Metals shortages and their impacts on the long term feasibility of

advertisement

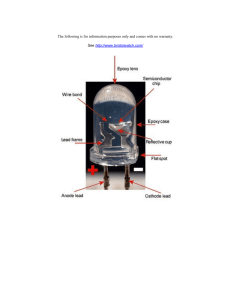

Metals Shortages and Their Impacts on the Long Term Feasibility of LED Supply Version 1 1 Introduction Most lighting policy measures have been concerned with encouraging the uptake of energy efficient lamps. Future improvements in the luminous efficacy1 of electric lamps are based around the widespread availability and use of light-emitting diodes (LEDs). However, raw material availability is a potential concern. LEDs contain rare elements such as gallium and indium. Any future shortages of these elements might limit the number of LEDs that can be produced, or at least increase their cost and reduce uptake. This is an important issue because MTP models and strategies are based on the premise that LED usage will grow substantially. This Briefing Note reviews current LED composition and identifies long term trends in prices and availability of LED materials, such as gallium and indium. Using data from the MTP models, future demand for LEDs and these materials is identified. This Report outlines the future feasibility of long term large scale LED production, and presents the results of long term modelling to assess the impact on LED market of raw material shortages. The feasibility of recycling gallium and indium from LEDs is also discussed. 2 LED composition LEDs are diodes which emit light in a range of colours when an electric current is passed through them in one direction. This phenomenon is called electroluminescence. Early LEDs were made from gallium arsenide and emitted invisible infrared radiation. The first commercial red LEDs made from gallium arsenide phosphide appeared in the late 1960s, green LEDs made from gallium phosphide appeared in the 1970s, but blue LEDs made from gallium nitride appeared only in the 1990s owing to the technological hurdles that first had to be overcome. Currently LEDs are made from a variety of semiconductor materials that combine the elements gallium, aluminium and indium with arsenic, phosphorus and nitrogen. Table 1 below shows some examples of semiconductor materials used in the 1 The luminous efficacy of a lamp is the ratio of the quantity of light emitted by the lamp divided by the power consumed by the lamp and ballast. Version: 1 First created: 30/03/11 Updated: 11/04/11 Last reviewed: 11/04/11 1 of 9 Cosmin Ticleanu and Paul Littlefair BRE manufacture of LEDs. Silicon carbide and sapphire can be used as substrates2 for blue LEDs to improve their efficiency. Table 1 Examples of semiconductor materials used in the manufacture of LEDs Semiconductor material Aluminium gallium arsenide Aluminium indium gallium phosphide Gallium arsenide phosphide Indium gallium nitride Gallium nitride Abbreviation AlGaAs AlInGaP GaAsP InGaN GaN LED light colour Red Red, Orange, Yellow Red, Orange, Yellow Green, Blue Green, Blue White light LEDs can be made by combining red, green and blue LED chips3 or by coating a blue or green LED chip with a phosphor to convert UV rays emitted by the chip into visible light. Cerium-doped4 yttrium aluminium garnet is often used as the phosphor coating for white LEDs, but terbium and gadolinium can also be used as a substitute for cerium. White LEDs can also be made by coating near ultraviolet emitting LEDs with a mixture of high efficiency europium based red and blue emitting phosphors plus green emitting copper and aluminium-doped zinc sulphide. Other components enclosed in the LED device 5 contain additional metals such as gold, silver, iron, copper, nickel and lead. Gold has low electrical and thermal resistivity and assists the thermal management of LEDs, while silver is valuable as a reflective coating and metallic finishing. Therefore, gold is used in the conductive metallic wires to connect the electrodes to the LED chip and in the finishing on the heat sink, stud bumps and solder layer, while a silver coating is used to increase efficiency of light reflection from LEDs or as the coating and finishing on the heat sink, or in adhesives and glue. As part of a recent study (Seong et al, 2011) on potential environmental impacts of LEDs, the average metallic content of LEDs of various colours and low (50 to 400mcd6) and high (900 to 10,000 mcd) luminous intensities was determined and the results can be found in Figure 1. The average weight of an LED chip analysed in this study was 300mg. 2 A substrate is a thin slice of material serving as the foundation upon which the LED chip is deposited. 3 An LED chip is the slice of semiconducting material doped with impurities to create the p-n junction where energy in the form of photons is emitted by electrons falling into lower energy levels after meeting holes. 