NEss THERMOMETER

advertisement

Direct Drive NON-MERCURY

FILLED TYPE TEMPERA TURE

~[Jj}@~

~WDll~!JD~

HIGH

QUALITY.

REPEATABILITY.

DUABILITY.

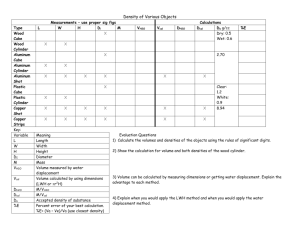

The NEss thermometer is superior to other systems because it pro­

vides an evenly graduated scale without the use of a multiplying

mechanism or delicate geared segments, pinions or h3ir springs.

The pointer action is direct drive with no multiplying mechanism.

This results in a most rugged instrument suitable for installations

which, by necessity, have severe vibration and shock.

The mechanical difference between the NEss tht'rmometer and a

conventional type thermometer is shown in Fig 1.

Because of its

"gearless" mechanism, the" NEss" thermometer as the followinC] advantages as

compared with conventional type thermometers.

1. Excellent stability.

2. Less trouble because of its simple mechanism.

3. MorA dlJrability against vibration and shock.

4. Smoother movement of pointer action.

5. Greater sensitivity and faster response to changE.'s in temperatures.

6. Better accuracies.

Compensations Bimetal oJrnpensator for head 3nd line as unit, correc ts for a.mbip.nt temperature

change.

Double lead compensator (consists of two bourdon tubes and capillary tubes)

available if specified.

INTERIOR MECHANISM

THERMOMETER

Housing

Driving Shaft

Capillary Tube

Bimetal Compensator

Bourdon Tube

Sensing

Bulb

Zero-Adjust

Capillary Tube

/

Scale Plate

Capillary

Pointer

Crystal

-------­

Covering Ring

Gasket

* CONVENTIONAL

TYPE MECHANISM

NESS THERMOMETER MECHANISM

SIDE VIEW of N-type Bourdon Tube

CD

®

- @

(4)

@

CD

CD Pointer

® Compensator (standard)

Pointer

~ C-type Bourdon

@ N-type Bourdon Tude

@ Gear Mechanism

@ Hairspring

@ Adjustment

NEss

THERMOMETER

Use No Gear

Gear Mechanism

Conventional-type THERMOMETER

Fig.

STANDARD SPECIFICATIONS

(applicable on all models except "AGNESS", Compact type & Eccentric type)

CASE"

Case ar black enameled cast aluminum, glass cry tal and "0" ring seal

Standard model is case compensi'lted. Double capillary, case and line compensated, are also available.

304 stainless steel cases are available as an option. 316 stainless steel case is availi'lble for 6" dial size only.

DIAL

Black numbers on While dial.

White on Black is available as well.

Three dial sizes 3" (75mm), 4" (lOOmm), 6" (lSOmm) nominal.

CAPILLARY

3m (1 Ofeet) 304 stainless steel tube in 304 stainless steel flexible armor is sli'lndard. Maximum length lor liquid

filled guaQes is 10m (33feel), 30m (98feel) for gas filled gauges and 50m (160feet) for double capillary line

compensated type.

SENSING

BULBS

Low temperature gauge have 1Omm diameter x 1OOmm length standard bulbs With 1/2" NPT sliding union con­ nection, High temperature Qauaes, those ilhove 400"(, have 12mm x 1OOmm length bulbs with 1/2" NPT sliding

union connection. Available solid union, w/unlons, plain I)ulbs. and bulbs with lhermowells, Standard bulbs are

304 stainless steel. 3/4" unions are available as n oplion. Please refer to page 19 for details.

MOUNTING

Select back f1anae surlace mount, front flange panel mount. or LJracket mount.

Please refer to page 5-18 for details

DEGREE OF IP66 (Deck Watertigllt - IEC) Certified

PROTECTION

(ENCLOSURE)

ACCURACY

± 2% Full scale

OPTIONS

.31 6 stainless steel capillary and armor.

• Bulb diameter and bulb lenqlh, consult representative.

• Thermowells.

• Connecting thread size or flange size.

• Changing selling point inner or external set.

• External junction hox.

• Accuracy of ± 1% of rull scale (lor liquid filled type indicators only)

The indicator, capillary, and sensing bulb are a single unit filled with liquid or gas. These liquides or gases

will respond properly in spite of any peripheral temperature changes. The compensator exists in order to

dutomatically control any changes owing to temperature fluctuations in these liquids and gases, which are

highly susceptible to temperature changes under normal circumstances.

For Single Capillary Types

,,r-­

---------------------,

@

,,

,,

I

CD.~

.

®:

I

Because the compensator is housed within the case,

it j<:, rIt~cessary to keep the capillary at the same tem­

perdture as the case. This type of compensator is

called a "Case Compensator" or a "Bi-metallic Com­

pcn~~tor". Our Qduges having this type compenc,ator

have "S" at the end of their model numher.

CD Indicator

,I ® Compensating

.

,, auxiliary

® Bourdon Tube

@

___________

J:

I

~

I

I

I

I

I

,

I

@ Case Interior

(5) Capillary

@ Sensing Bulb

/(5)

For Double Capillary Types

-------- ----.,

r-

I

I

I

,,,

,,

,

L

_

-

r

L

-.

~

,

J

j

,, CD Main Bourdon

,

® Main Capillary

(3) Compensating

Bourdon

@ Auxiliary Capillary

@ Sensing Bulb

($1

In each gauge the bourdon tubes and the capillaries

are grouped into two sets. One set is for temperature

measurement, while the other set is for temperature

compensation. This gauge will compensate reliably

even under local temperature fluctuation.

This feature is called "Full Compensation" and places

this gauge a grade above gauges with so-called "CJ.se

Compensation" Our products having full compensation

have "D" at the end of their model number, those with

case compensation are likewise coded "S",

Examples of when "Full Compensator" is necessary

EX. 1

Great fluctuation in temperature "lolllJ

the periphery 01 the capillary when

here IS scarcely any empera ure

change on the indicator.

