The implementation of self checking systems in Belgium

advertisement

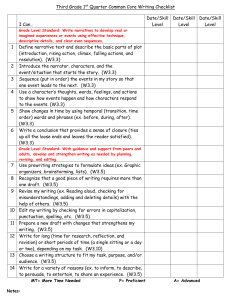

Federal Agency for the Safety of the Food Chain The implementation of self checking systems in Belgium Herman Diricks Director-general Control Policy Content • • • • Context National legislation Development of (national) guides Validation and certification of SCS (self-checking system) • Impact of certified SCS on inspection results Measuring food safety and comparing self checking systems - 17/11/2010 2 1 Context Measuring food safety and comparing self checking systems - 17/11/2010 3 New food/feed policy since 2000 • Taking into account the principles of White Book on Food Safety • Reorganization of civil service in general and inspection services in the food chain in particular – One inspection service for the food chain: FASFC – Independent risk assessment body (Scientific Committee of the FASFC) – Federal Public Service is responsible for standards • Own financing of the FASFC – Contributions (levy) – Retributions (fees) Measuring food safety and comparing self checking systems - 17/11/2010 4 2 Our goal : optimizing food chain checks Suppliers of agriculture (feed industry, raw materials, pesticides) Agriculture Food industry Wholesale business Retail Hotels, Restaurants, Pubs Transport Measuring food safety and comparing self checking systems - 17/11/2010 5 History of self checking I • ‘Pre’-history – Implementation of HACCP principles for good hygiene practices based on hygiene directives (e.g. 93/43/EEC) • Initial Business plan (December 2000) – Intention to impose on FBO (food business operators) to implement self checking systems (SCS) based on registration of operators, traceability and mandatory notification – Establish priorities between sectors based on risk – Impact on personnel and finance to be determined • General Food Law (2002) Measuring food safety and comparing self checking systems - 17/11/2010 6 3 History of self checking II • National legislation on self checking (2003) • Hygiene package • Business plan 2005-2008 – – – – Implementation Royal Decree (RD) on self checking Validation of self checking systems by the FASFC Calculated impact on inspection plan Evolution of the human resources is function of certified/validated self checking systems • Business plan 2009-2011 Measuring food safety and comparing self checking systems - 17/11/2010 7 Implementation of self checking systems Business operator of the food chain With an independently certified self checking system (SCS) No independent guarantees With a formally developed scs Without a formally developed scs External audit/ Testing/inspection accredited control bodies audit audit Information Inspection Inspection Inspection FASFC Measuring food safety and comparing self checking systems - 17/11/2010 8 4 National legislation Measuring food safety and comparing self checking systems - 17/11/2010 9 Royal Decree on self checking (2003) • Based on General Food Law • Impose self checking system for FBO – Has to be implemented for food safety – Optional for quality aspects • Food and feedstuff – Based on HACCP • Traceability • Mandatory notification (even for laboratories/certifying bodies) • Rules for developing and accepting guides • Possibility to delegate validation of self checking systems to inspection/certification bodies Measuring food safety and comparing self checking systems - 17/11/2010 10 5 Ministerial Decree on implementation of self checking in certain FBO (2005) • Scope – B to C : max 5 FTE’s or < 400 m2 – B to B : max 2 FTE’s • If processing food/feed: – – – – Application of GHP CCP’s, corrective actions, critical values from guide Only NC’s have to be registrated Documentation on HACCP = guide • Traceability – Based on delivery notes or other accompanying doc’s – Registration of data : within 7 d – Archiving documents 6 months (after UB/BB date) Measuring food safety and comparing self checking systems - 17/11/2010 11 Development of (national) guides Measuring food safety and comparing self checking systems - 17/11/2010 12 6 Self checking guides - content • • • • Scope Consultation with all stakeholders Document resources Content : including all elements concerning : – – – – GMP (Good Manufacturing Practices) GHP (Good Hygienic Practices) HACCP (Hazard analysis and critical control points) * Legislation • Certification rules • Distribution of the guide * Food and feed not primary sector Measuring food safety and comparing self checking systems - 17/11/2010 13 Self checking guides - approval process Measuring food safety and comparing self checking systems - 17/11/2010 14 7 Role of guide managers • • • • • • • Development Maintenance Promotion Training Follow-up of certifying bodies Cost covering activities Development of sector sampling plans Measuring food safety and comparing self checking systems - 17/11/2010 15 Validation and certification of SCS Measuring food safety and comparing self checking systems - 17/11/2010 16 8 Terminology - audits vs inspections ‘Audit’ ‘Inspection’ • On demand of the FBO • Certifying body or FASFC • System audit • Initiative FASFC • Prerogative FASFC • Check-lists audits • Check-lists inspections (hygiene, self checking traceability, labeling, ..) • Part of inspection plan Measuring food safety and comparing self checking systems - 17/11/2010 17 Motivators validation/certification • Bonus on levy (contribution) • Lower inspection frequencies based on an objective calculation with an important weight for the presence of a validated self checking system – General policy – Specific policy for processing plants using products of animal origin • Condition for export of certain products to certain countries (e.g. meat Russia) • B tot C : visual sign (‘Smiley’) Measuring food safety and comparing self checking systems - 17/11/2010 18 9 State of play : approved guides 35 100,00% 90,00% 30 80,00% 25 70,00% 60,00% 20 50,00% number of approved guides coverage (%) 15 40,00% 30,00% 10 20,00% 5 10,00% 0 0,00% 2004 2005 2006 2007 2008 2009 2010 Measuring food safety and comparing self checking systems - 17/11/2010 19 State of play certification • Guides complemented with – Check-lists – FAQ – Guidelines for certification bodies • Significant number of certification bodies approved for the different guides • Critical mass reached in some sectors • Bonus / Malus in 2010 : 50/60% (2011 : 50/100%) • From design to maintenance of the guides – Commitment of sectors – Attention needed for small & medium sized business operators Measuring food safety and comparing self checking systems - 17/11/2010 20 10 State of play (fully validated) • • • • • Suppliers of primary production : 300 Primary production : 8.400 Transformation : 300 Distribution : 320 Horeca (hotels, restaurants, pubs, catering) : 170 Measuring food safety and comparing self checking systems - 17/11/2010 21 Impact of SCS on inspection results Measuring food safety and comparing self checking systems - 17/11/2010 22 11 2 examples • Comparison of inspection results (expressed as results of check-lists) of operators with or without validated SCS year 2010 • Comparison of inspection results of processing plants of certain products of animal origin (used in calculating risk profiles) for the year 2008/2009 (implementing RD 22/12/05) Measuring food safety and comparing self checking systems - 17/11/2010 23 Example 1 : impact of validated SCS on inspection results 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% with 3% without 18% satisfactory with remarks 9% 19% satisfactory 88% 64% unsatisfactory Measuring food safety and comparing self checking systems - 17/11/2010 24 12 Ex 1 : distribution of non satisfactory inspections Type checklist total non satisf % non satisf Type checklist total non satisf % non satisf non validated SCS validated SCS self checking 10077 4984 46,41 % usage of pesticides 1139 113 4,17 % infrastructure and hygiene 29646 9087 27,34 % fytosanitary inspections 291 21 0,81 % ban on smoking 11307 1539 13,58 % animal health 699 21 0,80 % usage of pesticides 1570 263 9,71 % transport 238 9 0,66 % labelling and packaging 5977 595 8,59 % animal welfare 2460 55 0,62 % traceability 19203 1799 7,89 % labelling and packaging 946 39 0,56 % waste management (1774) 2701 189 5,92 % self checking 663 58 0,54 % packaging materials 958 52 5,18 % notification 12112 524 3,78 % infrastructure and hygiene 3590 167 0,50 % transport 1134 49 3,57 % epidemiogical