3 and constitutes a complex mixture involving many

species and equilibria.79 Residual AlMe3 (either free or associated) present in MAO

participates in many of these equilibria and a formulation as [AlOMe]n·(AlMe3)x is

therefore more appropriate. MAO is thought to serve three important purposes in

homogeneous catalytic olefin polymerisation. Firstly, when transition-metal halide

complexes are used as catalyst precursor, MAO will methylate this precatalyst to

generate species with metal-methyl bonds. Secondly, MAO acts as a Lewis acid

species in abstracting an alkyl (or halide) anion R– from the transition metal,

generating a cationic metal-alkyl species with a weakly nucleophilic [R-MAO]– anion

as counterion. Thirdly, the excess MAO used in activating the catalyst can

conveniently scavenge impurities from the feed/medium, thus protecting the active

catalyst species. Nevertheless, there are some disadvantages associated with the

use of MAO as activator. It appears that the alkyl abstraction process and the

concomitant generation of the weakly nucleophilic anion requires a substantial

excess of MAO to be at its most effective (at least several hundreds of equivalents,

frequently more). This, combined with the relatively high cost of MAO, makes it less

attractive for industrial application. In addition, the poorly defined nature of MAO

makes it more difficult to establish the true nature of the active species in MAO

activated systems.

1.3.2 Activation by abstraction of halide or alkyl ligands

Due to the disadvantages attached to the use of MAO as activator (described above),

alternative activation strategies have been actively pursued (Scheme 1.2). Activators,

other than MAO, have been developed which react with catalyst precursors in a

stoichiometric ratio to give active catalysts with a well-defined composition and

structure. These so-called ‘single-component’ systems provide an opportunity to

study the catalytic species in much more detail. The alternative activators however,

often require alkylated metal centres in the precatalyst. In most cases, such

precatalysts are conveniently obtained by alkylation of dihalide complexes using

alkylaluminum, alkyllithium or Grignard reagents.

5

Chapter 1

An alkyl halide precursor can be dehalogenated by treatment with an alkali or silver

salt resulting in the precipitation of the alkali or silver halide. The resulting cationic

transition metal complex is left with a vacant site and its charge is balanced by the

anion provided by the abstracting agent. Alternatively, the vacancy can be created by

treatment of a dialkyl metal complex with a Brønsted acid. Protonation eliminates an

alkane and generates an alkyl cation with a vacancy. The proton is usually

introduced in the form of an oxonium or ammonium salt. The conjugate base of the

Brønsted acid (e.g. Et2O or C6H5NMe2) may coordinate to the metal centre, however

this is not necessarily problematic as these are quite weak Lewis bases, in particular

with the less electrophlic late transition metals. Nevertheless, it is mandatory that the

complementary anion displays very weak nucleophilicity (vide infra).

A third route to cationic single component catalysts involves abstraction of an alkyl

anion from a dialkyl precursor by a strong Lewis acid. Reaction of a metal dialkyl

complex [LnMR2] with triphenylcarbenium (trityl) salts provides an electron deficient

monoalkyl

cation

[LnMR]+

with

concomitant

formation

of

RCPh3.

Tris(pentafluorphenyl)borane,80 B(C6F5)3 is also frequently used as alkyl abstracting

agent. In this case, the cationic species will be accompanied by the borate anion

[RB(C6F5)3]– which incorporates the alkyl group formerly attached to the metal centre

of the catalyst precursor. A fourth method for dealkylation consists of oxidative

cleavage of the M–R bond using e.g. ferrocinium of silver salts.81

R

R

alkyl

abstraction

(Ligand)M

R

Counterion

(Ligand)M

halide

abstraction

R

(Ligand)M

X

MAO

X

dialkylation

monoalkylation

(Ligand)M

X

Scheme 1.2 Generation of cationic active species

1.4 Basic demands for catalytic activity

Although active catalytic systems described in section 1.3 are obtained from different

precursors in combination with various activators, they are believed to produce the

same cationic active species (Scheme 1.2). In all cases, at least one alkyl group

remains bound to the cationic transition metal complex. The activity of [(Cp)2ZrX2],

[(α-diimine)NiX2] or [(PDI)FeX2] precatalysts can be rationalised by invoking the

electron deficient cations [(Cp2)Zr(IV)R]+, [(α-diimine)]Ni(II)R]+ and [(PDI)Fe(II)R]+,

respectively as the catalytically active species. These cationic species [(Ligand)MR]+

all have valence electron counts of 14 (or less).

6

Introduction

For the early transition metals, it has been shown that the ionic species

[(Cp’)2ZrR][XB(C6F5)3] (R = Me, CH2Ph, X= R, C6F5) are active for olefin

polymerisation without the need for an additional cocatalyst.82-86 Brookhart and others

have undertaken detailed mechanistic studies to establish the nature and reactivity of

the late transition metal α-diimine systems. Single-component catalysts were

generated by alkyl abstraction from the alkylated precursors [(α-diimine)MR2] (M= Ni,

Pd). It was found that the electron deficient cations [(α-diimine)MR]+ are indeed

responsible for the polymerisation activity.87-91 Many theoretical studies on the αdiimine Ni and Pd catalysts have been based upon these cations as the active

species.92-102 For the Fe and Co catalysts, however, the presumed active species

[(PDI)MR]+, has not been isolated thus far (see section 1.6).

One common property of the active species is the presence of a metal carbon σbond. This is involved in the migratory insertion process with the alkene substrate,

leading to the C–C bond formation. Secondly, their low electron counts (≤ 14 VE)

suggest that at least two empty valence orbitals are required for high activity. For

insertion to take place, an empty coordination site (vacancy) is needed cis to the

metal carbon σ-bond. These three seem to be the minimal criteria for polymerisation

activity. For late transition metals, associative displacement of the growing polymer

chain has to be prevented (otherwise only dimers or low oligomers are formed). This

requires specific steric protection of the active centre. The examples of catalysts that

are mentioned in this paragraph all involve cationic active species. Although

positively charged metal alkyl catalysts indeed generally show higher activities in

olefin polymerisation than isoelectronic neutral species, the cationic nature is not a

prerequisite for activity. This is demonstrated by the highly active neutral Ni catalysts

discussed in section 1.1.

1.5 Cation-anion interactions

For those catalysts which react with an activator to give a cationic species, the

conditions of coordinative and electronic unsaturation demand that the interaction

between cation and anion is absent or weak. Therefore, the charge of the cation

must be counterbalanced by a weakly coordinating anion, since more nucleophilic

anions will occupy the free coordination site essential for polymerisation activity.

Coordination of the anion is usually a reversible process and the monomer competes

with the anion for the active site.

However, since polymerisation reactions are often performed in solvents of low

polarity, the active catalyst cannot be considered as an entirely free cation

accompanied by a ‘spectator’ anion. Due to the Coulombic attraction, the anion is

always in close proximity to the active site. However, adequate steric protection of

the metal centre may preclude close association of the ion pair. In fact, the activity of

a cationic polymerisation catalyst turns out to be directly dependent on the degree of

association between the cationic metal centre and the counterion.103,104 In cases

where the steric protection of the metal centre is insufficient, coordination of the anion

can even lead to irreversible degradation of the anion by the highly electrophilic

cation, which results in deactivation of the catalyst system. Thus, the interactions

between cation and anion determine to a large extent the thermal stability103,105 (and

consequently on catalyst lifetime) of ionic catalyst systems. Cation-anion interactions

can also have a marked influence on chain transfer characteristics and, with some

special anions, on the stereoregulation of α-olefin polymerisation.106,107 The well7

Chapter 1

known fluorinated tetraaryl borate anions [B(C6F5)4]– and [B(3,5-(CF3)-C6H3)4]– are

among the most weakly coordinating anions.103,108,109 The electronegative fluorine

atoms dissipate the negative charge on the boron atom, thus reducing the overall

nucleophilicity of the anion.

