Seismic Performance of Structural D-region of Existing RC

Comparison of Seismic Performance of D-region of Existing RC

Structures Designed with Different Recommendations

Balthasar Novák

1

, K.Ramanjaneyulu

2

, Constanze Roehm

3

and Saptarshi Sasmal

4

1

Professor, ILEK, Universitaet Stuttgart, Germany;

Centre, Chennai, India;

3

2

Deputy Director, Structural Engineering Research

PhD scholar, ILEK, Universitaet Stuttgart, Germany;

4

Scientist, Structural

Engineering Research Centre, Chennai, India and PhD Scholar, ILEK, Universitaet Stuttgart, Germany

Email:

3 constanze.roehm@ilek.uni-stuttgart.de;

4 saptarshi@sercm.org

Synopsis:

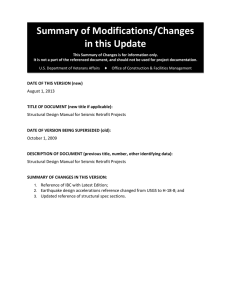

Gravity load designed (GLD) structures are vulnerable to any major earthquake and it demands for immediate assessment of their seismic performance to avoid any undesirable collapse. Nevertheless, there is no such information on comparative performance of existing structures designed based on prevailing practicing standards in different stages of their development. Further, stipulated provisions for seismic design of structures differ from one standard to another. In the present study, these issues are covered by considering different stages of Eurocode and Indian Standards provisions for designing the reinforced concrete structure. Further, an exterior beam column joint (D-region) of a building frame has been selected as the target sub-assemblage to be studied under reversed cyclic load. The study is aimed at evaluating seismic performance of the structural component designed according to the prevailing guidelines and has brought out the implications of the differences in the guidelines on seismic performance. It is found that the

GLD structure is severely vulnerable to even medium earthquake. Among the seismically designed specimens without ductile detailing, Indian Standard exhibits better performance over the Eurocode (10% more energy dissipation) under large drift ratio, and among the seismically designed and properly detailed specimens, Eurocode design with medium ductility could not perform as good as Indian Standard design (25% less energy dissipation).

Therefore, earthquake design and ductile detailing provisions of different standards and their progressive improvements have a considerable influence on seismic performance of reinforced concrete structures.

Key words: beam-column joint, D-region study, drift ratio, ductile detailing, energy dissipation, seismic performance

Page 1 of 18

Comparison of Seismic Performance of D-region of Existing RC

Structures Designed with Different Recommendations

Balthasar Novák, K.Ramanjaneyulu, Constanze Roehm and Saptarshi Sasmal

Synopsis:

Gravity load designed (GLD) structures are vulnerable to any major earthquake and it demands for immediate assessment of their seismic performance to avoid any undesirable collapse. Nevertheless, there is no such information on comparative performance of existing structures designed based on prevailing practicing standards in different stages of their development. Further, stipulated provisions for seismic design of structures differ from one standard to another. In the present study, these issues are covered by considering different stages of Eurocode and Indian Standards provisions for designing the reinforced concrete structure. Further, an exterior beam column joint (D-region) of a building frame has been selected as the target sub-assemblage to be studied under reversed cyclic load. The study is aimed at evaluating seismic performance of the structural component designed according to the prevailing guidelines and has brought out the implications of the differences in the guidelines on seismic performance. It is found that the

GLD structure is severely vulnerable to even medium earthquake. Among the seismically designed specimens without ductile detailing, Indian Standard exhibits better performance over the Eurocode (10% more energy dissipation) under large drift ratio, and among the seismically designed and properly detailed specimens, Eurocode design with medium ductility could not perform as good as Indian Standard design (25% less energy dissipation).

Therefore, earthquake design and ductile detailing provisions of different standards and their progressive improvements have a considerable influence on seismic performance of reinforced concrete structures.

