New in the US: SMA America Inc.

advertisement

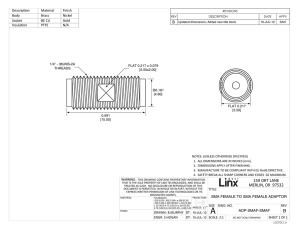

April 2001 New in the US: SMA America Inc. Leading supplier of grid tied PV inverters in Europe SMA Regelsysteme GmbH of Niestetal, Germany has founded a new subsidiary in Grass Valley, California. SMA America Inc. is a joint venture between SMA Regelsysteme GmbH and SMA’s exclusive worldwide distributor, Rosendahl Energietechnik GmbH. With the creation of the new subsidiary, the company is responding to the emergence of a viable North American market for grid tied PV systems. SMA America Inc. will support the growth of this new market segment. President of SMA America The new SMA building with a PV-façade 60 °C ambient temperature ratings. The modular design approach can be John Berdner scaled to virtually any sysFounded in 1981, SMA tem size while reducing Regelsysteme GmbH has grown to over DC wiring and overall installation costs. 400 employees and is the leading supString inverters are available in sizes plier of grid tied PV inverters in Europe. from 700 Watts to 2,500 Watts and With over 40,000 units in the field, include localized maximum power SMA’s innovative Sunny Boy line of string tracking to maximize array energy yield. inverters has become the most successful grid tied PV products to date. SMA SMA also manufactures large grid tied products were ranked first and second in inverters and modular inverters for a recent comparison of ten different hybrid systems with batteries. The Sunny inverter systems in Germany’s prestiCentral products are designed for large gious Stiftung Warentest magazine. centralized PV systems with ratings from 20 kW to over 1 MW in size. SMA’s innoThe string inverter concept, pioneered vative new Sunny Island inverter is a by SMA, offers a number of advantages modular, multi-mode, inverter charger over other grid tied inverters available designed for hybrid systems with battertoday (you will find more information on ies. The Sunny Island integrates seamthe string technology on page 4). To lessly with Sunny Boy string inverters and allow installation in virtually any locaother generation sources to create tion, the Sunny Boy products feature sophisticated hybrid power systems completely sealed, powder coated while minimizing design effort. All memstainless steel enclosures and –25 °C to bers of the Sunny Family utilize SMA’s comprehensive Powerline Communication system to provide an unprecedented level of options for data collection, display, and system control. SMA is quality certified to DIN ISO 9001 and operates three distinct business units: PV Technology, Industrial Microprocessors, and Power Conversion Systems for Railway Applications. The company’s Sunny Family of PV inverters are CE and TÜV approved. With the addition of the UL listing at the beginning of this year, SMA has become the first inverter company to offer PV inverter products that meet global regulatory requirements. Mr. John Berdner (photo) has been appointed President of SMA America Inc. He is well-known in the PV-industry and has more than 20 years´ experience in the field of electronics and photovoltaics. For more information contact SMA America Inc., or visit our website at www.SMA-AMERICA.com. 14 good reasons ... 649 Sunny Boys at Herne/Germany Sunny Boys for island grids 850 Sunny Boys at Sydney/Olympic Stadium why to use PV inverters from SMA SMA Regelsysteme GmbH was founded in 1981. The main field of activity in the early days was the development and production of inverters for decentralized electricity supply systems. Today 400 qualified employees develop and produce high-tech industrial microprocessor components, energy-supply systems for railway coaches, and trend setting PV system technology for world-wide usage. System Technology for PV-systems Today SMA has become a well-known supplier of high-tech microprocessor components, energy supply systems for railway coaches and inverters for electricity conversion of photovoltaic power plants. SMA works in the fields of windenergy conversion, PV technology, hybrid systems such as hydrogen cell technology and wind-diesel-battery systems. In the field of energy conversion and system technology for PV-plants SMA has become pioneer for advanced system design as well as European market leader. From 1986 to 1989 SMA developed and produced centralized inverter systems in output ranges of 20 to 500 kW with the grid-controlled thyristor based systems of the PV-WR-T series. As part of the “1000-Roof-Program”, a subsidy program started in 1990 and funded by the German government, SMA introduced the PV-WR inverter. With sizes from 1 to 5 kW the PV-WR set fundamental standards for redundant grid monitoring, communication, and EMC. 1. New Sunny Boys The development of modular system technology resulted in the trend setting Sunny Boy string inverter family. More than 60 MW AC of total inverter power have been installed to date, defining new standards in PV technology. In spring 2000, SMA added another inverter to the Sunny Boy Family. Due to the increasing demand for higher voltages and power levels we launched the Sunny Boy 1100E with an extended input voltage range of 150 to 400 V DC. Our customers now