EX. 3

20C

LIQuid temperature measurement in a

tank With aned temperature

dlStnbutlon

\

____

~r._

- ­ - - 4Q<::

---EX. 2

Great temperalure f1uclualiull" ill botll

the capillary and indicator.

r------,

,-1O-00C,

,,,

,,,

,

,

,

,

I

L

10 50 r.

FX 4

The Call1l1iHY experience~ nnn lJn,fnrm

temperature c:ondltinn~

r-----l

, 10 50'C'

:, CS)

\ :

I

,.---, ,.---, ,.---,

I

I

I oO·C " 30e 11-IO·e, L

,

.J

~c=

G

The temperature conditions illustrated above are for reference purposes

not limited to these.

I

I

I

I

II

II

II

II

I

II

II

I

II

II

II

II

I

I

I

I

I

I

-l

'----'

only~

the possible conditions are

"J \

:I. ~11~o/ll"

r, ~ '~~'

;. ,"I",

i

,

,

I'

I

,I I~J • : " ,

t';!. f

-

I.

I

"

,

I

'j

•

r:

't,:

.

,I,

: lI'... ,

'

.L.

SCALE RANGE TABLE

Mod.No.

1-­

Range in 'C

3"

4"

6"

Range in 'F

Mod.No.

Mod.No. Range dual in

,

-

* -200~+50

00

5

,

2

01

:~

-

5

I

*-100~+200

2

2

02

-~

2

03

2

2

t>

tt

I

04

05

06

-20~

80

07

2

2

2

1

1

1

1

1

2

2

1

13

2

2

2

14

2

2

2

-

0~120

62

0~150

10

12

* *0~100

2

64

I

32~300

-­ -

2

2

65

32~400

5

5

66

32~500

81

'

O'~ 150'C

32~300'F

82

-i!--­

0~200'C

83

32~400'F

--­

16

t

5

17

18

19

*0~400

10

_

5

5

5

5

10

-f--­

50'C

-20~120'F

L

32~21 0

63

--­

15

-30~

80

-

"..

09

-- ­

61

08

-

- ­

10

.

20

*0~500

10

10

10

21

*0~600

10

10

10

68

I

69

84

r-.

0- 600·C

*32~1112'F

* Gas Fillf,d

* * 1'C graduation

is available as an option (for 4" dial size only)

· Ranges listed above are most frequently specified, Consult factory for special ranges,

· Standard: Black lettering on White background.

· If your application is of a special nature, let us know your exact requirements and our proven design and engineer­

ing experience will he placed at your disposal.

4

I MODEL TUS-2S (FLUSH MOUNTING)

Model No ADl

A

Dia

--­

3" 4"

6"

BIC

D

0

N

60

5

7

7

1.l2: 7~ j 6060

110 100 92

140 125 ~

93

206 190 168 140

I'b

Mal~

1

P Bron7e - - ­

Aluminum

NBR

Glass

Aluminum Alloy

Aluminum Alloy

PART NAME

1'0ll,le,

2 Scale Plate

3 - Gasket 4 Glass Disk

5 : Covering Ring

6 IlousinCl

[MODEL

TOS-2S

-

(FLUSH MOUNTING)

----

Model No AD2

3

~N

3"

4"

6"

o

c:

Q

N

- 110' 100 t 92

70 60

. 140 , 125~1 11 2 93' 60

206 190 168

140' 60

I 57

A

Dia

H

I

I

6

:

"

,

j

11011511,0

.

Dia

,

3'

4'

G'

I'b

1

,

TBP-2

Glilss

AluminlJm Alloy

Aluminum Alloy

J

(PANEL MOUNTING)

,

I'

~

2

I

3 '

4

Al

B C 0

'110

100

I

92'• 70

•

t

•

+.!:!O • 125, 112, 93

.206 190 168 140

PART NAME

POlI,tpr

Scale Plate

Gasket

Glass Disk

(overillSJ R'ng

Housin

I MODEL TBP-3

',J

. '-.\

F

18

18

18

K

M

80 I 87

102' 106

154,158

F~

r:

f---¥.­

r-Z7

MlmTnum

(PANEL MOUNTING)

Model No A05

Dia

''ji}~h-_

".

L

N

_ _~_--,Mrtlerial

P-8,ollze

~ITlinuln

NBR

Glass

Alia

Alumi'lUll1 Allo

............ l,-­

3

4"

6"

L

A

C

I

' 110 I 92

: 140: 112:

206 168

0

70

93

140

.

F

J

18

18

18

60

60

60

K

0

M

'20

80 ~~

102 106_ 20

154 158 20

~

'

PART NAMF

POlllier

2 Scale Plale

3 ; Gasket

I'b

1

11ft'DISk

5 Covering Ring

6

Ilous,ng

7 T Mounllnn Kil

5

~f\J~R

Model No AD3

0­

f

7

Mate'ial

l-c-:.BronLe

Aluminum

MODEL

s' J

I

I

I'b

PART NAME

1 Po,nlpr

2 I Scalp Plill!,!

3 Gasket

11 Glass Disk

5 Covering Ring

t

I

,

Material

P-Bronzc

Aluminum

NOR

Glass

Aluminum /\lloy

Aluminum AII~

30455

-

~

4

,

5

SU-AD-2

MODEL

(EVERY ANGLE)

J

Model Nn B05

4"

6'

2

­

D

T

112 93

1168 140

60

60

PART NAME

POinter

Scale Plate

f'b

1

",-,.,

C

Dia

c-­

.J : G~kel

4

~I-

5

6

I Glass Disk

Zo

I K

11O;~(

154

146±5

3" available

Material

_-+-,P,-,---=Br OllLe

Aluminum

NBR

Glass

Aluminum .:.:A:.:.:llo~_ _--1

Aluminum

304S-::'S'------­

Coverrn R~

Iiousinf)

7 Stem

8 Locking Nut

9 Adjustatile Elbow Jornt

-1O~ Lockin Pin

304SS

Aluminum Alloy

304SS

I MODEL SBS-2

CONNECTIO~

(BACK

Model Nn B02

\

3·

C

92

Dia

1.."

