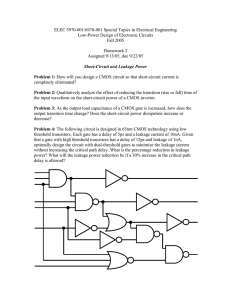

Leakage Current and Defect Characterization of Short

advertisement