Since single-component cationic systems are well-defined ionic organometallic

compounds, these catalysts allow detailed study of cation and anion as well as of

their interactions. When B(C6F5)3 is used as abstracting agent, the presence of the R

group in the [RB(C6F5)3]– anion renders it more coordinating than e.g. [B(C6F5)4]- and,

depending on the nature of the cation, the alkyl moiety may bridge between the

boron and the metal centre. In case of a methyl bridge, the methyl hydrogens are

bent away from B and oriented toward the metal centre.82-84,110,111 If a benzyl group is

abstracted, the boron-bound benzyl is often found to coordinate to the metal by its πelectrons (Figure 1.5B).84,112,113

R

(Ligand)M

F

(Ligand)M

Me

F

B

R

F

F

A

F

F

F

F

B

3

F

F

3

B

Figure 1.5 Cation-anion interactions after methyl (A) and benzyl (B) abstraction by

B(C6F5)3

Horton et al. have correlated the 19F NMR shifts of alkyltris(pentafluorophenyl) anions

to their degree of association with cationic d0 metal cations in the ion pairs

[LnMR][RB(C6F5)3] (R = Me, CH2Ph). It was observed that a chemical shift difference

between the meta and para fluorine resonances (∆δ(m,p)) of 3 – 6 ppm is

characteristic for coordination of the alkyl moiety in the anion to the cation, whereas a

smaller value (≤ 3 ppm) for ∆δ(m.p) indicates noncoordination.114 19F NMR

spectroscopy can thus be used to differentiate between contact ion pairs and

(solvent) separated ion pairs.115 Two dimensional 19F{1H} HOESY116 (heteronuclear

NOESY) NMR spectroscopy has been applied to study the interactions between the

tetrafluoroborate anion and the electrophilic α-diimine complexes [(αdiimine)PtMe(η2-olefin)]+, which are catalytically inactive model systems for the

analogous Ni(II) and Pd(II) polymerisation catalysts. The model system confirms that

the iPr groups on the aryl nitrogen substituents effectively shield the axial positions of

the metal centre, as H···F-interactions between the anion and the Pt-methyl and

olefinic protons were not observed.117

Many new boranes and borate anions containing fluorinated aryl groups have been

synthesised with the aim of generating ever more weakly coordinating or chemically

more inert counterions for cationic olefin polymerisation catalysts.79,118-122 The central

atom of the anion is no longer the exclusive realm of the group XIII elements.

Recently, the scope of weakly coordinating anions has been widened by investigation

8

Introduction

of perfluoraryloxymetalates as counterions, which contain a transition metal as the

central atom.123

1.6 Active species in iron and cobalt pyridine-2,6-diimine

systems

From section 1.4, it becomes clear that the major criteria for homogeneous transition

metal catalysts for olefin polymerisation are electronic unsaturation and the presence

of a metal carbon bond cis to a vacant coordination site. In contrast to the welldocumented early transition metal and Ni(II) α-diimine systems, the nature of active

species in the Fe(II) and Co(II) PDI systems is not very well established. Despite

intensive research efforts, many questions about the mechanism still remain

unanswered, especially those with regard to the nature of the active species.

In analogy to the single component systems known for early transition metals and the

Ni and Pd α-diimine systems, an electron deficient, cationic alkyl species [(PDI)MR]+

(M = Fe, Co) is generally proposed to be responsible for the polymerisation activity.

Although experimental evidence for the involvement of such species is lacking,

several theoretical studies have been based on this assumption. For the cobalt

catalyst, a low spin doublet (S = 1) ground state is proposed for the 15-valence

electron alkyl cation.124 For the iron catalyst, ab initio calculations by Griffith et al. as

well as density functional calculations by Deng et al., propose a singlet (S = 0)

ground state for the 14 valence electron alkyl cation.125,126 In contrast, Khoroshun et

al., using a different functional, conclude that it must have a triplet or quintet ground

state.127

The iron catalyst precursors are usually activated with aluminoxane cocatalysts and

polymerisation results are strongly dependent on the type or activator.128,129 On the

basis of NMR data, Bryliakov has proposed dinuclear Fe-Al complexes as the active

catalyst, however none of these species has actually been isolated.130 In contrast to

the early transition metals and to the Ni and Pd catalysts, a single-component

catalyst based on the (PDI)M system (M = Fe, Co) has not been reported. This is due

to the fact that dialkylation of the dihalide precatalysts to obtain [(PDI)MR2] is not

straightforward. This hampers studies directed towards alkyl abstraction, leading to

the supposed cationic monoalkyl species. Furthermore, experimental work on the Fe

and Co systems is complicated by the paramagnetic nature of the complexes.

For the iron dihalide precursor, dialkylation appears to lead to decomposition with

concomitant formation of the dialkyl coupling product, suggesting reductive

elimination from an intrinsic dialkyl species [(PDI)FeR2].131,132 Cationic PDI Fe(II)

precatalysts without iron-alkyl bonds have been prepared by halide abstraction from

the dihalide complexes using AgSbF6. The resulting monohalide species are

stablised by MeCN or THF and have [BPh4]– as the counterion. Halide-free cations

are obtained in the presence of acetylacetonate. All these ionic systems form active

polymerisation catalysts when activated with MAO or when treated with AlMe3 (10

equiv.) in combination with B(C6F5)3 (1 equiv.).131 On the basis of EPR and

Mössbauer studies, Gibson et al. have suggested that the active species obtained

from activation with MAO contains iron in the +3 oxidation state.133

9

Chapter 1

In the case of cobalt, attempted dialkylation leads to formal reduction to the

diamagnetic cobalt(I) monoalkyl [(PDI)CoR].* The monoalkyl itself is unreactive

towards ethene, but in the presence of strong Lewis acids like MAO or

Al2Me6/B(C6F5)3 it was found to form an active polymerisation catalyst. The ionic

dinitrogen adduct [(PDI)Co(N2)][MeB(C6F5)3] is obtained upon methyl abstraction

from the monomethyl Co(I) species [(PDI)CoMe]. 1H NMR studies show that the ionic

species

slowly

polymerises

ethene

leaving

the

ethene

adduct

[(PDI)Co(C2H4)][MeB(C6F5)3] after consumption of the monomer. Note that these

precursors do not contain a cobalt-carbon σ-bond and it is still unclear how

polymerisation is initiated from the cationic species. Speculation on possible

pathways may include reductive coupling of two ethene molecules, C-H activation of

ethene or reaction of bound ethene with B(C6F5)3 to form a zwitterionic species, all of

which involve the Co(III) oxidation state.134-137 Thus far, it is not clear whether similar

redox processes as those found for Co, are also operational in the Fe case. In this

context, it is interesting that identical polymerisation activities are found irrespective

of the oxidation state of the halide precursor, i.e. [(PDI)FeCl2] or [(PDI)FeCl3]. This

probably reflects initial reduction of the Fe(III) precursor to Fe(II) by the Al

cocatalyst.59,138

The synthetic inaccessibility of the Fe(II) and Co(II) dialkyl PDI derivatives has thus

far prevented isolation of the monoalkyl cations by alkyl abstraction routes. This has

prompted the Brookhart group to study the Ru(II) and Rh(III) analogues. For these

second row transition metals, the diamagnetic target alkyl cations have been

prepared as their ethene adducts [(PDI)RuMe(C2H4)]+ and [(PDI)RhMe(C2H4)]2+,

respectively. These, however showed little to no polymerisation activity.139 Also the

Rh(I) monoalkyls [(PDI)RhR] produced no polymer upon activation with MAO.140

1.7 Electron deficient iron hydrocarbyls

If iron-based homogeneous olefin polymerisation is to be understood in full detail,

fundamental knowledge about electron deficient iron alkyls and their reactivity is

indispensable. Synthesis methodology and reactivity studies of electronically

unsaturated iron alkyls may be extrapolated to existing catalytic systems and can

possibly lead to the development of new catalysts.