3"

4"

6"

•­

L

)

8

I

PART NAME

Pointer

---

I

Add 4 inches

for high temp

Range Over

300'(

70

112 93

168 140

-.

tf

f'b

I

*

K

D

Material

P-Bronze

_

S cale Plate

---+-Aluminum

3 Gasket

~R

_

4

Glass Disk

I Gla.-=.ss=---_:-::-_

5 , Cnvp.ring Ring

Alumrnum Alloy

6 I Housing

I\luminum

7 RICjld SIP.m

304SS

8 ' Fixed Screw

30455

MODEL

5U5-2

J

(STAND TYPE)

Model Nn BOl

•

X

54+5

54±5

54±5

Dia

3'

4'

6'

r

f'b

1

,

2

,.J-'

4

5

6

7

-8

Material

PART NAMf:

, POinter

P-Bron~

--

Aluminum

NBR

Scale Plate

Gaskel

Glnss Disk

Coverin]LRirl.9..-­

'1uusilly

Rrgld Stem

FIXed Scr~

MODEL

SUL-3

---

_.

---

~-

-

Aluminum Alloy

Aluminum

- 304SS

13045s-­

~

(L STYLE)

Model No B06

Din

3'­

4

6'

tt1

-

1

?

3

4

5

6

r

I&­

60

fiO

PART NAME

POinter

Scale Plate

Gasket

Glass Disk

~_Cov(!llng

Housill

r1Tri9

K

-j-Zo

80

10?

154

120±5

131 ±5

157t5

*

Add 4 inclles

for high temp

RanC)e Ovp.r

300'C

_ Materral

P-Bronze

I

I\lul1lrn~

NBR

, Glass -

-­

I\IUl1lim111l Alloy _ _

Alurnillum

6

AGNESS-II

THERMOMETER

SPECIFICATIONS

(Fig. 1)

.SCALE (Standard)

.BULB

Dial Size: 4 inch (Nominal)

CODE No.

005

-30~

70'C

2'C

008

o~

50'C

1'C

010

0~100'C

2'C

0~150'C

2'C

0~200'C

5'C

0~300'C

5"C

012

TYPE

CODE

Sliding union

type (Std)

C

L

--

Please note that sliding union-type bulbs have

no effect against r>rp.SSlJrl~. If yOlJ put the bulb on

pressurized vessel, please use thermowell for

your safety.

t

013

015

I

1/2"NPT Thread Std.

Min. Grad

RANGE

If your application is of a special nature,

let us know your exact requirements and

put "X" at the end of Part Number

~,

8m/m

10m/m (Std.)

SUS304

S6 : SUS316

Outside diameter

6m/m

Code of Material

S4

~o

,"t­

'I'

---~7

"

.~

,

. \.,

. i'll

Ii:'.', :

"~I

, J:'

I.,'

PART

NUMBERING

SYSTEM

In case of Std. Spec

Ex.-l

I

AGNESS- II

Optiunal Urder

I-I

010

I-I

I-I'----;-X-JI-I

Ex.-21-AG-N-ES-S--II

S4

I-I

10

I-I

150

I

Ex)

S6

I-I

8

I-~-~

~ Thermo bulb length in m/m

- - - - - - - - O D . of thermo bulb in m/m

Material of thermo bulb

Xl: Black letter in White

' - - - - - - - - - Code No. of Range (Fig-l)

X2:Scale range 32-210F

X3 :Thermowell (as per

' - - - - - - - - - - - - - - MODEL

another drawings)

L

t

*Previous Model AGNESS is still aVi.lilabc (100mm, 150mm)

Please consult your sales agent for details.

I

l

f

;"---0_--.

MODEL

TUL-20

(FLUSH

~OUNTING)

Model No A09

,or ( ) )

No

I

,

~

1

•

'0

15

,,

10

•

]

-~

1

2

j

PART NAME

Pointer

Scale Plate

--­

~ -

3 r:asket

4

Glass Disk

- 5 I Covering Ring

6 _ Housing

[ MODEL

~N

Matenal

P-Bronze

Aluminum

NBR

- --Glass

Aluminum Allay

Aluminum Alloy

TU.§-2S-0

(FLUSH MOUNTING)

