DIV 17 - Instrumentation - the Stellar J Corporation

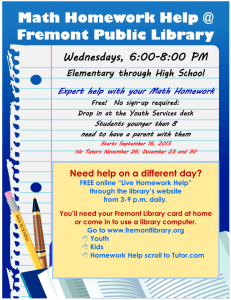

advertisement