Introduction: In various parts of the world, reinforced concrete structures even in seismic zones have been designed only for gravity load. Such structures though performing well under conventional gravity load case, could lead to questionable structural performance under earthquake. In most cases, those structures are vulnerable to any major earthquake and so these structures need immediate assessment to avoid a collapse which brings a huge loss of human lives and economy that the world has witnessed for several times. Moreover, for new structures, the specifications and detailing provisions, though available to a certain extent, have to be considered in such a way that the structure would be able to resist seismic actions. Generally, a three phase approach is followed to describe a structure under earthquake loading, i.e. (i) the structure must have adequate lateral stiffness to control the inter-story drifts such that no damage would occur to non-structural elements during minor but frequently occurring earthquakes, (ii) during moderate earthquakes, some damage to

Page 2 of 18

non-structural elements is permitted, but the structural element must have adequate strength to remain elastic so that no damage would occur, and (iii) during rare and strong earthquakes, the structure must be ductile enough to prevent collapse by aiming for repairable damage which would ascertain economic feasibility.

In last few decades, a number of research works have been carried out to understand the behaviour of existing buildings and possible improvements in structural design under earthquake loading. Beaufait and Williams

1

presented a study on behaviour of reinforced concrete portal frames under sway loading to investigate the role of joint reinforcement steel on ultimate load capacity of the structure. Two types of sway loading (cyclic and unidirectional) were considered for a number of portal frames where the cyclic sway loading was used to represent the simplified seismic loading. Durrani and Wight

2

and Ehsani and Wight

3 discussed the seismic behaviour of interior and exterior beam-column joints, respectively, under seismic loading where the specimens were designed according to the recommendations of ACI-ASCE Committee 352

4

. The findings were compared with the ductile beam-column joints of moment resisting frames to identify the role of joint hoop reinforcement. Ahmed and Shah

5

discussed the behaviour of hoop confined concrete under high strain rates. Based on the results obtained from the study, empirical equations were proposed to predict the effect of strain rate on material property of concrete. It was observed that for both plain and hoop confined concrete , there was an increase in elasticity, maximum stress with corresponding strain, but it was difficult to obtain the post peak behaviour of plain concrete.

Aycardi et al.

6

studied the performance of gravity load designed (GLD) sub-assemblages

(according to ACI 318-89

7

) under seismic loading. Parameters like axial load level, with and without lap splice were studied. It was also attempted to analytically model the seismic behaviour and to identify the parameters which play the key role under seismic loading.

Bracci et al.

8

conducted a series of tests to evaluate the seismic resistance of GLD structural frames (according to ACI 318-89

7

). A 3 storied reinforced concrete scaled model was

Page 3 of 18

experimented under various level of earthquake. Both global and local performance of the structure and its components were studied to determine the strength and deformation capacity under seismic loading. The major observation was that the GLD structures mainly suffered from strong beam-weak column behaviour with poor reinforcement detailing. El-Attar et al.

9

brought out a study on behaviour of GLD reinforced concrete buildings (according to

ACI 318

7

) under seismic loading. It was found that GLD reinforced concrete buildings without walls would experience very large deformations associated with considerable stiffness degradation during a moderate earthquake.

Simulated seismic load tests on reinforced concrete interior and exterior beam-column joints with substandard reinforcement details (pre-1970s) were described by Hakuto et al.

10

, by considering an existing reinforced concrete building designed in late 1950s (based on New

Zealand code which does not conform to present NZS 3101:1995

11

). It was pointed out that moment resisting frames with such detailing would show extremely poor performance under severe earthquake. A gravity load collapse mechanism of reinforced concrete frames was investigated by Elwood and Moehle

12

using a shake table to observe the process of dynamic shear and axial load failures. The reinforced concrete frame was characterised by low ductile columns with a predominant shear failure mode which accelerates the lateral strength degradation procedure. It was concluded that axial stress on the column influences the behaviour of the column during shaking, particularly after shear failure. Dhakal et al.

13

carried out an experimental study on dynamic response of GLD (according to British standard

BS8110

14

) reinforced concrete connections. It was observed that, though the connection zones are most important parts in dissipating energy during earthquake, most of the GLD connections are weaker than the adjoining structure and failed in shear.