J

Model No A07

6" aV3ilabic

PART NAME

Pointer

Scale Plale

-~ Gasket

4 GI3SS Disk

~ I Covering Ring

6 I Housin.Q.

Material

P-f\rnn7P

Aluminum

NBR

Glass

Aluminum Allay

Aluminum Alloy

No,

1

2

MODEL

I

,

TBP-30

(PANEL

-

~

-

MOUNT~N~~

Model No AOa

J

No

1

I'ART NAME

Pointer

I

Matcri~ _ _

P-Bronze

~2---t-is~c'-:a+:le-=;p~l:-:at--=-e~~~~-----r--l';:A;:-'Iu==m"=in"'"u=-m

Gaskel

NBf<

~~~~_I

Gldss Oisk

Glass

~

CovprinCj Rinq

Aluminum AII~

1-"6c--5crew

130455

7 Ilousrng ~~~~~~!I:;;-luc-;-m;;;in~u",m--,-,----:A;I.:.::I-O'-!..y-_-_-_-_-_-_-1_1

8

FIXing Nut

__ + 30455

9

Panel Mountinf) Kit

304SS

3

4

8

I

J

! MODEL SU-AD-20

(EVERY ANGLE-)­

Model No B09

.110

PART NAM[

Poinler

2 Scalp Plale

3 G.lsket

4 Glass O;$k

Coveflng Rrng

6 Screw

7- Housrng

Locking Nul

9 I Adjustable E:lbow joinl

10 I Luckin\) PH'

Material

1

P Bron?'"

Aluminum

~NBR

Glass

AI minum Alloy

30455

Aluminum Allo_y_ _

304S5

I\ILJ.Inmum Allcry_

30455

ra

585-20 (BACK CONNECTION)

MODEL

Model No B08

C

D

A d 4 rnches

33' 93

54±5

for hrgh lemp

1*Rdnge

Over

300C

Pi\RT Ni\ME

rainier

2 Scale Plale

3 Gaskel - 4 • Glass Disk

5 I Coveflng Ring

6 5crew

7 : IiouSH19

8 Union Nul

110

1

·

·

9

,

­

• Aluminum Allay

30455

I Ali7minLlm Alluy

30455

.

30455

SUS-20 (STAND TYPE)

--

l

Model No B07

J

".

-

I Glass

MOlll1tlng Scrt:w

MODEL

,

Malerial

Bran?€'

---I\lumlnllm

- -' NBR

,P

Dia

4

C

D

133

93

I - I

X

54+5

;dd 4 Inches

for high temp

L---'-_--''''''----'''''--'L-''-'-=:.::.......J Range Over

30m::

110

1

2

3

4

G

Covering~

7

8

9

~rial

PART NAME

Pointer

5calp PlaiR

Gasket

Glass Disk

Screw

Hou5,n'l

Union ul

Mounllng Screw

P Bron7f~ - - Aluminum

NOR

-.

Glass

Alilillinum Alloy

~04SS

• Aluminum Alloy

304SS

--304SS

I

-

- -

I MODEL TUL-HSP

80

(FLUSH MOUNTING)

Model No Al0

4" stanr!;wi.

6" available

f\O

l~ ~I"

i'•

',I'

...

'd,n .

1

2

3

4

5

6

7

I POinterPART NAME

Material

P Bronze

Aluminum

AIIJminum Allov

SCilie Plate

Converi,~inq

i

~

Alumfnurn~

Iiousing

Oillnlel

Oil Inlet Cap

Mounting Kit

_

Aluminllm Allov

AhJminllm Allov

304SS or Steel

I

"

_MODEL

"

TBP-HSP

(PANEL

MOUNTING)~

Model No A28

4" only.

f\O

1

2

3

4

5

6

7

>

..)

..

,,'

,.

Material

f1-BJOnzc

Aluminum

Ah~minum Allov

Aluminum Allov

PART NAME

Pointer

Scale Plate

Coverin Rin

Housll~

Alu'!1inulT~oy

0iflnlel

Oil Inlel Cap

Mountlnq Kit

Aluminum Allov

304SS or Steel

1

PANFl ("III

.

MODEL

SU-AD-HSP

(EVERY ANGLE)

Model No 812

4" only.

No

PAm NAMI:1 I Pointer

2 Scale Platl';

3 Covering Ring

4 . Locking Nut

G Adjustable [I bow

Joint

f)

Shaft

(

Lockm Pin

8 : Oil Inlet Cap

011 Inlet

9

10 Housing

I

.

n\ . .'

MODEL

"1

Material

P-Bronze

-Aluminum

--

AlllminlJl'fl.~

304SS

Aluminum Alia

-304SS

:1045S

~

- ~lTli!!!:'.r:nAlloy

Aluminum Alia

Aluminum Alloy

SUS-HSP

~

--

(STAND TYPE)

--­

Model No 816

...~ :0..

,

r

~.~

-{ff~

TIl

4" only.

I

1

PART NAME

I'ointe'

Malerial

P-Bronze

2

5cillel-'l~

AiurnH1Ulll

No

3 : CoverinlL Rin

Oil Inlel Cap

4

5[

~

I

';0'"

6

7

8

0-+

011 Inlel

~--=-=-Iiousino

Rigid St~

Union Nut

Mounting Screw

Alumlnllm

: Aluminum

Aluminum

. Alu~1ll

304SS

304S5

t 30455

Allo

Alloy_

Alloy

Alloy

*

Add ~ incllcs

for high temp

Range Over

::lOOt.:

10

I he temperature switch encloses one or two electrical S.PD.T contacts which are adjusted to create ON

or OFF signal(s) when temperature reach(es) at the desired set point(s).

MICRO SNAP ACTION SWITCI j:

Set point

-ME

2 Set points

-MEE

Pushing opE~ration of small actuator can switch comparatively larger current betcen ON

and OFF. As a cam is installed on the pointer, a lobe is located to push switch's actuator.

As the temperature reaches the predetermined level, the lobe pushes the actuator for ON

or OFF action. The standdrd option i~-; SP.D.T(Single Poll" Double Throw.) For 2 contacts,

2 sets of cams & switches are used.

INTERIOR MECHANISM

For Single Capillary Types

["pilla

For Double Capillary Types

Hourcfon Tllbe

TLJhe

D,st"nl Piece

/

Compensator / /

//

/

,/

Center G_car /

Cam Gear//

Sellin Gear

~...

;

Selllnq Gear

. \ Set Screw

11

The following thermometers are especially designed to signal or control when temperatures go beyond

