Nonlinear Control System Design using a Gain Scheduling

advertisement

i

Nonlinear C o n t r o l S y s t e m D e s i g n

u s i n g a Gain S c h e d u l i n g Technique

A Thesis Presented t o

The F a c u l t y o f t h e College o f Engineering and Technology

Ohio U n i v e r s i t y

In Partial Fulfillment

o f t h e R e q u i r e m e n t s f o r t h e Degree

Master o f Science

by

Metin Songchai kul)

,/

March, 1993

iii

Table of contents

Page

Acknowledgements.....

...........................................................................

iv

Abstract ............

.

.

..................................................................................... v

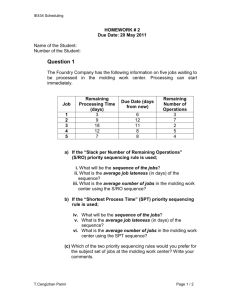

Chapter 1

Introduction.........................................................................

1

Chapter 2 Theory.......................................................................................

3

2.1 Basics of Lyapunov S t a b i l i t y Theory ............................3

.....................13

2 . 2 Linear Controller Design ...,...........

.

.

.

......................................

2 . 3 Gain Scheduling..................

.

.

.

29

..

Chapter 3 Missile Flight Control Problem.............

.

32

3 . 1 Mathematical Description of M i s s i l e Mode1...........3 3

3 . 2 Design Objectives ............................................................

36

Chapter 4

Design Steps...................................................................

38

4.1 Equilibrium Point Selection ..........................................

38

4 . 2 Linearization around each E q u i l i b r i u m Point .........41

4.3 Linear Controller Designs..............................................

43

4.4 Scheduling the Set o f Linear C o n t r o l l e r s ................60

Chapter 5

Summary and Conclusions ................................

References. ...........

......

Appendix A

77

...........................................................................

79

Computer programs..................................................

A1

Acknow ledaement

1 w i s h e s t o express sincere appreciation t o my advisor Dr.

Douglas Lawrence, f o r h i s support and guidance throughout the

course of t h i s study, w i t h o u t w h i c h the completion o f t h i s t h e s i s

would n o t have been possible.

A p p r e c i a t i o n i s extended t o the member o f t h e examination

c o m m i t t e e f o r s a c r i f i c i n g t h e i r free time, and g i v i n g t h e i r valuable

c r i t i c i s m s : Dr. Aysin Yeltekin , Dr. Dennis I r w i n and Dr. Brain Fabien.

Special appreciation i s extended t o my f a m i l y : Pramot, Arunee

and Nutharin Songchaikul, f o r t h e i r encouragement and support which

I have been able t o depend on.

Also, thanks t o Srikasem's f a m i l y who a l w a y s help and care

throughout the years of m y academic i n Ohio University.

F i n a l l y , deepest thanks t o my special f r i e n d Nuthaya f o r her

help i n typing.

Abstract

Real i s t i c models o f engineering s y s t e m s of t e n are nonlinear.

As a consequence, t h e dynamical b e h a v i o r o f a s y s t e m t o be

c o n t r o l l e d changes w i t h the operating region.

I n recent years, one

design methodology t o c o n t r o l t h i s e f f e c t , c a l l e d Gain Scheduling,

has proven t o be successful. The basic idea o f gain scheduling i s t o

break the c o n t r o l design process i n t o t w o steps. The f i r s t step i s t o

l i n e a r i z e the model about one or more operating p o i n t s . Then l i n e a r

design methods are applied t o the linearized model a t each operating

p o i n t i n order t o o b t a i n t h e s t a b i l i z e d s y s t e m w i t h i n t h e design

objectives. The f i n a l step, the actual gain scheduling, i s obtained by

scheduling o r i n t e r p o l a t i n g the gains of t h e l o c a l operating p o i n t s

designs i n o r d e r t o handle t h e n o n l i n e a r a s p e c t s o f t h e design

problem.

I n t h i s thesis, a nonlinear c o n t r o l l e r w i l l be designed using a

gain scheduling technique f o r a h y p o t h e t i c a l m i s s i l e model.

The

m i s s i l e considered here i s the same as discussed i n recent papers on

g a i n scheduling.

Here, a nonlinear a u t o p i l o t i s designed u s i n g

c l a s s i c a l servomechanism theory and s t a t e f e e d b a c k k t a t e observer

based techniques.

C h a ~ t e r1

Introduction

I t i s a w e l l - k n o w n f a c t t h a t a r e a l i s t i c s y s t e m model f o r

engineering applications i s nonlinear.

dynamical behavior of

As a consequence, t h e

a system t o be c o n t r o l l e d changes w i t h the

operating region. One design method t o handle t h i s e f f e c t i s called "

Gain Scheduling " .

Recently, several papers have described studies

of gain scheduling i n c o n t r o l s y s t e m design both i n l i n e a r s y s t e m

aspects and nonlinear s y s t e m aspects, and of those studies, many

have focused on the application of gain scheduling i n f l i g h t c o n t r o l

problems as published i n [5], [9], [ I 01, [ I 11, [ I 21, and [ 131. These

s t u d i e s have demonstrated t h a t gain scheduling can be a successful

design methodology f o r many applications o f engineering. The design

process f o r gain scheduling involves 2 basic steps.

1 . The s y s t e m t o be c o n t r o l l e d i s l i n e a r i z e d a t s e v e r a l

e q u i l i b r i u m p o i n t s (The equi 1 i b r i u m p o i n t s should be s e l e c t e d t o

cover the desired operating range). Then, f o r each 1 inearized plant, a

l i n e a r t i m e - i n v a r i a n t design technique i s applied t o c r e a t e a l o c a l

c o n t r o l l e r w h i c h s a t i s f i e s t h e design o b j e c t i v e s

f o r the system

when operating s u f f i c i e n t l y close t o the given e q u i l i b r i u m p o i n t .

2. The a c t u a l gain scheduling i s obtained by " s c h e d u l i n g " or

2

i n t e r p o l a t i n g the gains of the c o n t r o l l e r s i n step 1 between the

equilibrium points. In this way, a nonlinear controller f o r a nonlinear

system w i l l be obtained.

Despite i t s popularity, the gain scheduling method s t i l l has

some r e s t r i c t i o n s . For example, the operating condition i s normally

specified by the value of one or more exogenous variables and the

scheduled gain depends on the instantaneous values o f these

variables.

The studies described in [ I 31 show t h a t current gain

scheduling i s necessarily l i m i t e d t o s l o w v a r i a t i o n s i n t h e

scheduling variables. Previously, t h i s l i m i t a t i o n was j u s t i f i e d only

through implementation and simulation, but [ l 11, [13], and a recent

paper 151 shows a mathematical formula to j u s t i f y t h i s r e s t r i c t i o n .

In t h i s thesis, the author w i l l use the gain scheduling

technique t o design a nonlinear controller f o r a hypothetical m i s s i l e

model, The m i s s i l e considered here i s the same as discussed i n [9101, but, instead of using an H-infinity controller as done i n 191, the

author w i l l employ type- 1 servo system as the controller.

Chapter 2 explains the theory that w i l l be used throughout this

thesis. Chapter 3 describes the m i s s i l e model. The design process

and simulation r e s u l t s w i l l be discussed i n Chapter 4. Chapter 5

w i l l set f o r t h the conclusions of t h i s design work.

C h a ~ t e r2

Theory

In t h i s chapter the theory that related to t h i s thesis w i l l be

reviewed. First, the basics of the Lyapunov s t a b i l i t y theory w i l l be

given. The detail i n this section w i l l include the theory of nonlinear

system, equilibrium point, s t a b i l i t y i n the sense of Lyapunov and

linearization. Next, the theory of linear control design, type- 1 servo

system w i l l be described. Last, the technique f o r gain scheduling

w i 1 1 be considered.

2.1 Basics of Lva~unovS t a b i l i t v Theory

For a given control system, the f i r s t and most important

aspect t o be determined i s i t s s t a b i l i t y . A system i s described as

stable i f when we s t a r t the system somewhere around a desired

operating point, the system w i l l operate around t h i s point f o r all

future time.

I f the system i s linear and t i m e - i n v a r i a n t , many

c r i t e r i a are available f o r determining s t a b i l i t y such as the Nyquist

S t a b i l i t y C r i t e r i a and Routh's S t a b i l i t y Criteria.

nonlinear, or time-varying,

I f the system i s

one cannot apply these c r i t e r i a ,

The

most useful theory f o r determining the s t a b i l i t y of a nonlinear

4

and/or time-varying system i s Lyapunov S t a b i l i t y Theory.

Lyapunov's work, The General Problem o f Plot ion Stability.,

together w i t h t w o methods f o r s t a b i l i t y analysis (the linearization

method and the direct method) was published i n 1892 by the Russian

mathematician Alex Mi khai louich Lyapunov. However, t h i s theory did

not r e c e i v e much a t t e n t i o n u n t i l the e a r l y

1 9 6 0 ' s when the

p u b l i c a t i o n of the work of Lure's and a book by La Salle and

Lefschetz brought Lyapunov's work t o the f o r e f r o n t o f the control

engineering community. Today, Lyapunov's 1 inearizat ion method has

come t o represent the theoretical j u s t i f icatiorl of linear control,

w h i l e Lyapunov's direct method has become the most important tool

for nonlinear system analysis and design [ 141.

The Theory of Lyapunov also plays an important r o l e i n the

design o f a controller f o r a nonlinear system.

I n order t o provide

foundational information regarding Lyapunov Theory, the f o l l o w i n g

terms are defined and explained:

- Nonlinear System

A nonlinear dynamic system can be represented by a s e t of

nonlinear d i f f e r e n t i a l equation of the form

x

=

f(x,u,t)

where

X- 1 i.

,m

U =

Y1

,p x 1 output or measurement vector

...