A comparative study on seismic behaviour of columns in ordinary and intermediate moment resisting frames (according to ACI 318-02

15

) was carried out by Han and Jee

16

. It was pointed out that all the ordinary and intermediate moment resisting frames have strength

Page 4 of 18

larger than specified by ACI 318 and show a considerably high drift capacity. Seismic performance of scaled exterior beam-column joints designed according to modern building codes were investigated by Tsonos

17

. Scaled beam-column joints were designed according to Eurocode 2

18

& Eurocode 8

19

; ACI 318-02

15

& ACI 352R-02

20

and new Greek Earthquake

Resistant Code

21

and tested under cyclic loading. It was observed that the joint designed according to ACI 352R-02

20

and one of the joints based on Eurocode 2

18

and Eurocode 8

19 performed satisfactorily under cyclic loading whereas the other joints could not meet the desired performance stipulated by Eurocode and Greek code.

From the review of existing literature on seismic performance of existing reinforced concrete structures, it is found that though a considerable number of research works have been carried out in this field, there is no adequate information on (i) comparative performance of existing structures designed according to the available knowledge and prevailing guidelines at different times spanning from gravity load design concept to fully earthquake resistant design, and (ii) seismic performance of existing structures analysed for same expected seismic load but designed and detailed according to different guidelines/standards. These two issues are covered in the present study which would lead to a better understanding on performance of existing reinforced concrete structures under seismic loading.

Present study: Since most of the research works on seismic performance of reinforced concrete structures have considered American standard (ACI-318), New Zealand standard

(NZS 3101) or British standard (BS 8110) for designing the existing structure, in this study

European Codes (Eurocode 2

18

and Eurocode 8

19

) and Indian Standards of practice (IS 456-

2000

22

and IS 13920-1993

23

) for seismic design have been considered for analysis, design and detailing the beam-column joints of a most regular and conventional RC structure. Both codes have an extensive use in Europe and South-East Asia which are prominently seismic prone zones. Moreover , previous earthquakes have demonstrated that due to sudden discontinuity of the geometry, exterior joints are more vulnerable to seismic loading than the

Page 5 of 18

interior one because it demands to explore additional parameters such as bond slip of reinforcement. Hence, in this study the exterior beam-column joint has been chosen to study the performance under seismic loading.

Response spectrum analysis of the selected RC building (shown in Fig. 1) has been carried out and the exterior joint (selected sub-assemblage) has been designed and detailed based on different types of existing design considerations as (i) only gravity load design, (ii) seismic design as per the codal provisions but without any special ductile detailing and (iii) seismic design as per the codal provisions with special ductile detailing specified by the corresponding standards. These specimens represent the existing condition of buildings designed according to the available knowledge and prevailing guidelines at different times spanning from gravity load design concept to fully earthquake resistant design. A detailed experimental study has been carried out to investigate the seismic performance of the structural component.

Specimen description: Total six numbers of specimens have been designed and detailed based on Eurocode and Indian Standards and for three different stages of codal evolution

(described in Table 1). Out of specimen 1 and specimen 2, only one of the specimens

(specimen 1) was tested because it is found that gravity load design based on either of the codes produce almost same type of reinforcement detailing for the specimens. Further, there is a provision in Eurocode to choose the level of ductility as medium or high. Since the high ductile detailing from Eurocode is comparable to ductile detailing of Indian Standard (SP-5), only one specimen using medium ductility provision from Eurocode (SP-6) has been investigated in this study. Grades of concrete and steel for the specimens have been taken as M30 and Fe500 respectively. It is understandable that the GLD structures (representing pre-1970s) with so high strength of steel may not be feasible, but to bring uniformity among the test specimens, such strength has been chosen and designed accordingly. All subassemblages have the same general and cross-sectional dimensions: height of column is

Page 6 of 18

3800mm and length of beam is 1700 mm with cross-sections of (300 x 300)mm and (300 x