4 Cerium-doping is the introduction of cerium impurities into the pure semiconductor in order to modulate its electrical properties. 5 An LED device is the entire light-emitting diode which converts electrical energy into light. 6 1 mcd (millicandela) is 1/1000 of 1 candela, the SI measuring unit of the luminous intensity Version: 1 First created: 30/03/11 Updated: 11/04/11 Last reviewed: 11/04/11 2 of 9 Cosmin Ticleanu and Paul Littlefair BRE Figure 1 Average metallic content (mg) of the analysed LEDs Average metallic content (mg) 1000 98.355 100 10 0.7819 0.6304 1 0.2796 0.1218 0.1 0.0351 0.0153 0.021 0.0079 0.01 0.001 0.0209 0.0003 Silver Nickel Phosphorus Metals present in LEDs Lead Iron Indium Gold Gallium Copper Arsenic Aluminium 0.0001 The results confirmed that the LEDs analysed contained high levels of iron, nickel and copper. The lead content of the low-intensity red LED was also high. However, because elements like iron, copper, nickel and lead are commonly used in many types of industry and products, and they are widely available, this Briefing Note refers mainly to specific elements used in the manufacture of LEDs, such as gold, silver, gallium and indium. Little research has been undertaken so far in order to determine the metallic contents of LEDs, and information provided by LED manufacturers does not include the quantities of different metals in their products. For this reason, the values determined by the study mentioned above (Seong et al, 2011) were used as reference values for the following analysis. This study does not include any data relevant to the content of phosphors of white LEDs, and given the lack of relevant information the amount of yttrium was estimated from data about Philips Lumileds LumiramicTM phosphor technology (Schnick, 2009). 3 Costs and availability of LED metals Due to the growth of semiconductor production following a rapidly increasing market for electronic devices and a growing range of applications, availability of materials and associated price increases have become a source of concern in the last decade. Approximately 95% of the world’s supply of gallium is used for the production of compound semiconductors (Davis, 2001), while indium is being consumed in unprecedented quantities for making flat-panel displays. Both gallium and indium are also used to manufacture solar cells and high-efficiency LED lighting products. Version: 1 First created: 30/03/11 Updated: 11/04/11 Last reviewed: 11/04/11 3 of 9 Cosmin Ticleanu and Paul Littlefair BRE Raw material availability is a potential concern. Most LEDs are based around gallium and indium compounds, and both gallium and indium are rare elements. This is likely to limit the number of LEDs that can be produced. A study by Kleijn at the University of Leiden has highlighted the shortage of gallium and indium, and concludes that it is likely not to contribute to more than 1% of solar cells for this reason (Cohen, 2007). LEDs use less gallium and indium than solar cells, but it is likely that in the medium term alternative materials will have to be identified. Another study by Reller at the University of Augsburg has also concluded that world supplies of indium could run out by 2017 (Cohen, 2007). The European Commission has published a list of 14 critical raw materials at EU level, which display a particularly high risk of supply shortage in the next 10 years (EC, 2011). Gallium and indium are on this list, as they are essential in the production of various electronic devices, and the EU is completely dependent on imports, with China accounting for 97% of world production in 2009. No recycling or substitution processes for gallium and indium are currently commercially viable. Gold and silver are not currently listed as critical materials. Another article also draws attention on metal shortages and the role of recycling (Rhodes, 2008). It includes gold, indium and silver amongst metals under threat and estimates the world total reserve and the expected time of exhaustion based on current rates of production and their principal uses, as shown in Table 2 below. Furthermore, it is predicted that the growth in world population, along with the emergence of new technologies will result in some key metals being used up rapidly: indium in 5 to 10 years, and silver in 15 to 20 years (Rhodes, 2008). Table 2 Estimates of world reserve and depletion time for critical metals Metal World reserve Estimated depletion time Gold 89,700 tonnes 45 years Silver 569,000 tonnes 29 years Indium 6,000 tonnes 13 years The main sources for gallium are from the aluminium ore bauxite, and from zinc ores. The US Geological Survey estimates the gallium content of world deposits to be more than a billion kilograms (USGS, 2002-2011). These estimates assume a gallium concentration of 50 parts per million. The main source for indium is a zinc sulphide