- YP

1 input or control vector

-

Y2

Y=

,n x 1 state vector

-

I n the case where the system does not e x p l i c i t l y contain

control input variables, the system i s described by the f o l l o w i n g

equation.

x = f(x,t)

The number of states n i s called the order of the system. A

s o l u t i o n x ( t ) of Equation (2.1-2) i s r e f e r r e d t o as the system

t r a j e c t o r y i n the state space for t 2 0

- Equilibrium Point

Definition:

A

state x u

i s an e q u i l i b r i u m s t a t e ( o r

~ q u i l i b r i u mp o i n t ) o f the system i f once x ( t l is equal t o x u , i t

remains equal t o xu for a i l future time.

Mathematically, t h i s d e f i n i t i o n means t h a t an e q u i l i b r i u m

point of the system i s a t r i p l e (xo,uo,yo of a constant state, input

and output such that

f(~g,uo,t)" 0

Many s t a b i l i t y problems are n a t u r a l l y f o r m u l a t e d w i t h

respected to equilibrium points.

- S t a b i l i t y i n the sense of Lyapunov

Definition:

stable i f , f o r any

then /' x f t l

The Equilibrium s t a t e

xo

=

0 i s said to be

R>U, there exist r>U,, such that i f I/ x(UI //< r,

I/< R f o r a l l t>U. Otherwise, the equilibrium point i s

8

system t r a j e c t o r i e s , which s t a r t closely t o the equi l i brium point,

actually converge t o the equilibrium point as t i m e goes t o i n f i n i t y .

Also, i t i s necessary t o know how f a s t the system trajectories w i l l

converge t o the equilibrium point. The following definitions address

these concepts.

Definition: An equilibrium point xu

=

U i s as,ymptotical/y

stable i f i t i s stable,, and i f in addition there ~ . x i s t ssome r > 0

such that

If x(UI If < r implies that x(tl

Definition: .An equilibrium point

7'

U as

xu

=

t

7

'

a,.

0 i s e.xponential1,~

stable i f there exist two s t r i c t l y positive numbers

a and A such

that

V t > 0 , 11 x(t) 11 I a Ilx(0) lle-At

for a1 1 x(Ul in some ha l l Br around the origin.

These s t a b i l i t y definitions are formulated to characterize the

l o c a l behavior of systems when the system operates near an

equilibrium point. Local properties do not describe the behavior of

the system when the i n i t i a l state i s some distance away f r o m the

equil ibrium point. The following d e f i n i t i o n describes a concept o f

s t a b i l i t y i n t h i s case.

Definition:

I f asymptotic (or e.xponential) s t a b i l i t y holds

f o r any i n i t i a l state,, the equilibrium point

i s said t o be

asymptotically (or e.xponentially) stable in the large.

I t is also

called globally asymptotically (or e.xponentiall,~)stable.

-

Linearization

The l a s t s t a b i l i t y theorem that w i l l be given i s the important

theorem f o r t h i s gain scheduling technique. This theorem give the

idea o f the s t a b i l i t y f o r nonlinear systems w i t h s l o w l y varying

inputs. I t i s used t o guarantee nonlocal performance of the nonlinear

system. The t3eorem and the details of the proof are discussed i n

[S]. Here, the theorem i n [51 w i l l be given again as;

For the system described as

~ ( t =) f(x(t), u(t)) , x(b) =xo , t 2 to

assume

( H I ) f: R* x

~ m - +

i s t w i c e continuously differentiable

(H2) there i s bounded, open set

r c R~

and a continuously

10

d i f f e r e n t i a b l e f u n c t i o n x:;input value u

E

R" such t h a t f o r each constant

r, ~(x(u),U) =O,

(H3) t h e r e i s a A

> Osuch t h a t

f o r each u E

r, t h e

eigenvalues

have r e a l p a r t s no greater than -A.

of (~V~X)(X(U),U)

Theorem: Suppose t h e s y s t e m ( 1 . 1 ) s a t i s f i e s ( t i 1 ), (H2), and ( H 3 ) .

Then t h e r e i s a p* > o such t h a t given any p

E

(0, p*] and T > 0 , there

e x i s t 6,(p), B2(p, T)> 0 f o r w h i c h t h e f o l l o w i n g p r o p e r t y holds.

continuously d i f f e r e n t i a b l e input u ( t ) s a t i s f i e s

~ ( t E)

If a

11 xo - x(u(to)) 11 <a1 f o r

r, t 2 to and

then t h e corresponding s o l u t i o n o f t h e s y s t e m given above s a t i s f i e s

II x(t>- x(u(t)) II < P ,

t

2 to.

Now t h e l i n e a r i z a t i o n method w i 1 1 be discussed.

linearization method

Lyapunov's

i s concerned w i t h t h e l o c a l s t a b i l i t y o f a

11

nonlinear system. The idea of t h i s approach comes from the w e l l known f a c t that a nonlinear system, when operated i n a s u f f i c i e n t l y

small neighborhood of an equilibrium point, may behave much l i k e a

linear system. This method involves linearizing the given system in

the neighborhood of an e q u i l i b r i u m point and d e t e r m i n i n g the

behavior of the nonlinear system's t r a j e c t o r i e s by studying t h i s

1 inearized system using 1 inear system techniques.

Mathematically, the idea i s to expand the nonlinear functions

i n t o a Taylor series around the equilibrium point and r e t a i n only the

linear term, neglecting the higher-order terms provided they are

small compared to the linear term. Consider the nonlinear dynamics

system described below;

Recall an e q u i l i b r i u m p o i n t of the s y s t e m i s a t r i p l e

( x ~ ~ ou1 of~ constant

~ Y

state, input, and output such that

f(xo,uo,t) = 0

for all t 2 to

Define Jacobian matrices

By Taylor Series Expansion of f and g, the functions f and g

can be expanded around the equilibrium state and input (xo,uo)

as

f ( x , ~ , t=) f(x0,u0,t) + A(x0,uO,t)(x - xo)+ B(xO,uO,t)(u - uo) + hot's

(2.1-6)

g(x,u,t) = g(q,uo,t) + C(xo,uO,t)(X - xo)+ D(%,u0,t) (U - uo) + hot's

(2.1-7)

where hot's means higher-order terms

Assuming that the higher-order terms are s m a l l enough t o be

neglected one can approximate these functions as

f(x,u,t) = A(xg,uo,t) (x - xo)+ B(xo,~o,t)(u - uo)

then define deviation variables

x6 = x - xo

u6 = u - uo

Ya = Y - Yo,

Since x ( t ) i s a constant v e c t o r

Using the linear approximation of f and g around e q u i l i b r i u m

s t a t e and i n p u t one can t h e n d e s c r i b e a l i n e a r s y s t e m t h a t

approximates the behavior of the nonlinear system (2.1-3) near the

e q u i l i b r i u m p o i n t as

y6(t) = C(xo,uO,t)xa(t) + D(xo,uo,t>uij(t)

(2.1-8)

Based on the l i n e a r i z e d s y s t e m (2.1-8>, one can apply l i n e a r

design techniques t o guarantee the s t a b i l i t y of tP~iss y s t e m .

2.2 Linear Controller Desian

The design o f the c o n t r o l l e r , w h i c h regulates the given m i s s i l e

i n t h i s t h e s i s problem, employs a type- l servo s y s t e m based on the

pole placement approach and s t a t e observers . Theorems r e l a t e d t o

t h i s d e s i g n i n c l u d e p o l e p l a c e m e n t d e s i g n and t h e d e s i g n o f

observers.

-

Pole Placement

Consider SISO system

x=Ax+Bu

where

x = s t a t e vector (n

x

1 vector)

Y = output signal (scalar)

u

=

control signal ( s c a l a r )

A

=

n x n constant m a t r i x

B = n x 1 constant m a t r i x

C

=

1

x n constant m a t r i x

The c o n t r o l signal w i l l be

us-Kx.

The 1 x n vector K i s called the s t a t e feedback gain v e c t o r .

S u b s t i t u t i n g Equation (2.2-3) i n t o Equation (2.2-1 ), w e obtain

The s o l u t i o n o f Equation (2.2-4)

i s given by

The s t a b i l i t y of t h i s system i s determined by the eigenvalues

of the m a t r i x (A-BK).

By choosing a proper K, one can construct the

m a t r i x (A-BK) such that i t i s asymptotically stable. This problem

of placing the closed-loop poles a t the desired location i s called the

pole placement problem. The technique used t o solve t h i s problem

c o n s t r u c t s an a s y m p t o t i c a l l y s t a b l e closed-loop

s y s t e m by

specifying the desired locat ions f o r the closed-.loop poles.

By

assuming the control law t o be u = -Kx, one can determine the

feedback gain vector K such that the closed-loop system as shown i n

FIGURE 2.2- 1 w ill have a desired characteristic equation.

FIGURE 2.2-1 Block diagram w i t h u = -Kx

16

When using t h i s technique, one must meet the necessary and

sufficient

condition that

controllable.

the

system state

i s completely

Algebraically, t h i s i s equivalent t o nonsingularity of

C ( A P B ) = [ B A B . - - A " - ~ B ]Note,

all

t h e n x n controllability matrix

s t a t e v a r i a b l e s are assumed t o be available and measurable f o r

feedback.

D e t a i l e d i n f o r m a t i o n c o n c e r n i n g t h i s technique i s

explained i n [61.

feedback

An approach f o r the d e t e r m i n a t i o n o f the s t a t e

K p r e s e n t e d n e x t w a s developed by

gain m a t r i x

J.E.Ackermann. This approach i s known as Ackermann's formula.

Ackermann's formula

The s t a t e equation f o r t h i s system i s given by

x=Ax+Bu.

Assume that the system i s completely s t a t e controllable

.