400)mm respectively. The geometry of the components (top and bottom portion of column and beam length from joint face) was chosen to match the bending moment distribution at the joint for which it was designed. The reinforcement details of the specimens are also presented in Table 1. Only Specimens 5 and 6 include seismic detailing. Beam and column stirrup spacings are tabulated for joint and required adjacent zones for the confinement, then followed by the rest part of the member respectively. The test specimens were instrumented with strain gages bonded on beam and column reinforcements (main bars, ties, stirrups) and

LVDTs (linear variable displacement transducers), which were mounted on the joint surface as well as attached to the beam and the column to measure deflections along the length of beam and column and to calculate the rotation of the joint.

Test set up and loading : The test set up has been arranged on the test floor so that the beam-column joint is horizontally resting on the floor and the cyclic load is applied in the plane of the test floor. Vertical arrangement has been avoided to make the test arrangement simplified and to apply a predefined axial load in column through a hydraulic jack resting on test floor. The schematic and actual test set up are shown in Fig. 2. About 300 kN of axial load was applied to the column through a hydraulic jack positioned between the column and one of the reaction blocks. The axial load was kept constant during the test. The lateral load was applied on the beam tip in displacement control according to the load history shown in

Fig. 3. Reversed cyclic load is applied in terms of drift ratio (%) of the component where the drift is calculated as

Drift ratio (%) =

l l b

100

Where

l and l b

are the applied displacement at the beam tip and the length of the beam from column face to the application point of the displacement respectively.

Page 7 of 18

The amplitudes of the peaks in the displacement history were multiples of the yield displacement, whereas the yield displacement was defined as the tip displacement corresponding to yielding of the beam top reinforcement at the column face. Three complete cycles were performed at each displacement ductility level, if possible up to the maximum travel of the actuator. The lateral displacement increments have been applied in a quasistatic reverse cyclic manner. Although in the case of seismic action the loading rates are higher than the rates corresponding to static conditions, it is advantageous since the quasistatic cyclic testing allows a careful monitoring of the specimen behaviour during the test and that strain-rate effects do not affect the material behaviour.

Results and discussion : During the test of the specimens, it was observed that the failure of the GLD specimen (SP-1) is due to inadequacy of bond capacity of bottom main reinforcement in beam as there is no such detailing against reverse loading (as shown in Fig.

4). When the structure is designed for earthquake loading but no such ductile detailing is adopted (SP-3 and SP-4), the behaviour is much improved in comparison with SP-1, but predominant shear failure of the joints and wedging out of concrete in joint has occurred (as shown in Figs. 5-6). The failure pattern of both the specimens (based on Indian Standard and

Eurocode) is qualitatively the same. Cover cracking at the back of the column and loosening of concrete integrity have been also noted under higher level of loading. Finally, the specimens designed for earthquake load and detailed as per ductility requirement (SP-5 and

SP-6) showed a similar mode of failure as observed for SP-3 and SP-4, but with a spreading of the wedge continuing in both top and bottom part of the column (shown in Figs. 7-8).

Though at initial stage of loading, bending cracks occurred in the beam and column outside the joint, no such contribution in dissipating energy was noticed in further steps. Hence, the major energy dissipation had taken place in the joint region only.

Page 8 of 18

The most important parameter for seismic performance of structural D-regions can be described by load-displacement hysteresis during the cyclic loading which can indicate the ductility capacity and energy dissipation efficiency of the component. It is well proven that the beam-column joint of reinforced concrete structures is the single crucial component in dissipating seismic energy during earthquake. In view of this, load-displacement hysteresis diagrams for each specimen (SP-1, SP-3, SP-4, SP-5 and SP-6) are presented in Fig. 9, where these figures are drawn by obtaining the actuator data to get a fair qualitative behaviour of the specimens. It shows the poor performance of the GLD structure and the consequent improvement of the seismic performance as the design and detailing provisions are upgraded. It is important to mention here that, though SP-3 and SP-4 show an improved performance in comparison with SP-1, hysteresis behaviour has not been enhanced to the desired extent due to its lacking in ductile detailing. This inadequacy is solved by the next level of specimens, i.e. ductile detailed specimens (SP-5 and SP-6). Beside the qualitative comparison, it is required to obtain the energy dissipation capacity of each of the joints which would reflect the quantitative seismic performance. The cumulative energy dissipation capacity with respect to the drift ratio of all the specimens considered in this study is presented (as shown in Fig. 10) by considering the actual response from the LVDT placed opposite to the actuator at the beam tip. The figure clearly depicts the improvement of the specimens designed according to the upgradation of the standards. Among the seismically analysed specimens without ductility detailing, though both the specimens (based on Indian

