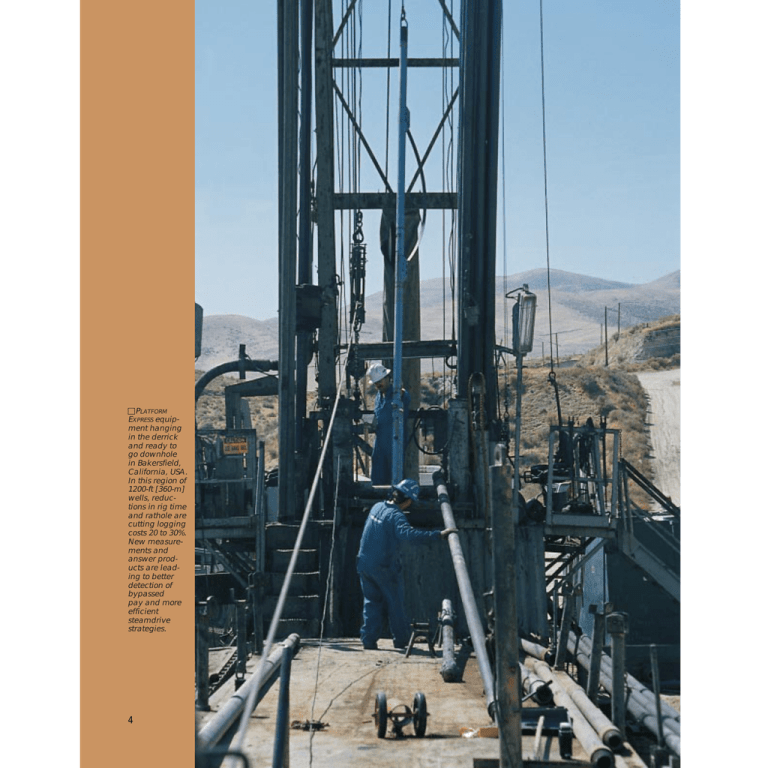

A First Look at PLATFORM EXPRESS Measurements

advertisement