benefit from increased output power for the same price. Do you want more? The transformerless Sunny Boy 2000 has 20 % more power than the previous model while the price has remained the same. SMA’s most powerful inverter – the Sunny Boy 2500 – offers our best price to performance ratio yet. In the beginning of 2002 we will launch the first inverter with multi-string technology: the Sunny Boy 5000 Multi-String. With its ultra wide input voltage range, the multi-string inverter can operate with virtually all standard PV modules. The advantages of the modular string technology were also used for the development of island type PV-plants. This approach resulted in our Sunny Island battery inverter. This inverter is the first to support a modular, expandable system design for utility independent electricity systems. Continuous improvement combined with the implementation of advanced system strategies are the basis of our position as a trend setting market leader ensuring continuous growth of solar energy usage. 2. SMA – A strong partner into the future SMA Regelsysteme GmbH with 400 employees is a high-tech company with continual 30—40 % annual growth. The company is the largest supplier of gridinteractive PV inverters in Europe. SMA has gained experience from: ● Over60MWACof total “Sunny Boy string inverter” power installed so far ● Over 40,000 “Sunny Boy” string inverters sold ● Deliveries into nearly every European, North, and South American country as well as India, Korea, Japan and Australia. 3. Trend Setting Technology For over 15 years now SMA has been at the cutting edge of PV technology. The company has played a major role in PV developments and contributed to considerably increasing market acceptance of grid-interactive PV technology. 4. Serial Production The “Sunny Boy” inverter range has been on the market for over six years. From the very beginning we designed it for large-scale serial production. During 1999 alone, more than 8,000 Sunny Boys were delivered. With our recently expanded production capabilities we can double these figures each year for several years to come. This ensures that we can produce any number of inverters, no matter how strong the demand might be. The Sunny Boys’ production optimised design means you can count on longterm high quality. 5. Safety The “Sunny Boy” from SMA is the first inverter to comply with all applicable national and international standards. Furthermore, SMA has always been a pioneer in new safety technologies such as redundant anti-islanding protection and all-pole sensitive GFCI – offering a maximum of protection. Independent institutions have certified that the Sunny Boys from SMA comply with all applicable standards (such as UL and EC Standards covering low volt- age and EMC). Ask for proof – we will be happy to show you the corresponding certificates. 6. Long Life The Sunny Boys are designed for a MTBF of over 100,000 hours and more than 20 years of operation. In order to achieve this long life SMA selects only the best available components such as selected electrolyte capacitors with the best available temperature performance, etc. 7. Outdoor Mounting SMA is the first manufacturer to design all its inverters for outdoor operation. The stainless-steel cases comply with protection class IP65 (NEMA 4x). The electronics even operate in extreme weather conditions with ambient temperatures of –25 °C to +60 °C. Over 60 MW AC of total SMA inverter power have been installed to date. SMA therefore has extensive experience with the outside mounting and every detail is continually improved. No other manufacturer of PV inverters has such extensive and long-term experience in outdoor mounting of inverters. 8. Easy to Install In order to save time and cost during installation, all “Sunny Boys” have a very simple and practical three-point mounting system. SMA was the first manufacturer to use an electrical connection system with safe-to-touch plugs. This simplifies installation and allows the wiring to be prepared in the workshop in order to save time on site later. 9. Accessories Numerous accessories for SMA inverters are available including measuring and monitoring systems, PC visualization software, and external displays. A fax report automatically generated by the system can inform you about the operation of your plant. In case of a fail- For detailed information on our communication equipment, please see our “Sunny Boy Communication” brochure. needs. On request, we can also train your employees on your own premises. Our comprehensive training program combined with the excellent quality of our products ensures the customer’s long-term satisfaction. 10. Powerline Communication 13. Project Planning SMA is the only producer of inverters that use Powerline communication. No additional specialized data cables are needed for transmission of all data. Instead, data is simply transmitted over the existing power cables. With SMA’s powerline carrier system, PV plants can be easily monitored at extremely low costs. SMA has installed several thousand of these devices to date. With over six years of experience, SMA has the best know-how and is the largest supplier of this data transmission technology. Using its years of experience in PV technology, SMA supports its customers in the project planning phase of largescale PV plants. On request, an experienced team of SMA employees can manage the commissioning or even the installation of PV plants on any site worldwide. ure a report is automatically faxed to any number desired. 