Standard and Eurocode) show a similar performance under low drift ratio, the specimen designed according to Indian Standard (SP-3) exhibits better performance (with a 10% more energy dissipation capacity) over the Eurocode (SP-4) with the increase in drift ratio. This is due to higher percentage of reinforcement in both beam and column in specimen (SP-3). It is further to note that the specimen (SP-6) has been designed according to Eurocode medium ductile (DCM) design, hence performs not to that extent as that of the specimen designed according to Indian Standard ductile design (25% less energy dissipation) which aims at full ductility.

Page 9 of 18

Conclusion: In the present study, two widely used structural design guidelines (Eurocode and Indian Standard) have been considered to evaluate the seismic performance of the structural D-region with three different stages of codal evolution (GLD; seismic design without ductile detailing; and seismic design with ductile detailing). The central objective of the study is to evaluate the performance of the existing structures designed according to the prevailing guidelines and further to identify the implications of the differences in the guidelines on the seismic performance. It is observed that both the GLD and seismic design without ductile detailed specimens possess a low energy dissipation capacity in comparison with the ductile one. The specimens of second level (seismically designed but without ductile detailing), though provide almost same deformability, the specimen designed according to

Indian Standard (SP-3) exhibits better performance over the Eurocode (SP-4) under higher drift ratio, due to higher percentage of reinforcement in both beam and column in specimen

(SP-3). Further, among the third level specimens (ductile detailed specimen), the one based on Indian Standard (SP-5) shows superior performance over the Eurocode design. It is due to the fact that a medium ductility specification from Eurocode is adopted in this study and further an option for high ductility still remains in Eurocode. On the other hand, there is no such provision in Indian code to choose level of ductility than to provide the full ductile detailing. The present study emphasises the fact that the existing reinforced concrete structures which were GLD or non-ductile, require immediate and adequate upgradation to avoid any catastrophic failure. Further, the structures with proper ductile detailing though show a noticeable improvement in seismic performance, it differs from one code to another and the detailing provisions of either code lead to put question on their practicability which can be solved by further research on smart detailing or by using new materials. For example, first test has been performed using fiber reinforced concrete in the joint region which showed a significant improvement of the joint itself. The details of this test, however, are not included in this paper.

Page 10 of 18

Acknowledgements: The authors are thankful to Dr. N.Lakshmanan, Director, SERC, for his suggestions, constant encourangement and providing excellent facility for conducting the tests at SERC, Chennai, India. The support received from the management, scientists and staff of SERC is also duly acknowledged.

References:

1.

2.

3.

4.

5.

6.

Beaufait, F. and Williams, R. R., “Experimental Study of Reinforced Concrete Frames

Subjected to Alternating Sway Forces”, ACI J. Proc., V. 65, No. 11, 1968, pp. 980-

984

Durrani, A. J. and Wight, J. K., “Behavior of Interior Beam-to-Column Connections

Under EarthquakeType Loading”, ACI J. Proc., V. 82, No. 3, 1985, pp. 343-349

Ehsani, M. R. and Wight, J. K., “Exterior Reinforced Concrete Beam-to-Column

Connections Subjected to EarthquakeType Loading”, ACI J. Proc., V. 82, No. 4,

1985, pp. 492-499

ACIASCE Committee 352, “ Recommendations for Design of Beam-Column Joints in

Monolithic Reinforced Concrete Structures ”, American Concrete Institute, 1976

Ahmad, S. H. and Shah, S.P., “Behavior of Hoop Confined Concrete Under High

Strain Rates”, ACI J. Proc., V. 82, No. 5, 1985, pp. 634-647

Aycardi, L.E., Mander, J. B. and Reinhorn, A. M. , “Seismic Resistance of Reinforced

Concrete Frame Structures Designed Only for Gravity Loads: Experimental

Performance of Subassemblages, ACI Structural J, V. 91, No. 5,1994, pp. 552-563

7.

