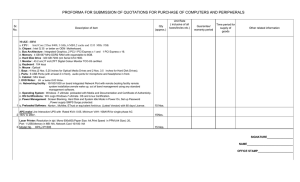

Page 1 of 4 G-Schedule - For maintenance of 33 KV sub

G-Schedule - For maintenance of 33 KV sub-station on turnkey basis

( 33/11 KV Sub-station with one power transformer with 1 incomer and 4 out going feeders)

Tender Inviting Authority: Superintending Engineer(TW), JVVNL, Jaipur

Name of Work: "Supply & Erection of material for maintenance of 33 KV sub-station on turnkey basis .

Contract No. JPD/SE/TW/TN-263

S.No

Details of item Unit

1 Labour charges for over all inspection of sub-station with two transformer for job requiring works analysis and testing of dielectric strength of oil, insulation resistance value and earth per transformer resistivity etc.

2

Add for each power transformer.

3 Up keep of existing earthing system a Supply & laying of earth mesh at sub-station as per approved map & design using MS flat 50 x per transformer

1 complete job

6 mm & MS rod 20 mm dia including laying of flat at the depth 0.65 mtr & MS rod at 3 meter depth welding & jointing at joints, structures & equipments etc in switchyard area of 35 M x

35 M as per drawing b Excavation of trench of 0.65 mtr depth 7 0.5 mtr width

Normal soil

Hard Soil

Ordinary rock ( where blasting is not required.)

Hard rock ( where blasting is required.) c Laying of MS Flat & MS Rod in 0.65 Mtr. Deep excavated trench and welding of MS Flat & MS

Rod continuously with 100 mm overlapping for straight joint including coating of MS flat joint with molten bitumen and covering joint with bitumen and impregnated tape to protect from rust.

1 CUM

1 CUM

1 CUM

1 CUM

1 Mtr d Shaping of MS Flat for connecting the equipments with earth mesh. The work includes the welding of MS Flat with equipments / structure and also with earth mesh. The work also

1 Mtr includes coating of MS flat joints with molten bitumen and covering joint with bitumen and impregnated tape to protect from rust.

4 Preparation of spikes made of M.S Rod of 20 mm dia and 3 Mtr.length as per design and requirment to be driven in earth by mechanical means and Providing & .fastening of suitable clampswith the M.S. Rod, connection of earth wire/stay wire/MS flat in clamp depending on type of soil: a Where drilling is not required b Where drilling is required

Per nos

Per nos

Per nos 5 Earthing of new 33/11 KV S/S with bentonite compound (including material ) involving following activities.

a Digging of 10.5 ft. deep pit of 4 ' dia ( approx 132 cu.ft) b Supply of 2" G.I pipe with cap(including fabrication of 30 holes in the periphery of pipe) c Making chamber for water pouring including cast iron manhole cover d Supply cost of 200 kg bentonite compound with making slurry e Supply of black cotton soil approx 80 cu.ft.

6 Connecting electrode with Mesh Earthing

7 Labour charges for opening the transformer tank top cover(if required to facilitate maintenance of transformer) after removing required accessories.Including all required T&P Up to 5 MVA transformer.

per trans

8 Preventing oil leakage by changing main gasket with material after removing cover.

a Upto 1.6 MVA transformer b c

Above 1.6 MVA & upto 3.15 MVA transformer.

Above 3.15 MVA & upto 5 MVA transformer.

per trans per trans per trans per trans

Qty

1.00

Unit cost for

Supply

Unit cost for ETC

Total cost of Supply Total cost of ETC

0.00

773.32

0.00

773.32

1.00

1

0

0

0

0

0

0

7

3

1

1

0

1

0

0.00

84647.49

0

0

0

0

142.89

0

596.92

596.92

834.91

0

0

0

0

258.50

499.73

105.76

133.22

261.00

773.98

22.45

33.81

166.07

543.66

4936.26

3772.29

1322.26

1639.10

1810.67

0.00

84647.49

0.00

0.00

0.00

0.00

0.00

0.00

4178.44

1790.76

834.91

0.00

0.00

0.00

0.00

258.50

499.73

0.00

0.00

0.00

0.00

0.00

0.00

1162.49

1630.98

4936.26

3772.29

0.00

1639.10

0.00

Page 1 of 4

S.No

Details of item Unit

9 Change of HV/LV bushing gasket ring and rubber washers including supply of required material & draining /re-filling of oil as required.

(a) For additional HV/LV bushing work.

Nos

Nos

* This amount will not be payable incase the work of removing of Top cover gasket is also awarded in the same order.

10 a b

11

12

13

Change of gaskets of valves/radiator / Buchhloze's Relay including cost of gaskets etc.

Valve's/Buchhloze's Relay

Radiator Valves.

Providing & Fixing (including replacement) of HV/LV bushing of reputed make & bushing rod of brass matel including cost of gasket & rubber rings .Gasket makes are TABROSS,TIGER, ZEBRA and any other reputed make.

