Temperature Measurement Solutions

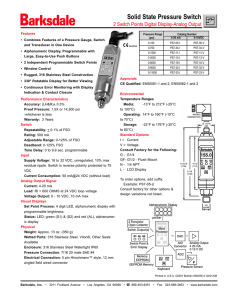

advertisement