Iron is found in oxidation states ranging from –II to +VI.141 However, organoiron

compounds have mainly been reported for Fe(II). Even for the very common +III

oxidation state, organometallic species are scarce in literature. The rich

organometallic chemistry of Fe(II) deals for the larger part with diamagnetic,

electronically saturated, 18-valence electron compounds. In most cases the valence

shell of iron is completed by strong-field ligands like Cp or CO.142

Literature reports on isolable, electronically unsaturated, (i.e. 14 valence electrons or

less) iron hydrocarbyls, are rather scarce. As a consequence, reactivity studies

involving such complexes are limited as well. Cationic, electron deficient iron

hydrocarbyls are completely unknown. Iron hydrocarbyls are usually obtained by

treatment of halide precursors with organolithium or Grignard reagents.142 In general,

stable compounds are isolated only if alkyl ligands without β-H atoms are employed.

*

Alkylation of the first row Mn(II) dihalide (inactive for polymerisation) has also resulted in

reduction yielding inactive formally Mn(I) monoalkyl species.194

10

Introduction

Furthermore, in order to obtain low electron counts, sterically hindered alkyls or aryls

are preferred, since these limit coordination numbers.

1.7.1 Homoleptic aryl and alkyl complexes

Homoleptic iron(II) aryl complexes143 include the neutral tetramesityldiiron [FeMes2]2

(Figure 1.6A) and the structurally similar [Fe(2,4,6-iPr3-C6H2)]2 (10 valence

electrons)144-147 in which two of the mesityls bridge the iron centres in the dimer.148-151

Only for the extraordinary bulky 2,4,6-tBu3-C6H2 (Mes*), a mononuclear, twocoordinate complex [Fe(Mes*)2] is obtained.152,153 Anionic, homoleptic aryls are

represented by [Li(OEt2)]4[FePh4] (16 valence electrons, Fe(0))154 and the

tetranaphthyl ferrate [Li(OEt2)]2 [Fe(naphthyl)4] (14 valence electrons, Fe(II)).155

The only isolated homoleptic iron alkyls are the Fe(IV) complex tetrakis(1norbornyl)iron156 (12 VE) (Figure 1.6B) and the dialkyl [Fe(C(SiMe3)3)] (10 VE).157-159

The former complex owes its stability to the fact that the iron is bonded to the

bridgehead carbons, which precludes decomposition by β-H elimination, the latter

lacks β-hydrogens. Due to steric crowding, these complexes are inert towards Lewis

bases.156 The dialkyl [Fe(CH2SiMe3)2] has been mentioned as the product of the

reaction between FeCl2 and LiCH2SiMe3, but experimental or characterisation data

are unavailable.160 Similarly, preparation of [Fe(CH2Ph)2] has been claimed, but its

isolation is doubtful.161 Anionic, homoleptic Fe(II) akyl complexes are represented by

the tetraalkylferrates [FeR4]2– which result from exhaustive alkylation of FeCl2 or

FeCl3 and can be isolated as their dilithium salts.162,163 The intermediate FeMe2

cannot be isolated and decomposes in THF at ca. –10 °C.163 Homoleptic Fe(III) aryl

or alkyl complexes are unknown.

Fe

Fe

4

Fe

A

B

Figure 1.6 Homoleptic iron hydrocarbyls

1.7.2 Diaryl and dialkyl complexes with stabilising ligands

Reaction of the homoleptic diaryls [FeMes2]2 or [Fe(2,4,6-iPr3C6H2)]2 with Lewis

bases gives rise to 3- or 4-coordinated diaryl complexes of the type [LnFeMes2] with

valence electron counts of 12 or 14 (L = phosphane, aminophosphane, phosphite,

chelating diphosphane, (o-disubstituted) pyridine, chelating diamine, α-diimines,

nitrile, n = 1,2 depending on the steric demands of L).145,147,149,151,164 A systematic

11

Chapter 1

investigation of the geometries and electronic structures of [L2FeMes2] compounds

was reported very recently by Chirik and coworkers.165 High-spin, S = 2 tetrahedral

complexes are observed with monodentate or chelating amines. Monodentate

phosphanes and phosphites form planar, S = 1 complexes. With chelating

phosphanes, both geometries are possible, depending on the substituents on the

chelating P atoms. Aryl substituents yield planar structures, while alkyl substituents

furnish tetrahedral compounds. Alternatively, stabilised iron diaryls can be obtained

by arylation of halide precursor complexes. Thus, Chatt and Shaw prepared the

planar, S = 1 bisaryl trans-[(PEt2Ph)2FeAr2] (Ar = C6Cl6) by reaction of the

corresponding dichloride with C6Cl6MgBr.165,166 The use of o-disubstituted aryls

seems crucial for stabilisation of the planar S = 1 configuration.165,166 The doubly

orthometallated

complex

[κ4C,C,N,N{(C6H4CH2)(CH3)NCH2CH2N(CH3)(CH2C6H4)}Fe] is stabilised by coordination of the

diamine moiety in the bisaryl ligand.167 Similar stabilisation by a Lewis basic side arm

is found for the bisaryl complex [{κ2C,N-(C6H4P(Ph)2=NSiMe3)}2Fe].168

Electron deficient Fe(II) dialkyls have been stabilised by chelating diphosphane

ligands with sterically demanding substituents. The complexes [(dippe)FeR2] (Figure

1.7A) (dippe = 1,2-bis(diisopropylphosphino)ethane) were obtained by treatment of

the corresponding dibromides with dialkyl magnesium reagents (dippe = 1,2bis(diisopropylphosphino)ethane).169 With smaller alkyls (e.g. Et or tBu),

decomposition in benzene or toluene takes place above 0 °C, producing

[(dippe)Fe(η6-arene)] which is assumed to result from solvent trapping by intrinsic

decomposition products.170 Nitrogen donor ligands have also been reported to

stabilise 14 VE iron alkyls. The complex [(TMEDA)FeCH2Ph)2], (TMEDA = N,N’tetramethylethylenediamine) was only observed by 1H NMR spectroscopy.171,172 Alkyl

ligands bearing a pyridine donor have successfully been employed in the tetrahedral

complexes [Fe(R2C(2-py))2] (Figure 1.7B) and [(TMEDA)Fe(R2C(2-py))] (14 VE).173175

Chirik recently reported a series of Fe(II) dialkyls supported by diimine or diamine

ligands (Figure 1.7C–E).176 Alkyl ligands with considerable sterical demands like

benzyl, (trimethylsilyl)methyl or neopentyl are required. Attempts to introduce smaller

alkyls, e.g. methyl, ethyl or benzyl, resulted in reduction to Fe(0) and dissociation of

the ancillary ligand.