ore, where indium concentration varies from 1 part per million to 100 parts per million. Because gallium and indium can only be accessed if the deposits are economic, it is estimated that only a small proportion of the gallium and indium in these ores is economically recoverable. However, in his study Reller also estimates that zinc could be used up by 2037 (Cohen, 2007), while Cohen (2007) states that zinc could be exhausted in 20-30 years if predicted new technologies appear and the population grows. Based on the data provided by the US Geological Survey for world resources and production of the metals and rare earths discussed above, estimates of the depletion periods for these elements have been derived. Although the available data may not entirely reflect the current global situation, it is clear that some elements present an increased potential of depletion in the coming decades. The most critical elements appear to be indium and yttrium, which could be depleted by 2018 and 2022, respectively. Version: 1 First created: 30/03/11 Updated: 11/04/11 Last reviewed: 11/04/11 4 of 9 Cosmin Ticleanu and Paul Littlefair BRE Due to high demand for the materials that are used for LED production, pressure has been put on raw material prices and the imminent depletion of raw material could already be seen in these prices. The high costs of these materials are mainly caused by the rarity of the source metals, but metal prices have varied significantly in the past years. The price of several metals like gallium and indium fell dramatically following the 2008 economic crash, but improving economic conditions subsequently increased prices. The price of other metals like gold and silver has increased gradually in the past years. shows the price of gold, silver, gallium, indium and yttrium in past years (USGS, 2002-2011), along with the price evolution of the average LED metal contents. Table 3 Table 3 Prices of raw metals and of average LED metal contents Year Gold Raw metal ($/ounce) LED content (¢/LED) Silver Raw metal ($/ounce) LED content (¢/LED) Gallium Raw metal ($/kg) LED content (¢/LED) Indium Raw metal ($/kg) LED content (¢/LED) 2002 2003 2004 2005 2006 2007 2008 2009 2010 311 365 411 440 606 699 874 975 1200 0.0230 0.0270 0.0304 0.0326 0.0449 0.0518 0.0647 0.0722 0.0889 4.62 4.91 6.69 7.15 11.61 13.43 15.02 14.69 17.75 0.0020 0.0021 0.0029 0.0031 0.0050 0.0058 0.0065 0.0063 0.0076 530 411 494 512 443 530 579 449 670 0.0008 0.0006 0.0008 0.0008 0.0007 0.0008 0.0009 0.0007 0.0010 97 170 643 810 918 795 685 500 565 2.9E-06 5.1E-06 1.9E-05 2.4E-05 2.8E-05 2.4E-05 2.1E-05 1.5E-05 1.7E05 Version: 1 First created: 30/03/11 Updated: 11/04/11 Last reviewed: 11/04/11 5 of 9 Cosmin Ticleanu and Paul Littlefair BRE As can be seen from Table 3 above, the price of each metal contained in one LED chip is very low and although it is estimated that it will grow gradually, it will continue to have a low value. Following the same average price increase, analysis shows that by the year 2030 it is expected that one LED chip will contain gold in value of 1.7p0, silver in value of 0.15p, gallium in value of 0.02p, indium in value of 0.01p and yttrium in value of 0.01p. Based on this estimation, it seems that metal price increases of the sort already encountered will not affect the price of LEDs too much. However, faster depletion of such metals might lead to an accentuated price increase for raw metals. On the other hand, LED prices are expected to decrease in coming years due to their increasing quantities on the lighting market. Price increases for raw metals might slow down the rate of decrease in prices for LEDs. Paradoxically, it is typical for the price and costs of extraction of raw metals to decline initially as the metal is produced and reserves are depleted. Technological innovation can lead to lower exploration costs, which in turn can cause the price to fall over time, until eventually scarcity of the resource causes the price to rise. The true scarcity is only revealed towards the end of exhaustion, when an intense price rise occurs with a huge cut in production. The true size of the resource base is unpredictable, and therefore it is possible for a very high magnitude price increase to occur over one or two years after a hundred years of declining prices and increasing production (Reynolds, 1999). 