Ackermann's formula i s given as

K = [0 0 ... 0 11 [B f AB

f A*B f . . . i

B]-'a(~)

and

a (s) = ( s - ~ i()s - ~ 2 ). . . ( s - c I ~ )

=

sn+ a 1 s n - l + . . . +a,.ls

where p 1 .p2, ... .pn

=

+ an

the desired closed-loop poles.

(2.2-6)

-

Design of S t a t e Observers

I n the pole placement approach, one assumes t h a t a l l s t a t e

variables are available f o r feedback.

For a fir-st o r second order

s y s t e m , f u l l s t a t e feedback i s not an unreasonable e x p e c t a t i o n .

However, f o r most high order systems, a l l s t a t e v a r i a b l e s are n o t

available f o r feedback; t o implement pole-placement design i n these

s y s t e m s , i t i s necessary t o e s t i m a t e these u n a v a i l a b l e s t a t e

v a r i a b l e s f r o m the measurements t h a t can be made on the system.

The method used t o e s t i m a t e the unavailable s t a t e s i s commonly

c a l l e d a s t a t e observer

A s t a t e observer e s t i m a t e s t h e s t a t e

v a r i a b l e s based on the measurements o f the o u t p u t and c o n t r o l

variables w i t h a r b i t r a r i l y specified e r r o r dynamics, b u t can only do

so on the condition that the system i s completely observable. Also,

[6]has provided proof of t h i s f a c t

A f u l l - o r d e r s t a t e observer i s one t h a t e s t i m a t e s a l l s t a t e s

v a r i a b l e s o f t h e s y s t e m regardless o f w h e t h e r o r n o t they are

d i r e c t l y measurable. A minimum-order s t a t e observer i s defined as

an observer t h a t e s t i m a t e s only t h e m i n i m u m number of s t a t e

variables.

T h i s thesis w i l l only consider the f u l l order s t a t e observer

t

Use ? t o designate the observed s t a t e vector f o r

Assume that state x i s t o be approximated by the state ? of

the dynamic model as show i n FIGURE 2.2-2

X

+

b

B

q=>

+

1/s

2

Y

C

+

U

A

-

2

+

+

B X,

,

u +

-

-

-X

l/s :

>u

A ,

L

3

C

-

4

+

4

FIGURE 2.2-2 Block diagram o f system w i t h full-order s t a t e observer

From FI GURE (2.2-2),

;=A?+BU+L(~-G)

(2.2-9)

which represents the state observer w i t h y and u as input and

-x as output.

19

To obtain the observer e r r o r equation, s u b t r a c t Equation ( 2 . 2 9) f r o m Equation ( 2 . 2 - 7 )

x - 2 = Ax+Bu - Ax?-Bu-L(Cx-Cs = (A-LC) (x -

x)

(2.2- 10)

Define the d i f f e r e n c e between x and ii as t h e e r r o r v e c t o r or

e = X-ii and Equation (2.2- 10) becomes

e = (A-LC) e .

(2.2- 1 1)

T h i s i l l u s t r a t e s t h a t t h e eigenvalues of t h e m a t r i x A - L C

determine the dynamic behavior of the e r r o r v e c t o r .

I f t h e eigenvalues of m a t r i x A-LC are chosen i n such a way

that the error system 2 2 - I

i s exponentially stable w i t h

acceptable r a t e o f decay, then any e r r o r v e c t o r w i l l tend t o zero

w i t h adequate speed.

Since the problem o f designing a f u l l - o r d e r observer requires

t h a t the observer gain m a t r i x L be such t h a t A-LC

has desired

eigenvalues, t h i s problem resembles t h e pole placement problem.

Thus, using the Principle of Duality, l e t

z = A*Z + C*V

and assume the control signal y t o be

v

=

-L*z

(2.2- 12)

20

L e t I J ~ . I J ~ . .Pn

be t h e d e s i r e d eigenvalues o f t h e s t a t e

observer m a t r i x , and assume the dual s y s t e m i s completely s t a t e

c o n t r o l lable.

Furthermore, t a k i n g the same

p i ' s as the desired

eigenvalues o f the s t a t e feedback gain m a t r i x , one can w r i t e :

Is1 - (A* - C8L*)I= (s - pl)(s- pZ)...(s - p,)

Since (A*-c

*L*1 has

the same eigenvalues as

can determine the observer gain

(A-LC),

L by f i r s t d e t e r m i n i n g L*

one

i n the

pole placement approach

Ackermann's

Formula

Consider Equation (2.2- 12) and Equation (2.2- 13)

The Ackermann Formula f o r pole placement can be w r i t t e n as

L* = [O 0 ... 0 11 [C*

A'C*

I ...

(A*)"-~c*]"a(A)

Taking transposes, one w i l l obtain Ackermann's Formula f o r

the s t a t e observer gain as

and

where

P ~ . P ...

~ ..Pn = the desired eigenvalues of observer e r r o r

dynamics.

I n t h e pole placement design process, w e assumed t h a t the

actual s t a t e x ( t ) was available f o r feedback; however, the actual

s t a t e x ( t ) may not be measurable. Therefore, w e need t o design an

observer and use the observed s t a t e

G(t)

f o r feedback.

Thus, t h e

design step involves a two-stages, f i r s t determine the feedback gain

m a t r i x K t o y i e l d the desired closed-loop c h a r a c t e r i s t i c equation

assuming s t a t e feedback and second d e t e r m i n e t h e observer gain

m a t r i x L t o y i e l d the desired observer c h a r a c t e r i s t i c equation. The

e f f e c t o f using

g(t) instead

of the actual s t a t e x(t) on t h e closed-

loop control system i s discussed i n [ 6 ] . Thus, only the conclusion o f

t h i s e f f e c t w i l l be mentioned.

22

Since the characteristic equation that described the dynamics

of the observed-state feedback control system i s given as

I sI-A+BK I 1 sI-A+LCI

=0

Obviously, i t shows that the closed-loop poles of the combined

observer-state feedback system comprise the poles due t o the pole

placement design together w i t h the poles due t o the observer design.

This means that the pole placement design and the observer design

can be done separately and combined together t o f o r m the observerstate feedback control system.

-

Servo s y s t e m

FIGURE 2.2-3 Block diagram of Type-1 servp system

In the discussion of pole placement and the design of a state

observer, only a closed-loop system w h i c h has no input was

considered. The purpose of such a design I s t o r e t u r n a l l s t a t e

variables from t h e i r i n i t i a l values t o values of zero when the states

23

have been perturbed. Such a system i s called a regulator. However,

many c o n t r o l s y s t e m s , i n c l u d i n g the c o n t r o l s y s t e m discussed i n

t h i s thesis, require the system output t o t r a c k an external reference

input.

I n such cases, t h i s n e c e s s i t a t e s m o d i f y i n g t h e design

equation of t h e pole placement and the s t a t e observer. These types

o f s y s t e m s a r e known as servo s y s t e m s

and a r e i l l u s t r a t e d i n

FI GURE 2.2-3.

Servo system design involves c o n s t r u c t i n g compensators and

feedback l a w s t h a t y i e l d a stable (BIB0 and / o r a s y m p t o t i c ) closedloop system able t o t r a c k a specified class of reference signals. In

FIGURE 2.2-3, the i n t e g r a t o r , together w i t h s t a t e feedback scheme,

i s used t o

s t a b i l i z e the s y s t e m and a s y m p t o t i c a l l y t r a c k s t e p

reference inputs w i t h zero steady-state e r r o r .

Since the given p l a n t ( m i s s i l e problem) does n o t i n v o l v e an

integrator, t h i s thesis w i l l consider only the design theory o f a type

1 servo s y s t e m w h e r e t h e p l a n t has no i n t e g r a t o r .

As mentioned

e a r l i e r , i n m o s t cases, n o t a l l s t a t e v a r i a b l e s can be d i r e c t l y

measured, theref ore t h i s consideration of servo s y s t e m design w i l l

also include a discussion o f the s t a t e observer.

A type- 1 servo

s y s t e m where the plant has no i n t e g r a t o r i s shown i n FIGURE 2.2-4.

FIGURE 2.2-4 Block dlagram o f type- 1 servo s y s t e m w i t h s t a t e observer

F r o m t h i s figure, w e have

x(t) = Ax(t) + Bu(t)

The c o n t r o l l a w i s described as

where

u(t)

=

control signal ( s c a l a r )

y(t)

=

plant output signal (scalar)

r(t)= reference input signal

c(t)

=

output of i n t e g r a t o r ( s t a t e variable o f t h e system)

I t w i l l be assumed t h a t :

1 . The plant i s controllable and observable

2. The plant has no pole a t s=O

3. The plant has no zero a t s=O

Assume t h a t the r e f e r e n c e i n p u t ( r ( t ) = s t e p f u n c t i o n ) i s

applied a t t

=

0 . As a consequence of the e f f e c t of t h e a d d i t i o n of

the observer on a closed-loop system, the pole placement design and

the observer design can be design separately and combined together

t o f o r m the observer-state feedback system. Thus, f r o m FIGURE 2.24, w e w i l l use the pole placement approach t o design gain K and K i

t o s t a b i l i z e the system. Then the observer design f o r gain L w i l l be

app 1 ied.