12

Introduction

iPr

P

SiMe3

Me3Si

iPr

N

R

Fe

Fe

P

iPr

N

R

SiMe3

SiMe3

iPr

C

R = CH2SiMe3, CH2CiMe3, CMe3,

CH2CMe2Ph, CH2Ph, CH2C6H4Me

iPr

D

O

iPr

N

N

Fe

iPr

R

C

R = CH2SiMe3

Me3C

Fe

iPr

R

N

N

N

R

O

D

R = CH2SiMe3, CMe3, CH2Ph

CMe3

Fe

R

R

N

R

E

R = CH2SiMe3, CH2Ph

Figure 1.7 Stabilised Fe(II) dialkyls

The only Fe(III) dialkyl complex was reported very recently. The dimethyl complex is

stabilised by a monoanionic 1,8-bis(iminocarbazolide) ligand (Figure 1.8).177

Ph

N

N

Fe

Me

Me

N

Ph

Figure 1.8

1.7.3 Monoalkyl complexes with stabilising ligands

Iron(II) monoalkyls with 14 valence electrons have been prepared using substituted

derivatives of hydrotris(pyrazolyl)hydroborate.178 In spite of its formal electron

deficiency, the ethyl complex [(TpiPr)FeEt] (Figure 1.9A) is resistant to β-H

elimination.179-182 A monoanionic mixed P,N-donor ligand was used by Fryzuk to

stabilise the 14 valence electron iron monoalkyls [{N(SiMe2CH2PPh2)2}FeR] (R =

CH2SiMe3, CH(SiMe3)2).183 Gibson has reported a 14 VE methyl Fe(II) complex

supported by a monoanionic 1,8-bis(iminocarbazolide) ligand (Figure 1.9B).177 As a

part of our own research strategy (section 1.8), we have employed the β-diketiminate

ligand to synthesise Fe monoalkyls with a formal electron count of 12VE (Figure

1.9C). In the course of this research the group of Holland has also intensively studied

this family of Fe(II) monoalkyls with a wide variety of hydrocarbyls.184-187 A more

detailed discussion can be found in Chapter 4.

13

Chapter 1

Fe(III) monoalkyls and monoaryls with 15 VE have been isolated with diananionic

tetradentate ligands that enforce square pyramidal geometry, e.g. porphyrin or salen

(N,N’-ethylenebis(salicylaldiminato)).188-192 The iron-carbon bonds in these

complexes however, are of limited stability due to rapid homolysis.193

H

iPr

iPr

iPr

B

R'

N

N

N

N

N

N

N

N

iPr Fe

iPr

R'

Ar

iPr

Fe

Me

N

Ar

Ar

N

N

Fe

Ar

R

CH3

A

B

Ar = 2,4,6-Me3C6H2

C

Ar = 2,6-iPr2C6H3,

R’= tBu, Me

Figure 1.9

1.8 Research objectives and strategy

Active species in homogeneously catalysed olefin polymerisation are generally

cationic, electron deficient (i.e. formal electron count ≤ 14) transition metal alkyls, but

for the (PDI)Fe-system the nature of the active species is still unclear. Therefore,

fundamental research directed at synthesis and characterisation of new, electron

deficient iron alkyls can be valuable for the design of new Fe-based polymerisation

catalysts. Such compounds are still relatively rare in literature and consequently, the

generation of cationic iron derivatives through alkyl abstractions has remained an

unexplored field of research. Alkyl abstraction studies may yield useful information on

interactions of highly electrophilic cations with substrates, solvents and anions. This

information can provide further insight into mechanisms of propagation, inhibition and

deactivation of Fe-based catalysts. Thus far, only one type of iron catalyst, based on

the PDI ligand framework, has proved to be highly active for olefin polymerisation and

it is not clear why Fe(II) and the PDI ligand form an apparently uniquely effective

combination. This forms an incentive to develop new ligands for use with Fe as

polymerisation catalysts.

As the iron(II) pyridine-2,6-diimine system has so far not proved to be very suitable

for studying organoiron derivatives, it is not the ligand of choice for this research.

However, some of its properties will be conserved in the ligands to be used in this

research. The ligands must provide adequate steric protection to the Fe centre. This

limits the number of ligands around Fe(II), thus ensuring complexes with low electron

counts. For the same reason, ligands should donate no more than 6 electrons to the

metal. One approach is to change the ligand system from a meridional N3 system to

a facial one while keeping the number and type of donor atoms unaffected. One

intrinsic difficulty with neutral ligands is the stability of iron dialkyls which in general

14

Introduction

suffer from reductive elimination. Therefore, monoanionic ligands form an attractive

alternative since they will lead to neutral, monoalkyl Fe(II) species.

Characterisation of the iron halides and hydrocarbyls can be complicated due to the

expected paramagnetism of these compounds. NMR spectroscopy may not always

reveal structural information, although it can still be useful to provide ‘fingerprints’ of

the compounds. X-ray diffraction will therefore be an important complementary

characterisation method. The targeted Fe(II) alkyls will be screened for insertion

chemistry with olefins. Although no reports have appeared to date on neutral Fe(II)

monoalkyls with high catalytic activity olefin polymerisation, it cannot be excluded a

priori that highly electrophilic Fe(II) monoalkyls may be active.

In order to further increase the electrophilicity of the iron centre, generation of

cationic species will be investigated using perfluoroarylborane and -borate alkyl

abstracting agents. In the case of Fe(II) monoalkyls, alkyl abstraction will lead to

cations without an Fe–C bond required for olefin insertion, and therefore catalytic

activity may not be expected. However, the lack of a reactive Fe–C bond also permits

study of interactions of the cations with alkenes, solvents, Lewis bases and

associated anions without interference of reactions involving the Fe–C bond. 19F

NMR spectroscopy can be a valuable tool to investigate these interactions.

1.9 Outline

The four subsequent chapters (2 – 5) deal with the synthesis and characterisation of

electron deficient iron alkyls supported by anionic and neutral nitrogen donor ligands.

Chapter 2 starts with an overview of the rich coordination chemistry of the amidinate

ligand as well as its applications and synthesis. The sterically demanding

benzamidinate ligand [PhC(NAr)2]– (Ar = 2,6-iPr2C6H3) is chosen for stabilisation of

electron deficient iron alkyls. Complexation to Fe(II) is described as well as the role of

added Lewis bases in attempts to obtain monoalkyl derivatives.

Chapter 3 describes the Fe(II) coordination chemistry of two functionalised

benzamidinate ligands [RNC(Ph)NCH2CH2NMe2]– (R = Ar, SiMe3). These ligands

have an N,N-dimethylaminoethyl substituent on one of the nitrogen atoms, making

the ligand a potential tridentate donor. The preparation and characterisation of

dinuclear chloro complexes and their reactivity towards alkylating agents will be

discussed.

In Chapter 4, the chelate ring of the monoanionic bidentate ligand is expanded by 2

carbon atoms by the use of β-diketiminates, [HC{C(Me)NAr}2]–, which are expected

to bind more strongly to Fe(II) than the amidinates. First, this type of ligand is briefly

introduced by discussing its synthesis, coordination chemistry and applications.

Synthesis and characterisation of Fe(II) monoalkyls and some exploratory reactivity

studies will be reported.

In Chapter 5, an approach is chosen that differs from that of the previous three

chapters. Here, a neutral tridentate nitrogen donor ligand is introduced. The pyridylsubstituted β-diketimine ligand [HC(2-py)(C(Me)NAr)2], contains the same number

and type of donor atoms as the PDI ligand used by Brookhart and Gibson. In contrast

to the PDI ligand, this ligand can only coordinate facially to a metal centre. Ligand

synthesis is reported, as well as its introduction onto Fe(II) and alkylation of the iron

complex.

15

Chapter 1

In Chapter 6, the reactivity of the Fe(II) alkyls isolated in Chapters 2 – 4 towards

several borane and borate alkyl abstraction reagents is investigated. The fluoroarylsubstituted borate anions make 19F NMR spectroscopy a valuable tool to probe the

association of the generated ion pairs. Very weak interactions can be revealed due to

the paramagnetism of the d6 Fe(II) cations, which induces large shifts and significant

line broadening in the 19F NMR spectra.