4 Feasibility of recycling of metals from LEDs While recycling of base metals such as gold and silver from scrap is a mature part of the metal industry, current efforts to recover and recycle rare metals are far less well advanced. For metals such as gallium and indium, recycling is the only way to extend the lifetime of critical sectors of the electronics industry, including LEDs. While gallium from old scrap is not currently recycled, substantial quantities of new scrap generated in the manufacture of devices based on gallium arsenide are reprocessed. Indium is currently most commonly recovered from the indium tin oxide recycling process (USGS, 2002-2011), which is concentrated in countries where indium tin oxide production and sputtering take place, such as China, Japan and the Republic of Korea. Nevertheless, the European Commission has cited a recycling rate of 0% for gallium and 0.3% for indium (EC, 2011). Higher recycling rates would reduce the pressure on demand for primary raw metals, help to reuse metals which would otherwise be wasted, and reduce energy consumption and greenhouse gas emissions from extraction and processing. Although they are globally recycled on a large scale, there is no detailed information about recycling gold and silver used in the manufacture of LEDs. Current technology allows recycling of gold used for conductive wires, stud bumps, solder layer and finishing on the heat sink. Silver used as the coating and finishing on the heat sink can also be recycled. There is not sufficient information about recycling of gallium Version: 1 First created: 30/03/11 Updated: 11/04/11 Last reviewed: 11/04/11 6 of 9 Cosmin Ticleanu and Paul Littlefair BRE and indium used in different semiconductor materials to create the light-emitting diode. Manufacturers of LEDs say that they use virgin raw materials for this process. The WEEE European Commission Directive encourages materials recycling and requires electrical and electronic equipment to be taken to a suitable authorised treatment facility at the end of its life so that it can be treated / dismantled and materials recovered for recycling where possible (EC, 2003). LEDs are within the scope of this Directive, which proposes targets equal to 65% of the average weight of the electrical and electronic equipment. 5 Feasibility of long term large scale LED production Based on data taken from the MTP models, it can be estimated that the number of LEDs sold in the UK will continuously grow in the coming years. For instance, the number of LED lamps sold on the UK market may be 40 times higher than the current LED sales level. Considering the same evolution of LED worldwide sales, and based on the assumption that the number of LED lamps sold in a country depends on the size of the economy of that country in relation to the world global economy measured by Gross National Income, it can be estimated that the average number of new LED lamps sold worldwide may exceed 250 million units by the year 2030 (based on expert assumption). The world production of different metals in coming years can be estimated based on recent production data. With the reference value for the average metal content in section 2 above, the relative metal demand for LEDs can be determined in the long term. Table 4 below summarises the results of the research, carried out for this report, on the feasibility of LED production by the use of different elements, for the year 2010. Table 4 Overall results of the research study World Relative LED production raw material in 2010 demand (tonnes) (%) Gold (price unit: ounce) 0.021 2,500 0.000185 Silver (price unit: ounce) 0.1218 22,200 0.0001 Gallium (price unit: kg) 0.0153 106 0.003 Indium (price unit: kg) 0.0003 574 0.00001 Yttrium (price unit: kg) 2.269 8,900 0.00562 LED content (mg) World reserve in 2010 (tonnes) Recycling level in 2010 (tonnes) Estimated depletion year Current price (£/unit) Current price per LED chip (p/LED) 51,000 707 (a) 778 0.0576 510,000 5,520 (a) 11.51 0.0049 (b) 0 (b) 434 0.0007 6,000 5 2017 366 0.00001 540,000 0 2021 56 0.0127 Notes to Table 4: (a) Depletion years for gold and silver are difficult to estimate because of the high level of recycling and the possibility that this could increase further. (b) World reserves of gallium are difficult to estimate because gallium is extracted from small quantities in other ores, and the amounts available depend on the proportion of gallium in these ores that can be economically extracted. Version: 1 First created: 30/03/11 Updated: 11/04/11 Last reviewed: 11/04/11 7 of 9 Cosmin Ticleanu and Paul Littlefair BRE Despite the significant future increase in LED sales, the relative demand for metals required for the manufacture of LEDs is very low compared to world total demand of the same metal. This is shown in the third column of Table 4, which gives the percentage of world production that is used to make LEDs. It can be predicted that by 2030 LEDs would require 0.006% of the world production of gold, 0.0009% of the world production of silver, and 0.011% of the world production of gallium. Moreover, there has been a continuous increase in LED luminous efficacy over recent years and it is predicted that it will improve further in the future. Together with the