Assuming the actual s t a t e s x ( t ) are a v a i l a b l e f o r feedback,

one can f o r m t h e dynamic equation of type- 1 servo s y s t e m as

An a s y m p t o t i c a l l y stable system w i l l be designed such t h a t f o r

t -> m, x(t),

f(t), and u(t) approach c o n s t a n t

values, denoted xss, fss, and us,

respectively. Further, f(t) -> 0 and

r(t)

=

r, t 2 0 as

A t steady state, one has

Since r(t)

i s a s t e p i n p u t , t h u s r(t)

=

r (constant).

f r o m Equation (2.2-21) and defining

subtracting Equation (2.2-22)

x(t) - xss = xe(t>

E(t>

w e have

- ESS = Ee(t)

By

where

ue(t> = -Q(t)

+

KiEe(t>

Define a new (n+ 1 ) th-order error vector e(t) by

then Equation (2.2-23) becomes

$(t) = &t)

+ Bue(t)

where

The control signal u,(t)

becomes

where

K=[K

I

-Ki]

The idea of f i r s t design stage i n type-1 servo system i s t o

design a stable ( n + l ) t h - o r d e r regular system t h a t w i l l b r i n g the

new error

c(t) t o

zero. And the s t a t e error equation of t h i s system

can be found by putting Equation (2.2-25) into Equation (2.2-24)

$(t) =

(-i

BK) a t )

Therefore, i f the desired eigenvalues o f m a t r i x

X-BK

are

28

specified as p l , p2 , ..., pn + I i n order t o have the zero steady state

e r r o r , the s t a t e feedback gain m a t r i x K and the i n t e g r a l gain

constant K i can be determined by the pole placement approach.

Now consider the s t a t e observer t o design the gain L. To

obtain the observer e r r o r equation, subtracting Equation ( 2 . 2 - 2 0 )

from Equation (2.2- 16), we have

x - i? = Ax+Bu - Ax--Bu-L(Cx-C%) = (A-LC) (x - 2 )

(2.2-26)

Define the difference between x and ii as the error vector e or

e = (A-LC)e

(2.2-27)

From Equation (2.2-27), we see that the dynamic behavior of

the e r r o r vector i s determined 5y the eigenvalues of m a t r i x A-LC.

I f the eigenvalues o f m a t r i x A-LC are chosen i n such a way that the

dynamic behavior of the error vector i s asymptotically stable and i s

adequately fast, then any error vector w i l l tend t o zero w i t h an

adequate speed. Since we assumed t h a t t h i s system i s completely

observable, the gain L of state observer approach can be chosen by

specification of the desired eigenvalues

A-LC.

F1, F2 , .... -pn

of the m a t r i x

A t t h i s point, one can f i n d the gain K, K i and L which makes

t h i s type-1 servo system have z e r o steady state error.

Next the closed-loop s t a t e equation o f t h i s type-1 servo

29

system i n FIGURE 2.2-4 w i l l be developed for future reference i n the

design steps.

Consider Equation (2.2- 1 6 ) - Equation (2.2-20);

Put Equati on(2.2- 1 9)into Equation (2.2- 16) t o obtain

~ ( t =) Ax(t) + B ( - E ( t ) + Kic(t) )

Put Equation (2.2- 17) into Equation (2.2- 18) t o obtain

Putting Equation ( 2 . 2 - 17), (2.2- 19)) and (2.2-28) into Equation (2.220) yields finally,

Thus, the combination of Equation (2.2-28), (2.2-29)) and (2.230) gives the closed-loop system as

-

?

A

LC

-C

-BK

A-BK-LC

BKi

13Ki

0

0

]

x(t)

%t)

-

SO)

+

,

[H ]

dt)

2-3 Gain Schedulinq

R e a l i s t i c models of

engineering s y s t e m s are t y p i c a l l y

nonlinear. In studying control system design, an important e f f e c t of

t h i s kind o f system emerges: the dynamic behavior of a system t o be

c o n t r o l l e d changes w i t h the operating region.

An approach t o

handling t h i s e f f e c t i s called "Gain Scheduling".

As f i r s t noted, current gain scheduling practice i s l i m i t e d t o

s l o w v a r i a t i o n of exogenous scheduling variables.

Thus i n the

considered model, the operating condition had t o be arranged so that

i t would be s p e c i f i e d by the value of one o r more exogenous

variables, then the gains w i l l be scheduled according t o the

instantaneous values of the exogenous variable. The model of the

system w i l l resemble as shown i n FIGURE 2.3-1.

w( t),exogenous (scheduling) variables

r(t)

r

Nonlinear

Controller

u(t)

Nonlinear

plant

FIGURE 2.3- 1 System f o r applying gain scheduling

The application of gain scheduling t o the controller design i s

divided into 4 steps:

1 , select a set of equilibrium points t o cover desired operating

range

2. linearize the plant around each equilibrium point

3. design a linear controller for each linearization

4. schedule the set of linear controllers

To determine an equilibrium point (step I ) , set

f(x,u,t)=O and

The linearization about an equilibrium point i n step 2 involves

expanding f and g i n a Taylor series at the equilibrium point and

neglecting the higher order terms.

32

The type 1 servo system w i l l be designed f o r each linear

controller i n step 3 as previously described.

Scheduling or interpolating the set of linear controllers i n the

l a s t step has the basic idea t o interpolate the linear c o n t r o l l e r a t

intermediate operating conditions. That is, a scheme i s devised f o r

changing the gains i n the c o n t r o l l e r s based on the operating

condition of the system. The details of scheduling techniques used

i n t h i s thesis w i l l be discussed i n chapter 4.4.

C h a ~ t e r3

M i s s i l e F l i a h t Control Problem

Consider m i s s i l e - a i r f r a m e c o n t r o l problem i l l u s t r a t e d i n

FI GURE 3- 1 .

attack

Fin defection

Velocity vector

FIGURE 3- 1 M i s s i l e Fl ight control problem

When the vehicle i s f l y i n g w i t h an angle of a t t a c k ( a ) , l i f t i s

developed.

T h i s l i f t may be represented as a c t i n g a t a c e n t r a l

l o c a t i o n ( c e n t e r o f pressure). The vehicle w i l l be s t a t i c a l l y s t a b l e

o r u n s t a b l e ( w i t h o u t c o r r e c t i v e t a i 1 d e f e c t i o n s ) depending on the

l o c a t i o h of the center of pressure r e l a t i v e t o t h e c e n t e r of mass [21.

The problem focused on i n t h i s t h e s i s i s t h a t o f c o n t r o l l i n g t h i s

vehicle t o t r a c k commanded normal acceleration by generating a t a i l

f i n defection angle. The a u t o p i l o t w h i c h needs t o be designed w i l l

34

accept a normal acceleration command f r o m some o u t e r guidance

system. The f i r s t p a r t of t h i s chapter w i l l introduce the description

of a hypothetical m i s s i l e model t h a t w i l l be used i n the f o l l o w i n g

design discussion. Some of the m i s s i l e ' s v a r i a b l e are measured by

gyros and accelerometers. The l a s t p a r t of t h i s chapter w i l l show

the requirements of the autopilot design. The process o f t h i s design

w i l l be discussed i n the next chapter.

3.1 Mathematical D e s c r i ~ t i o nof Missile Model

The m i s s i l e f l i g h t control problem used i n the t h e s i s design i s

shown i n FIGURE 3.1-1.

M( t)

6

b actuator

6

b a i r frame

-b accel erome t o r

-b

pitch rate

FIGURE 3.1- 1 The block diagram of m i s s i l e model

A i r f r a m e Dynamics

h(t>= &M(t)G[a(t>,6(t),M(t)lcos(a(t>>+q(t)

Actuator Dynamics

Output

Variables

a(t) = angle of attack, range -20'1 a 5 20'

M(t) = Mach number, range 2 M 4

q(t) = pitch rate.

GC(t)= commanded tail fin deflection angle

6(t) = actual tail fin deflection angle.

qc(t) = commanded normal acceleration.

qz(t) = actual normal acceleration.

note: The angles a r e measured i n degrees.

The a c c e l e r a t i o n i s measured i n gees

Simulation Variable

36

F o r simulation purposes, a state equation for Mach number i s

defined as

Aerodynamic Coefficients

Constants

where

(0.7) PoS/mv,

K,

=

Ax

= (0.7) PoSCa/m

Po = static pressure a t 20,000 f t

s = surface area = 0.44 f t 2

m

=

mass

=

13.98 slugs

=

973.3 l b s / f t 2

37

vs =

speed of sound a t 20,000 f t

=

1036.4 ft/sec

d = diameter =0.75 f t

IY = pitch moment of inertia

=

182.5 slug-ft2

Ca = drag coefficient = -1.5

=0.7

3.2 Desian Obiectives

The requirements of the design are as follows:

( 1 ) Obtain robust s t a b i l i t y over the operating range. The

operating range i s specified by the angle of attack

a and Mach

number M and consists of those points (a,M) such that

-200sas200

and 2 s M s

(

altitude = 20,000 f t . ) .

38

( 2 ) Track step normal acceleration commands w i t h t i m e

constants of approximately 0.25 second or less.

( 3 ) Maintain greater than 30 dB attenuation at 300 rad/sec f o r

the open-loop linearized transfer function w i t h the loop broken at

the actuator input. This requirement seeks t o avoid e x c i t i n g the

unmodelled structural dynamics.

Chapter 4

Gain Schedulina Desian

I n t h i s c h a p t e r t h e n o n l i n e a r s y s t e m design u s i n g a g a i n

scheduling technique w i l l be discussed.

An a u t o p i l o t w i l l be

designed i n o r d e r t o c o n t r o l t h e m i s s i l e p r o b l e m discussed i n

chapter 3.

By using the gain scheduling technique t h e a u t o p i l o t

design i s divided i n t o 4 steps as

1 , e q u i l i b r i u m point selection

2. l i n e a r i z a t i o n around each e q u i l i b r i u m p o i n t

3, l i n e a r control l e r designs

4. schedclling the set o f linear c o n t r o l l e r s .

Each o f these des'ign s t e p s w i l l be discussed n e x t

After

obtaining the a u t o p i l o t f r o m the design method, t h e local s t a b i l i t y

of the m i s s i l e w i l l be checked. And a t t h e end o f t h i s chapter t h e

s i m u l a t i o n by SIMULAB w i l l be applied t o t h e m i s s i l e i n order t o

check t h e m i s s i 1 e's performance.