8.

9.

American Concrete Institute Committee ACI 31889, “ Building Code Requirements for

Reinforced Concrete (ACI 31889)”, American Concrete Institute, Detroit, 1989, 351 pp.

Bracci, J. M., Reinhorn, A. M. and Mander, J. B., “Seismic Resistance of Reinforced

Concrete Frame Structures Designed for Gravity Loads: Performance of Structural

System”, ACI Structural J., V. 92, No. 5, 1995, pp. 597-609

El-

Attar, A. G., White, R. N. and Gergely, P., “Behaviour of Gravity Load Designed

Reinforced Concrete Buildings Subjected to Earthquakes”, ACI Structural J., V. 94,

No. 2, 1997, pp. 133-145

10. Hakuto, S., Park, R. and Tanaka, H., “Seismic Load Tests on Interior and Exterior

BeamColumn Joints with Substandard Reinforcing Details”, ACI Structural J., V. 97,

No. 1, 2000, pp. 11-25

11. NZS 3101, “ The Design of Concrete Structures “,1995, Standards New Zealand,

Wellington, 1995

12. Elwood, K. J. and Moehle, J . P., “Shake Table Tests on The Gravity Load Collapse of Reinforced Concrete Frames”, Seventh US National Conference on Earthquake

Engineering, Boston, MA, Earthquake Engineering Research Institute, July 2002

13. Dhakal, R.P., Pan, T.-C., Irawan, P., Tsai, K.-C., Lin, K.-C. and Chen, C.-H.,

“Experimental Study on the Dynamic Response of Gravity-Designed Reinforced

Concrete C onnections”, Engineering Structures, V. 27, No. 1, 2005, pp. 75-87

14. BS 8110, “ Structural Use of Concrete- Code of Practice for Design and Construction ”,

London: British Standards Institution; 1985

Page 11 of 18

15. American Concrete Institute Committee ACI31802“ Building Code Requirements for

Reinforced Concrete (ACI 31802)”, ACI 318-95, 99, 02, Detroit, Michigan, 1995,

1999, 2002

16. Han, S. W. and Jee, N.Y

., “Seismic Behaviours of Columns in Ordinary and

Intermediate Moment Resisting Concrete Frames”, Engineering Structures, V. 27,

No. 6, 2005, pp. 951 –962

17.

Tsonos, A.G., “Cyclic Load Behavior of Reinforced Concrete Beam-Column

Subassemblages of Modern Stru ctures”, ACI Structural J., V. 104, No. 4, 2007, pp.

468-478

18. CEN Technical Committee 250, “ Eurocode 2: Design of Concrete Structures-Part:1-1:

General rules and rules for buildings” (EN 1992-1-1:2004), CEN, Berlin, Germany,

2005, 248 pp.

19. CEN Technical Com mittee 250/SC8, “ Eurocode 8: Design of Structures for

Earthquake Resistance-Part: 1: General Rules, Seismic Actions and Rules for

Buildings (ENV 1998-1:2004 ),” CEN, Berlin, Germany, 2006, 192 pp.

20. Joint ACIASCE Committee 352, “ Recommendations for Design of Beam-Column

Connections in Monolithic Reinforced Concrete Structures (ACI 352R02),” American

Concrete Institute, Farmington Hills, Michigan, 2002, 37 pp.