progress in LED technology allowing LEDs to be used in applications other than just directional lighting, this scenario may lead to a greater increase in LED global demand. Nevertheless, this does not seem to affect excessively the relative metal demand mentioned above, and it may be concluded that long term large scale LED production would not have impacts on metal resources in the next few decades. However, the reverse phenomenon might occur with a decrease in world metal reserves due to other sources of demand. As estimates predict that several metals used in the manufacture of LEDs may reach depletion in 6 to 45 years, strong impacts might be expected on the LED market. Recycling would help prolong LED metal reserves, but long life time expectations up to 50,000 hours (approximately 11.5 years for an average operating time of 12 hours daily) may not allow recycling to meet its aim for some rare metals, such as indium which is expected to reach exhaustion in 6 years. Whereas gold and silver could be replaced with other materials of equivalent physical properties, the challenge is to find materials suitable to replace those elements with high risk of depletion in the coming decades, such as indium and yttrium. 6 Conclusions The metal market generally follows a cyclical pattern based on supply and demand. Strong economic growth leads to a major rise in demand for raw materials which may reflect in high price levels. Whereas, innovation in extraction technologies may decrease metal prices until scarcity becomes probable. According to various studies, specific metals used in the manufacture of LEDs, such as rare metals like gallium and indium, but also base metals like gold and silver, are expected to reach exhaustion in periods of time of as little as 6 years (which is the case for indium). Gallium and indium, which are essential metals in the manufacture of LEDs, are listed among the 14 critical raw materials, with a particularly high risk of supply shortage in the next 10 years, and no recycling or substitution processes are currently commercially viable for these metals. Yttrium is another element used in phosphor coatings of LEDs which has a significant risk of depletion in the next 10 years. Version: 1 First created: 30/03/11 Updated: 11/04/11 Last reviewed: 11/04/11 8 of 9 Cosmin Ticleanu and Paul Littlefair BRE Gold and silver are not currently listed as critical materials, and they are widely recycled in the metal industry. Long term modelling, to assess the relation between LED market future evolution and raw metal shortage potential, has shown that future increase of LED sales levels will not significantly affect the metal reserves. This is because LEDs only contain very small amounts of the rare elements. However, it is possible that metals shortages, especially of indium, might have strong impacts on LED large scale production. In order to counteract this risk, alternative materials are needed. 7 References Cohen, D. (2007) ‘Earth’s natural wealth: an audit’, New Scientist, 2605:34-41 Davis, S. (2001) ‘Capacity Issues in the Material Supply Chain’. On-line Digest, The International Conference on Compound Semiconductor Manufacturing Technology. Available at: www.csmantech.org/Digests/2001/PDF/1_3_Davis_V3.pdf EC (2003) ‘Directive 2002/96/EC of the European Parliament and of the Council of 27 January 2003 on waste electrical and electronic equipment (WEEE)’, Official Journal L 037, 13/02/2003, p. 24–39. Available at: http://eurlex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:32002L0096:EN:HTML EC (2011) ‘European Commission Communication 25 Tackling the challenges in commodity markets and on raw materials’. Available at: http://ec.europa.eu/enterprise/policies/rawmaterials/files/docs/communication_en.pdf Reynolds, D. B. (1999) ‘The mineral economy: how prices and costs can falsely signal decreasing scarcity’. Ecological Economics, 31(1999):155-166 Rhodes, C. (2008) ‘Metals shortages’. Available at: http://scitizen.com/futureenergies/metals-shortages-_a-14-2223.html Schnick, W. (2009) ‘Shine a light with nitrides’, physica status solidi (RRL) – Rapid Research Letters, 3 (7-8): A113–A114 Seong-Rim, L., Kang, D., Ogunseitan, O.A. & Schoenung, J.M. (2011) ‘Potential Environmental Impacts of Light-Emitting Diodes (LEDs): Metallic Resources, Toxicity and Hazardous Waste Classification’, Environmental Science & Technology, 45:320327 Steen, B. (1999) ‘A systematic approach to environmental priority strategies in product development (EPS)’, Chalmers University of Technology. Available at: http://www.cpm.chalmers.se/document/reports/99/1999_4.pdf USGS (2002-2011) US Geological Survey. Available at: http://www.usgs.gov Version: 1 First created: 30/03/11 Updated: 11/04/11 Last reviewed: 11/04/11 9 of 9 Cosmin Ticleanu and Paul Littlefair BRE