Basics of Measurement - Productivity Quality, Inc.

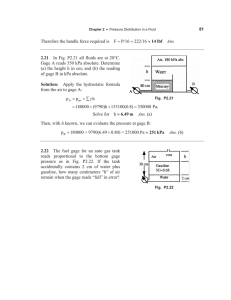

advertisement