21. ERC-1995, “ New Greek Earthquake Resistant Code ,” Athens, Greece, 1995, 145 pp.

(in Greek)

22. Indian Standard (IS-4562000), “ Plain and Reinforced Concrete - Code of Practice ”,

Bureau of Indian Standards, New Delhi, 2000

23. Indian Standard (IS-139201993), “ Ductile Detailing of Reinforced Concrete

Structures Subjected to Seismic Forces — Code of Practice ”, Bureau of Indian

Standards, New Delhi, 2002

Page 12 of 18

Table 1: Specimens details

Specimens

Specimen-1 (

GLD

Specimen-3 (

SP-1

SP-3

)

)

GLD+Seismic Load

Specimen-4 ( SP-4 )

GLD+Seismic Load

Specimen-5 ( SP-5 )

GLD+Seismic

Load+ductile detailing

Specimen-6 ( SP-6 )

GLD+Seismic

Load+ductile detailing (medium)

Code of practice Reinforcement details

IS 456-2000

IS 456-2000

EC 2: 1-1:2004,

EN 1990:2002

EC 8 (EN 1998-

1:2004)

IS 456-2000, IS

13920-1998

EC 2: 1-1:2004,

EN 1990:2002

EC 8 (EN 1998-

1:2004)

Beam main

(2+2

(2+1

*

*

)-16

top

)-16

bot

(* =extra reinf)

4-25

top

4-16

+1-25

bot

3-16

+2-25

top

5-16

bot

4-25

top

4-16

+1-25

bot

5-20

3-20

top

bot

Column main

4-25

Beam stirrup

2

L

-8

@130 c/c

12-25

2

8-25

12-25

8-25

@110 c/c

2

2

2

L

L

L

L

-8

-8

-10

-10

@100/150 c/c

@100 /120 c/c

@120 c/c

Column stirrup

2

L

-8

@300 c/c

2

L

-8

@140 c/c

2

L

-8

@130 c/c

2

L

-10

@75/150 c/c

2

L

-

10

@120/200 c/c

Page 13 of 18

Figures:

Sub-assembly considered

3.5m

3.5m

3.5m

6m 6m 6m

Fig.1 General arrangement of the building frame considered for the study

(a)

(b)

Fig. 2 (a) Schematic diagram of the test set up placed on test floor, (b) actual set up [at

SERC, Chennai]

Page 14 of 18

10

9

8

7

6

5

4

3

2

1

0

-7

-8

-9

-10

-1

-2

-3

-4

-5

-6

Time

Fig.3 Typical cyclic load history adopted in experiments

Fig. 4 Failure pattern of Specimen 1 (SP-1) Fig. 5 Failure pattern of Specimen 3 (SP-3)

Fig. 6 Failure pattern of Specimen 4 (SP-4) Fig. 7 Failure pattern of Specimen 5 (SP-5)

Page 15 of 18

Fig. 8 Failure pattern of Specimen 6 (SP-6)

-60 -40

Load-Displacem ent for SP-1

60

-20

40

20

0

-20

0

-40

20

-60

-80

-100

Displacement (mm)

40 60

-150 -100

Load-Displacem ent for SP-3

150

100

50

-50

0

-50

0 50

-100

-150

Displacement (mm)

100 150

Page 16 of 18

-150 -100

Load-Displacem ent for SP-4

150

100

-50

50

0

-50

0 50

-100

-150

Displacement (mm)

100 150

-150 -100

Load-Displacem ent for SP-5

200

150

100

50

-50

0

-50

0

-100

-150

-200

50

Displacement (mm)

100 150

-150 -100

Load-Displacem ent for SP-6

150

100

50

-50

0

-50

0

-100

50

-150

Displacement (mm)

100 150

Fig. 9 Load displacement hysteresis of the specimens (SP-1, SP-3, SP-4, SP-5 and SP-

6 respectively)

Page 17 of 18

40

30

20

10

0

0

80

70

60

50

SP-1 SP-3 SP-4 SP-5 SP-6

1 2 3 4

Input drift ratio (%)

5 6 7

Fig. 10 Cumulative energy dissipation capabilities of the specimens

8

Page 18 of 18