predetermined high or low limits, and at the same time give accurate temperature indications.

Up to 2 circuits can be controlled by one instrument with one or two switches installed as speCified.

Micro Switch

MOD CODE (one set point),(two set points)

Contact Capacity

5A 125V AC

Max Voltage Used

Withstand Voltage

Housln~ and

-ME, -MEE

non-,ndUCllvP

200V AC

Trrrrllllill

Number of contacts available

2000V AC 1 min.

1 S.P.D.T/ Set Point

12

TUS-2S-ME

MODEL

Model Nn C01

Dia

3"

I­

4"

6"

-

A

B

C D N

110 100 92 70 ~

1'10 125 11~ ~ 7206 190 168 140 7

cp .,

......

)

No.

1

2

.-l

4

5

6

, -.'u

..

...

I

Material

PART NAME

Pointer

Scale PicHe

Gasket

Glass Disk

Covelinq Rlllq

HouSIng

7

Ter~

8

9

Set POint Indicator

Set Screw

~ronle

Al'Jminum

Neoprene

Glass ~­

Aluminum AI'-'--Io~--­

Aluminum AII(''-')Y~_ _--I

Pllcnol resl'-.·n-,_

Brass Coated

Brass Coated--­

TBP-2-ME

MODEL

Model Nn C03

'[

... • .. 1

Dia

-

..

3"

4"

6"

No.

1

2

3

4

_;-­

+

!~ c I D

A

F

: 11 0 ~ 100 92 70: 18

140 125 112 93 18

: 206 190 168 140 18

t

Gla,;s Disk

Ring

Sct Point Indicator

I MODEL

+--s

7

7

TBP-3-ME

Model Nn C05

)

Dia

4"

6"

No.

1

2

l.

3

D:I

II

C

• 140 ' 1J2' 93

~ 206 ' 168 '(40

7

8

9

Material

P·Bronze

---_.

AtuminlJnl

Neoprene

--Glass

Aluminum Alloy

Aluminum Alloy

Phenol resin

Brass Coatcd

Brass Coated

PART NAME

POinter

: Scalc Plate

Gasket

Glas~ Dd

Covcrrnq Rlnq

~IIOuSln'1

Tprminal

Set Point Indicator

Sct Scrcw

MODEL

)

F

J

K M

1A A5: 102/106

IA 8t> I')4 15fl

r--=L'

5

.6

,

N

~

Aluminum

eOflfene

GIi1sS

Aluillinum Alloy

Ailiminum Alloy

Phenol rpsin

Brass Coaled

7 ' Telminal

,

I

80, 87

102 106

1!A'I58

Material

; P-Bronze

---­

PART NAME

POlnte=::r,--_ _

Scale Plate

Gasket

---­

5 : (overing

6 Hou~iny

8

KIM

l

TBP-40-ME

'" ,

Model Nn C09

hl

...

4" only

No.

1

.

,

I,

-2 Gld" Di,k

~3 ~Coverir'.9. ,R-,i"-,n~y__

~us~

5

6

7

8

13

PART NAME

Gaske'"Ct~ ..; --

I ermlnal !:lox

Cable Wire outlet

Set I'oint Irldicator

S<.:t SLlCW

Mate~_

•

._-+...cN~e,-"o~Plre".'n"e,--­__.

Gld"

~n1inufll Alloy

I-Aluminum Alloy

AluIlllnUIIl Alloy

!:lrass Coaled - - - ­

Brass Coated

01.1"' COdlL:LI

MODEL

Ora

No

1

2

3'

4'

6"

112

168

,

~

I 'T'r y ~O I ·X

70 8:'

25

54 t.5

93 i 85 ! 25 102

140 85

38 154 54 +-5

o

~+-5

PARI' NAME

~nLe

Scalc Plate

Gaskp.-.t--­

Glass Drsk

~ COVerll1C) RTrlg

-­

6 • Housirlg

7 Rigid Stern

8 Union Nut

9 MOUllliliU Suew

10 lermrlh.ll

11 - Set Point Indicator

12 Set S~

*T:add 079 inchs (20 mrll) Iur twu ~el "ornts

*

Add 4 inches

for hiqll tcmp

Ranljc Ovcr

300'(

Material

, Pornter

3

<1

C

~92

SBS-2-ME

-

Aluminum

Neoprene

Glass

Aluminum Alluy

Aluminum

304SS

304SS

304SS

Phenol resin

Brass Coated

Brass Coated

-

I~M_O_D_E:::.L==S~U--r-S_----,2_-_M_E---..:::;-:-*--"-(S::..:.-.cPECIAL)

J'

-.­

Oia

3'

4'

6"

C

0

9

70

. 112 93

168 140

'T

85

85

85

No

0.79 rnchs (20 mm) lor twu set points

f025415

1545415

PART NAMF

Pointcr

Scalp. Plate

3 Gasket--­

4 (;las5 Uisk

. 5COVerrn Rin

6 : Hou:iirlg

1 Rrgid Stern

8 ; Unron Nut

1

Muunlir!9 Screw

.

lOTermrnal

'11 Set rointlndrcator - - ;

12 SP.t Screw

1

2

* Tadd

K

• X

~ 54±5

~

MODEL

Add 4 rnches

for Iligh temp

Rilnge Over

300'C

Material

P-Bronze

Aluminum

Neoprene

Glass

Aluminum Alloy

Alurnirlu;n Alloy

304S5

304SS-­ -

_

304~

Phenol resin

Brass Coate-d--­

Brass Coatcd

SUL-3-ME

(SPECIAL)

Oia

3"

4"

6"

No

1

2

3

4

5 .

6~

7

8 •

9

10 •

11 '

·'T.ilrld 0.19 inchs (20 mm) for twu set "urnts

I"

I,.

PART NAM.

Pointer

Scale Plate

Gilskp.t

Glilss Disk

Covering Ring

Ilousrn

Riqid Stem

Elbow Joint

Set roint Indicator

Terminal

Sel Screw

MODEL

Material

P-Bron~

Alurnrnum - - ­

Np.o rene

I Glas_s__ ­

~UIl2!!..'U'" Alluy

Alumrnum Alloy

. 304SS

Cast Iron or 304SS

Brass Coated

Phenol

re~inBrass Coated

SUS-50-ME

(SPECI~

Dial sizp. 3" only

Material

,~,

PART N.8ME

P-Bronze

Pointer

Aluminum

Scale Plate

3 Gldss Orsk-­

Glass

4 Covp.ring Rin-g-­

Aluminum Alloy

Alumi[lli;Tl

Alloy

5 Ilousin51.

~ Synlllelic resi-n--­

6

I errninal Box

--+

--­

7 SetPornt Indicator __ + ~ass Coat~

I:lrass Coatp.rl

8 SP.t Screw

+2

1r

* An order has

10

have 10 pcs or more

14

MODEL

TE02

Explosion Proof

Model No Cll

r

.-!-0'

.:", -'

I,ter

i

110

~!'

:')

fij):

liZ

0

\

-