4.1 Eauilibrium Point Selection

From t h e m a t h e m a t i c a l d e s c r i p t i o n i n Chapter 3, t h e m i s s i l e

model i s w r i t t e n as a set o f nonlinear d i f f e r e n t i a l equations as

where

x

=

a 4 X 1 state vector so that

Thus,

=

K,M(t)G[a(t),G(t),M(t)lcos(a(t)) + q(t)

=,

f l(x(t),u(t),w(t))

To determine the e q u i l i b r i u m p o i n t s of t h i s system, by

definition,we set f(x,u,y)

=

0. Thus the set of equilibrium poirlts

i s calculated and shown as follows:

and

6(t) = - Isgn(a(t))laJa(t)13

dm

+ bmla(t)12+ G,($M(~) -7)la(t)ll

,

f~(x(t),u(t),w(t))= 0, i m p l y i n g t h a t

and

q(t) = KaM(t)C,[a(t),6(t),M(t)lcos

(a(t)) = 0:

q(a,M) = -K,MCJa,G(a,M),Mlcos

(a)

and the constant operating point o f the output f u n c t i o n i s calculated

as

g(x(t),u(t>,w(t>)= y

rl,(t)

and

= KzM2(t)G[a(t),G(t),M(t)l:

rlz(a,M) = KzM2G[a,G(a,M),Ml

4.2 Linearization around each eauilibrium point.

The nonlinear plant i s given as

where

To linearize the nonlinear system,

we use the Taylor series

expansion of f and g around an equilibrium s t a t e and neglecting the

higher-order term of order greater than 2, which are assumed t o be

small, we have

where

Z(t)

= x(t)

- x(a,M)

G(t) = 1Z(t) - rlz(a,M)

The Jacoblan m a t r i c e s A(a,M),

-I

B(a,M),

C(a,M)are

calculated as

44

The c o e f f i c i e n t m a t r i c e s of the 1 ineari zed p l a n t are c a l c u l a t e d

v i a PROGRAMftl s h o w n i n appendix f o r any e q u i l i b r i u m p o i n t

s p e c i f i e d by (a,M).

4.3 Linear Controller Desians

As mentioned earlier, i n order t o design a c o n t r o l l e r t o c o n t r o l

nonlinear plants, i t i s necessary t o break the c o n t r o l design process

i n t o t w o steps. F i r s t , one m u s t design local linear c o n t r o l l e r s based

on 1 i n e a r i z a t i o n o f t h e n o n l i n e a r p l a n t s a t s e v e r a l d i f f e r e n t

operating conditions. Second, one m u s t i n t e r p o l a t e t h e gains of the

local designs. The process o f a linear c o n t r o l l e r design i s described

below.

I n designing these c o n t r o l l e r s , the p l a n t t h a t w e consider i s

t h e l i n e a r i z e d p l a n t c a l c u l a t e d frorn S e c t i o n 4.2, s i n c e i t i s

necessary t o design a c o n t r o l l e r f o r t h e l i n e a r i z e d p l a n t a t several

d i f f e r e n t operating points.

points at a

;1 2 , 3

Here, consider 3 d i f f e r e n t o p e r a t i n g

and (1;,4).

I t was previously observed i n

[9]t h a t the solutions are a f f e c t e d by v a r i a t i o n s i n Mach numbers and

o n l y w e a k l y a f f e c t e d by changes i n angle o f a t t a c k ; t h e r e f o r e ,

0

s e l e c t i n g an angle o f a t t a c k a t

10 f o r each o f t h r e e Mach numbers

r e p r e s e n t s a reasonable compromise i n t h a t t h i s value r e p r e s e n t s

the m i d p o i n t of the desired operating range. The f i r s t o b j e c t i v e f o r

45

t h i s s t e p i s , f o r f i x e d Mach number, the c o n t r o l l e r m u s t s t a b i l i z e a l l

p l a n t l i n e a r i z a t i o n s corresponding t o a l l values of

b e t w e e n -200 < a < 200

angle o f a t t a c k

By s y m m e t r y p r o p e r t i e s o f the p l a n t

description, one need consider only

$<

a < 2$

The type 1 servo system based on pole placement i s u t i l i z e d i n

order t o design the desired c o n t r o l l e r . Since some o f s t a t e variables

are not available f o r measurement, the s t a t e observer i s placed i n t o

t h i s servo system.

D e t a i l s about t h i s type-1 servo s y s t e m w e r e

given i n Section 2.2 f r o m w h i c h the closed -loop system i s described

In order t o meet the design o b j e c t i v e , the open-loop t r a n s f e r

f u n c t i o n of the l i n e a r i z e d system requires t h e loop t o be opened a t

the input to the actuator.

Before going f u r t h e r t o t h e c o n t r o l l e r

46

design step, the open-loop s y s t e m i s developed here. FIGURE 4.3- 1

shows a blclck diagram of the open-loop s y s t e m w h i c h i s developed

f r o m FIGURE 2.2-4.

FIGURE 4 3 - 1 B l o c k d 1 2 c r w -

gf

o a e n - l o g p 5ys:en

The dynamics o f the open-loop system i s described as

-

r

A

0

0

LC A-LC 0

-C

0

O J

1

d t i 1

%(ti + [ E 3 ] u l ( t )

- f(t)

J

I n Chapter 2.2, a method t o f i n d the g a i n

K o f the p o l e

placement design and the gain L of the s t a t e observer w a s given by

using Ackermann's formula. However, i n t h i s c o n t r o l l e r design step

these can be found d i r e c t l y by using the "PLACE" command i n the

Control System Toolbox of MATLAB.

The f i r s t design i s calculated i n PROGRAM #2. The p l a n t used

i s t h e l i n e a r i z e d p l a n t f r o m PROGRAMXl.

suitable gain vector

In determining the

K that gives the best overall system

performance, the several d i f f e r e n t m a t r i c e s

K are examined v i a

computer s i m u l a t i o n t o o b t a i n the response c h a r a c t e r i s t i c s o f the

s y s t e m The m a t r i x K i s based on the s e l e c t i o n o f the eigenvalues

w h i c h give the desired c h a r a c t e r i s t i c equation. I n our design, a f t e r

several s i m u l a t i o n s t o check the system c h a r a c t e r i s t i c s , i t i s found

t h a t t h e e i genvalues a t [ - 3 6 . 3 , - 3 6 . 9 6 + 0 . 6 6 i , - 3 6 . 9 6 - 0 . 6 6 i ,

3 7 . 6 2 + 1 . 3 2 i , -37.62- 1 . 3 2 i l give the b e s t gain m a t r i x

K

-

that is

suitable f o r the design objectives.

The observer gain m a t r i c e s L are considered i n t h e same

manner as the gain

K .

48

The best gain m a t r i x L which gives the

suitable response for the design objectives i s defined by placing the

eigenvalues for states observer technique at [-6 16+ 1 1 i, -61 6-1 1 i, 627+22i, -627-2213.

In addition, PROGRAM "2 simulates the closed-loop system

step response and the frequency response of the open-loop system

From PROGRAM #2, the gain K, K i and L for the controller a t

0

the constant equi librium point

0

0

(a,M); ( 10,2), ( 1 0,3), and ( 10,4) are

given respectively as

at fixed Mach number 2:

KK2

=

[-5.7 137e+00, -4.56 13e-0 1 , -4.0079e-0 1 , - 1 . 1 296e-031

Ki2

=

6.3689e+O1

KL2'= [-7.7941 e+02, -7.6420e+04, 2.0806e+03, -2.5828e+051

at fixed Mach number 3:

KK3

=

Ki3

=

[-2.2529e+00, - 1.7727e-0 1 , -4.0539e-0 1 , - 1 . 1 405e-031

1.4099e+01

KL3'= [-4.0547e+02, -3.9609e+04, 9.19 1 8e+02, - 1.1657e+05]

at fixed Mach Number 4:

KK4 = [ - 1.3009e+00, -9.5867e-02, -4.0555e-0 1 , - 1 . 1 457e-031

K i 4 = 5.0734e+00

where

KK2=the gain K design a t f i x e d Mach number 2

K i 2 = t h e gain K i design a t f i x e d Mach number 2

KL2=the gain L design a t f i x e d Mach number 2

and KK3, K i 3 , KL3, KK4, K i 4 and KL4 are defined i n the same but a t

the f i x e d Mach number 3 and 4 r e s p e c t i v e l y .

The s t e p response of the closed-loop l i n e a r s y s t e m a t t h r e e

c o n s t a n t o p e r a t i n g p o i n t s a r e p i c t u r e d i n FIGURE4.3-2, w h i c h

i l l u s t r a t e s t h a t t h e o u t p u t t r a c k s t h e s t e p command w i t h t i m e

c o n s t a n t s l e s s than 0 . 2 5 sec. FIGURE 4 . 3 - 3 describes t h e frequency

response of t h e open-lcop system a t those e q u i l i b r i u m points; w i t h a

frequency of 3 0 0 rad/sec, a l l t h e magnitude are l e s s than -30 dB.

B o t h graphs d e m o n s t r a t e t h a t the p r e v i o u s l y s p e c i f i e d eigenvalues

y i e l d gains K, K i and L w h i c h achieve t h e design o b j e c t i v e s .

0

FIGURE 4.3-2 Step Response of closed-loop system at M=2, 3 , and 4 ,alfa= 10

Frequency (radlsec)

0

FIGURE 4.3-3 Frequency Response of open loop system at M=2, 3, and 4 ,alfa= 1 0

51

As p r e v i o u s l y noted, a c o n t r o l l e r a t a f i x e d Mach number m u s t

s a t i s f y t h e design o b j e c t i v e s over t h e range o f an angle of a t t a c k

between

6 to

200 Thus PROGRAM "3 i s c r e a t e d i n o r d e r t o check

t h e s t a b i l i t y o f the s y s t e m as t h e angle o f a t t a c k v a r i e s .