The work described in the chapters 2 and 3 revealed that amidinates are kinetically

quite labile ligands. This resulted in ligand redistribution reactions, yielding Fe(II)

bis(amidinate) complexes that apparently are thermodynamically favoured. Due to

this stability, bis(amidinate) complexes offer good perspectives for an in-depth study

of the coordination chemistry of sterically hindered amidinates. In Chapter 7, a series

of bis(amidinate) complexes of the 3d metals with sterically demanding

benzamidinate ligands is described. Structural parameters, spectroscopic and

magnetic properties of the bis(amidinate) complexes are compared to assess the

effect of metal and ligand variation. Some exploratory reactivity studies are included

as well.

16

Introduction

1.10 References

1. Brintzinger, H. H.; Fischer, D.; Mülhaupt, R.; Rieger, B.; Waymouth, R. M. Angew. Chem. Int.

Ed. Engl. 1995, 34, 1143-1170.

2. Boffa, L. S.; Novak, B. M. Chem. Rev. 2000, 100, 1479-1493.

3. Peuckert, M.; Keim, W. Organometallics 1983, 2, 594- 597.

4. Keim, W.; Schulz, R. P. J. Mol. Catal. 1994, 92, 21.

5. Keim, W. New J. Chem. 1987, 11, 531-534.

6. Keim, W.; Kowaldt, F. H.; Goddard, R.; Kruger, C. Angew. Chem. , Int. Ed. Engl. 1978, 17, 466447.

7. Keim, W.; Hoffmann, B.; Lodewick, R.; Peuckert, M.; Schmitt, G J. Mol. Catal. 1979, 6, 79-97.

8. Keim, W. J. Mol. Catal. 1989, 52, 19-25.

9. Hirose, K.; Keim, W. J. Mol. Catal. 1992, 73, 271-276.

10. Keim, W. Angew. Chem. , Int. Ed. Engl. 1990, 29, 235-244.

11. Fryzuk, M. D.; Gao, X. L.; Rettig, S. J. Can. J. Chem. 1995, 73, 1175-1180.

12. Drent, E.; Budzelaar, P. H. M. Chem. Rev. 1996, 96, 663-681.

13. Starzewski, K. A. O.; Witte, J. Angew. Chem. , Int. Ed. Engl. 1985, 24, 599-601.

14. Klabunde, U.; Ittel, S. D. J. Mol. Catal. 1987, 41, 123-134.

15. De Renzi, A.; Panunzi, A.; Vitagliano, A. J. Chem. Soc. Chem. Commun. 1976, 47-47.

16. Killian, C. M.; Johnson, L. K.; Brookhart, M. Organometallics 1997, 16, 2005-2007.

17. Svejda, S. A.; Brookhart, M. Organometallics 1999, 18, 65-74.

18. Plentz Meneghetti, S.; Lutz, P. J.; Kress, J. Organometallics 1999, 18, 2734-2737.

19. Connor, E. F.; Younkin, T. R.; Henderson, J. I.; Waltman, A. W.; Grubbs, R. H. Chem. Commun.

2003, 2272-2273.

20. Shao, C.; Sun, W.-H.; Li, Z.; Hu, Y.; Han, L. Cat. Commun. 2002, 405-410 .

21. Ionkin, A. S.; Marshall, W. J. Organometallics 2004, 23, 3276-3283.

22. Kinnunen, T-J. J.; Haukka, M.; Pakkanen, T. T.; Pakkanen, T. A. J. Organomet. Chem. 2000,

613, 257-262.

23. Laine, T. V.; Piironen, U.; Lappalainen, K.; Klinga, M.; Aitola, E.; Leskela, M. J. Organomet.

Chem. 2001, 606, 112-124.

24. Schleis, T.; Spaniol, T. P.; Okuda, J.; Heinemann, J.; Mulhaupt, R. J. Organomet. Chem. 1998,

569, 159-167.

25. Schleis, T.; Heinemann, J.; Spaniol, T. P.; Mulhaupt, R.; Okuda, J. Inorg. Chem. Commun. 1

1998, 431 -434.

26. Schmid, M.; Eberhard, R.; Klinga, M.; Leskelä, M.; Rieger, B. Organometallics 2001, 20, 23212330.

27. Feldman, J.; McLain, S. J.; Parthasarathy, A.; Marshall, W. J.; Calabrese, J. C.; Arthur, S. D.

Organometallics 1997, 16, 1514-1516.

28. Sauthier, M.; Leca, F.; Fernando de Souza, R.; Bernardo-Gusmão, K.; Fernando Trevisan

Querioz, L.; Toupet, L.; Réau, R. New J. Chem. 2003, 26, 630-635.

29. Krajete, A.; Steiner, G.; Kopacka, H.; Ongania, K.-H.; Wurst, K.; Kristen, M. O.; PreishubelPflügl, P.; Bildstein, B. Eur. J. Inorg. Chem. 2004, 1740-1752.

30. Liu, W.; Malinoski, J. M.; Brookhart, M. Organometallics 2002, 21, 2836-2838.

31. Malinoski, J. M.; White, P. S.; Brookhart, M. Organometallics 2003, 22, 621-623.

32. Cooley, N. A.; Green, S. M.; Wass, D. F.; Heslop, K.; Orpen, A. G.; Pringle, P. Organometallics

2001, 20, 4769-4771.

33. Dennet, J. N. L.; Gillon, A. L.; Heslop, K.; Hyett, D. J.; Fleming, J. S.; Lloyd-Jones, C. E.; Orpen,

A. G.; Pringle, P. G.; Wass, D. F. Organometallics 2004, 23, 6077-6079.

34. Ikeda, S.; Ohhata, F.; Miyoshi, M.; Tanaka, R.; Minami, T.; Ozawa, F. ; Yoshifuji, M. Angew.

Chem. Int. Ed. 2000, 39, 4512-4513.

35. Ionkin, A.; Marshall, W. Chem. Commun. 2003, 710-711.

36. Daugulis, O.; Brookhart, M. Organometallics 2003, 21, 5926-5934.

37. Speiser, F.; Braunstein, P.; Saussine, L. Organometallics 2004, 23 , 2633-2640.

38. Speiser, F.; Braunstein, P.; Saussine, L. Organometallics 2004, 23 , 2625-2632.

39. Brassat, I.; Keim, W.; Killat, S.; Möthrath, M.; Mastrorilli, P.; Nobile, C. F.; Suranna, G. P. J. Mol.

Catal. A 2000, 157, 41-58.

40. Sun, W.-H.; Li, Z.; Hu, H.; Wu, B.; Yang, H.; Yang, H.; Zhu, N.; Leng, X.; Wang, H. New J.

Chem. 2002, 26, 1474-1478.

41. Guan, Z.; Marshall, W. J. Organometallics 2002, 21, 3580-3586.

17

Chapter 1

42. Chen, H.-P.; Liu, Y.-H.; Peng, S.-M.; Liu, S.-T. Organometallics 2003, 22, 4893-4899.

43. Speiser, F.; Braunstein, P.; Saussine, L.; Welter, R. Inorg. Chem. 2004, 43, 1649-1658.

44. Wang, C.; Friedrich, S.; Younkin, T. R.; Li, R. T.; Grubbs, R. H.; Bansleben, D. A.; Day, M. W.

Organometallics 1998, 17, 3149-3151.

45. Younkin, T. R.; Connor, E. F.; Henderson, J. I.; Friedrich, S. K.; Grubbs, R. H.; Bansleben, D. A.

Science 2000, 287, 460-462.