HV Side

Upto 1.6 MVA transformer

Above 1.6 MVA & upto 3.15 MVA transformer.

Above 3.15 MVA & upto 5 MVA transformer.

LV Side

Upto 1.6 MVA transformer

Above 1.6 MVA & upto 3.15 MVA transformer.

Above 3.15 MVA & upto 5 MVA transformer.

Dehydration/Filteration and reconditioning of transformer oil (electricity shall be supplied by deptt.) as per norms and testing thereof in presence of sub-station Incharge.

Cleaning of oil scale deposits over the body and radiators of power transformer with thinner/detergent and de-rusting in perfect manner.

Upto 1.6 MVA transformer

Above 1.6 MVA & upto 3.15 MVA transformer.

Above 3.15 MVA & upto 5 MVA transformer.

Nos.

Nos.

Nos.

Nos.

Nos.

Nos.

Nos.

Nos.

Ltr.

Nos.

Nos.

Nos.

e f

15 c d a b

14 Replacement of oil temperature indicator, Winding temperature indicator,silica gel container ,Presser relief device

,Magnetic oil level gauge,.Gas operated Buchhloz relay (including all required accessories.)

Oil temperature indicator

WindingTemperature indicator

Silica gel container

Presser relief device Make ATBUS

Magnetic oil level gauge.Make ATBUS

Gas operated Buchhloz relay( Double floating type make ATBUS)

Spray Painting of the power transformer from out side with two coats of synthetic enamel paint of required shade after cleaning the body and radiators with preparation of surface by rubbing & applying primer coats and putty etc. and making smooth surface with the fine emary cloth including required material and tools.

5 MVA Transformer

2.5MVA/3.15 MVA Transformer

1.6 MVA T ransformer

16 Checking, tightening & replacement of jumpers, clamps connectors of bus bar including transformer & equipments of substation.Material to be provided by Nigam ,If required.

17

18

33/11 KV S/S with 1 power transformer

33/11 KV S/S with 2 power transformer

33/11 KV S/S with 3 power transformer

Replacement of damaged bus bar conductor including re-jumpering etc.

Bus Bar with ACSR PANTHER

Bus Bar with ACSR DOG

Replacement of damaged pin/post insulators including re-binding and jumpering etc.

33 KV Pin/Post Insulator

Nos.

Nos.

Nos.

Nos.

Nos.

Nos.

Per Nos.

Per Nos.

Per Nos.

Nos.

Nos.

Nos.

Per Wire (10 MTR

LENGTH)

Per Wire (10 MTR

LENGTH)

Nos.

Qty

0

1800

0

1

0

1

0

1

1

1

0

1

0

1

1

1

1

1

1

1

Unit cost for

Supply

0

Unit cost for ETC

943.07

Total cost of Supply Total cost of ETC

0.00

943.07

0 0 169.76

0.00

0.00

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

105.62

252.71

1161.90

2218.06

2218.06

454.54

1557.96

1557.96

3.74

914.87

1133.57

1324.06

1791.87

1791.87

1791.87

4903.93

3960.86

3960.86

0

1

0

0

0

1

0

0

2829.22

2357.68

0

Material shall be supplied by

0 2074.71

Material shall be

1

Nigam

0 supplied by

1063.76

0

0

1407.01

1812.60

1452.87

654.41

558.35

364.12

179.92

15.07

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

654.41

179.92

105.62

252.71

0.00

2218.06

0.00

0.00

1557.96

0.00

6732.00

0.00

1133.57

0.00

1791.87

1791.87

1791.87

4903.93

3960.86

3960.86

0.00

2357.68

0.00

1063.76

0.00

0.00

0.00

364.12

15.07

Page 2 of 4

S.No

19

Details of item

11 KV Pin/Post Insulator

Replacement of damaged disc insulator with hardware, if required including jumpering etc.

On 33 KV side

On 11 KV side

20 Replacement of damaged jumpers including fixing P.G. clamps, 'T' clamps and connectors at both ends. Including proper tightaning of M.S. Nuts & Bolts.

ACSR PANTHER

ACSR DOG/RACOON

Unit

Nos.

Per string (3 DISC

INSULATOR+1

HARDWARE)

Per string (2 DISC

INSULATOR+1

HARDWARE)

Nos.

Nos.

Qty

21 Replacement of 33 KV/11 KV lightening arrestors including jumpering and earth connections etc. in all respect.

33 KV L.A.

11 KV L.A.

Note:- If separate earthing is not provided for LA, the same shall be provided in accrodance with the

22 provisions for the activity.

Repair & maintenance of 33 KV/11 KV Isolator/ G.O. Switch for smooth operation including replacement of G.O. clamps, jaws, blades & post insulators etc. and checking of operating mechanism, oiling/greasing complete in all respect.

23

33 KV Isolator/ G.O. Switch

11 KV Isolator/ G.O. Switch

Welding of fabricated MS Sheet box of 2 mm thickness for locking arrangement of power transformer valves to curb transformer oil having dimensions

200x160x180 mm for filter valve of Power Transformer

160x100x120 mm for conservator drain valve

40x 50x40 mm for radiator air release cap

60x 50x60 mm for conservator cap

Nos.

