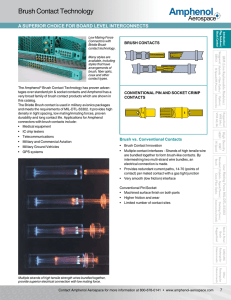

LRM - Amphenol Aerospace

advertisement