46. Hicks, F. A.; Brookhart, M. Organometallics 2001, 20, 3217-3219.

47. Zhang, D.; Jin, G.-X.; Hu, N.-H. Eur. J. Inorg. Chem. 2003, 1570-1576.

48. Jenkins, J. C.; Brookhart, M. Organometallics 2003, 22, 250-256.

49. Michalak, A.; Ziegler, T. Organometallics 2003, 22, 2069-2079.

50. Zhang, D.; Jin, G.-X. Organometallics 2003, 22, 2851-2854.

51. Hicks, F. A.; Jenkins, J. C.; Brookhart, M. Organometallics 2003, 22, 3533-3545.

52. Jenkins, J. C.; Brookhart, M. J. Am. Chem. Soc. 2004, 126, 5827-5842.

53. Hu, T.; Tang, L.-M.; Li, X.-F.; Li, Y.-S.; Hu, N.-H. Organometallics 2005, 24, 2628-2632.

54. Gibson, V. C.; Tomov, A.; White, A. J. P.; Williams, D. J. Chem. Commun. 2001, 719-721.

55. Gibson, V. C.; Tomov, A. Chem. Commun. 2001, 1964-1965.

56. Lee, B. Y.; Bu, X.; Bazan, G. C. Organometallics 2001, 20, 5425-5431.

57. Boussie, T., Murphy, V., and Van Beek, J. A., 1999, WO 99/05154 to SYMYX Technologies.

58. Britovsek, G. J. P.; Gibson, V. C.; Kimberley, B. S.; Maddox, P. J.; McTavish, S. J.; Solan, G. A.;

White, A. J. P.; Williams, D. J. Chem. Commun. 1998, 849-850.

59. Small, B. L.; Brookhart, M.; Bennett, A. M. A. J. Am. Chem. Soc. 1998, 120, 4049-4050.

60. Britovsek, G. J. P.; Mastroianni, S.; Solan, G. A.; Baugh, S. P. D.; Redshaw, C.; Gibson, V. C.;

White, A. J. P.; Williams, D. J.; Elsegood, M. R. J. Chemistry, a European Journal 2000, 6,

2221-2231.

61. Bianchini, C.; Giambastiani, G.; Guerrero, I. R.; Meli, A.; Passaglia, E.; Gragnoli, T.

Organometallics 2004, 23, 6087-6089.

62. Small, B. L.; Brookhart, M. J. Am. Chem. Soc. 1998, 120, 7143-7144.

63. Bianchini, C.; Mantovani, G.; Meli, A.; Migliacci, F.; Zanobini, F.; Laschi, F.; Sommazzi, A. Eur.

J. Inorg. Chem. 2003, 1620-1631.

64. Small, B. L. Organometallics 2003, 22, 3178-3183.

65. Chen, Y.; Qian, C.; Sun, J. Organometallics 2003, 22, 1231-1236.

66. Britovsek, G. J. P.; Gibson, V. C.; Kimberley, B. S.; Mastroianni, S.; Redshaw, C.; Solan, G. A.;

White, A. J. P.; Williams, D. J. J. Chem. Soc. , Dalton Trans. 2001, 1639-1644.

67. Amort, C.; Malaun, M.; Krajete, A.; Kopacka, H.; Wurst, K.; Christ, M. ; Lilge, D.; Kristen, M. O.;

Bildstein, B. Appl. Organometal. Chem. 2002, 16, 506-516.

68. Britovsek, G. J. P.; Gibson, V. C.; Mastroianni, S.; Oakes, D. C. H.; Redshaw, C.; Solan, G. A.;

White, A. J. P.; Williams, D. J. Eur. J. Inorg. Chem. 2001, 431-437.

69. Danopoulos, A. A.; Wright, J. A.; Motherwell, W. B.; Ellwood, S. Organometallics 2004, 23,

4807-4810.

70. Al-Benna, S; Sarsfield, M. J.; Thornton-Pett, M.; Ormsby, D. L.; Maddox, P. J.; Brès, P.;

Bochmann, M. J. Chem. Soc. Dalton. Trans. 2000, 4247-4257.

71. Britovsek, G. J. P.; Gibson, V. C.; Hoarau, O. D.; Spitzmesser, S. K.; White, A. J. P.; Williams,

D. J. Inorg. Chem. 2003, 42, 3454-3465.

72. Dawson, D. M.; Walker, D. A.; Thornton-Pett, M.; Bochmann, M. J. Chem. Soc. Dalton. Trans.

2000, 459-466.

73. Matsunaga, P. T., 1999, WO9957159 to Exxon Chemical Patents Inc.

74. LePichon, L.; Stephan, D. W.; Gao, X. L.; Wang, Q. Organometallics 2002, 21, 1362-1366.

75. de Bruin, B.; Bill, E.; Bothe, E.; Weyhermüller, T.; Wieghardt, K. Inorg. Chem. 2000, 39, 29362947.

76. Kaminsky, W.; Kulper, K.; Brintzinger, H. H.; Wild, F. R. W. P. Angew. Chem. Int. Ed. Engl.

1985, 24, 507-508.

77. Sinn, H.; Kaminsky, W. Adv. Organomet. Chem. 1980, 18, 99-149.

78. Sinn, H.; Kaminsky, W.; Vollmer, H.-J.; Woldt, R. Angew. Chem. Int. Ed. Engl. 1980, 19, 390392.

79. Chen, E. Y. X.; Marks, T. J. Chem. Rev. 2000, 100, 1391-1434.

80. Piers, W. E.; Chivers, T. Chem. Soc. Rev. 1997, 26, 345-354.

81. Jordan, R. F.; LaPointe, R. E.; Bajgur, C. S.; Echols, S. F.; Willett, R. J. Am. Chem. Soc. 1987,

109, 4111-4113.

82. Yang, X.; Stern, C. L.; Marks, T. J. J. Am. Chem. Soc. 1991, 113, 3623-3625.

83. Yang, X.; Stern, C. L.; Marks, T. J. J. Am. Chem. Soc. 1994, 116, 10015-10031.

18

Introduction

84. Bochmann, M.; Lancaster, S. J.; Hursthouse, M. B.; Malik, K. M. A. Organometallics 1994, 13,

2235-2243.

85. Chien, J. C. W.; Tsai, W.-M.; Rausch, M. D. J. Am. Chem. Soc. 1991, 113, 8570-8571.

86. Bochmann, M.; Lancaster, S. J. Organometallics 1993, 21, 633-640.

87. Johnson, L. K.; Killian, C. M.; Brookhart, M. J. Am. Chem. Soc. 1995, 117, 6414-6415.

88. Gottfried, A. C.; Brookhart, M. Macromolecules 2001, 34, 1140-1142.

89. Strauch, J. W.; Erker, G.; Kehr, G.; Fröhlich, R. Angew. Chem. Int. Ed. 2002, 41, 2543-2546.

90. Svejda, S. A.; Johnson, L. K.; Brookhart, M. J. Am. Chem. Soc. 1999, 121, 10634-10635.

91. Tempel, D. J.; Johnson, L. K.; Huff, R. L.; White, P. S.; Brookhart, M. J. Am. Chem. Soc. 2000,

122, 6686-6700.

92. Deng, L.; Woo, T. K.; Cavallo, L.; Margl, P.; Ziegler, T. J. Am. Chem. Soc. 1997, 119, 61776186.

93. Deng, L.; Margl, P.; Ziegler, T. J. Am. Chem. Soc. 1997, 119, 1094-1100.

94. Musaev, D. G.; Froese, R. D. J.; Svensson, M.; Morokuma, K. J. Am. Chem. Soc. 1997, 119,

367-374.

95. Musaev, D. G.; Svensson, M.; Morokuma, K.; Stromberg, S.; Zetterberg, K.; Siegbahn, P. E. M.

Organometallics 1997, 16, 1933-1945.