surveillance 1195 14 0,33 % animal health 1931 90 3,42 % 75 2,89 % 489 10 0,31 % 298 9 2,87 % Medicines and guidance 1319 16 0,31 % fytosanitary inspections infrastructure and hygiene (approval) epidemiogical surveillance 2300 waste management (1774) 3013 113 2,69 % ban on smoking packaging materials 22 0,00 % 45 3 0,30 % Medicines and guidance 3876 115 2,21 % traceability 3589 41 0,18 % animal welfare 6369 188 2,13 % notification 1754 9 0,06 % other 266 4 1,29 % 18500 576 3,11 % 112741 19675 17,45 % Measuring food safety and comparing self checking systems - 17/11/2010 25 Ex 2 : inspection results in certain processing plants To determine the individual inspection frequency (base/low/high) a risk profile is determined Measuring food safety and comparing self checking systems -17/11/2010 26 13 Ex 2 : Results of inspections Results of different inspection check lists for different activities are weighted and translated into one value. NC inspections(%) NC inspections (cumul) 100% 35% 30% 25% 20% 15% 10% 5% 0% 80% 60% 40% non validated validated 20% 0% 0 1 2 3 4 5 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 6 7 8 9 10 weighted average NC weighted average NC Measuring food safety and comparing self checking systems - 17/11/2010 27 Business plan 2009-2011 • Improve financial incentives • Redirect inspections towards FBO without SCS • Develop specific communication towards sectors with FBO without SCS • Guides remain references but have to evolve • Take into account specific needs of small and medium enterprises • Promote through training Facilitate complementarities between guides and commercial standards such as GMP Measuring food safety and comparing self checking systems - 17/11/2010 28 14 Thank you for your attention Measuring food safety and comparing self checking systems - 17/11/2010 29 Abbreviations • • • • • • • • • • • • • • BB : Best before B to B : business to business B to C : business to consumer CCP : Critical control point FASFC : Federal Agency for the Safety of the Food Chain FBO : Food Business operators FTE : full time equivalent GHP : Good Hygiene Practices GMP : Good Manufacturing Practices HACCP : Hazard Analysis and Critical Control Points NC : non conformity RD : Royal decree SCS : self-checking systems UB : use-by date Measuring food safety and comparing self checking systems - 17/11/2010 30 15 List of approved guides • • • • • • • • • • • • • G-001 Guide on feed G-002 Guide on diary products G-003 Guide on butchers G-004 Guide on brewers G-005 Guide on ice cream G-006 Guide on poultry slaughterhouses and cutting plants G-007 Guide on food retail trade G-009 Guide on transport and storage of raw milk G-010 Guide on pesticides G-011 Guide on food supplements G-012 Guide on primary plant production G-014 Guide on processing and trade of potatoes, fruit and vegetables G-017 Guide on transport by road and storage of food Measuring food safety and comparing self checking systems - 17/11/2010 31 List of approved guides • • • • • • • • • • • • • • • G-018 Guide on slaughterhouses and cutting plants for fat stock G-019 Guide on meat products/ ready to eat / salads G-020 Guide on mills G-022 Guide on chocolate, biscuit and confectionery G-023 Guide on catering business G-025 Guide on collectivity kitchens G-026 Guide on bakers G-027 Guide on coffee-roasting houses G-028 Guide on organic fertilizers G-029 Guide on water, soft drinks G-030 Guide on apiculture G-033 Guide on contractors G-036 Guide on potting compost G-037 Guide on primary animal production G-038 Guide on trade of cereals and agrosupplies Measuring food safety and comparing self checking systems - 17/11/2010 32 16 Belgian legislation • Royal decree 14/11/2004 concerning self-checking, mandatory notification and traceability in the food chain • Ministerial decree 24/10/2005 concerning the relaxation of requirements relative to self-checking an traceability in certain businesses of the foodstuff sector • Royal decree 22/12/05 fixing inspection frequencies for the food business operators of the meat and fish sector in the inspection program of the Agency, necessitating the presence of an inspector of the Agency Measuring food safety and comparing self checking systems - 17/11/2010 33 17