This

program uses t h e c o n s t a n t gain K, K i and L found e a r l i e r a t each

f i x e d constant operating points.

The same p l a n t c o e f f i c i e n t s

m a t r i c e s a t those p o i n t s are use t o be t h e c o e f f i c i e n t s m a t r i c e s of

the s t a t e observer i n the considered system.

For convenience i n representing the design s t e p and output, the

a u t h o r n o w w i l l f i r s t consider t h e c o n t r o l l e r design s t e p a t t h e

f i x e d Mach number 2.

The f i x e d Mach number 3 and 4 w i l l be

addressed l a t e r .

The s i m u l a t i o n a r e a p p l i e d t o t h e c o n t r o l l e r w h i c h a r e

designed i n PROGRAMs3 t o check t h e s t a b i l i t y of t h e s y s t e m as the

angle of a t t a c k vary b e t w e e n

to

26

We s i m u l a t e d PROGRAMz3

w i t h a l l t h e angle of a t t a c k i n t h e range of i n t e r e s t .

Around t h e

0

c o n s t a n t o p e r a t i n g design p o i n t (a,M)

=

(10,2), t h e c o n t r o l l e r can

s a t i s f y a l l the design o b j e c t i v e s , but when t h e angles of a t t a c k are

changed, t h e c o n t r o l l e r performance i s degraded.

I t means t h a t the

c o n t r o l l e r i s able t o s t a b i l i z e t h e s y s t e m o n l y a t t h e v a l u e s o f

0

a t t a c k w h i c h do not d i f f e r much f r o m the design p o i n t , a = l o . When

t h e angle o f a t t a c k changes s i g n i f i c a n t l y , t h e c o n t r o l l e r cannot

52

stabilize the system.

A t t e m p t s t o s e l e c t d i f f e r e n t design p o i n t s

corresponding t o d i f f e r e n t angle o f a t t a c k y i e l d comparable r e s u l t s .

The l i n e a r s i m u l a t i o n s a t d i f f e r e n t angle o f a t t a c k a r e s h o w n

i n FIGURE 4 . 3 - 4 and FIGURE 4 . 3 - 5 .

FIGURE 4 . 3 - 4 s h o w s t h e s t e p

responses o f the closed-loop s y s t e m a t the c o n s t a n t Mach number 2

0

0

0

and t h e angle o f a t t a c k 0, 10, and 2 0 . The frequency responses o f

t h e open-loop s y s t e m a t t h e same design p o i n t s v a l u e s a r e displayed

i n FIGURE 4.3-5. The p r o b l e m o f t h e c o n t r o l l e r w h i c h m e n t i o n e d a r e

c l e a r l y s h o w n f r o m these graphs

Now consider the design step a t t h e f i x e d Mach number 3 and 4.

We a l s o s i m u l a t e the s y s t e m a t these f i x e d Mach number w i t h a l l the

0

0

angle o f a t t a c k f r o m 0 t o 20. The p r o b l e m encountered a t t h e f i x e d

Mach numbers 3 and 4 r e s e m b l e as s h o w n t h a t f a c e d a t f i x e d Mach

number 2.

With

s i g n i f i c a n t changes o f t h e angle o f a t t a c k , t h e

c o n t r o l l e r performance i s degraded. FIGURE 4 . 3 - 6 - FIGURE 4 . 3 - 9 are

m a n i p u l a t e d as t h e same a s FIGURE 4.3-4, and FIGURE 4.3-5. FIGURE

4 . 3 - 6 , and FIGURE 4.3-8 s h o w s t e p r e s p o n s e o f t h e c l o s e d - l o o p

s y s t e m a t f i x e d Mach number 3 and 4 r e s p e c t i v e l y .

0

0

I n t h e s e graph

0

t h e d i s t i n c t angle o f a t t a c k a t 0, 10 and 20 a r e chosen. FIGURE 4.3-

7, and FIGURE 4 . 3 - 9 i l l u s t r a t e t h e open-loop's f r e q u e n c y responses

a t t h e same angle o f a t t a c k values f o r f i x e d Mach number 3 and 4.

L

......... :a d o

-: a-10'

1.5 -

--

++++ : a -20'

-

1-

a

*+*

n.

a

0

-

-

-0.5

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

time(sec)

FIGURE 4.3-4 Step Response of closed-loop system at M=2.

Frequency (radlsec)

FIGURE 4.3-5 Frequency Response of open loop system at M=2.

0.5

time(sec)

FIGURE 4.3-6 Step Response of closed-loop system at M=3.

Frequency (radiscc)

FIGURE 4.3-7 Frequency Response of open loop system a t N=3.

time(sec)

FIGURE 4.3-8 Step Response of closed-loop system at M=4.

Frequency (radlsec)

FIGURE 4.3-9 Frequency Response of open loop system a t W-4.

56

We redesign the c o n t r o l l e r again as c a l c u l a t e i n PROGRAM # 4 .

Once again, f i r s t consider the design s t e p a t the f i x e d Mach number 2

and then a t the f i x e d Mach numbers 3 and 4.

In t h e new design, use t h e same gain K, K i , and L b u t l e t the

l i n e a r i z e d p l a n t c o e f f i c i e n t m a t r i c e s used i n the s t a t e observer v a r y

w i t h angle o f a t t a c k as i n d i c a t e d i n S e c t i o n 4.2. By l e t t i n g t h e

c o e f f i c i e n t m a t r i c e s of t h e observer depend on angle o f a t t a c k , step

response and frequency response o f t h e 1 i n e a r i z e d m i s s i l e model

w i t h type- 1 servo s y s t e m a t f i x e d Mach number 2 m e e t t h e design

0

0

o b j e c t i v e s a t a l l angle o f a t t a c k b e t w e e n 0 t o 20. Three d i f f e r e n t

angle of a t t a c k

6 ;1

0

and 2 0 are chosen t o v e r i f y these r e s u l t s as

shown i n FIGURE 4.3- 10 and FIGURE 4.3- 1 1 .

Next, consider the c o n t r o l l e r design a t the f i x e d Mach numbers

3 and 4 by u s i n g the same c o n s i d e r a t i o n b u t changing t h e gains (K,

K i , and L).

The s i m u l a t i o n r e s u l t s are also the same as w e discuss

i n design a t f i x e d Mach number 2 f o r a l l the angle o f a t t a c k b e t w e e n

0

0

0 t o 20. The closed-loop s t e p responses and open-loop frequency

responses are shown i n FIGURE 4.3- 12 and FIGURE 4.3-1 3 f o r f i x e d

Mach number 3 and i n FIGURE 4 . 3 - 1 4 and FIGURE 4 . 3 - 1 5 f o r f i x e d

Mach number 4 , r e s p e c t i v e l y .

The s i m u l a t i o n response a t t h r e e

d i f f e r e n t angles o f a t t a c k are shown in these graphs.

Thus w e can conclude t h a t t h e l i n e a r c o n t r o l l e r w h i c h i s

57

designed by t h e chosen eigenvalues g i v e n e a r l i e r and l e t t i n g t h e

c o e f f i c i e n t s m a t r i c e s of t h e observer p a r t of t h e c o n t r o l l e r depend

on angle o f a t t a c k as w e l l as Mach number, t h e l i n e a r i z e d closedloop s y s t e m f o r f i x e d Mach number (M=2,3,4) and a l l angle of a t t a c k

i s s t a b l e and m e e t s the design s p e c i f i c a t i o n s .

time(sec)

FIGURE 4.3- 10 Step Response of closed-loop system at M=2.

tirne(sec)

FIGURE 4.3- 1 2 Step Response of closed-loop system at M=3.

Frequency (radlsec)

FIGURE 4.3- 13 Frequency Response of open loop system at M=3.

FIGURE 4.3- 1 5 Frequency Response of open loop system at M=4.

4.4 Schedulina the Set of Linear Controllers

Gain scheduling i s broken i n t o t w o s t e p s .

The f i r s t s t e p

involves designing a local c o n t r o l l e r based on 1 i n e a r i z a t i o n of the

nonlinear p l a n t a t several d i f f e r e n t e q u i l i b r i u m p o i n t s . T h i s w a s

accomplished i n t h e p r e v i o u s s e c t i o n .

The l o c a l c o n t r o l l e r w a s

0

0

designed a t three d i f f e r e n t equi l i b r i u m p o i n t s ( ( a,M)=( 10,2), ( 10,3),

0

1

0

4 Each e q u i l i b r i u m point gives a s p e c i f i e d gain w h i c h makes

the c o n t r o l l e r capable of s a t i s f y i n g the system requirements l o c a l l y

around each design point.

The second step, t o be discussed i n t h i s chapter, r e q u i r e s

i n t e r p o l a t i n g , or "schedul ing", the qains of t h e l i n e a r designs t o

o b t a i n a nonlinear c o n t r o l l e r . The three s p e c i f i e d gains f r o m t h e

local c o n t r o l l e r are r e w r i t t e n as f o l l o w s :

A t f i x e d Mach number 2:

A t f i x e d Mach number 3 :

KK3

=

[-2.2529e+00, - 1.7727e-0 1 , -4.0539e-0 1 , - 1.1 405e-031

Ki3

=

1.4099e+O1

At fixed Mach Number 4:

KK4

=

[ - 1.3009e+00, -9.5867e-02, -4.0555e-0 1, - 1 . 1 457e-031

Ki4

=

5.0734e+00

KL4'= [-2.7506e+02, -2.68 1 3e+04, 5.1287e=02, -6.6569e+041

It i s known from the linear controller analysis that the gains

at each fixed Mach number can stabilize the linearized plant at the

f i x e d number and over the entire range of the angle of attack

0

0

between 0 to 20. In considering this problem, an attempt i s made to

schedule a l l these gains when the Mach nurriber i s different from the

fixed point. This means that the gain i s defined when the value of

the Mach number l i e s between the Mach numbers

2 and 3

or the

Mach numbers 3 and 4, or outside the range 2 5 M i 4.