96. Froese, R. D. J.; Musaev, D. G.; Morokuma, K. J. Am. Chem. Soc. 1998, 120, 1581-1587.

97. Siegbahn, P. E. M.; Stromberg, S.; Zetterberg, K. Organometallics 1996, 15, 5542-5550.

98. Stromberg, S.; Zetterberg, K.; Siegbahn, P. E. M. J. Chem. Soc. Dalton. Trans. 1997, 41474152.

99. von Schenck, H.; Strömberg, S.; Zetterberg, K.; Ludwig, M.; Akermark, B.; Svensson, M.

Organometallics 2001, 20, 2813-2819.

100. Woo, T. K.; Blöchl, P. E.; Ziegler, T. J. Phys. Chem. A 2000, 104, 121-129.

101. Michalak, A.; Ziegler, T. Organometallics 1999, 18, 3998-4004.

102. Michalak, A.; Ziegler, T. Organometallics 2000, 19, 1850-1858.

103. Jia, L.; Yang, X.; Stern, C. L.; Marks, T. J. Organometallics 1997, 16, 842-857.

104. Landis, C. R.; Rosaaen, K. A.; Sillars, D. R. J. Am. Chem. Soc. 2003, 125, 1710-1711.

105. Jia, L.; Yang, X.; Ishihara, A.; Marks, T. J. Organometallics 1995, 14, 3135-3137.

106. Chen, E. Y. X.; Metz, M. V.; Li, L.; Stern, C. L.; Marks, T. J. J. Am. Chem. Soc. 1998, 120,

107. Busico, V.; Van Axel Castelli, V.; Aprea, P.; Cipullo, R.; Segre, A.; Talarico, G.; Vacatello, M. J.

Am. Chem. Soc. 2003, 125, 5451-5460.

108. Yang, X.; Stern, C. L.; Marks, T. J. Organometallics 1991, 10, 840-842.

109. Brookhart, M.; Grant, B.; Volpe, A. F. Organometallics 1992, 11, 3920-3922.

110. Hayes, P. G.; Piers, W. E.; McDonald, R. J. Am. Chem. Soc. 2002, 124, 2132-2133.

111. Marks, T. J. Acc. Chem. Res. 1992, 25, 57-65.

112. Pellecchia, C.; Grassi, A.; Immirzi, A. J. Am. Chem. Soc. 1993, 115, 1160-1162.

113. Lee, L. W. M.; Piers, W. E.; Elsegood, M. R. J.; Clegg, W.; Parvez, M. Organometallics 1999,

18, 2947-2949.

114. Horton, A. D.; de With, J.; van der Linden, A. J.; van de Weg, H. Organometallics 1996, 15,

2672-2674.

115. Horton, A. D. Organometallics 1996, 15, 2675-2677.

116. Hofstetter, C.; Pochapsky, T. C. Magn. Reson. Chem. 2000, 38, 90-94.

117. Zuccaccia, C; Macchioni, A.; Orabona, I.; Ruffo, F. Organometallics 1999, 18, 4367-4372.

118. Rodriguez, G.; Brant, P. Organometallics 2001, 20, 2417-2420.

119. Krossing, I.; Raabe, I. Angew. Chem. Int. Ed. 2004, 43, 2066-2090.

120. Chase, P. A.; Piers, W. E.; Patrick, B. A. J. Am. Chem. Soc. 2000, 122, 12911-12912.

121. Lancaster, S. J.; Rodriguez, A.; Lara-Sanchez, A.; Hannant, M. D.; Walker, D. A.; Hughes, D.

H.; Bochmann, M. Organometallics 2002, 21, 451-453.

122. Metz, M. V.; Schwartz, D. J.; Stern, C. L.; Marks, T. J. Organometallics 2002, 21, 4159-4168.

123. Metz, M. V.; Sun, Y.; Stern, C. L.; Marks, T. J. Organometallics 2002, 21, 3691-3702.

124. Margl, P.; Deng, L.; Ziegler, T. Organometallics 1999, 18, 5701-5708.

125. Deng, L.; Margl, P.; Ziegler, T. J. Am. Chem. Soc. 1999, 121, 6479-6487.

126. Griffiths, E. A. H.; Britovsek, G. J. P.; Gibson, V. C.; Gould, I. R. Chem. Commun. 1999, 13331334.

127. Khoroshun, D. V.; Musaev, D. G.; Vreven, T.; Morokuma, K. Organometallics 2001, 20, 20072026.

128. Kumar, K. R.; Sivaram, S. Macromol. Chem. Phys. 23-2-2000, 201, 1513-1520.

129. Britovsek, G. J. P.; Cohen, S. A.; Gibson, V. C.; van Meurs, M. J. Am. Chem. Soc. 2004, 126,

10701-10712.

19

Chapter 1

130. Bryliakov, K. P.; Semikolenova, N. V.; Zakharov, V. A.; Talsi, E. P. Organometallics 2004, 23,

5375-5378.

131. Britovsek, G. J. P.; Gibson, V. C.; Spitzmesser, S. K.; Tellmann, K. P.; White, A. J. P.; Williams,

D. J. J. Chem. Soc. , Dalton Trans. 2002, 1159-1171.

132. Gibson, V. C.; Britovsek, G. J. P.; Spitzmesser, S. K. Polymer preprints 2000, 41, 446-446.

133. Britovsek, G. J. P.; Clentsmith, G. K. B.; Gibson, V. C.; Goodgame, D. M. L.; McTavish, S. J.;

Pankhurst, Q. A. Cat. Commun. 2002, 3, 207-211.

134. Gibson, V. C.; Humphries, M. J.; Tellmann, K. P.; Wass, D. F.; White, A. J. P.; Williams, D. J.

Chem. Commun. 2001, 2252-2253.

135. Gibson, V. C.; Tellmann, K. P.; Humphries, M. J.; Wass, D. F. Chem. Commun. 2002, 23162317.

136. Kooistra, T. M.; Knijnenburg, Q.; Smits, J. M. M.; Horton, A. D.; Budzelaar, P. H. M.; Gal, A. W.

Angew. Chem. Int. Ed. 2001, 40, 4719-4722.

137. Humphries, M. J.; Tellmann, K. P.; Gibson, V. C.; White, A. J. P.; Williams, D. J.

Organometallics 2005, 24, 2039-2050.

138. Britovsek, G. J. P.; Bruce, M.; Gibson, V. C.; Kimberley, B. S.; Maddox, P. J.; Mastroianni, S.;

McTavish, S. J.; Redshaw, C.; Solan, G. A.; Stromberg, S.; White, A. J. P.; Williams, D. J. J.

Am. Chem. Soc. 1999, 121, 8728-8740.

139. Dias, E. L.; Brookhart, M.; White, P. S. Organometallics 2000, 19 , 4995-5004.

140. Kooistra, T. M.; Hetterscheid, D. G. H.; Schwartz, E.; Knijnenburg, Q.; Budzelaar, P. H. M.; Gal,

A. W. Inorg. Chim. Acta 2004, 357, 2945-2952.

141. Hawker, P. N. and Twigg, M. V., Iron(II) and Lower states; in Comprehensive Coordination

Chemistry, The synthesis, reactions, properties & applications of coordination compounds

Pergamon; Oxford, 1987, p. 1179-1288.

1

142. Johnson, M. D., Mononuclear iron compounds with η -hydrocarbon ligands; in Comprehensive

Organometallic Chemistry, the synthesis, reactions and structure of organometallic compounds

Pergamon; Oxford, 1982, p. 331-376.