,

j:­

y~::

J,

~!

~

Conduct conn.

PF l/2 (Std)

@,'.

One set point or

(1 -SP.D.T)

(2) Scale range

See page 3

(3) C.lpillary

1m (Std).

(4) Thermobulb

TI1read

PT l/2 (Std.)

Slirling union typE.: only

0

M

,IL

,G"

Microswitch

l

,t\. ",

~

<:.~::~.

(1) Electrical

contact

•

I

Two set points

(2-S.P.D.T)

10m (Single capillary) Max.,

Material of Housing:

Aluminum

Electrical

rating

AC250V 3A (Non inductive)

AC 125V 5A (Non inductive)

DC 125V 0 AA (Non inductive)

50m (Double capillary) Max.

'" J

Material

S4:SUS304 (SLlndard)

S6:SUS316 (Available as optiun)

Uutside diameter:

8mm.

1 ?mm,

10mm.

(5) Please specify the following items for order

Item

For example

Model

TE02-ME-S

Scale range

O~

11

Outside diameter of thermobulb

Style of thermowell

<P

1 OO'C

10

BJPI 150LbRF x <P 15 x 200mm

Material of thermowell

SUS304

Electrical rating

ACl OOV 3A

Others

TAG No, Quantity, Order number, Other option

-

15

I MODEL TE03-ME

I

_

Explosion Proof

(Ex IIB+H,T4) Model Nn C14

.~

( 1) Electrical

contact

Microswitch

One set point or

(1 -SP.D.T)

Two set pOints

(2-S.P.D.T)

Electrical

rating

AC250V 3A (Non inductive)

AC 125V 5A (Non inductive)

DC 1?5V O.4A (Non inductive)

(2) Scale range

Range

-30~

Min. Scale

70"C

Range

150"C

2"C

O~

O~

50"C

l"C

0~200"C

2"C

* Range in deg. F

O~

1OO"C

2"C

0~300'C

5'C

is also available

--

* Other ranges in -

200

(3) Capillary

3m (Std),

(4) Thermobulb

ThrC'ad

PT '/2 (Std)

* Slidin~1 union type only

- 600 deg C is also available as specials.

10m (Single capillary) Max.,

50m (Double capillary) Max.

===ss=-­

I

Material

-

L .,

S4SUS304 (Standard)

S6SUS316 (Available upon request)

Outside diameter:

(b) OrderinC]

Min. Scale

2'(

Bmm.

10mm,

12mm

(6m/m as a special order)

Please specify the following items.

Items

Example

I---

I

-

Description

--+----­

Model

TE03-ME-S

Single capillary with one set point

Range

0~1

Scale range of

OO"C

O~

100 deg. C

I-

Capillary

-

3m

Capillary length of 3m (Standard)

-

-

-

Bulb dia

<p10

Thermobulb diameter of <p 10 (1 Omm)

Style of thermowell

Yes

If not required, please specify so.

Size of thermowell

--­

Material of thermaell

1B JIS 10KRF

Standard inner thread 1/2" PT

<p 15 x 200

Out. dia. 1Omm Length 200mm

Rating

S4

S4=SUS304

I

AC1 OOV 3A

-­

-

S6=SUS316

I Please specify your needs

Please contact us for further assistance for ordering.

16

,

."\.

;',".

MODEL SUO-M 1RU-S

MODEL TOS-M 1UU-S

Unit Type

Adaptive to installation condition, more thJn several standard model numbers are available, please select

the proper one by capillary's outlet, terminal box's and cable ground locations.

..

..

..

..

..

..

..

~

17

Description

Ambient Temp

Compensation

Conduit

Location

CIN

In truction

S

Single Capillary

D

Double Capillary

U

Underneath

L

Left hand side

R

Right hand side

T

Top

U

Underneath

L

R

Left hand side

---Right hand side

1

1 Set Point

2

2 Set Points

Switch Type

M

Microswitch

Mounting

Method

0

Without Mounting Flange

S

Surface Mounting

Capillary or

Stem Oullet

Location

0

Top

U

Underneath

B

Backside (Rigid stem only)

Indicating

Method

T

Remote Reading

S

Rigid Stem

Terminal Box

Location

No. of Switch

- --

-

Please note that slinding union-type bulbs have no effect against pressure. If you put the bulb on pressu­

rized vessel, a thermowell will be needed.

Mdx. slilll~ pressure O. 'iMPil

(1) Fixed Screw Type

(4) Fixed Union Capillary Type

Max. stalic presswe O.!JMPa

L8tjU­

-E

~(?) With thermowell type

(5) Sliding Union Type for remote reading only

Max. ,lalie pre"lIre 1Mf'a

f'led~(>

reler 10 paye 20

IllUiMOWELL

~---I(3) Plain Bulb Type

(6) Sliding Union type for rigid stem type only

VOLUME of the Thermobulb compared to mercury filled type.

Out dia 8 rjJ

NEss

-

O~

50'C

140mm

0--100'C

70

150"C

45

0-200·C

40

0~300·C

25

O~

Out dia 10 ep

NEss

.

-

Out dia 12 ep

NEss

:t ~:; Fm

MF

404

202

135

MF

MF

':~

j

25

63

20

45

20

60

15

50

MF: Mercury filled conventionill type

Standard Out Uia Size of Thermobulb.

(

) oplion

Liquid filled

Single Capillary

8 10 12 14 rP

Double Capillary (8)

101214rP

'

i

R=

eQx

=0.8

.­

,,

I

I

. flange

o~

8

50'C

0~100

0~200

0~3:"0

"0~400

Gg=~gg

10

12

( 16)

I

75

50

30

70'

40

140

I 40

I

25