F o r the gain scheduling method, K i i s considered f i r s t . At the

fixed Mach numbers 2, 3 and 4, the values of the gain K i are known.

To f a c i l i t a t e an understanding of the discussion that follows, these

3 values a r e shown in the FIGURE 4.4- 1 .

From t h i s figure, one can see that a t each fixed Mach number

2, 3, and 4, the gain K i i s set a t the known values. Thus, when the

Mach number i n the considered system l i e s a t one of these fixed

63

points, the appropriate gain K i w i l l be used i n the controller.

2

3

4

Mach number

FIGURE 4.4- 1 Scheduling the gain Ki

Now consider the points between the f i x e d Mach numbers 2

and 3 and draw a l i n e between these t w o points. An equation can

then be created f o r t h i s line. The same can be done between the

fixed Mach numbers 3 and 4.

Recall now, the equation of the l i n e j o i n i n g between t w o

poi n t s P(xi,y1) and P(x2,yz):

Using t h i s t w o equations, one can obtain the gain K i as a

function of Mach number, w r i t t e n Ki(M). Therefore, when the Mach

number i s given between either the t w o fixed points 2 and 3 or the

t w o fixed points 3 and 4, one can find the gain K i

64

related t o the

corresponding Mach number.

One can schedule the gains

K and the gain

L, i n the same

manner t o obtain K(M) and L(M).

Gain "scheduling" i s the most important component of

the

nonlinear controller design and w i 1 1 be u t i l i z e d f o r the remainder of

t h i s thesis. The M - f i l e from MATLAB i s w r i t t e n t o calculate this.

The M-fi le i s named "schedu1ing.m" and i s described i n PROGRAM

#5.

Using PROGRAM l f 5 the gain scheduling i s created f o r the

nonl inear controller.

With the gain scheduling, i t i s expected that

our nonlinear controller w i 11 stabilize the nonlinear plant over the

e n t i r e operating range.

I n order t o c o n f i r m t h i s expectation, the

local s t a b i l i t y around any equilibrium point i n the desired range w i l l

be examined f i r s t and then the overall performance of the nonlinear

system w i t h the designed controller w i l l be examined by means of

simulation using SIMULAB.

- Checking the local stability of the linearized system.

For the discussion of local s t a b i l i t y , consider the nonlinear

control ler, the "Autopilot ". First, connect the autopilot t o the plant

65

and close t h i s loop. The block diagram i s i l l u s t r a t e d i n FIGURE 4.4-

-

nz

nc

Autopilot

) missile/actuator

.

FIGURE 4.4- 2 Block diagram of the missile model w i t h nonlinear controller

The closed-loop dynamic system i s given as

where

t=n,-nz

6, = -K(M)Z + Ki(M)t

where

fandgarethenonlinearfunctionofthemissilemodel

66

A t the constant operating point

fc,

(x,:,f,h,~)

=

o which implies that

Thus, a t any closed-loop constant o p e r a t i n g p o i n t , w e have

?(a,M)

so t h a t

= x(a,M)

Sz(a,M) = nz(a,M)

f(a,M) = &[Wa,M)

- K(M)x(a,M)I .

Next, 1 i n e a r i z a t i o n o f the nonlinear closed-loop s y s t e m around

t h i s set o f constant operating points yields a set o f linearized

s y s t e m s w h o s e p r o p e r t i e s w i 11 be analyzed. The J a c o b i a n m a t r i c e s

f o r t h i s l i n e a r i z a t i o n method are given a s f o l l o w s .

F r o m t h e closed-loop s y s t e m :

Define

G = %a3+bna2+cn(2-$M)a,

G,= 3 % a 2 + 2 b a + c , (2-$M)

The Jacobian m a t r i c e s t h a t describe t h e l i n e a r i z a t i o n of the

n o n l i n e a r c l o s e d - l o o p s y s t e m i n FIGURE 4.4-2 a r e c r e a t e d i n

PROGRAMlt6,

Included i n t h i s p r o g r a m i s t h e s i m u l a t e d s t e p

response of t h e linearized closed-loop s y s t e m i n order t o check t h e

local s t a b i l i t y of the system. For t h e l o c a l s t a b i l i t y , t h e l i n e a r i z e d

s y s t e m s w h i c h are s i m u l a t e d a t any c o n s t a n t o p e r a t i n g p o i n t s

should provide stable response i n the e n t i r e range o f i n t e r e s t .

A s f i r s t m e n t i o n f o r t h e l o c a l s t a b i l i t y check, m o r e t h a n

hundred p o i n t s o f the f i x e d Mach number and t h e angle o f a t t a c k i n

68

the interested range are simulated and checked. Each step response

f r o m those simulations show the a b i l i t y to track the step command

w h i c h indicated the local s t a b i l i t y of the linearized system. Also,

these step responses s a t i s f y the design objectives of t i m e constant

less than 0 . 2 5 second.

To v e r i f y the conclusion, the simulation a t the angle of attack

00 and

0

2 0 w i t h the f i x e d Mach number 2.3, 2.3, 3.3, and 3.7 are

examined.

The step response which provided the s t a b i l i t y of the

l i n e a r i z e d s y s t e m w i t h t i m e c o n s t a n t l y than 0 . 2 5 second are

i l l u s t r a t e d i n FIGURE 4.4-3 and FIGURE 4.4-5. The frequency

response of the open-loop system w h i c h less than - 3 0 dB a t 3 0 0

radian/second are shown i n FIGURE 4.4-4 and FIGURE 4.4-6.

time(sec)

0

FIGURE 4.4-3 Step Response of the linearized system at alfa=O.

Frequency (radlsec)

0

FIGURE 4.4-4 Frequency Response of open loop linearized system at alfa=O.

FIGURE 4.4-5 Step Response of the linearized system at alfa.26

Frequency (rad/sec)

0

FIGURE 4.4- 6 Frequency Response of open loop linearized system a t alfa=20.

71

- Checking Performance of the Nonlinear Controller

Previously, a nonlinear a u t o p i l o t i s created by scheduling the

gains of the 1 inear c o n t r o l l e r s designed a t 3 d i f f e r e n t e q u i l i b r i u m

points. A t the conclusion o f t h a t chapter, local s t a b i l i t y around any

e q u i l i b r i u m p o i n t o f t h e s y s t e m w a s checked.

The r e s u l t s

demonstrated t h a t the autopi l o t can s t a b i l i z e t h e nonl inear system

l o c a l l y around any operating point i n the desired range.

Since w e r e q u i r e t h a t t h e a u t o p i l o t s t a b i l i z e t h e s y s t e m

throughout the e n t i r e operating range, a program f o r s i m u l a t i n g

nonlinear dynamic systems, SIMULAB, w i 1 1 be employed i n order t o

verify this stability.

For s i m u l a t i o n purpose, t h e a u t o p i l o t i s connected t o t h e

m i s s i l e as shown i n FIGURE 4 . 4 - 7 . The v a r i a b l e s i n t h i s b l o c k

diagram t h a t are fedback are the actual v e r t i c a l a c c e l e r a t i o n ( e t a )

and the Mach number (M). Note; the Mach number generated in t h i s

program i s not p r o p e r l y p a r t o f t h e p l a n t b u t i t i s included f o r

s i m u l a t i o n purposes. PROGRAMZ7 and *8 contain t h e M-f i l e s o f t h e

s - f u n c t i o n s i l l u s t r a t e i n FIGURE 4.4-7.

" A u t o p i 1ot.m" i s an M - f i l e

w h i c h describes the autopi l o t , the designed c o n t r o l l e r . " M i s s i l e . m n

also, i s an M - f i l e w h i c h i s used t o describe the m i s s i l e and a c t u a t o r

dynamics.

73

To obtain the response of t h i s system over the e n t i r e range of

the Mach number 2 and 4, the Mach number are consider as 4 range;

4.0-3.5, 3.5-3.0, 3.0-2.5, and 2.5-2.0. The simulations are designed

t o s i m u l a t e each of these range. The f i r s t s i m u l a t i o n output are

shown i n FIGURE 4.4-8. The graph shows the response of the system

compared to the step command.

system

I t show that the response of the

can track the step command w i t h t i m e constant less than

0.25 second which i s the requirement of the design objectives. Also,

i n FIGURE 4.4-8 , the Mach number p r o f i l e ( s t a r t i n g a t Mach number

=

4)i s shown.

I n FIGURE 4 . 4 - 9 - FIGURE 4.4-1 1 i l l u s t r a t e the s i m u l a t i o n

output as the same as i n FIGURE 4 4 - 8 . The difference i n these graph

i s the range of the Mach number. From these graphs, one obviously

sees t h a t no m a t t e r what the range of the Mach number are

considered, the system i s able to track the step command w i t h t i m e

constant less than 0.25 second. Thus , w i t h these data, i t i s clearly

show t h a t the dynamic c o n t r o l l e r y i e l d s stable and well-behaved

response which s a t i s f i e s the design objectives.

40

.----step command

-

acceleration

i

-

..

I

-

,

I

-

-

-10-

-20

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

time(sec)

FIGURE 4.4-8 Step Response of the missile model starting at M=4.

time(sec)

Mach number for simulation i n FIGURE 4.4-8,

- - - - - - step command

-

-

acceleration

-

-

-

-10 -

-20.

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

FIGURE 4.4-9 Step Response of the missile model starting at M=3.5

time(sec)

Mach number for simulation i n FIGURE 4.4-9.

time(sec)

FIGURE 4.4- 10 Step Response of the missile model starting at M=3.

time(scc)

Mach number for simulation i n FIGURE 4.4- 10.

time(sec)

FIGURE 4.4- 1 1 Step Response of the missile model starting at M=2.5.

time(sec)

Mach number for simulation in FIGURE 4.4- 1 1 .

