Public Projects Manual

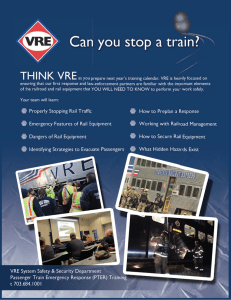

advertisement