30

J

20

20

I

15

I

25

_ _ _ _ _-----'~.200~50 1455

I

15

20 115

195 120

I

235

150

110

I

12

1J

14

not available

Minimum Size of Thermobulb.

The Volume of the Thermobulb clepends on the Scale Range

mm

Single Capillary Type (- S)

r1x

Gas filled

10

80

mm

Double Capillary Type (-D)

Ranqe

0111

fi,a

I

8

10

O~ 50"C

O~

100

0-200

0~350

_I

80

4:"

I

12

180

j 115

90

60

45

30

35

25 I

14

16

80

60

45! _35_

_ _t_J.....--'L

Please add 25mm or more in Cilse of plain bulb Iype

"Gas Filled

18

Pipe(P) .. - - - - - - - - - - Straight Type (S) - Straight Type (S) - Screw (S) - [

Straight Type (S) - Drilled Bar Stock(D)

Taper Type (T)

Taper Type (T)

PiPe(p) - - - - - - - - - - - S t r a i g h t Type(S)-Flange(F) - {

~,.-----;[

Drilled Bar Stock(D) [

Straight Type (S) - Taper Type(T)

- [ Straight 1 ype (S) - Taper Type (T)

Weld-in (W)

19

- - - - - - - - - - - - - 1[

Straight Type (S) - Taper Type (T)

1A

2

2B

3A

3B

4

5

6

7

8

9

10

< Indicator>

.---_1_.-,-Model No.

2. Compensator

S=Single Capillary Type

3. Dial size

2- 1> 50

3- 1> 75

D=Double Capillary Typ<, (10m or more)

4= 1> 100

4. Scale range

6= 1> 150

6. Connection size

I

1 - 2 - 3 - 4 - 5. Thermowell O=Without - 6 - 7

7. Rating

JIS. ANSI, etc.

l·······~·_~·_~--~

10

W=With

J

11

-

1~

-

13

_ _J

8. Type of thermowell

9. Inner thread

10 Materials

1=304SS,

2=316SS,

3=316LSS,

X=others

1 1. Thermobulb model

A=Sliding Union Type, R=Fixed Union Type, S=Plain Bulb

X=olhers

<Contact>

12 Thermobulb malerial

1=304SS, 2=316SS, X=olhers

13. Malerial of flexible tube

F=304SS, V=Flexible lube PVC covered

14. Volta e

I '5"1 '6

~ - -l~ -

}§-

Ope,ation mode

t -18 T'1~1-

22

]-~

I - l~Capillar

len th

~mobUlb~nglh

17.CO~

- - 1=15A(PF1 12)

4=20A(PF3/4)

X=olhers

-[23

22. O.Dof Thermobulb

21. 1.0.01 Thermowell

20. 00.01 Thermowell(D?)

19. 00. f Thermowell(Dl)

18. Option

20

For eliminating the missing specification or

mis-understanding for Ihe technical confirma­

tion, the complele specificalion is a vital one.

Please copy the specification sheet on p e

22 and fill out. It will be a big help to InanufJc

ture the requested products accUiately and

swiftly.

t •• , - . . . "

(

Please enter dale prepared, your company and section names, as well as Tele­

phone No., Order No. and File No.

Instrument Location nrtme if necessary to express on the instrument. If

not. leave It blank.

2.

Specify Tag

o. if it is required. If not, leave it blank.

3.

Select and mark Tag No. indlcatin<J localion. If not. leave it blank.

4.

Setect and mark Tag No. indicating method. If not, leave it blitnk.

5.

Select and mark the ambient teilipelature compensation method

6

Refer the CAT. and indicate Model

7.

Indicate nominal dial size. Ex) Dia

8.

Select and mark case color: Std. is Munsell N1. 2 (black)

9.

Select and mark scale plate color: Std. is white letter on black.

10.

Select and indicille scale range;

Ex) 0 l00"C or 32 -·210'F

11.

Select and mark scale division;

please refer the CAT. for standard spec.

j

~

1---.1-·

2

specify material names for capillary and flexible armor

not speCified.

Leave it blank. it

2

18

19

Mark the thermobulb style .

ark when Well IS reqUired. If not, leave it blan .

When Well IS reqUired, specify the Morlel No. by the table on rage 19.

When Well is not required, leave it blank.

17.

Specify the material when Well is required. Leave it illrlllk, if not re

qUlred.

18.

Indicate tank mnlerial for thermobulb. If not. leave il blank .

. 9.

SpeCify thread of flange sile lor thermobulb. In case 01 wi h well. speci­

fy Installation dim nsions of well.

20.

Specify proof pressure for lhermoillllil. No need to specify In case of

standard spec.

21.

SpeCify vanous dimensions of thermobllib.

1­

o

- - - ­

13.

6.

5 17

100mm

Enter capillary length (in unit of meier)

. 4.

t

~-17

12

15.

-0

CAT.

fJAGE ;

DESCRIPTION

ITEM

NO.

-

--

~­

t

22.

23.

24.

25

26.

27.

28.

NOTE:

A) In case Ihe entry is same as left side column, may use

Bl AbbreViations for material are as follows:

SUS O~

S~

5U53 6

Others

21

56

X

., mark.

,

.

: 11.

",

Company Name:

-

----­

I-­

Dale prepared

Person 10 conlact:

No

No.

File No.'

No.

I

Location

2

lAG No

ame

--I-=- -­

. L

0 I Selle

TAG Nu Indleatlng

ocatlon

Case

Tag No. Indicaling Method