Chapter 5

Summary and Conclusions

In t h i s thesis, w e study the design o f an a u t o p i l o t by applying

gain schedul ing, new c o n t r o l l e r design technique, t o the example of

nonlinear system.

scheduling

As w e mentioned e a r l i e r , a l t h o u g h t h e gain

i s a successful

technique

i n many e n g i n e e r i n g

application, i t has a r e s t r i c t i o n on the exogenous variable w h i c h had

t o vary slowly.

I n the example problem o r m i s s i l e f i g h t c o n t r o l

p r o b l e m , t h e Mach number i s considered t o be t h i s exogenous

var iable.

In Chapter 3, a l l tne matheniatics d e s c r i p t i o n of t h e m i s s i l e

problem together w i t h a s t a t e equation o f t h e Mach number w e r e

defined ( A s t a t e equation f o r the Mach number w a s n o t a proper p a r t

o f t h e m i s s i l e s y s t e m but t h i s equation w a s necessary i n t h e

s i m u l a t i o n p a r t f o r checking the performance o f t h e autopi lot.).

The d e t a i l s o f the design procedure w e r e discussed i n Chapter

4. F i r s t , the linear c o n t r o l l e r s were designed f r o m l i n e a r i z e d plant

data a t 3 d i f f e r e n t constant operating p o i n t s . Since the c o n t r o l l e r s

designed there used 1 inear t ime-invariant technique, our c o n t r o l l e r s

can guarantee only local performance and nominal s t a b i l i t y o f t h e

m i s s i l e . The open-loop frequency response of the 1 inearized system

79

s h o w s t h a t a t 300 radian/second the magnitude w a s l e s s than -30

dB. T h a t i s one o f t h e designed r e q u i r e m e n t s t h a t seeks t o a v o i d

e x c i t i n g t h e unmodel l e d s t r u c t u r a l dynamics.

L a s t , t h e gains o f

those c o n t r o l l e r are scheduled, and the a u t o p i l o t w i t h t h e scheduled

g a i n s w a s s i m u l a t e d t o check f o r t h e m i s s i l e p e r f o r m a n c e .

The

r e s u l t f r o m t h e s i m u l a t i o n show t h e a b i l i t y o f t h e a u t o p i l o t t o

0

0

s t a b i l i z e the s y s t e m w i t h i n the operating range (-20 5 a _ <

20 and 2 5

M 3 4 ). T h i s r e s u l t i s also s a t i s f i e s the design o b j e c t i v e s .

Since t h e m i s s i l e ' s performance m e t a l l design o b j e c t i v e s , i t

i s concluded t h a t t h e a u t o p i l o t , t h e c o n t r o l l e r , designed by u s i n g a

gain scheduling i s achieved.

References

[I].

Doebelin, E. O., " C o n t r o l S y s t e m P r i n c i p l e s a n d D e s i g n " . J o h n

W i l e y & Sons, Inc., 1 9 8 5 .

[ 2 ] . Dragoslav, D. S., " N o n l i n e a r S y s t e m s " . J o h n W i l e y & Sons, I n c . ,

1969.

[3].

K a i 1 a t h , T., " L i n e a r S y s t e m s " .

P r e n t i c e - H a l 1,

I n c . ,New

Jersey, 1 980.

[4]. K h a l i l , H. K.,and

K o k o t o v i c , P. V., "On S t a b i l i t y P r o p e r t i e s o f

N o n l i n e a r S y s t e m s w i t h S l o w l y V a r y i n g I n p u t s " , l EEE T r a n s a c t i o n s

on A u t o m a t i c Control, v o l . 36, no. 2, pp. 2 2 9 , 1 9 9 1 .

151. L a w r e n c e , D. A,, and Rugh, W. J., "On a S t a b i l i t y T h e o r e m f o r

Nonl i n e a r S y s t e m s w i t h S l o w l y V a r y i n g I n p u t s " . l EEE T r a n s a c t i o n s

on A u t o m a t i c C o n t r o l , v o l 35, no, 7, pp. 8 6 0 - 8 6 4 , 1 9 9 0 .

[61. Ogata, K., "Modern C o n t r o l Engineering ". P r e n t i ce-Hall, I nc. ,New

Jersey, 1990.

t

171. P h i l l i p s , C. L., and Harbor, R. D., "Feedback C o n t r o l S y s t e m s "

P r e n t i ce-Hal 1, Inc. ,New J e r s e y , 1 9 8 8 .

[81. P h i l l i p s , C. L.,and Nagle, H. T., " D i g i t a l C o n t r o l S y s t e m A n a l y s i s

and D e s i g n ". P r e n t i ce-Hall, I nc. ,New J e r s e y , 1 9 9 0 .

81

[9]. R e i c h e r t , R., T., " D y n a m i c S c h e d u l i n g o f Modern-Robust-Control

A u t o p i l o t Designs f o r M i s s i l e

".

IEEE C o n t r o l S y s t e m Magazine,

october, pp.35-42, 1992.

[ 101. Reichert,R. T., " G a i n S c h e d u l i n g f o r H - l n f i n i t y C o n t r o l l e r s : A

Flight Control Example". Technical

Report,The John Hopkins

U n i v e r s i t y , ECE, 9 2 - 9 3 .

[1

11. Rugh,

W. J., " A n a l y t i c a l F r a m e w o r k f o r Gain S c h e d u l i n g " , IEEE

c o n t r o l S y s t e m s Magazine, v o l . 1 1 , no. 1 , pp. 7 9 - 8 4 , 1 9 9 1 .

[12].

Shamma, J. S.,and A t h a n s , M., " A n a l y s i s o f Gain S c h e d u l e d

Control f o r Nonlinear Plants

" ,

l EEE T r a n s a c t i o n s on A u t o m a t i c

C o n t r o l , v o l . 35, no. 8, pp. 8 9 8 - 9 0 7 , 1 9 9 0 .

[13].

Shamma, J. S.,and A t h a n s , M., " G a i n S c h e d u l i n g P o t e n t i a l

Hazards and P o s s i b l e Remedies " . l EEE c o n t r o l S y s t e m s Magazine, v o l .

12, no. 3, pp. 10 1 - 1 0 7 , 1 9 9 2 .

[ 141. S l o t i n e , J.-J., E., " A p p l i e d N o n l i n e a r C o n t r o l " . P r e n t i c e - H a l l ,

I n c . ,New J e r s e y , 1 9 9 1

[ 151.

V i dyasagar, M., "Nonl i n e a r S y s t e m A n a l y s i s ". P r e n t i c e - H a l l ,

I n c . , New J e r s e y , 1 9 7 8 .

% PROGRAM # 1

% Linearization of nonlinear system

m=input('The value of Mach number (m)=')

alfa=input('The value of the angle of attack (alfa) = ' )

%

%

Airframe and actuator constants

Kalfa=0.02069;

damp=0.7;

%

%

Kq=l. 23196;

Wa=150;

Kz121.4432;

Ax=32.1648;

Some constants that change from degree to radian

alfan= alfa*pi/l80;

Kalfan= 1.18587;

Kzn= 0.6661697;

Kqn=70.586;

% Aerodynamic coefficients

%

an=0.000103;

bn=-0.00945;

cn=-0.1696;

am-0.000215;

bm=-0.0195;

cm=0.051;

Cn=an*alfaA3+bn*alfaA2+cnf(2-m/3)*alfa;

~m=am+alfa~3+bm*alfa^2+cm*(8*m/3-7)*alfa;

%

%

dn=-0.034;

dm=-0.206;

Differential values

cnd=3*an*alfaA2+2*bn*alfa+cnt(2-m/3);

~md=3*am*alfa~2+2*bm+alfa+cmt(8fm/3-7);

delta=-cm/dm;

.

%

Jacobian matrices

8

all=~alfan*m*(Cnd*cos(alfan)-(Cn+dnfdelta)*sin(alfan)*pi/l80);

a12=1;

al3=Kalfan*m*dn*cos(alfan);

a14=0;

a21=Kqn*mA2*Cmd;

a22=O;

a23=Kqn*mA2*dm;

a24=0;

a31=0;

a32=0;

a33=0;

a34=1;

a4 1-0;

a42=O;

a4 3=-WaA2;

a44=-2 *damp*Wa;

%

%

The the linearized system

aa=[all,al2,a13,a14;a21,aZZ,a22Ia23,a24;a31la32,a33la34;a4lla42la43la44]

bb=[bll;b21;b31;b41]

cc=[cll,c12,~13,~14]

% PROGRAM # 2

% ~inearizationof

A2

nonlinear system

m=input ('The value of Mach number (m) = ' )

alfa=input('The value of the angle of attack (alfa) = ' I

%

% Airframe and actuator constant

Kalfa=0.02069;

damp=O.7;

%

%

Kq=1.23196;

Wa=150;

Kz=21.4432;

Ax=32.1648;

Some constant that change from degree to radian

alfan= alfa*pi/l80;

Kalfan= 1.18587;

%

%

Aerodynamic coefficients

%

%

Some differential value

%

%

Jacobian matrix

Kzn= 0.6661697;

Kqn=70.586;

ades=[all,al2,al3,al4;a21,a22,a23,a24;a3l,a32,a33,a34;a4l,a42,a43,a44];

bdes=[bll;b21;b31;b41];

cdes=[cll,cl2,cl3,cl4];

% sk=pole locatin

%

%

%

%

%

Controller design step

Finding the gain K for poles placement

sk=the desired eigenvalues

q=[0;0;0;01;

sk=[-36.3,-36.96+0.66*i,-36.96-0.66*i,-37.62+1.32*i,-37.62-1.32*il;

abar=[ades,q;-cdes,OI;