11. Customer Service SMA has a team of technicians and engineers with over 10 years´ experience in the development and production of PV inverters for grid supply. With their detailed knowledge of operating conditions, regulations for inter-connection to the grid, and grid conditions in nearly every country on the globe they will gladly help you with any problem you might have. In addition, SMA customers benefit from ● A customer service hotline ● A 24-hour exchange service ● Two-year warranty-standard ● Option to extend the warranty to 5 years or more ● Repairs at a fixed rate ● Free-of-charge software updates via internet ● Up-to-date documentation and information on our homepage: www.SMA-AMERICA.com 14. Quality SMA production complies with ISO 9001. The company has been Q1 supplier to customers such as Deutsche Bahn AG (German Railways) for years. Furthermore SMA has been successfully audited as a supplier to various customers in the automobile and electronics industry such as Volkswagen, Phoenix and ABB. The Sunny Boy was the first PV inverter incorporated into a PV system to receive the “TÜV PROOF” certificate by TÜV Rheinland. This quality certificate stands for excellent technical and practical features. In a 1999 test of PV modules and inverters our devices were qualified “good” (Sunny Boy 850) and “very good” (Sunny Boy 1500). For detailed test results please see the leaflet “Sunny Boys, the test winners”. 12. Training SMA offers its customers regular seminars and training courses. With over 10 years of practical experience in running these training classes, SMA has been able to work out an up-to-date training program responding to actual practical SMA America Inc. John S. Berdner 20830 Red Dog Road Grass Valley, CA 95945, USA Phone: 530.273.4895 Fax: 530.274.7271 e-mail: berdner@SMA-AMERICA.com The Sunny Boy 2500 Now Available in the US! The Sunny Boy 2500 is the first string inverter to be listed according to the latest UL 1741 guidelines. Active antiislanding protection to meet the stringent IEEE 929 requirements and an integral Ground Fault Detector Interrupter are standard features. The string inverter technology, developed by SMA, has revolutionized PV applications in Europe and made the SMA inverters the favorite of European customers. SMA is the European market leader of inverters with a power range of up to 5 kW. String Technology utilizes a small number of PV-modules connected in series to create a “string“. A small number of strings are connected to individual inverters that feed the electricity of the string directly to the grid. The string inverter concept minimizes the complexity of the DC wiring system and reduces overall system costs. The energy produced by the PV system is combined on the AC side, making system design very simple. Using multiple string inverters, larger PV plants can be easily created with minimal design effort. The Sunny Boy 2500, with a nominal output power of 2200 W and a maximum output power of 2500 W, is the largest member of the Sunny Boy family. The high maximum efficiency of 94 % and large heat sink eliminates the need for cooling fans. This design allows the use of a completely sealed, NEMA 4X enclosure to provide protection against dirt, dust, and water thereby insuring a long, trouble free life. The powder coated, stainless steel NEMA 4X enclosure and an extended ambient temperature range of – 25 °C to + 60 °C means the Sunny Boy 2500 can be mounted outdoors in almost any location. Now UL listed! A very wide DC input voltage range of 250 – 600 V DC and the ability to con- nect up to three parallel strings, allows the system designer to use nearly any module configuration. Experience in Europe has shown that the economically ideal system design is with a PV array size of 2,700 to 3,400 Wp at standard test conditions. The inverter’s operating data including PV voltage, output power, and daily power production can be viewed using the optional “Sunny Display” – a twoline LCD integrated in the lid. In larger PV-systems, data from multiple inverters can be stored and viewed using the SWR-COM plug in modem and a PC or via the stand alone “Sunny Boy Control” data logging devices. Other possible communications options include plug in RS232 and RS485 modules. All of the various options for communication and data display are described in detail in the “Sunny Boy Communication”. The newest member of the Sunny Boy Family, the Sunny Boy 1100E will be launched by SMA in the end of 2001. This smaller string inverter shares all of the advanced features of the Sunny Boy 2500 but with an input voltage range of 150—400 V. The lower input voltage range and lower output power rating make the 1100E an ideal choice for smaller systems. Look for more detailed information on the new 1100E and other developments from SMA in the next issue of Sunny Boy Info or on the World Wide Web at: www.SMA-AMERICA.com .