4

I

-----1­

1­

5

I Adhe.

----­

~

, Ca,e

Scale

-, Case

M~.

JA~a

Glass

~

,. S S. plate

SSplale

..J Single

Temp. Compensatron Method

6

~-

1S(~le

Glass

Lead

I Double Lead.:...,,

_ Sln~le Lead

Double Leaas

-S

_

D

- S

GI~ss

-

Scale

ICa_,_e

S S. plate

I I Glass

_

Adhe

S. S pl_al_e

I

I

_ S,nqle Lead

Double :::Le::a=ds=-­

-_O

L

_

LJ SI/.gle Lead

I I Double Leads

-S

-D

-S

-0

-

Model No.

-r­

7

Dial Size

8

Case color

1

Std .. Bldlk

CMunsell

o Wht.

~

9

Scale Color

10

Scale Range

II

Mlo. Division on SCdie

12

Capillary Lenglh

13

Capillary Mat'I

Flex. Armur Mat'I

'4

Thermobulb Model

,5

Well MIg, Method

Well Model

17

Well Mal'l

18

Thermohllih Mat'I

19

Thd, r1ange Dim.

.-J Whl

[J Wht. Ilr. on Blk.

Blk.

I [Jlk. Llr on Wht.

L 'C

.

LF

[ J Std

Std

,

1

m

m

Fixed I Sliding U Olhers I I Fixed

I Sliding

] Others ~ Fixed

Plain

I Flexible

+,::L=-l.:...p::la.:...ln.:... I Flexible

J Plain

Welding I I Special boring

0 Welding

Special bering

cJ Welding

BOling

[J Other

I Boring l ()I_he_r

...:=-:::: Boring

C Fixed

Slidlog [ ] Others

Flexible

L

I

, Welding

SpeCIal horing

OIlier

I D.

dl

·F

oD

Ly

L:

IL9'

-

~

0.0. 02

02:

a;

~

I.D.

ell

Lg

L

I 0

d'

D

-

-

0.0 d

Well Inner Tllread

No. 01 set polnls

25

Ratlnq

-

-

26

Operatioo Mode

27

Remarks

1­

28

Qly

I Iln'1. Set

"lExt·1. Sel

11

set pOint

;] 2 sPt [lOlnls

- r~!lC

I DC

vol Is

volts

-

[lrl·1. Sct

[IExt

Sel

-­

r 'sel point

~? sel [lOlnt,

I

AC

....J DC

L

valls

volts

.CJ

-s

co

Lg

1

00 02

::J~t

L:

0.0, d:

~~

I

__

1.0. d l

~

Thermohllih Dim.

Lq

I:

-

~'Set

'Ext't. Set

I

I sci pOIf.t

2 set pUIf'!>

vailS

volls

-

D DI

00 01'

00 01:

24

1 Otller

-

-­

Sci pOint Adjustment

Others

C SpeCial boring

1Boring

-I

------il

f-­

23

-

I

I

0.0.

2?

J Sliding

C

::J FleXible

[ 1Plain

Thermobulb Proal-Press

?I

Std.

-~

m

m

-

U"C

I "F

~

U

I

-t-­

20

~ht:LUn

I ] lJlk. L11. 00 Wht.

IF

l

cJ

I

::J Munsell

JC

J Std.

_______+C::=

1

'6

[ Std .. Black

CMunsell

UC

I IF

I

I I Sid. [Jlack

S d . Black

--' Munsell

tlr on Blk.

Blk Llr on Wht

I tr. 00 Blk.

_ _ _-t-=I-=J_lJlk. Llr on Whl

Nom. Size

am Size

Nom Size

Nom. Si7e

-

Ext'1. Sct

-

I

SCi POIOt

I

2 :,el poiots

--­

11 AC

r I DC

volts

valls

-

Oil Refinery Plant

Pump [Illel

Oullel

Oil Cooler [nlel

(Jutlet

Compressor Air Outlet

Air Tn let

Boiler Slc£lm Temp

He£lvy Oil Temp

Oil rig Plant

Gas Plant

Heavy Oil Temp

C.ooling W£ltcr Temp

Gas Temp

Electric Power Plant

Nuclear Power Plant

Pump Tnlet

Outlet

Lvaporator Inlet

OUll..:t

Heater

Inkl

Outlet

Pur,' Water

Drain WaleI'

High Pressure Water

Turbin Oil

Thrust Metal Temp

Bearing Luhricant Oil

Ste£lm Supply

Return

Control OJ I

Air Ejeclor WaleI'

Hoi IeI' Feed Water

Oil Cookr Supply

Cooling Water

Air Cooler WaleI'

Turbin Outlet Steam

Exh£lust Ste£lm Temp

Gland Seal Steam

Condensation Tank

Condensatiun Pump

LPG Plant

LNG Plant

Diesel Engin

Oil Temp

fuel Uil Temp

Cooling Water Temp

Exh;\lIst Gas Temp

Turbin Bearing

Coupling Side

Shafl Fne!

Gear Rox

Dearing Temp

Pump

Casing

Coupling:

Stuffing Box Gland

(icar Box

Bearing Temp

Submarine

Sea WaleI' Temp

Heavy Oil Temp

PUle Air Temp

Ship Build CO.,

Oil Serviee Tank

Oil Set Tank

Blend Oil Inkt

Fuel Oil Purifier Inlet

Lubricant Oil Purifier

Exhaust (ias Temp

Pinion Shan Rearing Ternp

Diesel Air Temp

Bear Shaft Bearing Temp

Oil Reservoir Oil remp

Acellmllialer

Sea Oil Temp

L P(i Tank

Chemical Plant

Fertilizer Plant

Food Plant

Sugar Plant

Milk Plant

Oil Tank

Powder Tank

Cement Plant

Ice Freezer

Milk Evaporator

Condensor

Baking Powder Mixer

Chocolate Mixer

Beer Plant

Soap Plant

Mayonaise Plant

Film Plant

Rayon Plant

Tire Plant

Injection Machine

Pulp Plant

Paper Plant

Water Plant

Desalination Plant

Shaft Temp of Heavy Machinery

Bearing Temp of Motor

Air Conditioning Plant

WaleI' supply

return

Air supply

rcl urn

Steel Company

Shaft Temp of Mill

l.uhricanL Oil Temp

All information and specifications in this catalog are current at the tIme of printing' (h:Jnql'"

in product design and specifications may occur without notice. Contact your area fddUlY

representative or the factory for the current revision of this catalog.

Our local representative is

OJ. 04. 1.000