Nos.

Nos.

Nos.

per valve per valve per valve per valve

24 Maintenance of existing lighting fixtures including replacement of all defective spares & wire if required and commissoning thereof.

HPMV/HPSV lighting fixtures

Halogen lamps/ flood light fixtures

Tube light fixtures

Nos.

Nos.

Nos.

25 Providing and fixing of insulating coat on live metal parts of HV equipments

26 Providing and fixing of 15.9KV BDV film for 11kv jumpers/equipment parts/hazards locations at accident prone zone

27 Providing and fixing of insulated mats

28 R&M of 33KV & 11KV breakers /NIOSK and C&R Panel (beyond GP) and associated equipments per sqm.

per running meter of film sqm

28.1

28.2

Complete overhauling and replacement of parts 33 KV VCBs

Complete overhauling and replacement of parts 11 KV VCBs

Nos.

Nos.

1

1

1

0

2

3

12

Unit cost for

Supply

28.62

1142.66

597.23

165.55

135.67

3947.81

2265.07

Spare parts, if any, shall be

1 supplied by

4

0

0

Unit cost for ETC

11.33

135.76

92.48

71.61

32.07

143.35

Spare

47.14

parts, if

258.50

4

1000

0

0

0

0

0

0

0

0

386.40

261.46

85.01

88.87

0

6

Material shall be supplied by

6 Nigam 0

0

0

Material shall be

97.24

57.19

2303.84

196.2

58.00

2.90

10 4116.06

Cost of spares Cost of

0.00

shall be payable as per actuals spares shall be payable as per

1

5

0

0 540.00

Total cost of Supply Total cost of ETC

28.62

1142.66

597.23

0.00

271.34

11843.43

27180.84

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

9215.36

196200.00

41160.60

0.00

0.00

11.33

135.76

92.48

0.00

64.14

430.05

565.68

386.66

1034.00

0.00

0.00

0.00

0.00

1018.56

0.00

343.14

232.00

2900.00

0.00

540.00

2700.00

Page 3 of 4

S.No

Details of item

28.3

Repair and Maintenance of Battery set and Battery charger including maintaining specific gravity battery level, cleaning checking & tightening of battery terminals in all respect. It includes measuring and recording of voltage of each battery

28.3.1 110 V

28.4

Repair and Maintenance of 33 KV/11 KV Control and relay panel (Beyond GP) and associated equipments and replacement of defective part

28.4.1 Change of spares

28.4.2 Complete overhauling and checking

29 Providing of fire fighting equipment

Fire extinguisher

Sand buckets with sands etc.(6 buckets and 1 steel stand)

30 Installation , testing as per Nigams norms & commissioning of new 11KV CT PT set (all sizes) on erected supports including jumpering,crimping of lugs/ clamping earth connection of body &conducting pre commissioning test before energization and satisfactory operation in all respect

30.1

Removal of damaged 11 KV CT PT Set from existing structures

31 Assembly,installation & commisioning of 11 KV Roster switchs on erected structures with stting for accurate operation including fixing of allied accessories completed in all respect with post insulators and jumpering on both ends for connection with systm.The nuts & bolts will be supplied by contractor for which payment will be made as per prevailing Dicom store issue rates.

Unit

Nos.

Nos.

Nos.

Nos.

Nos.

Set

Set per nos

Qty Unit cost for

Supply

Unit cost for ETC

1 0 660.00

2

1

1

1

1

1

4 Supply by Nigam

0

8000

2000

0

0

0

270.00

660.00

100.00

50.00

589.75

412.78

1413.26

Total cost of Supply Total cost of ETC

0.00

0.00

0.00

16000.00

2000.00

0.00

0.00

0.00

660.00

270.00

660.00

200.00

50.00

589.75

412.78

5653.04

32 Painting of steel structure with priming coats or ready mixed red-oxide paint 2 coats of approved make on steel works after cleaning with wire brush / sand paper.(including cost of red oxide)

32.1

On old surface

33 Painting of yard steel structures with aluminium paint of approved brand and manufacturer to give an even surface.(including cost aluminium paint)

33.1

On old works with one coats.

34 LS cost of all possible spare parts

Total for one Substation (Supply+Erection) (in Rs.) sq.mtr

sq.mtr

Total Cost for 254 Nos. Substation

Total Cost for 254 Nos. Substation (Supply+Erection)

100

100

0.00

21.25

0.00

2125.00

0.00

Total

30.14

0.00

20000.00

417926.01

491631.93

3014.00

73705.92

106153206.54

18721303.68

124874510.22

Note:- The quantities mentioned in the above schedule are tentative for one sub-station. However, payment shall be made as per actual quantities which will be assessed after detailed survey with the Nigam's Engineer.

AEN(TW-II) XEN(TW-II) Sr.AO(W) SE(TW)

Page 4 of 4