143. Koschmieder, S. U.; Wilkinson, G. Polyhedron 1991, 10, 135-173.

144. Müller, H.; Seidel, W.; Görls, H. J. Organomet. Chem. 1993, 445, 133-136.

145. Lattermann, K.-J.; Seidel, W. Z. Chem. 1982, 23, 31- 31.

146. Lattermann, K.-J.; Seidel, W.; Schade, W. Z. Chem. 1984, 24, 262-263.

147. Seidel, W.; Lattermann, K.-J. Z. Anorg. Allg. Chem. 1982, 488, 69-74.

148. Machelett, B. Z. Chem. 1975, 16, 116-117.

149. Magill, C. P.; Floriani, C.; Chiesi-Villa, A.; Rizzoli, C. Inorg. Chem. 1993, 33, 1928-1933.

150. Klose, A.; Solari, E.; Ferguson, R.; Floriani, C. Organometallics 1993, 12, 2414-2416.

151. Klose, A.; Solari, E.; Floriani, C.; Chiesi-Villa, A.; Rizzoli, C.; Re, N. J. Am. Chem. Soc. 1994 ,

116, 9123-9135.

152. Müller, H.; Seidel, W.; Görls, H. Angew. Chem. Int. Ed. Engl. 1995, 34, 325-327.

153. Wehmschulte, R. J.; Power, P. P. Organometallics 1995, 14, 3264-3267.

154. Bazhenova, T. A.; Lobkovskaya, R. M.; Shibaeva, R. P.; Shilov, A. E.; Shilova, A. K.; Gruselle,

M.; Leny, G.; Tchoubar, B. J. Organomet. Chem. 1983, 244, 265-272.

155. Bazhenova, T. A.; Lobkovskaya, R. M.; Shibaeva, R. P.; Shilova, A. K.; Gruselle, M.; Leny, G.;

Deschamps, E. J. Organomet. Chem. 1983, 244, 375-382.

156. Bower, B. K.; Tennent, H. G. J. Am. Chem. Soc. 1972, 94, 2512-2514.

157. Viefhaus, T.; Schwarz, W.; Hübler, K.; Locke, K.; Weidlein, J. Z. Anorg. Allg. Chem. 2001, 627 ,

715-725.

158. Reiff, W. M.; Lapointe, A. M.; Witten, E. H. J. Am. Chem. Soc. 2004, 126, 10206-10207.

159. Lapointe, A. M. Inorg. Chim. Acta 2003, 345, 359-362.

160. Yagupsky, G.; Mowat, W.; Shortland, A.; Wilkinson, G. Chem. Commun. 1970, 1369-1370.

161. Krüerke, U. and Slawisch, A., Eisen-Organische Verbindungen; in Gmelin Handbuch der

Anorganischen Chemie Springer; Berlin, 1976,

162. Spiegl, H. J.; Groh, G.; Berthold, H. J. Z. Anorg. Allg. Chem. 1973, 398, 225-322.

163. Kauffmann, T. Angew. Chem. Int. Ed. Engl. 1996, 35, 386-403.

164. Müller, H.; Seidel, W.; Görls, H. Z. Anorg. Allg. Chem. 1996, 622, 1269-1273.

165. Hawrelak, E. J.; Bernskoetter, W. H.; Lobkovsky, E.; Yee, G. T.; Bill, E.; Chirik, P. J. Inorg.

Chem. 2005, 44, 3103-3111.

166. Chatt, J.; Shaw, B. L. J. Chem. Soc. 1961, 285-290.

167. Küpper, F.-W. J. Organomet. Chem. 1968, 13, 219-225.

168. Wingerter, S.; Pfeiffer, M.; Stey, T.; Bolboacá, M.; Kiefer, W.; Chandrasekhar, V.; Stalke, D.

Organometallics 2001, 20, 2730-2735.

20

Introduction

169.

170.

171.

172.

173.

174.

175.

176.

177.

178.

179.

180.

181.

182.

183.

184.

185.

186.

187.

188.

189.

190.

191.

192.

193.

194.

Hermes, A. R.; Girolami, G. S. Organometallics 1987, 6, 763-768.

Hermes, A. R.; Warren, T. H.; Girolami, G. S. J. Chem. Soc. Dalton. Trans. 1995, 301-305.

Hill, D. H.; Sen, A. J. Am. Chem. Soc. 1988, 110, 1650-1652.

Hill, D. H.; Parvez, M. A.; Sen, A. J. Am. Chem. Soc. 1994, 116, 2889-2901.

Lee, H. K.; Luo, B. S.; Mak, T. C. W.; Leung, W. P. J. Organomet. Chem. 1995, 489, C71-C73.

Leung, W. P.; Lee, H. K.; Weng, L. H.; Luo, B. S.; Zhou, Z. Y.; Mak, T. C. W. Organometallics

1996, 15, 1785-1792.

Hursthouse, M. B.; Izod, K.; Motevalli, M.; Thornton, P. Polyhedron 1996, 15, 135-145.

Bart, S. C.; Hawrelak, E. J.; Schmisseur, A. K.; Lobkovsky, E.; Chirik, P. J. Organometallics

2004, 23, 237-246.

Gibson, V. C.; Spitzmesser, S. K.; White, A. J. P.; Williams, D. J. J. Chem. Soc. , Dalton Trans.

2003, 2718-2727.

Akita, M. J. Organomet. Chem. 2004, 689, 4540-4551.

Akita, M.; Shirasawa, N.; Hikichi, S.; Mora-oka, Y. Chem. Commun. 1998, 973-974.

Shirasawa, N.; Akita, M.; Hikichi, S.; Morokuma, K. Chem. Commun. 1999, 417-418.

Shirasawa, N.; Nguyet, T. T.; Hikichi, S.; Moro-oka, Y.; Akita, M. Organometallics 2001, 20,

3582-3598.

Kisko, J. L.; Hascall, T.; Parkin, G. J. Am. Chem. Soc. 1998, 120 , 10561-10562.

Fryzuk, M. D.; Leznoff, D. B.; Ma, E. S. F.; Tettig, S. J.; Young Jr.V.G. Organometallics 1998,

17, 2313-2323.

Andres, H.; Bominaar, E. L.; Smith, J. M.; Eckert, N. A.; Holland, P. L.; Münck, E. J. Am. Chem.

Soc. 2002, 124, 3012-3025.

Smith, J. M.; Lachicotte, R. J.; Holland, P. L. Organometallics 2002, 21, 4808-4814.

Vela, J.; Smith, J. M.; Lachicotte, R. J.; Holland, P. L. Chem. Commun. 2002, 2886-2887.

Vela, J.; Vaddadi, S.; Cundari, T. R.; Smith, J. M.; Gregory, E. A.; Lachicotte, R. J.;

Flaschenriem, C. J.; Holland, P. L. Organometallics 2004, 23, 5226-5239.

Kadish, K. M.; Tabard, A.; Van Caemelbecke, E.; Aukauloo, A. M.; Richard, P.; Guilard, R.

Inorg. Chem. 1998, 37, 6168-6175.

Floriani, C.; Calderazzo, F. J. Chem. Soc. (A) 1971, 3665-3669.

Balch, A. L.; Olmstead, M. M.; Safari, N.; St.Claire, T. N. Inorg. Chem. 1994, 33, 2815-2822.

Goedken, V. L.; Peng, S.-M.; Park, Y. J. Am. Chem. Soc. 1974, 96, 284-285.

Doppelt, P. Inorg. Chem. 1984, 23 , 4009-4011.

1

6

Kerber, R. C., Mononuclear Iron Compounds with η -η Hydrocarbon Ligands; in

Comprehensive Organometallic Chemistry II: A review of the literature 1982-1994 Elsevier;

Oxford, 1995, p. 101-230.

Reardon, D.; Aharonian, G.; Gambarotta, S.; Yap, G. P. A. Organometallics 2002, 21, 786-788.

21

22